'87 S4 Auto: ride height after restauration

#16

RL Community Team

Rennlist Member

Rennlist Member

On the front wheels you can access the collars just by turning the wheels all the way in one direction.

The following users liked this post:

Smitje 928 (02-20-2023)

#17

Team Owner

Pete, I would not suggest to use that air hammer to turn the loaded / or unloaded collars.

what looks like it might be working can result in the nut seizing to the threaded ring and then the whole part will turn,

thus meaning the shocks will have to be taken apart to fix the now unadjustable loosened ring.

I would suggest to remove the car weight from the perch by jacking the front end off the ground,

turn the wheels to the right , then adjust the front collars,

I use a spanner wrench from Ohlins found on Amazon for 18.00 and wear a pair of gloves.

Then jack the car up under the rear cross member use a 2 X 4 on the jack pad use jack stands

this procedure can be done on a flat surface with a floor jack, jack stands and piece of cardboard.

and takes about 4 mins a wheel.

Use of the Ohlins wrench imparts no damage to the notched adjusters,

NOT hammering with an air hammer on the adjuster collars will increase the chance they will not loosen the threaded rings,

and thus the adjustablity of the shocks should not change

NOTE using an air hammer on the rings will deform the wrench slots,

thus making them unusable for future adjustments with a spanner wrench.

and if you miss you can also damage the face of the lower perch, this will make the nut harder to turn over a divot in the metal.

NOTE similar metal scarring damage occurs when channel locks are used to turn the adjusters.

NOTE the warning about loosening the inner rings applies to both Black / Red Boges with the press to fit threaded rings .

and Koni shocks that have had the threaded collars JB welded on.

what looks like it might be working can result in the nut seizing to the threaded ring and then the whole part will turn,

thus meaning the shocks will have to be taken apart to fix the now unadjustable loosened ring.

I would suggest to remove the car weight from the perch by jacking the front end off the ground,

turn the wheels to the right , then adjust the front collars,

I use a spanner wrench from Ohlins found on Amazon for 18.00 and wear a pair of gloves.

Then jack the car up under the rear cross member use a 2 X 4 on the jack pad use jack stands

this procedure can be done on a flat surface with a floor jack, jack stands and piece of cardboard.

and takes about 4 mins a wheel.

Use of the Ohlins wrench imparts no damage to the notched adjusters,

NOT hammering with an air hammer on the adjuster collars will increase the chance they will not loosen the threaded rings,

and thus the adjustablity of the shocks should not change

NOTE using an air hammer on the rings will deform the wrench slots,

thus making them unusable for future adjustments with a spanner wrench.

and if you miss you can also damage the face of the lower perch, this will make the nut harder to turn over a divot in the metal.

NOTE similar metal scarring damage occurs when channel locks are used to turn the adjusters.

NOTE the warning about loosening the inner rings applies to both Black / Red Boges with the press to fit threaded rings .

and Koni shocks that have had the threaded collars JB welded on.

The following 2 users liked this post by Mrmerlin:

Gary Knox (02-16-2023),

Smitje 928 (02-20-2023)

#18

RL Community Team

Rennlist Member

Rennlist Member

Stan, probably sage advice. I have the Bilsteins, so maybe that's a different collar/perch setup and it worked perfectly, but my cars also aren't crusty underneath.

The following users liked this post:

Smitje 928 (02-20-2023)

#19

For those in the know, how did Porsche originally set up the cars in the factory? Certainly they were not delivering them with 50+ miles on the odo, were they?

Is the answer in this video:

At about 15:28, they put the car on a shaker device. Besides just "safety testing" the assembly, might this be step one in settling the suspension? Then re-adjust after the tech's shakedown drive?

I guess a follow-up question is, are most other cars simply assembled, tested/ adjusted and shipped? Seems like a very cumbersome process with the 928, though initially justified by the high MSRP.

Cheers

Is the answer in this video:

I guess a follow-up question is, are most other cars simply assembled, tested/ adjusted and shipped? Seems like a very cumbersome process with the 928, though initially justified by the high MSRP.

Cheers

The following 2 users liked this post by RennHarry:

Smitje 928 (02-20-2023),

tv (02-25-2023)

#20

RL Community Team

Rennlist Member

Rennlist Member

That's one advantage to living in CA....the whole state is a shaker device

The following 4 users liked this post by Petza914:

#21

Rennlist Member

For those in the know, how did Porsche originally set up the cars in the factory? Certainly they were not delivering them with 50+ miles on the odo, were they?

Is the answer in this video:

https://www.youtube.com/watch?v=NdCp0cZLivQ

At about 15:28, they put the car on a shaker device. Besides just "safety testing" the assembly, might this be step one in settling the suspension? Then re-adjust after the tech's shakedown drive?

I guess a follow-up question is, are most other cars simply assembled, tested/ adjusted and shipped? Seems like a very cumbersome process with the 928, though initially justified by the high MSRP.

Cheers

Is the answer in this video:

https://www.youtube.com/watch?v=NdCp0cZLivQ

At about 15:28, they put the car on a shaker device. Besides just "safety testing" the assembly, might this be step one in settling the suspension? Then re-adjust after the tech's shakedown drive?

I guess a follow-up question is, are most other cars simply assembled, tested/ adjusted and shipped? Seems like a very cumbersome process with the 928, though initially justified by the high MSRP.

Cheers

That was an NVH test.

The factory procedure was to pull the chassis down,

The following 2 users liked this post by Speedtoys:

RennHarry (02-16-2023),

Smitje 928 (02-20-2023)

#22

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

For those in the know, how did Porsche originally set up the cars in the factory? Certainly they were not delivering them with 50+ miles on the odo, were they?

Is the answer in this video:

At about 15:28, they put the car on a shaker device. Besides just "safety testing" the assembly, might this be step one in settling the suspension? Then re-adjust after the tech's shakedown drive?

Is the answer in this video:

At about 15:28, they put the car on a shaker device. Besides just "safety testing" the assembly, might this be step one in settling the suspension? Then re-adjust after the tech's shakedown drive?

Anytime I lift the nose of a 928 I move it to my 4-post lift and pull the nose down.

The following 2 users liked this post by hacker-pschorr:

RennHarry (02-16-2023),

Smitje 928 (02-20-2023)

#23

Of course, one would assume that! I just meant, all the talk around here about leaving things loose for a mile or two, letting things settle, rinse and repeat etc. caused me to question if Porsche did anything like that during factory assembly. Sounds like the 928 is no different as far as factory assembly is concerned, and the very smart enthusiasts here have come up with a clever (and simple!) alternate procedure.

Thanks for explaining

Cheers

The following users liked this post:

Smitje 928 (02-20-2023)

#24

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Of course, one would assume that! I just meant, all the talk around here about leaving things loose for a mile or two, letting things settle, rinse and repeat etc. caused me to question if Porsche did anything like that during factory assembly. Sounds like the 928 is no different as far as factory assembly is concerned, and the very smart enthusiasts here have come up with a clever (and simple!) alternate procedure.

Thanks for explaining

Cheers

Thanks for explaining

Cheers

Also from the WSM:

Volume IV

Page 40-5

Bolt #19

From the manual:

"Screw in until only 2 threads are visible. Do not tighten to 120Nm (88 fltb) until assembly is completed and springs have settled"

Years ago (like 20) we had a local guy follow that procedure but forgot to actually torque those four bolts, they were "snug". He didn't make it 5 miles before one of them fell out and the other buggered up the threads really bad in the chassis.

As for the factory, since these cars have adjustable ride height and all got an alignment before leaving, I can only assume the followed these same procedures to adjust / set ride height and torque those bolts.

The following 2 users liked this post by hacker-pschorr:

RennHarry (02-16-2023),

Smitje 928 (02-20-2023)

#26

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

#27

Rennlist Member

Thread Starter

What I do to settle the front end after LCA removal is to leave the rear clamp bolts loose by 1 turn.

NOTE the rear LCA clamps capture metal alignment collars that are in the cross member pad area so they cant come free of the mounting pads,

BUT the rubber bushing will be able to twist in the clamped area with the clamp not fully tightened.

Also leave these bolts loose but snug

the lower shock bolt, as well as the upper sway bar link

and the lower sway bar link.

Go drive the car about 2 miles use the brakes a few times to load the front end, then park on a flat surface,

Get some cardboard and slide under under the car without jacking it up and tighten the rear LCA bolts.86 FT/Lbs

NOTE the front LCA bolts get tightened to 66 Ft/Lbs.

Then drive the car for 50 miles.

Note during this time if the car is still sitting hi i would suggest to drive it for 20 miles then measure the RH,

jack the car up and reset the ride height use Speedtoys link to figure how much you need to lower the car,

shoot for the hi side measurement as the RH will drop after a few hundred miles.

Make sure the adjuster collars are within 2 turns of each other

then while its on the alignment rack you can tighten the lower shock mount and the lower sway bar link bolts.

NOTE the rear LCA clamps capture metal alignment collars that are in the cross member pad area so they cant come free of the mounting pads,

BUT the rubber bushing will be able to twist in the clamped area with the clamp not fully tightened.

Also leave these bolts loose but snug

the lower shock bolt, as well as the upper sway bar link

and the lower sway bar link.

Go drive the car about 2 miles use the brakes a few times to load the front end, then park on a flat surface,

Get some cardboard and slide under under the car without jacking it up and tighten the rear LCA bolts.86 FT/Lbs

NOTE the front LCA bolts get tightened to 66 Ft/Lbs.

Then drive the car for 50 miles.

Note during this time if the car is still sitting hi i would suggest to drive it for 20 miles then measure the RH,

jack the car up and reset the ride height use Speedtoys link to figure how much you need to lower the car,

shoot for the hi side measurement as the RH will drop after a few hundred miles.

Make sure the adjuster collars are within 2 turns of each other

then while its on the alignment rack you can tighten the lower shock mount and the lower sway bar link bolts.

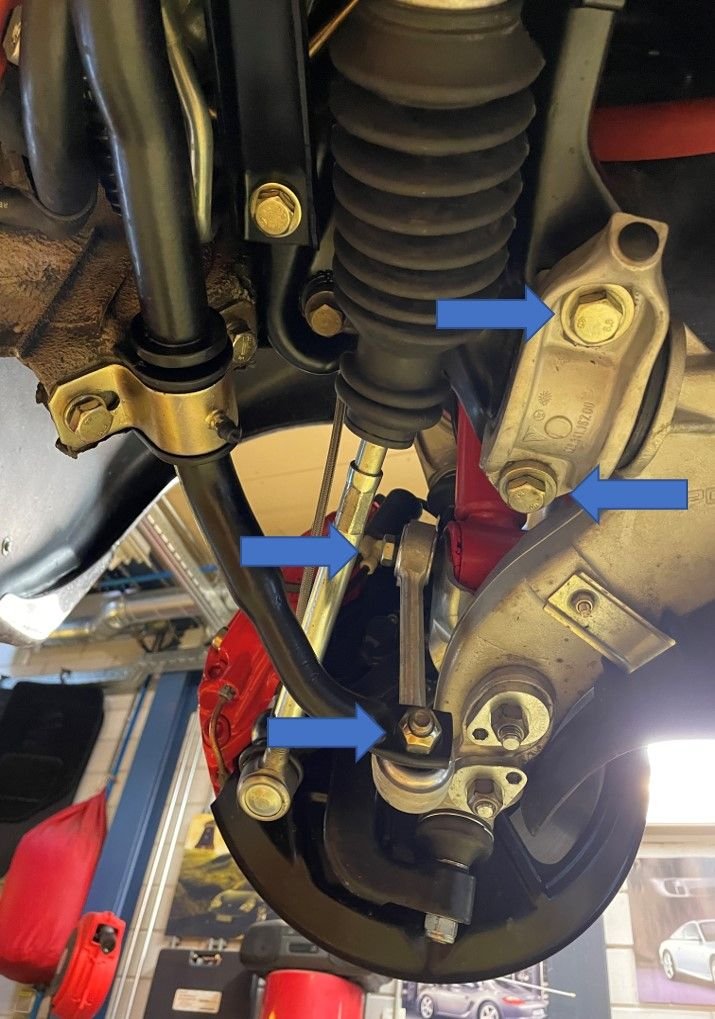

Just to be sure: are these all the bolts I need to loosen up?

Would you recommend loosening the bolts on the sway bar bushings as well? Or might that have a negative effect on the setting of the suspension?

#28

Team Owner

NO dont loosen the sway bar bushing bolts.

Yes all of those bolts in blue should be left loose but snug till you can drive the car.

final tighten the LCA clamp bolts with the car sitting on the ground.

The lower shock bolt and lower sway bar link bolts can be final tightened when the car is put on the alignment rack.

. Remember that simply pulling down the front end without having the slide plates under the tires will limit the amount that the suspension settles

.Meaning that The suspension wont really settle as much as you want it too .

I know it sounds good about pulling down the front end, BUT most owners dont have the slide plates,

and the car will usually get get driven to the rack that has the slide plates when the alignment happens ,

so no harm in leaving the bolts snug till then.

NOTE your still gonna find that with lots of new parts,

you want to let the car load all the parts ,

and driving the car does a way better job of letting the suspension parts find their home.

SO drive around a few miles, Then tighten the rear clamps,

Then put 50 miles on the chassis

prior to getting the alignment done.

NOTE after major work has been done.

IE LCA have been removed from their saddles.

This is how I have been doing this for the last 25 years,

it results in a more accurate alignment, a solid handling chassis

and a happy customer,

thats not bitching about brand new tires,

with worn out inner edges and 2000 miles on the car since I worked on it, BTDT.

Yes all of those bolts in blue should be left loose but snug till you can drive the car.

final tighten the LCA clamp bolts with the car sitting on the ground.

The lower shock bolt and lower sway bar link bolts can be final tightened when the car is put on the alignment rack.

. Remember that simply pulling down the front end without having the slide plates under the tires will limit the amount that the suspension settles

.Meaning that The suspension wont really settle as much as you want it too .

I know it sounds good about pulling down the front end, BUT most owners dont have the slide plates,

and the car will usually get get driven to the rack that has the slide plates when the alignment happens ,

so no harm in leaving the bolts snug till then.

NOTE your still gonna find that with lots of new parts,

you want to let the car load all the parts ,

and driving the car does a way better job of letting the suspension parts find their home.

SO drive around a few miles, Then tighten the rear clamps,

Then put 50 miles on the chassis

prior to getting the alignment done.

NOTE after major work has been done.

IE LCA have been removed from their saddles.

This is how I have been doing this for the last 25 years,

it results in a more accurate alignment, a solid handling chassis

and a happy customer,

thats not bitching about brand new tires,

with worn out inner edges and 2000 miles on the car since I worked on it, BTDT.

The following 3 users liked this post by Mrmerlin:

The following users liked this post:

Mrmerlin (02-22-2023)

#30

Former Sponsor

I'm not going to technically address this, or give any clues to the extend of what we do to make cars ride, with "fresh suspension" at lower front ride heights.

For one thing, I'm no longer posting "technical" stuff or clues about how to do things, here. And this stuff is very proprietary information, on top of that.

However, I will make a point which seems to escape everyone, here:

The cars left the factory at 183mm +/-10mm, front ride height. Certainly no lower than that, directly from the factory.

By the time they got here, bouncing across the ocean, for a month or two, they settled to somewhere between 173mm to 183mm.

No one could lower the early cars...where they sat is where they sat, until the springs "settled" and the control arms settled.

I seen "heated springs" to get these cars lower.

The "later cars", while they had adjustment ability, could not be lowered past 165mm, for certain. (Most all of the later adjusters were threaded almost all the way down, to get the ride height down, from the factory.)

Heck, Mark Anderson had made and sold several "productions runs" of lowering springs to be able to lower these cars....

Years later, as the springs settled in and the control arm bushings settled in, the ride heights did decrease.

And the cars could "drop" down into the 150mm range, unless someone raised them.

The whole point is that if you want a car at 150mm-160mm (with a fresh suspension), you are going to have to make some changes to what is there, to be able to accomplish that.

Or wait patiently, for a couple of years, allowing it to bounce itself lower.

For one thing, I'm no longer posting "technical" stuff or clues about how to do things, here. And this stuff is very proprietary information, on top of that.

However, I will make a point which seems to escape everyone, here:

The cars left the factory at 183mm +/-10mm, front ride height. Certainly no lower than that, directly from the factory.

By the time they got here, bouncing across the ocean, for a month or two, they settled to somewhere between 173mm to 183mm.

No one could lower the early cars...where they sat is where they sat, until the springs "settled" and the control arms settled.

I seen "heated springs" to get these cars lower.

The "later cars", while they had adjustment ability, could not be lowered past 165mm, for certain. (Most all of the later adjusters were threaded almost all the way down, to get the ride height down, from the factory.)

Heck, Mark Anderson had made and sold several "productions runs" of lowering springs to be able to lower these cars....

Years later, as the springs settled in and the control arm bushings settled in, the ride heights did decrease.

And the cars could "drop" down into the 150mm range, unless someone raised them.

The whole point is that if you want a car at 150mm-160mm (with a fresh suspension), you are going to have to make some changes to what is there, to be able to accomplish that.

Or wait patiently, for a couple of years, allowing it to bounce itself lower.

Last edited by GregBBRD; 02-24-2023 at 10:05 PM.

The following users liked this post:

Smitje 928 (02-25-2023)