Issue with bi-metallic washers in tensioner

#31

Rennlist Member

More cool...not heat related AT the washer..but not a linear spring either..

https://www.leespring.com/learn-abou...eville-washers

https://www.leespring.com/learn-abou...eville-washers

#33

Inventor

Rennlist Member

Rennlist Member

I have been saying for a long time that old discs probably do not work properly any longer. Nice to see that new discs are available and that some 'experts' finally listened.

The stock tensioner does none of what you are imagining. The belt is pre-stretched to a high static tension. Engine expansion from heat while running makes it even tighter. New stock tensioner discs flatten out when hot. When hot there is no spring and nothing to dampen as it becomes a fixed bolt tensioner.

Video of the belt being pulled over the oil pump gear as proof of tensioner worthiness is, uh, dumb. Belt flutter on the slack side, after it is spit out by the crank gear, is all the tensioner/damper is supposed to manage. Unfortunately, this is mostly uncontrolled with the stock tensioner, especially when cold, which is why there are several anti-flutter 'idler' pulleys and a 3-minute delay on the tension warning light.

Tension between gears is set by the load of the crank pulling the cams and oil/water pumps and going by cam timing, appears to be constant from startup, according to my testing with all available belts, below.

https://rennlist.com/forums/928-foru...am-timing.html

If you want reduced belt flutter between the pulled gears, run a Racing belt.

Video of the belt being pulled over the oil pump gear as proof of tensioner worthiness is, uh, dumb. Belt flutter on the slack side, after it is spit out by the crank gear, is all the tensioner/damper is supposed to manage. Unfortunately, this is mostly uncontrolled with the stock tensioner, especially when cold, which is why there are several anti-flutter 'idler' pulleys and a 3-minute delay on the tension warning light.

Tension between gears is set by the load of the crank pulling the cams and oil/water pumps and going by cam timing, appears to be constant from startup, according to my testing with all available belts, below.

https://rennlist.com/forums/928-foru...am-timing.html

If you want reduced belt flutter between the pulled gears, run a Racing belt.

The following users liked this post:

WestInc (07-16-2023)

#34

Rennlist Member

#35

Rennlist Member

I think it operates now as a non linear spring..expanding oil compresses it more/less depending on temperature and the washers react differently under different pressures.

I had no idea..nothing about em is..constant..by design.

Last edited by Speedtoys; 07-16-2023 at 07:47 PM.

#36

Rennlist Member

Belleville washers are most definitely non linear- as the compression tends towards flat the spring rate tends towards infinity [i.e. non compressible]. The oil acts of a heat conducter, a lubricant and a damper- nothing more than that.

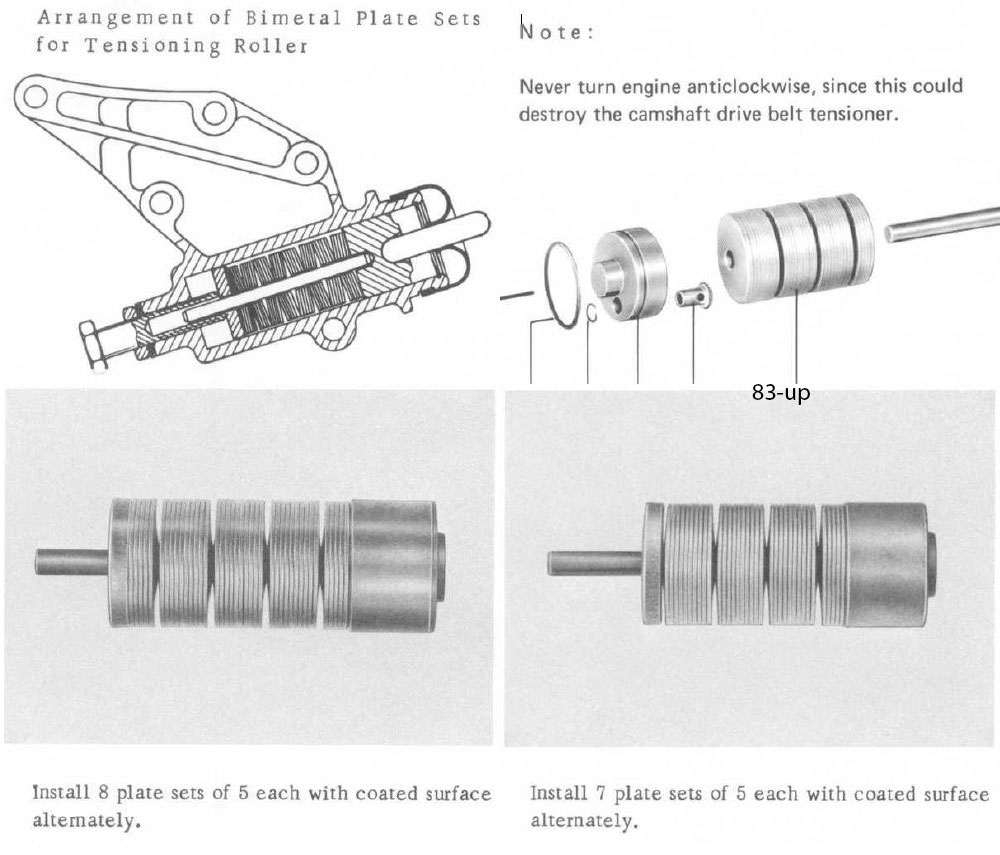

The washers have a thickness of 1.1mm and a height of approx 1.9 mm at zero degrees C so 0.8mm of travel to the point of being flattened. When heated to 100C the height drops to 1.7mm and thus 0.6mm to being flattened. On the later models with 35 washers they are configured in 7 groups of 5 washers stacked in series. Thus the reduction in length of the total pack is 7 x 0.2mm= 1.4mm thus considering that the operating temperature of the tensioner is no more than 90C the washers in relative terms are far from being flattened and would need to travel 7 x 0.6mm = 4.2mm to flatten out. I estimated that in operation the pack will likely compress about 2.0mm maximum when set correctly and thus why setting the tension with No1 cylinder at TDC on its firing stroke is critical to success. The assembly by design thus tries to stop the stock belt from fluttering or at the very least minimise such. As to how well it achieves this [or not] remains to be seen.

The washers will for sure have a finite fatigue life and knowing Porsche I suspect that may well be something like 300k miles or 500k km. Based on what I have seen the cam sprockets appear to fare less well and appear to have a service life of about 100k miles [which is not overly clever as I am concerned] and if nothing else that would align with Porsche service life for the timing belt. I dare say it is possible that our desert climate may have some impact on this. Although not recommended by Porsche the sprockets can be rejuvenated with a new coating if applied in a timely fashion- Colin [Lizard 928] provided this service for me and when I inspected them during a recent water pump issue they appeared to be holding up very well.

At the end of the day the system designers will have specified a design tension and that has to be met in order for the system to work irrespective of how it is achieved- that as per the Gates design practices.

The following users liked this post:

M. Requin (07-18-2023)

#37

Inventor

Rennlist Member

Rennlist Member

It has been well observed and it does not work well at all. In order to dampen flutter, the tensioner piston must lengthen and retract in real time to the length of the belt between the crank gear and the 1-4 gear. The stock discs can only retract due to temperature, not a direct measurement of the belt length.

The amount of 'loose' belt between the crank gear and the 1-4 gear will vary according to temperature, loading, and harmonics. As Geoffrey observed in his video, the belt will collect or be released at certain points between gears on the 'tight' side at different rpms and temperature. The stock tensioner discs are initially loaded statically to a certain tension at 'shop temperature' at a certain position in the stroke. They will only retract by temperature but there is very little compression loading except when the engine expands before the discs retract. They may expand slightly when unloaded (from excess 'loose' belt) but this is far less than the range you measured for temperature. This is why flutter is observed on the tensioner side and is why the 'idler' gears and 3-minute delay were incorporated.

Originally Posted by Gates Technical Bulletin

Because the hydraulic tensioner can operate with a larger range of dynamic belt lengths than a mechanical tensioner and due to the length of stroke of the actuator and the lever design, the hydraulic tensioner system is particularly suitable for large V6/V8 engines...

Last edited by PorKen; 07-17-2023 at 09:16 PM.

#38

Inventor

Rennlist Member

Rennlist Member

The stock tensioner discs are initially loaded statically to a certain tension at 'shop temperature' at a certain position in the stroke. They will only retract by temperature but there is very little compression loading except when the engine expands before the discs retract.

The following users liked this post:

Speedtoys (07-17-2023)

#39

Rennlist

Basic Site Sponsor

Basic Site Sponsor

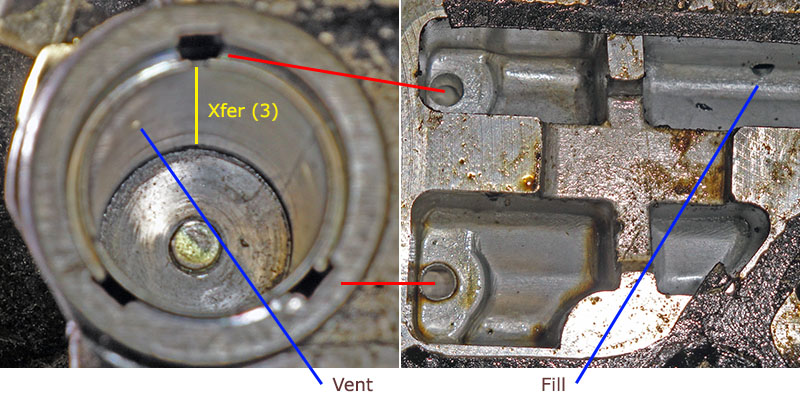

The most common issue with the stock bimetallic washers is that they wear on the inside diameter, from a lack of lubrication, caused by people who don't know what they are doing when servicing the belt/tensioner.

Pretty simple to look at a late model bimetallic washer (which are a goldish color) and see how "flat" they get. (The contact areas leave very obvious witness marks.)

I believe that Fred's math is very close to reality....they never get anywhere close to being completely flat, even when they are very old.

Pretty simple to look at a late model bimetallic washer (which are a goldish color) and see how "flat" they get. (The contact areas leave very obvious witness marks.)

I believe that Fred's math is very close to reality....they never get anywhere close to being completely flat, even when they are very old.

__________________

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

greg brown

714 879 9072

GregBBRD@aol.com

Semi-retired, as of Feb 1, 2023.

The days of free technical advice are over.

Free consultations will no longer be available.

Will still be in the shop, isolated and exclusively working on project cars, developmental work and products, engines and transmissions.

Have fun with your 928's people!

#40

Therefore I donít think Porsche was worried about damage to the disks from CC rotation, I believe it was more about keeping the belt loaded on the correct side before measuring the tension.

Is the later disk configuration of 7 stacks of 5 for the HD belt profile?

#41

Rennlist Member

Has anyone measured the force required to compress one of these belleville washers? The fact that a parallel stack adds the compression force. I would make a SWAG that a stack of 5 parallel washers would be somewhere at 600 lbf to flatten.

Therefore I donít think Porsche was worried about damage to the disks from CC rotation, I believe it was more about keeping the belt loaded on the correct side before measuring the tension.

Is the later disk configuration of 7 stacks of 5 for the HD belt profile?

Therefore I donít think Porsche was worried about damage to the disks from CC rotation, I believe it was more about keeping the belt loaded on the correct side before measuring the tension.

Is the later disk configuration of 7 stacks of 5 for the HD belt profile?

The manufacturer?

The charts are available online i'm sure.

#44

Inventor

Rennlist Member

Rennlist Member

Has anyone measured the force required to compress one of these belleville washers? The fact that a parallel stack adds the compression force. I would make a SWAG that a stack of 5 parallel washers would be somewhere at 600 lbf to flatten.

Therefore I don’t think Porsche was worried about damage to the disks from CC rotation, I believe it was more about keeping the belt loaded on the correct side before measuring the tension.

Therefore I don’t think Porsche was worried about damage to the disks from CC rotation, I believe it was more about keeping the belt loaded on the correct side before measuring the tension.

#45

Rennlist Member

Fred,

It has been well observed and it does not work well at all. In order to dampen flutter, the tensioner piston must lengthen and retract in real time to the length of the belt between the crank gear and the 1-4 gear. The stock discs can only retract due to temperature, not a direct measurement of the belt length.

It has been well observed and it does not work well at all. In order to dampen flutter, the tensioner piston must lengthen and retract in real time to the length of the belt between the crank gear and the 1-4 gear. The stock discs can only retract due to temperature, not a direct measurement of the belt length.

I get the impression that you are thinking of the stock tensioner as a mechanical tensioning device rather than a hydraulic device.