Piston Mods and Machining

#16

Three Wheelin'

hi Curtis....keep in mind that the stock pistons are "coated", but by either hard chrome or by iron/tin to keep the heat in the conbustion chamber, and minimize heat loss via the pistons/rings/pin.

Marc, interesting factoid, thanks for sharing!

This being the case, I would not be afraid to Ceramic coat the pistons. In fact if you didn't coat them with either Ceramic, Hard Chrome or iron/Tin after you machine the piston tops you may end up with degraded component performance that may result in an early failure.

Marc my problem was with coating the Piston Domes, Combustion Chambers and Valves with the Ceramic coating.

In the end, on the 10+/1 C/R motor I replaced the heads with another set of Iron Eagle's I had laying around and the engine was than streetable. I sold the coated heads to a friend who put them in his N/A street/strip Z28 and has been running well after several seasons.

Sometimes more is not better

______________________________

Back to the cylinder head, the below pic has an area highlighted in green that may need to be looked at.

Could this area not be cut out to lower the C/R?

JMHO, but if you take it off the head first, a person would not have to pull the engine and pistons out to get the C/R down.

Everything here is great, thanks for asking

Marc, interesting factoid, thanks for sharing!

This being the case, I would not be afraid to Ceramic coat the pistons. In fact if you didn't coat them with either Ceramic, Hard Chrome or iron/Tin after you machine the piston tops you may end up with degraded component performance that may result in an early failure.

Marc my problem was with coating the Piston Domes, Combustion Chambers and Valves with the Ceramic coating.

In the end, on the 10+/1 C/R motor I replaced the heads with another set of Iron Eagle's I had laying around and the engine was than streetable. I sold the coated heads to a friend who put them in his N/A street/strip Z28 and has been running well after several seasons.

Sometimes more is not better

______________________________

Back to the cylinder head, the below pic has an area highlighted in green that may need to be looked at.

Could this area not be cut out to lower the C/R?

JMHO, but if you take it off the head first, a person would not have to pull the engine and pistons out to get the C/R down.

Everything here is great, thanks for asking

Last edited by T_MaX; 01-09-2004 at 08:05 PM.

#17

Addict

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Join Date: Jan 2003

Location: Green Bay Wisconsin

Posts: 951

Likes: 0

Received 0 Likes

on

0 Posts

Hi Tony,

The one thing you still need to do is check how high the piston comes up in the bore. If it comes up 1mm above the deck or vise versa, below the deck you need to factor that into the equation. Do you still have the crank in the block? Here is a website that I use for a compression and displacement calculator.

http://www.angelfire.com/fl/procrastination/motor.html

If I plug in the factory specs and use a .5mm head gasket thickness I come up with 9.85:1 compression ratio. I used: 100mm bore, 78.9 stroke, 8 cylinders, 42cc head, -24cc piston, .5mm gasket. Now you can play.

As far as coating the tops of the pistons; I like the theory but I'm not sold on it. The factory doesn't do it. The new pistons today that run in alusil don't have any coating on the tops. The only thing they do in some select applications where they moved the wrist pin higher in the piston and reduced the top land height is to hard coat anodize the first ring groove. Now, NASCAR guys will hard coat the whole top of the piston but that is a different application from what we are doing.

I am absolutley not an authority on this subject but this is my initial opinion. I would not be concerned at all to machine a little off the tops of the pistons and run them that way. We cut valve reliefs in the 951 pistons and left them bare with no problems at all so why would this be any different.

The one thing you still need to do is check how high the piston comes up in the bore. If it comes up 1mm above the deck or vise versa, below the deck you need to factor that into the equation. Do you still have the crank in the block? Here is a website that I use for a compression and displacement calculator.

http://www.angelfire.com/fl/procrastination/motor.html

If I plug in the factory specs and use a .5mm head gasket thickness I come up with 9.85:1 compression ratio. I used: 100mm bore, 78.9 stroke, 8 cylinders, 42cc head, -24cc piston, .5mm gasket. Now you can play.

As far as coating the tops of the pistons; I like the theory but I'm not sold on it. The factory doesn't do it. The new pistons today that run in alusil don't have any coating on the tops. The only thing they do in some select applications where they moved the wrist pin higher in the piston and reduced the top land height is to hard coat anodize the first ring groove. Now, NASCAR guys will hard coat the whole top of the piston but that is a different application from what we are doing.

I am absolutley not an authority on this subject but this is my initial opinion. I would not be concerned at all to machine a little off the tops of the pistons and run them that way. We cut valve reliefs in the 951 pistons and left them bare with no problems at all so why would this be any different.

#18

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

I was probably doing this as you were typing.....

BTDT...it comes up to .003" .076mm below the cylinder wall at TDC

A bit repetative but i used a program this time to spit the answer out instead of my calculator....

From a cool little program at www.smokemup.com

I inputed all the data i had......

I think 10:1 on these motor is definitley on the high side!

Bore(Inches)=3.9370

Stroke(Inches)=3.1063

Connecting Rod Length(Inches)=5.9055

Cylinder Head Volume(cc)=40

Deck Height(Inches)=.003

Head Gasket Bore(Inches)=4.01575

Head Gasket Thickness(Inches)=.035

Piston to Cylinder Wall Clearance(Inches).000984

Top Ring Land Height(Inches)=.33464

Piston Dish Volume(cc)=24

Positive number is dished piston. Negative number is a domed piston.

------------------------------------------

Bore / Stroke Ratio: 1.267 : 1

Rod / Stroke Ratio: 1.901 : 1

Total volume: 691.972 cc's

Compressed volume: 72.184 cc's

Compression Ratio: 9.586 : 1

time for another too many numbers today!

too many numbers today!

I just edited this AGIAN!!..the new CR is above...for some odd reason the program gave me a different value the 2nd time around?????i ran it 3 frikn times now and that, Regis, is my final; answer...9.586:1!! <sigh>

BTDT...it comes up to .003" .076mm below the cylinder wall at TDC

A bit repetative but i used a program this time to spit the answer out instead of my calculator....

From a cool little program at www.smokemup.com

I inputed all the data i had......

I think 10:1 on these motor is definitley on the high side!

Bore(Inches)=3.9370

Stroke(Inches)=3.1063

Connecting Rod Length(Inches)=5.9055

Cylinder Head Volume(cc)=40

Deck Height(Inches)=.003

Head Gasket Bore(Inches)=4.01575

Head Gasket Thickness(Inches)=.035

Piston to Cylinder Wall Clearance(Inches).000984

Top Ring Land Height(Inches)=.33464

Piston Dish Volume(cc)=24

Positive number is dished piston. Negative number is a domed piston.

------------------------------------------

Bore / Stroke Ratio: 1.267 : 1

Rod / Stroke Ratio: 1.901 : 1

Total volume: 691.972 cc's

Compressed volume: 72.184 cc's

Compression Ratio: 9.586 : 1

time for another

too many numbers today!

too many numbers today!I just edited this AGIAN!!..the new CR is above...for some odd reason the program gave me a different value the 2nd time around?????i ran it 3 frikn times now and that, Regis, is my final; answer...9.586:1!! <sigh>

Last edited by Tony; 01-10-2004 at 06:16 PM.

#19

Addict

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Join Date: Jan 2003

Location: Green Bay Wisconsin

Posts: 951

Likes: 0

Received 0 Likes

on

0 Posts

I just measured the MLS gasket I have (with a calipers, not super acurate) and it is .040 (I think the stock one is .040 too) So, if you add the .003 AND you put the volume of the head at what the factory says (42cc) that gives you 9.295:1 ratio. Interesting.

#21

Addict

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Join Date: Jan 2003

Location: Green Bay Wisconsin

Posts: 951

Likes: 0

Received 0 Likes

on

0 Posts

I think if you only took 5-8cc out of the piston you might not have to re-balance. What is the rule on that???? There has to be a rule, there is always a rule. I guess you would need to know the weight of the 8cc of material though.

#22

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

There is a weight tolerance listed in the manuals for the pistons...a PLUS or MINUS value..i cant recall what it is though.

My MLS says .045 on the package. I just checked with my calipers also and get .047 if i give it a good squeeze.

would .045 be the installed/compressed thickness? I imagine it varies with different head torques.

My MLS says .045 on the package. I just checked with my calipers also and get .047 if i give it a good squeeze.

would .045 be the installed/compressed thickness? I imagine it varies with different head torques.

#24

Three Wheelin'

Tony, great thread with lots of good info!

Plugging in 1.0 mm for a 0.040" head gasket, and using the rest of Tim's numbers yields a 9.376 cr! That's quite a difference from the factory listed 10.0:1, but that number pretty much corresponds to both Adam's and now Tony's numbers.

I wonder how much the various tolerances are affected once the engine is at operating temperature?

For example, how much more would the crank-throw increase, and how much do the con-rods and pistons lengthen, all of which would move the piston higher up in the bore?

And how would operating temps affect the compressed thickness of the head gasket? With the block and heads at operating temp they are expanded in size which would cause them to clamp down harder upon the head gasket, making it not as high, and causing the head to be closer to the piston at TDC.

None of these things can be measured without the engine at operating temperature. It would be an interesting experiment if one was able to put all these parts in an oven at a set temperature and measure those parts while at the higher temp to see the size difference from room temperature.

Does anyone have a spare pizza oven?

By MURF:

http://www.angelfire.com/fl/procrastination/motor.html

If I plug in the factory specs and use a .5mm head gasket thickness I come up with 9.85:1 compression ratio. I used: 100mm bore, 78.9 stroke, 8 cylinders, 42cc head, -24cc piston, .5mm gasket.

http://www.angelfire.com/fl/procrastination/motor.html

If I plug in the factory specs and use a .5mm head gasket thickness I come up with 9.85:1 compression ratio. I used: 100mm bore, 78.9 stroke, 8 cylinders, 42cc head, -24cc piston, .5mm gasket.

I wonder how much the various tolerances are affected once the engine is at operating temperature?

For example, how much more would the crank-throw increase, and how much do the con-rods and pistons lengthen, all of which would move the piston higher up in the bore?

And how would operating temps affect the compressed thickness of the head gasket? With the block and heads at operating temp they are expanded in size which would cause them to clamp down harder upon the head gasket, making it not as high, and causing the head to be closer to the piston at TDC.

None of these things can be measured without the engine at operating temperature. It would be an interesting experiment if one was able to put all these parts in an oven at a set temperature and measure those parts while at the higher temp to see the size difference from room temperature.

Does anyone have a spare pizza oven?

#25

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

Well as Marc T has said many times regarding the piston/wall clearance...You hold a piston in your hand long enough, it wont fit in the bore!

Im sure it all adds up to some degree which is why the factory specs say 10:1 +0-.6 (I think thats what was mentioned in an ealier post) My guess is if we end up seeing more people doing similar things we will get more data that shows 10:1 may indeed be a rare thing....more of a Max limit that was perhaps found on some of the motors or a number they need to produce for emisions/fuel req. or some sort of certification?

I dunno

Im just glad im not the one who had to sit down from SCRATCH and design it all...and be thinking about all the variables involved...HOT ..COLD..expansion rates...clearances...weights..thickness.

Engineering is truely and amazing science.!!

Im sure it all adds up to some degree which is why the factory specs say 10:1 +0-.6 (I think thats what was mentioned in an ealier post) My guess is if we end up seeing more people doing similar things we will get more data that shows 10:1 may indeed be a rare thing....more of a Max limit that was perhaps found on some of the motors or a number they need to produce for emisions/fuel req. or some sort of certification?

I dunno

Im just glad im not the one who had to sit down from SCRATCH and design it all...and be thinking about all the variables involved...HOT ..COLD..expansion rates...clearances...weights..thickness.

Engineering is truely and amazing science.!!

#26

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

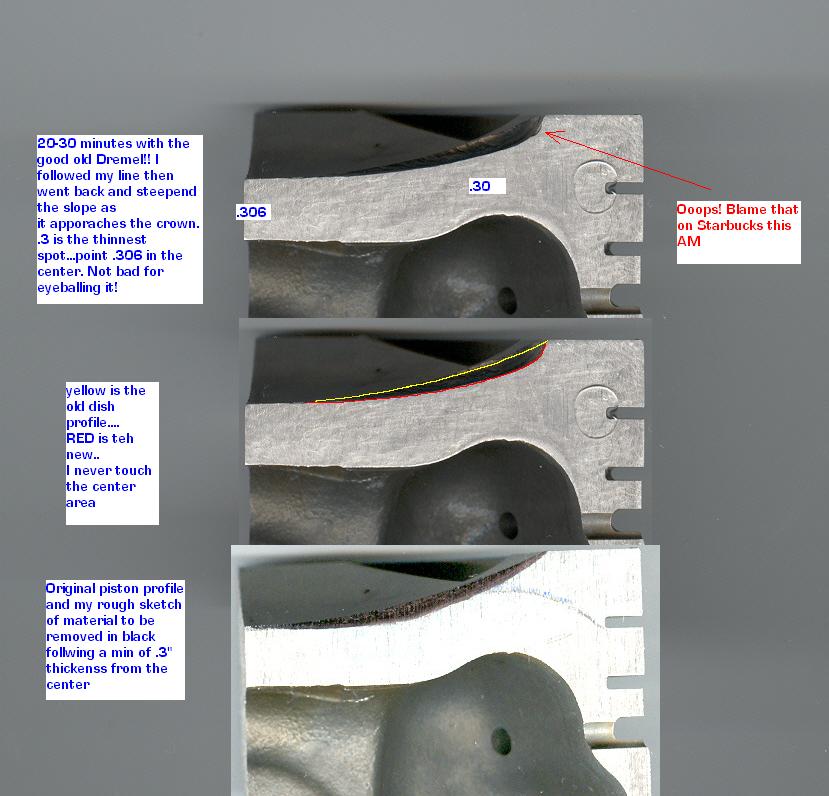

Man can not live with out a Dremel!!!

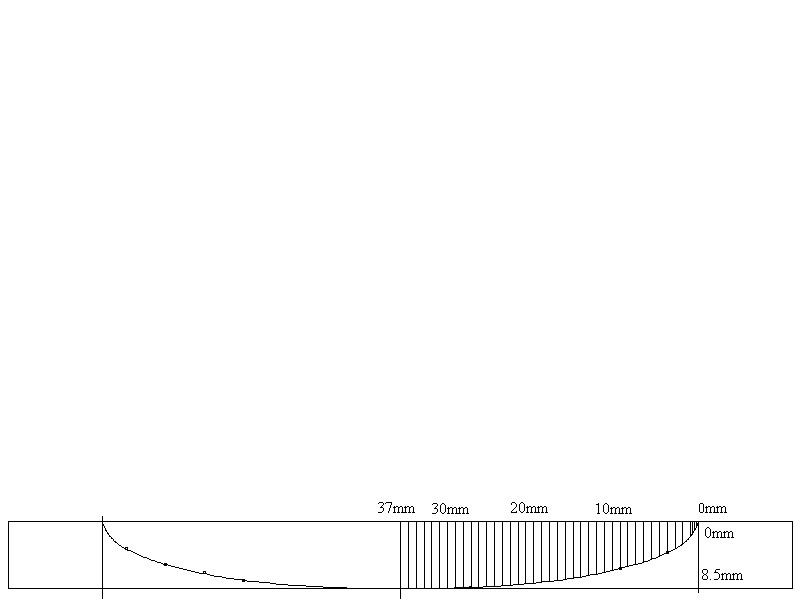

A shop should get an idea of what im looking for from this this?

they should be abe to figure it out...I hope

I guess i will see!

Im still guessing appx 6cc will be removed but it shouldnt be more?

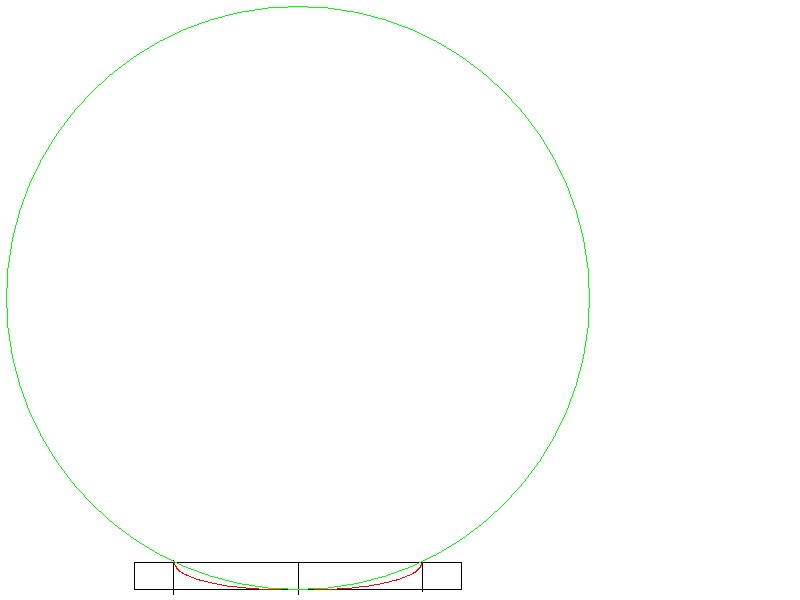

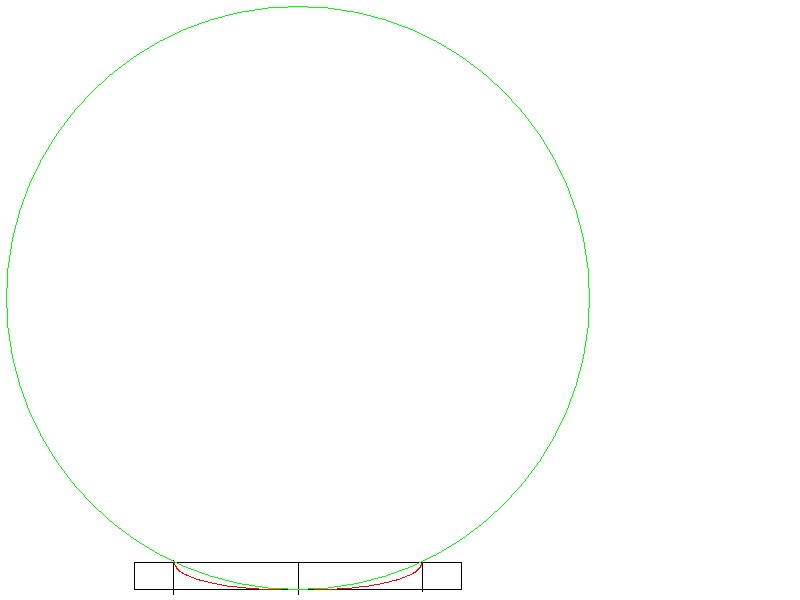

did some measuring, then put it on TurboCad..

-Cliff Clavin voice- "daaah...its ahhh well known fact that the...uh..circle that makes up the dish is 178.3mm in dia..and...uhhhh... the dish is the same depth as the top ring land, 8.54mm."

I learned that much. That will be the triva question at the next SITM!! haha

green is orignal dish...red is new

A shop should get an idea of what im looking for from this this?

they should be abe to figure it out...I hope

I guess i will see!

Im still guessing appx 6cc will be removed but it shouldnt be more?

did some measuring, then put it on TurboCad..

-Cliff Clavin voice- "daaah...its ahhh well known fact that the...uh..circle that makes up the dish is 178.3mm in dia..and...uhhhh... the dish is the same depth as the top ring land, 8.54mm."

I learned that much. That will be the triva question at the next SITM!! haha

green is orignal dish...red is new

Last edited by Tony; 01-09-2004 at 02:53 AM.

#27

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Thread Starter

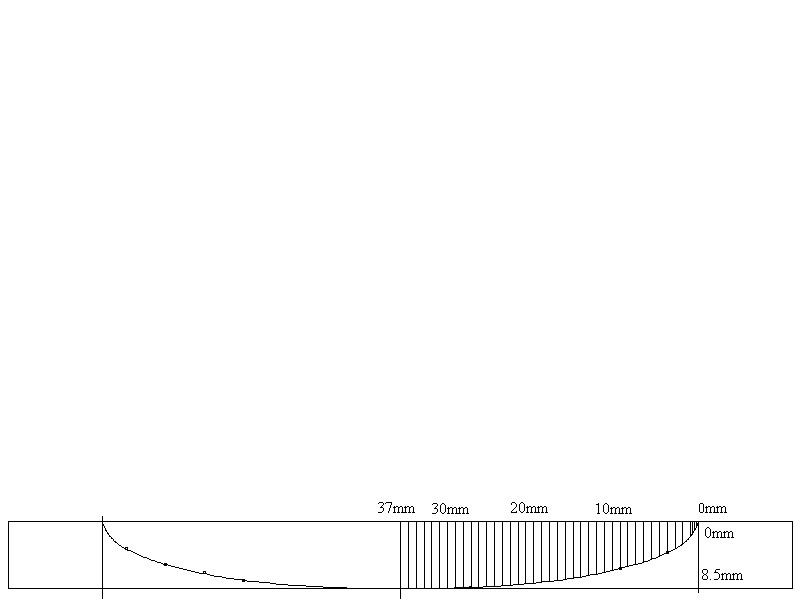

Well, i dropped the piston off at a shop today. I guess i will see what happens and what they come up with. I gave them that sketch above along with a bigger version that had the "dish slope" plotted every mm on an X/y type axis. Took a bit of manual labor plotting the slope and all but the Cad program sure helped.

this (below) is basically what i gave the guy and told him to run with it. I said no material from the center...steepen the slope near the edge of the crown. As long as there is more volume there than when i went in, i will be happy!

""""Slope Dimensions

“0” DISTANCE point starts at the edged of the crown and proceeds inward to the center of the piston.

“0” Depth point starts on top of the piston crown and proceeds down to an appx max of 8.5mm

Distance(mm)----depth (mm)

0.0-------0.0

.25-------.63

.5.0-------1.13

.75--------1.54

1.0--------1.88

2----------- etc etc etc etc etc..........

and this for a visual aid..

From this point when i get it back i will CC it again and see what i have. If i get 6 cc from it (may be tough the way i have it drawn) i should end up with 8.782:1 using the numbers below. POIFECT!!!

Bore(Inches)=3.9370

Stroke(Inches)=3.1063

Connecting Rod Length(Inches)=5.9055

Cylinder Head Volume(cc)=40

Deck Height(Inches)=.003

Head Gasket Bore(Inches)=3.947

Head Gasket Thickness(Inches)=.045 (as writen on the package)

Piston to Cylinder Wall Clearance(Inches).000984

Top Ring Land Height(Inches)=.33464

Piston Dish Volume(cc)=30

Positive number is dished piston. Negative number is a domed piston.

------------------------------------------

Bore / Stroke Ratio: 1.267 : 1

Rod / Stroke Ratio: 1.901 : 1

Total volume: 699.429 cc's

Compressed volume: 79.641cc's

Compression Ratio: 8.782: 1

We wont know until we try will we!!

Now where is that perfect world we live in???

Time for a Shiner.

this (below) is basically what i gave the guy and told him to run with it. I said no material from the center...steepen the slope near the edge of the crown. As long as there is more volume there than when i went in, i will be happy!

""""Slope Dimensions

“0” DISTANCE point starts at the edged of the crown and proceeds inward to the center of the piston.

“0” Depth point starts on top of the piston crown and proceeds down to an appx max of 8.5mm

Distance(mm)----depth (mm)

0.0-------0.0

.25-------.63

.5.0-------1.13

.75--------1.54

1.0--------1.88

2----------- etc etc etc etc etc..........

and this for a visual aid..

From this point when i get it back i will CC it again and see what i have. If i get 6 cc from it (may be tough the way i have it drawn) i should end up with 8.782:1 using the numbers below. POIFECT!!!

Bore(Inches)=3.9370

Stroke(Inches)=3.1063

Connecting Rod Length(Inches)=5.9055

Cylinder Head Volume(cc)=40

Deck Height(Inches)=.003

Head Gasket Bore(Inches)=3.947

Head Gasket Thickness(Inches)=.045 (as writen on the package)

Piston to Cylinder Wall Clearance(Inches).000984

Top Ring Land Height(Inches)=.33464

Piston Dish Volume(cc)=30

Positive number is dished piston. Negative number is a domed piston.

------------------------------------------

Bore / Stroke Ratio: 1.267 : 1

Rod / Stroke Ratio: 1.901 : 1

Total volume: 699.429 cc's

Compressed volume: 79.641cc's

Compression Ratio: 8.782: 1

We wont know until we try will we!!

Now where is that perfect world we live in???

Time for a Shiner.

Last edited by Tony; 01-10-2004 at 06:15 PM.

#28

Rennlist Member

Rennlist Site Sponsor

Remember that the block and heads are aluminum, which will expand more than will the steel connecting rods, so there will be a slight loss of compression when everything is up to temp.

(That is why we have bi-metallic Belleville washers in the "tensioner" - so that the timing belt isn't over-stressed as the block and heads expand.)

(That is why we have bi-metallic Belleville washers in the "tensioner" - so that the timing belt isn't over-stressed as the block and heads expand.)

#29

Three Wheelin'

Originally posted by WallyP

Remember that the block and heads are aluminum, which will expand more than will the steel connecting rods, so there will be a slight loss of compression when everything is up to temp.

(That is why we have bi-metallic Belleville washers in the "tensioner" - so that the timing belt isn't over-stressed as the block and heads expand.)

Remember that the block and heads are aluminum, which will expand more than will the steel connecting rods, so there will be a slight loss of compression when everything is up to temp.

(That is why we have bi-metallic Belleville washers in the "tensioner" - so that the timing belt isn't over-stressed as the block and heads expand.)

#30

I'm perplexed by this post. If you have the engine apart, why not shop options to just get rid of the cast pistons? I understand the fit is best with a cast piston, but lots of people have stories about them letting go under boost.

I think you are approacing it in the proper manner, that is to lower the compression a point or so. I look at ot this way, you have it apart go and source a set of 951 pistons, or have a custom set of forged pistons made for the car. Between pistons and the Nikasil, I'd guess I have $2000.00 there, but I no longer have to worry about them cracking under boost. It isn't just about detonation, the thermal loads on the piston can kill them quickly, especially running boost for extended periods of time. Forged units will conduct the heat away more quickly as well.

What you are doing with the pistons is exactly what Callaway did on all 944 turbo conversions and some (1983+) 928 twin turbo conversions. While this worked, I know of at least two 944 turbos that smashed off the lands and two 928s with the same fate. One guy with the 944 turbo did a high speed run with a bra on the car, stupid on his part, but it smashed out the ring lands.

I opted for the 2618 JE pistons, but there are probably better piston alloys out there you can use. In the process of the conversion, I also got to enjoy the luxury of new clean bores that have essentially zero miles.

I think if you keep the boost low enough, you will be alright but running one bar like that I would go forged, especially since you have it apart. I would also keep it so it zero decks out at the top of the stroke.

Just my $0.02

I think you are approacing it in the proper manner, that is to lower the compression a point or so. I look at ot this way, you have it apart go and source a set of 951 pistons, or have a custom set of forged pistons made for the car. Between pistons and the Nikasil, I'd guess I have $2000.00 there, but I no longer have to worry about them cracking under boost. It isn't just about detonation, the thermal loads on the piston can kill them quickly, especially running boost for extended periods of time. Forged units will conduct the heat away more quickly as well.

What you are doing with the pistons is exactly what Callaway did on all 944 turbo conversions and some (1983+) 928 twin turbo conversions. While this worked, I know of at least two 944 turbos that smashed off the lands and two 928s with the same fate. One guy with the 944 turbo did a high speed run with a bra on the car, stupid on his part, but it smashed out the ring lands.

I opted for the 2618 JE pistons, but there are probably better piston alloys out there you can use. In the process of the conversion, I also got to enjoy the luxury of new clean bores that have essentially zero miles.

I think if you keep the boost low enough, you will be alright but running one bar like that I would go forged, especially since you have it apart. I would also keep it so it zero decks out at the top of the stroke.

Just my $0.02