93 GTS Engine - Sleeved or normal?

#16

The Parts Whisperer

Rennlist

Site Sponsor

Rennlist

Site Sponsor

#17

Banned

I'd be looking for someone to scan a 928 block and come up with a solidworks file, however. I don't have any time or resources to do that part. However, if some enterprising dude had a good file that we could use to machine, heck yeah I'd clamp a hunk of billet in the machine and go to town.....

#18

Rennlist Member

That is quite an offer!

#19

Former Sponsor

#20

Banned

Why don't you guys develop the model, and I will make it then. I know very little about the 928 block other than the generalities. If you guys were to come up with the "killer design" and a model I could use to create a tool path, we could make a few assuming there was demand. We can figure out the machining, all you need to do is come up with a solidworks model of what the ideal block looks like.

Then we can machine it from a piece of 6061 and it would crush the stock block.

Then we can machine it from a piece of 6061 and it would crush the stock block.

#21

Former Sponsor

Why don't you guys develop the model, and I will make it then. I know very little about the 928 block other than the generalities. If you guys were to come up with the "killer design" and a model I could use to create a tool path, we could make a few assuming there was demand. We can figure out the machining, all you need to do is come up with a solidworks model of what the ideal block looks like.

Then we can machine it from a piece of 6061 and it would crush the stock block.

Then we can machine it from a piece of 6061 and it would crush the stock block.

With what you must have on your plate, that is an amazingly offer.

I'll talk to some solidworks people and see what is involved to do this.

#22

Rennlist Member

Join Date: Feb 2011

Location: Mostly in my workshop located in Sweden.

Posts: 2,234

Received 464 Likes

on

249 Posts

Alusil liner blanks.

http://www.pierburg-service.de/ximag...199_en_web.pdf

Honing of Alusil cylinders.

https://www.sunnen.com/NewsDetails.aspx?NewsID=11

┼ke

http://www.pierburg-service.de/ximag...199_en_web.pdf

Honing of Alusil cylinders.

https://www.sunnen.com/NewsDetails.aspx?NewsID=11

┼ke

Last edited by Strosek Ultra; 01-17-2019 at 02:54 PM.

#23

Banned

Yes, the stock blocks are certainly the limitation of making power. The silicon alloy is very brittle. A chunk of 6061 with some Nicosil liners would be...very nice.

With what you must have on your plate, that is an amazingly offer.

I'll talk to some solidworks people and see what is involved to do this.

With what you must have on your plate, that is an amazingly offer.

I'll talk to some solidworks people and see what is involved to do this.

This is what you need to do:

1. find your best block to use as a model

2. Have it scanned

3. Import that scan into solidworks

4. make all your proprietary changes, mods, improvements, whatever

5. Send that to me, where we will then create the toolpaths necessary to mill it.

6. We then mill it.

Obviously lots of little details between those steps, but you get the idea.

#25

Former Sponsor

#27

Rainman

Rennlist Member

Rennlist Member

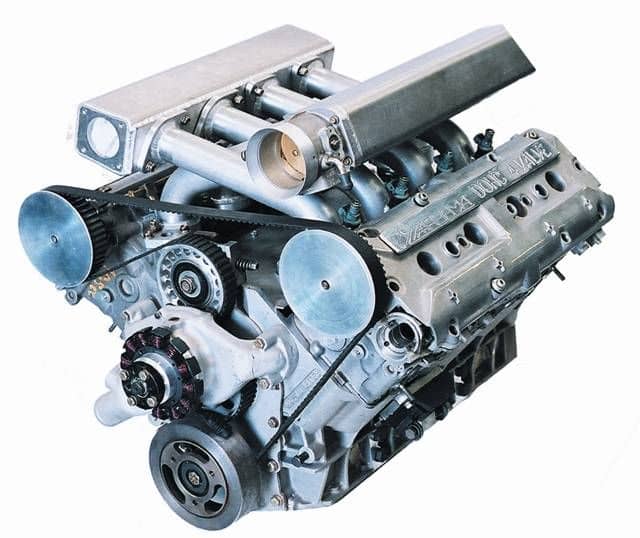

some similarities, even the bore spacing is nearly identical.

maybe one of the existing alum. 440 block manufacturers could be per$uaded to adjust their files for 4 head studs instead of 5/6, etc.

#28

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

have you ever looked at a 928 block and a Chrysler 440 block side by side?

some similarities, even the bore spacing is nearly identical.

maybe one of the existing alum. 440 block manufacturers could be per$uaded to adjust their files for 4 head studs instead of 5/6, etc.

some similarities, even the bore spacing is nearly identical.

maybe one of the existing alum. 440 block manufacturers could be per$uaded to adjust their files for 4 head studs instead of 5/6, etc.

There is a bonneville racer that manged to put 928 heads on a BBC.

#29

Former Sponsor

Yeah we are super busy but the reason I suggested it is that we *may* have some downtime soon. The foundry has thus far been making prototypes here and there, and there will probably be a delay for them to spool up to full production for us to get started, so I bet I will have pockets of time where this could be accomplished, but I definitely don't have the time to design the thing and even if I did, you're the 928 expert so.....

This is what you need to do:

1. find your best block to use as a model

2. Have it scanned

3. Import that scan into solidworks

4. make all your proprietary changes, mods, improvements, whatever

5. Send that to me, where we will then create the toolpaths necessary to mill it.

6. We then mill it.

Obviously lots of little details between those steps, but you get the idea.

This is what you need to do:

1. find your best block to use as a model

2. Have it scanned

3. Import that scan into solidworks

4. make all your proprietary changes, mods, improvements, whatever

5. Send that to me, where we will then create the toolpaths necessary to mill it.

6. We then mill it.

Obviously lots of little details between those steps, but you get the idea.

Rob Edwards wants to scan one, this weekend....to get it rolling.

#30

Former Sponsor