What are your HVAC pressures and dash temps

#46

Three Wheelin'

Thread Starter

with ambient temp of 96'F

my current pressure at 2k on low side is 34, and max high of WSM is 17.

my current pressure at 2k on high side is 300 and max high from WSM is 282.

not sure what this means, but I have taken some Freon out, and low side reading stays pretty much the same?

will the expansion valve attempt to keep things at a constant, regardless of the level? this would confirm a valve issue?

my current pressure at 2k on low side is 34, and max high of WSM is 17.

my current pressure at 2k on high side is 300 and max high from WSM is 282.

not sure what this means, but I have taken some Freon out, and low side reading stays pretty much the same?

will the expansion valve attempt to keep things at a constant, regardless of the level? this would confirm a valve issue?

#48

Rennlist Member

with ambient temp of 96'F

my current pressure at 2k on low side is 34, and max high of WSM is 17.

my current pressure at 2k on high side is 300 and max high from WSM is 282.

not sure what this means, but I have taken some Freon out, and low side reading stays pretty much the same?

will the expansion valve attempt to keep things at a constant, regardless of the level? this would confirm a valve issue?

my current pressure at 2k on low side is 34, and max high of WSM is 17.

my current pressure at 2k on high side is 300 and max high from WSM is 282.

not sure what this means, but I have taken some Freon out, and low side reading stays pretty much the same?

will the expansion valve attempt to keep things at a constant, regardless of the level? this would confirm a valve issue?

I'll have to Dbl check that at home, what page shows a max low side pressure of 17psi?

That like..15deg, way too cold/low. Again, ill look in mine, but 25psi feels "right'ish". Below freezing but not dramatically so given there's a freeze switch.

#52

Three Wheelin'

Thread Starter

is there anything other than the expansion valve that could be regulating low pressure number? why in the heck would my low pressure be constant, even as I remove Freon?

compressor seems fine, and condenser is either good or bad; cooling fans are working and engine is at proper temp.

compressor seems fine, and condenser is either good or bad; cooling fans are working and engine is at proper temp.

#53

Rennlist Member

I will tell you the 928’s AC is not really up to par for very humid locations (black with black interior) and less than 1/2 hour drives. It, as others explained, cannot both remove giant amounts of water and lower the temps. We are not Florida here in Iowa, but we get lots of 80-90% days with temps in the high 80s and 90s. The AC just can’t keep up. I get fog blowing out of my center vent because the system is overwhelmed. When Ron had it in California, it worked great, as it should. No humidity to deal with. My Chevy pickup (single cab) does a great job, but then there is no volume in that cabin.

#54

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

is there anything other than the expansion valve that could be regulating low pressure number? why in the heck would my low pressure be constant, even as I remove Freon?

compressor seems fine, and condenser is either good or bad; cooling fans are working and engine is at proper temp.

compressor seems fine, and condenser is either good or bad; cooling fans are working and engine is at proper temp.

The expansion valve adjusts refrigerant flow through the evaporator, based on the outlet temp to the compressor suction. That's where you are seeing low-side pressure. At a given compressor speed, the mass that the compressor pumps is related to the specific volume of the discharged refrigerant (varies by pressure and temperature). Bleeding refrigerant will cause the evaporator temperature to increase, especially as a smaller fraction of the flow into the expansion valve is liquid. So it opens more, increasing the flow volume through the evaporator and therefore the compressor suction pressure.

Go look now and see if the sight glass gas many bubbles, If there are any, don't bleed out any more refrigerant. In any case really, don't bleed out any refrigerant. Go drive the car, looking at passenger floor and your center vent temps at a steady cruise condition to see how much temp you are actually shedding across the evaporator. The RH in the cabin goes up as temps drop, assuming a constant amount of moisture in the same air, so an ambient RH and temp outside will be a bit of a help but not definitive. Mostly a licked-finger-in-the-wind SWAG at how much work the system is doing trying to remove moisture.

----

Focus your efforts on getting liquid to the expansion valve, and let it do its job. The receiver/drier is a reservoir for condensed liquid in its spare time. Slight changes in system load will raise or lower the high-side pressure, with the compressor efficiency and speed, with the specific volume of the refrigerant in the compressor and the amount of heat absorbed by the refrigerant (heat of evaporation plus change in refrigerant sensible heat) the causes of those changes. The expansion valve adjusts pretty well to the changing conditions, doing its best to meter the best amount of liquid into the evaporator. The system will find equilibrium for all those conditions.

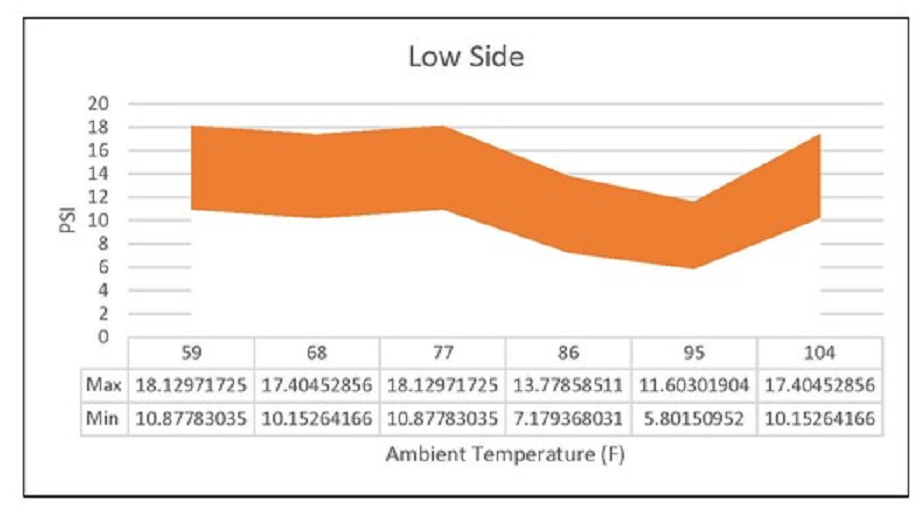

Maybe the easiest way to look at the WSM charts is to look at evaporator and ambient temps, and see how close your pressures are. In a system with no non-condensibles (air), worn wear components (compressor or expansion valve) or poor heat transfer (dirty condenser, dirty evaporator) are the only possible causes on pressures that don't match design. The subset of the heat transfer side is the flaps and doors, where heat can be allowed into the evaporator side. Regardless, the evaporation temp of the liquid refrigerant is exactly the number you see on the low-side gauge on the R134a ring. The condensing temperature is exactly the number you see on the high-side gauge. If you are passing liquid to the expansion valve, the evaporation temp inside the evaporator is exactly what's shown on the gauge. Similarly, the condensing temp inside the condenser is exactly the condensing temp shown on the gauge. Deltas between measured temp and the temp inside each of those exchangers is relative to the total heat being absorbed or shed. You are trying to account for that heat being absorbed or shed to explain the deltas. All ASSuming that you are passing liquid to the expansion valve.

I'm running out of ways to explain all this.

#55

Three Wheelin'

Thread Starter

dr. bob, greatly appreciate your diligence in helping me understand......don't give up on me...lol

I just reinstalled my old expansion valve and did a poor recharge without pulling a vacuum. it is 95' ambient and @ 2k, I have 15 on my low side and dash vent temp of 39'. I have lots of white foam/bubbles in the sight glass. perhaps the poor recharge? the AC shop told me if I change the valve and put in Freon, they would do a proper recharge on Tuesday for $20. with no charge for gas. I have a noon appt.

so was my new expansion valve bad, or improperly calibrated? the "original" one has a sticker with Egelhof, made in france, and R134a on it. the new one, that I bought from Griffiths, has a sticker with the brand kuehl, and nothing else. of note, the valve from Griffiths was twice the price of the one I got from roger for my rear AC, and when I called for help the owner was, to put it quire mildly, extremely rude

my AC is back and should be great after a proper evac and recharge. is the foam in the sight glass strictly an indication of low Freon, or air or moisture?

I just reinstalled my old expansion valve and did a poor recharge without pulling a vacuum. it is 95' ambient and @ 2k, I have 15 on my low side and dash vent temp of 39'. I have lots of white foam/bubbles in the sight glass. perhaps the poor recharge? the AC shop told me if I change the valve and put in Freon, they would do a proper recharge on Tuesday for $20. with no charge for gas. I have a noon appt.

so was my new expansion valve bad, or improperly calibrated? the "original" one has a sticker with Egelhof, made in france, and R134a on it. the new one, that I bought from Griffiths, has a sticker with the brand kuehl, and nothing else. of note, the valve from Griffiths was twice the price of the one I got from roger for my rear AC, and when I called for help the owner was, to put it quire mildly, extremely rude

my AC is back and should be great after a proper evac and recharge. is the foam in the sight glass strictly an indication of low Freon, or air or moisture?

Last edited by merchauser; 05-27-2019 at 02:19 PM.

#56

Rennlist Member

Paul,

Bubbles in the sight glass are invariably caused by non condensable gas- presumably air.

The expansion valve is the main modulating control on the system, the fans modulate to some extent but that is basically to help out when in traffic/running slow and has limited effect. Basically the expansion valve is trying to control the evaporator temperature at some point just above zero C. The freeze switch, as its name suggests, tries to prevent icing on the evaporator. The only way it can do this is to drop out the compressor if the temperature it detects reaches the set point which presumably is one or two degrees C max. This is where I see a conundrum in the WSM data for R134. If the freeze switch is working the system should naturally try to avoid the trip condition so it would need to try to control the temperature of the evaporator such that it is one or two degrees C above the freeze switch set point which is what the engineering world calls a trip function rather than a control function and when the freeze switch registers another calibrated temperature higher than the set point it kicks back in. Unfortunately I do not know these numbers so can only speculate as to what they may be.

Thus by my logic the evaporator should run at about 2 or 3 degrees C and given the evaporator is a rather crude serpentine air cooler, the approach temperature of the air flowing over the evaporator should be about 5 degrees C higher than the core temperature i.e. 8 degrees C and strangely enough that is about what my system seems to deliver consistently when the ambient temperature does not exceed 35C. Now the important bit to note at this stage - if the expansion valve is within its design range the vent temperature should be constant as should the low pressure given the two are inextricably linked. This is pretty much what we see on the 134 curves and in fact it shows values dropping as ambient temperature increases which to me is thermodynamic nonsense- it just may be a quirk of the way data was gather and the system responds but the notion that the vent temperature does not exceed 3 degrees C is just not technically possible if the freeze switch is functional.

Once the ambient reaches 35C the pressure and temperature start to take off and that is because the expansion valve presumably is now out of its control range and cannot flow any more refrigerant to compensate for the increasing ambient temperature and this is logical as the compressor has a fixed displacement. Obviously as the motor spins faster the compressor can move more gas but my testing suggests that it helps ac performance up to about 3.5k rpms and then makes no more difference. Have not quite figured this one out yet but I suspect all that happens is the high pressure increases but we cannot see this happening [obviously].

To understand what is going on one has to be able to interpret the Mollier diagram for the specific refrigerant being worked. This basically tells the engineer how much heat is flowing around the system. I took a look at the Mollier diagrams for both R12 and R134 and came to some interesting conclusions. Both systems run virtually identical pressures at zero degrees C temperature and this amounts to 3 bar A or two bars gauge [30 psig in round terms]. What this tells me is that if you are seeing pressures lower than this you probably do not have enough gas in the system. If you are seeing pressures down at 15 psig or even 10 psig then you should be worried as you may not be pumping enough gas to carry sufficient lube oil to support compressor operation and if so that would accelerate wear- not good.

So- using the logic implied above is the Porsche data correct or have they done something silly like call the evaporator temperature the vent temperature and something got lost in the translation?

Now let's move on to my favorite subject- relative humidity. In your neck of the woods you see similar conditions to my self, not quite as hot but possibly more humid than I see. Typical humidity around my beachfront villa is 40% to 50% and today the thermometer climbed above 40C for the first time this year. You typically see about 30C and 60% humidity. For those interested, when testing ac performance Porsche recommend that the motor run for 10 minutes- this is required to achieve "steady state". My testing suggests this is a very realistic number, possibly even a bit optimistic. So anyone doing measurement tests need to take this into account. Just as one has to measure at exactly 2k rpms and fan speed number 2 on the dial. Other numbers are meaningless. When I did this I got something like 24 psig on the inlet and 270 psig on the high pressure side. Rev the motor to 3k plus rpms and the pressure topped 300 psig. This does not align with the data in the WSM but it seems to align perfectly with other generic data. So which is correct? For purposes of discussion let's assume that when the system is running at steady state the air temperature leaving the cabin is warmed to about 25 C and the evaporator temperature is 5C. Considering the high pressure is about 20 barg and the low pressure is 2 barg [30 psig] the enthalpies of dry air compared to air at 66% RH tell us that the thermal duty of the RH case is twice that of the dry air case so no wonder that such makes a considerable performance difference. The bit one does not know is what the performance limits really are. My years of experience over here tell me that the system works quite OK up to 35C and after that it starts to struggle. If the humidity drops [as it does when motoring away from the coast and over the mountains, the humidity drops rapidly and the temperature goes up. I have driven in dryish temperatures of up to 44C and felt quite OK and with 50% to 60% relative humidity that number is 35C. In slow moving traffic that number drops to about 30C.

How Porsche got their LP data is beyond my comprehension- not saying they are wrong but it just does not make technical sense that I can relate to whereas their R12 data did when I ran on it. I need to recheck my numbers since fitting my recirc box and blower and cleaning up the evaporator but I do not expect much difference.

Pretty much my 2 cents worth on the subject matter.

Bubbles in the sight glass are invariably caused by non condensable gas- presumably air.

The expansion valve is the main modulating control on the system, the fans modulate to some extent but that is basically to help out when in traffic/running slow and has limited effect. Basically the expansion valve is trying to control the evaporator temperature at some point just above zero C. The freeze switch, as its name suggests, tries to prevent icing on the evaporator. The only way it can do this is to drop out the compressor if the temperature it detects reaches the set point which presumably is one or two degrees C max. This is where I see a conundrum in the WSM data for R134. If the freeze switch is working the system should naturally try to avoid the trip condition so it would need to try to control the temperature of the evaporator such that it is one or two degrees C above the freeze switch set point which is what the engineering world calls a trip function rather than a control function and when the freeze switch registers another calibrated temperature higher than the set point it kicks back in. Unfortunately I do not know these numbers so can only speculate as to what they may be.

Thus by my logic the evaporator should run at about 2 or 3 degrees C and given the evaporator is a rather crude serpentine air cooler, the approach temperature of the air flowing over the evaporator should be about 5 degrees C higher than the core temperature i.e. 8 degrees C and strangely enough that is about what my system seems to deliver consistently when the ambient temperature does not exceed 35C. Now the important bit to note at this stage - if the expansion valve is within its design range the vent temperature should be constant as should the low pressure given the two are inextricably linked. This is pretty much what we see on the 134 curves and in fact it shows values dropping as ambient temperature increases which to me is thermodynamic nonsense- it just may be a quirk of the way data was gather and the system responds but the notion that the vent temperature does not exceed 3 degrees C is just not technically possible if the freeze switch is functional.

Once the ambient reaches 35C the pressure and temperature start to take off and that is because the expansion valve presumably is now out of its control range and cannot flow any more refrigerant to compensate for the increasing ambient temperature and this is logical as the compressor has a fixed displacement. Obviously as the motor spins faster the compressor can move more gas but my testing suggests that it helps ac performance up to about 3.5k rpms and then makes no more difference. Have not quite figured this one out yet but I suspect all that happens is the high pressure increases but we cannot see this happening [obviously].

To understand what is going on one has to be able to interpret the Mollier diagram for the specific refrigerant being worked. This basically tells the engineer how much heat is flowing around the system. I took a look at the Mollier diagrams for both R12 and R134 and came to some interesting conclusions. Both systems run virtually identical pressures at zero degrees C temperature and this amounts to 3 bar A or two bars gauge [30 psig in round terms]. What this tells me is that if you are seeing pressures lower than this you probably do not have enough gas in the system. If you are seeing pressures down at 15 psig or even 10 psig then you should be worried as you may not be pumping enough gas to carry sufficient lube oil to support compressor operation and if so that would accelerate wear- not good.

So- using the logic implied above is the Porsche data correct or have they done something silly like call the evaporator temperature the vent temperature and something got lost in the translation?

Now let's move on to my favorite subject- relative humidity. In your neck of the woods you see similar conditions to my self, not quite as hot but possibly more humid than I see. Typical humidity around my beachfront villa is 40% to 50% and today the thermometer climbed above 40C for the first time this year. You typically see about 30C and 60% humidity. For those interested, when testing ac performance Porsche recommend that the motor run for 10 minutes- this is required to achieve "steady state". My testing suggests this is a very realistic number, possibly even a bit optimistic. So anyone doing measurement tests need to take this into account. Just as one has to measure at exactly 2k rpms and fan speed number 2 on the dial. Other numbers are meaningless. When I did this I got something like 24 psig on the inlet and 270 psig on the high pressure side. Rev the motor to 3k plus rpms and the pressure topped 300 psig. This does not align with the data in the WSM but it seems to align perfectly with other generic data. So which is correct? For purposes of discussion let's assume that when the system is running at steady state the air temperature leaving the cabin is warmed to about 25 C and the evaporator temperature is 5C. Considering the high pressure is about 20 barg and the low pressure is 2 barg [30 psig] the enthalpies of dry air compared to air at 66% RH tell us that the thermal duty of the RH case is twice that of the dry air case so no wonder that such makes a considerable performance difference. The bit one does not know is what the performance limits really are. My years of experience over here tell me that the system works quite OK up to 35C and after that it starts to struggle. If the humidity drops [as it does when motoring away from the coast and over the mountains, the humidity drops rapidly and the temperature goes up. I have driven in dryish temperatures of up to 44C and felt quite OK and with 50% to 60% relative humidity that number is 35C. In slow moving traffic that number drops to about 30C.

How Porsche got their LP data is beyond my comprehension- not saying they are wrong but it just does not make technical sense that I can relate to whereas their R12 data did when I ran on it. I need to recheck my numbers since fitting my recirc box and blower and cleaning up the evaporator but I do not expect much difference.

Pretty much my 2 cents worth on the subject matter.

#57

Rennlist Member

Neither.

It's been a lack of sanitary practices since the moment you asked Professor Alzheimer next door to help you.

When he lost track of what he put in the system, with the low quality evacuation that was performed on it...this thread could only go one way. Way back then, the only thing to have done was a proper vacuum and a proper full to then judge what else could possibly be wrong. But that was not available to us. So it's been a typical internet HVAC snipe hunt, wrapped around results of the job done, but not the quality of the job done.

And it culminated with useless HW swapping, zero evacuation done, and junk results.

Best thing you can do now is:

Pull a vacuum on it overnight.

Let it rest for 24hrs, see if it holds.

If it does, pull another overnighter before your AC shop appointment, inform them there is a vacuum on it now, verify it, let them properly refill it...do not open it up again to outside air.

The quicky machine (15min) vacuum they will pull on it now that you have contaminated the system again, will be useless...it needs houurrrrrs to undue moisture that has been in there, settling in the oil and dessicant...for weeks.

It's been a lack of sanitary practices since the moment you asked Professor Alzheimer next door to help you.

When he lost track of what he put in the system, with the low quality evacuation that was performed on it...this thread could only go one way. Way back then, the only thing to have done was a proper vacuum and a proper full to then judge what else could possibly be wrong. But that was not available to us. So it's been a typical internet HVAC snipe hunt, wrapped around results of the job done, but not the quality of the job done.

And it culminated with useless HW swapping, zero evacuation done, and junk results.

Best thing you can do now is:

Pull a vacuum on it overnight.

Let it rest for 24hrs, see if it holds.

If it does, pull another overnighter before your AC shop appointment, inform them there is a vacuum on it now, verify it, let them properly refill it...do not open it up again to outside air.

The quicky machine (15min) vacuum they will pull on it now that you have contaminated the system again, will be useless...it needs houurrrrrs to undue moisture that has been in there, settling in the oil and dessicant...for weeks.

#58

Three Wheelin'

Thread Starter

It's been a lack of sanitary practices since the moment you asked Professor Alzheimer next door to help you.

When he lost track of what he put in the system, with the low quality evacuation that was performed on it.

And it culminated with useless HW swapping, zero evacuation done, and junk results.

The quicky machine (15min) vacuum they will pull on it now that you have contaminated the system again, will be useless...it needs houurrrrrs to undue moisture that has been in there, settling in the oil and dessicant...for weeks.

the good news is my air is super freaky ice ice baby cold, and numbers are in WSM specs!

a few weeks ago I did a vacuum down to 360 microns and a refill to 91% of R12 specs. results were very good, but not perfect. high side was slightly low, suggesting a tad low on Freon. unfortunately, my home made low side port extension leaked, and I lost most of my charge. Griffiths suggested I replaced my 16 year old expansion valve and I thought it couldn't hurt. before installing, I rented an evac pump, changed the pump oil, and vacuumed in three 12 hour intervals for three days. certain overkill, but I got microns down to 300. tried a variety of fills from 80% to 91% and low side numbers never got below 34 (mostly above 40) and dash temps were at 54'. that's when I took the car to the AC shop. no change. then i went the other way and removed some gas, but low side stayed constant in the mid to high 30's.

yesterday, as the AC tech suggested, i reinstalled my original valve. the system was "open" for no more than 20 minutes. then, with no evacuation, no scale, and a manifold with a broken high side gauge, i charged to WSM low side values. with temp at 97', I filled to 12 on the low side gauge. dash vent temps were around 42' when i had to pack it in.

i just got back from a drive, ambient is 88',and the AC is amazing! most of the time the vent temp was 37-39, and at times down to 32. i think my freeze switch is finally getting some exercise. there were a few times when the sound of the air over the evaporator change pitch, slightly, and temp rose to 40. shortly the sound returned to the original pitch, and temp dropped again.

AC has been transformed and never worked this well. there is no question that the Kuehl expansion valve was the culprit. i thought Griffiths would be selling some supercharged "better" TEV, but when i asked, was told it was a non OEM generic. i don't know whether this was just a bad unit, or the calibration is not compatible with 928's. Griffiths charged twice the price of the one i got from roger (which worked perfectly), and when i called for customer service, he was rude and his behavior was uncalled for. seems like this is a pattern from long ago:

https://rennlist.com/forums/928-foru...-griffith.html

the big irony is that my successful result came from a crude and savage execution, without a proper evac, no fill by weight, and a broken down manifold.

the only issue is that my sight glass is milky. my horrendous eyesight cannot discern between bubbles, gas, and foam, so no idea if milky is good?

#59

Rennlist Member

jeff, I think you may have missed some of my posts? there were some early comedic errors, but was able to put those behind me.

the good news is my air is super freaky ice ice baby cold, and numbers are in WSM specs!

a few weeks ago I did a vacuum down to 360 microns and a refill to 91% of R12 specs. results were very good, but not perfect. high side was slightly low, suggesting a tad low on Freon. unfortunately, my home made low side port extension leaked, and I lost most of my charge. Griffiths suggested I replaced my 16 year old expansion valve and I thought it couldn't hurt. before installing, I rented an evac pump, changed the pump oil, and vacuumed in three 12 hour intervals for three days. certain overkill, but I got microns down to 300. tried a variety of fills from 80% to 91% and low side numbers never got below 34 (mostly above 40) and dash temps were at 54'. that's when I took the car to the AC shop. no change. then i went the other way and removed some gas, but low side stayed constant in the mid to high 30's.

yesterday, as the AC tech suggested, i reinstalled my original valve. the system was "open" for no more than 20 minutes. then, with no evacuation, no scale, and a manifold with a broken high side gauge, i charged to WSM low side values. with temp at 97', I filled to 12 on the low side gauge. dash vent temps were around 42' when i had to pack it in.

i just got back from a drive, ambient is 88',and the AC is amazing! most of the time the vent temp was 37-39, and at times down to 32. i think my freeze switch is finally getting some exercise. there were a few times when the sound of the air over the evaporator change pitch, slightly, and temp rose to 40. shortly the sound returned to the original pitch, and temp dropped again.

AC has been transformed and never worked this well. there is no question that the Kuehl expansion valve was the culprit. i thought Griffiths would be selling some supercharged "better" TEV, but when i asked, was told it was a non OEM generic. i don't know whether this was just a bad unit, or the calibration is not compatible with 928's. Griffiths charged twice the price of the one i got from roger (which worked perfectly), and when i called for customer service, he was rude and his behavior was uncalled for. seems like this is a pattern from long ago:

https://rennlist.com/forums/928-foru...-griffith.html

the big irony is that my successful result came from a crude and savage execution, without a proper evac, no fill by weight, and a broken down manifold.

the only issue is that my sight glass is milky. my horrendous eyesight cannot discern between bubbles, gas, and foam, so no idea if milky is good?

the good news is my air is super freaky ice ice baby cold, and numbers are in WSM specs!

a few weeks ago I did a vacuum down to 360 microns and a refill to 91% of R12 specs. results were very good, but not perfect. high side was slightly low, suggesting a tad low on Freon. unfortunately, my home made low side port extension leaked, and I lost most of my charge. Griffiths suggested I replaced my 16 year old expansion valve and I thought it couldn't hurt. before installing, I rented an evac pump, changed the pump oil, and vacuumed in three 12 hour intervals for three days. certain overkill, but I got microns down to 300. tried a variety of fills from 80% to 91% and low side numbers never got below 34 (mostly above 40) and dash temps were at 54'. that's when I took the car to the AC shop. no change. then i went the other way and removed some gas, but low side stayed constant in the mid to high 30's.

yesterday, as the AC tech suggested, i reinstalled my original valve. the system was "open" for no more than 20 minutes. then, with no evacuation, no scale, and a manifold with a broken high side gauge, i charged to WSM low side values. with temp at 97', I filled to 12 on the low side gauge. dash vent temps were around 42' when i had to pack it in.

i just got back from a drive, ambient is 88',and the AC is amazing! most of the time the vent temp was 37-39, and at times down to 32. i think my freeze switch is finally getting some exercise. there were a few times when the sound of the air over the evaporator change pitch, slightly, and temp rose to 40. shortly the sound returned to the original pitch, and temp dropped again.

AC has been transformed and never worked this well. there is no question that the Kuehl expansion valve was the culprit. i thought Griffiths would be selling some supercharged "better" TEV, but when i asked, was told it was a non OEM generic. i don't know whether this was just a bad unit, or the calibration is not compatible with 928's. Griffiths charged twice the price of the one i got from roger (which worked perfectly), and when i called for customer service, he was rude and his behavior was uncalled for. seems like this is a pattern from long ago:

https://rennlist.com/forums/928-foru...-griffith.html

the big irony is that my successful result came from a crude and savage execution, without a proper evac, no fill by weight, and a broken down manifold.

the only issue is that my sight glass is milky. my horrendous eyesight cannot discern between bubbles, gas, and foam, so no idea if milky is good?

#60

Three Wheelin'

Thread Starter

for sure, it was a bastardized recharge, but my air is so freaking cold and the numbers are spot on. now that I know I have the correct expansion valve, and my system is "capable" of performing like a thoroughbred, I would not be afraid to start over one more time. but what could I possibly gain?

is it possible that milky/foam could be a result of the lower that factory charge level necessary for R134a?

I am very curious to find out current fill rate/weight, but not arbitrarily.

is it possible that milky/foam could be a result of the lower that factory charge level necessary for R134a?

I am very curious to find out current fill rate/weight, but not arbitrarily.