Toothed Belt Service Light

#31

Electron Wrangler

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Editors Note: the following is part of a continuing series of stuff-PorKen-has-had-to-figure-out-because-the-so-called-expert(s)-never-bothered-to-verify-or-truly-understand-the-stock-system. They spent many hours measuring, trying to find fault in the PKT, but are/were content to 'assume' the stock system works as advertised.

Today's thought: the Belleville Washer Pack is not a spring at all. ALL of the 'spring' force is provided by belt stretch = tension.

The BWP is for warmup only. The washers are just too firm╣, compared to the (stock) belt to be a spring, when the engine is cold. When hot, the washers flatten out and the BWP is transparent, the assembly becomes a spacer for the adjusting bolt and nut.

Today's thought: the Belleville Washer Pack is not a spring at all. ALL of the 'spring' force is provided by belt stretch = tension.

The BWP is for warmup only. The washers are just too firm╣, compared to the (stock) belt to be a spring, when the engine is cold. When hot, the washers flatten out and the BWP is transparent, the assembly becomes a spacer for the adjusting bolt and nut.

And they certainly are a spring - that is the primary purpose. I think you are arguing that the belt exhibits more effective spring than the tensioner washers - maybe true up to point but it may not be so true after a certain range of extension. After all - the belts don't actually stretch much over their whole lifetime.

Alan

BTW This discussion is not related to the PKT. The Belleville washers are what makes the stock Porsche tensioner work.

And note I don't have ANY on my car - there is a PKT there now - thanks Ken!

#32

Rennlist Member

If you are traveling at high speed, lift off the throttle and the toothed belt warning comes on. Do a reset and it does not come on again uniles lift the throttle at high speed. Please remove the toothed gears and check the adjustment hub the toothed gears are mounted to. The hub may be cracked or broken causing vibration that will set of the warning light. And that vibration will break the cam where the key sets the hub position. —Experience

#33

That "certainty" concerning the oil level is truly ironic. As mentioned, my oil seal was compromised due to excessive force during refilling many moons ago and much oil leaked out. I noticed the washers were still "oily" when I last rebuilt the tensioner but the volume of oil was nil. Still, the Kemf tool checked the tension as dead window center and the warning light never come on.

#34

Rennlist Member

Ken was spot on with his description. The fact is that a lump of steel is "a spring" just that its spring rate is so high one cannot see the spring effect visually- Young's law applies to virtually every material.

In the case of the tensioner there are two different spring systems doing different jobs. The belt is the spring acting against the piston of the tensioner- that tension is preset in the cold condition such that as the system heats up and expands the belt eventually ends up at the correct tension. However, the complication is that the tension needed to ensure the belt does not jump when cold is such that when heated the tension then becomes too much. This is where the Belleville washer system kicks in. The Belleville washers are a precisely computed spring system designed to perform in a very specific way. This is why the packing arrangement is critical to successful operation and has a very specific mix of washers in series and in parallel. The theory is that as the washer pack heats up the Belleville washers relax a pre computed amount so that cold condition tension and the hot condition tension requirements can be met. Thus when fully warmed up the position of the tensioner piston will be slightly retracted compared to the cold position thus giving some modulating [indirect] control of the belt tension.

One thing I do not understand at the moment is Greg's observation that the tensioner alarm goes off if there is no oil in the tensioner. Logic suggests that without the oil the engine heat will not get to the washer pack as quickly so presumably would be overtensioned if oil is not present. If by some mechanism the washer pack in practice runs hotter without oil present [i.e the equilibrium when fully wamed up causes the oil to act as a coolant]- that might explain what Greg observes- no statement of fact here- just theorising what might be going on unless and until someone can come up with something more logical.

Thus the tensioner is in fact quite a bit more sophisticated than most might expect and expains why when it is working correctly it is somewhat bullet proof. This at least is what I concluded some years ago when I studied the tensioner to fathom out how it actually works.

The discussion I have tried to open up in this thread is whether the stock tensioner can reasonably be expected to catch a catastrophic failure and whether Porsche considered this a possibility in their design thinking.

Has anyone come across a situation where some owner saw an alarm, accepted it, ignored repeated alarms until something actually went pop? I can understand a scenario where something ultimately fails and the alarm goes off but does such happen with no pre-cursors in a system where the alarm was functional?

Good to note the OP found the belt was slack and has corrected that. Let's hope nothing untoward was going on to cause such- hopefully it was nothing more than ineptitude of the VW agent he took it to who probably eyeballed the tension not having an appropriate tool.

#35

Electron Wrangler

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Belleville washers (also known as belleville disc springs)

A Belleville washer, also known as a coned-disc spring,[1] conical spring washer,[2] disc spring, Belleville spring or cupped spring washer,

I don't see anywhere in the literature describing what you are both asserting - that there is a very significant temperature coefficient to the spring rate.

Independently it is also not at all obvious to me that this would be the case for a few hundred degrees of temperature delta from ambient on a metal disc. What is this esoteric construction material that behaves this way and why don't I see descriptions of it's behavior.

No Belleville washer manufacturers I can see specify a thermal spring coefficient - but this would be a critical parameter if what you assert is a key desired behavior.

I still don't buy it - I think it's just a densely packed high spring rate spring. Show me I'm wrong - where is the literature on this?

Alan

#36

Rennlist Member

Ken actually said it isn't a spring, I said it is a spring - that is the whole point of a belleville washer pack.

Belleville washers (also known as belleville disc springs)

No Belleville washer manufacturers I can see specify a thermal spring coefficient - but this would be a critical parameter if what you assert is a key desired behavior.

I still don't buy it - I think it's just a densely packed high spring rate spring. Show me I'm wrong - where is the literature on this?

Alan

Belleville washers (also known as belleville disc springs)

No Belleville washer manufacturers I can see specify a thermal spring coefficient - but this would be a critical parameter if what you assert is a key desired behavior.

I still don't buy it - I think it's just a densely packed high spring rate spring. Show me I'm wrong - where is the literature on this?

Alan

I was referring Ken's description of the modus operandi- as I pointed out even a lump of metal can be conceived as a spring and the Belleville washers are indeed a spring.

The point of the discussion is that the belt tension is primarily derived from the belt's reaction to the position of the plunger in the tensioner device. The Belleville pack has to have a function and as I understand from the research I did some time ago, that function is to apply a correction based on operating temperature of the pack- as it gets hotter the washers go flatter and the piston retracts slightly. Thus why some folks refer to the thing as a "de-tensioner" but that can only apply to the Bellevile pack itself not the thing as a whole that is most definitely a tensioning device.

If the above were not correct why else would the Belleville washers be present? The only alternative I could think of was to act as some kind of vibration absorption system but would a bolt with a lock nut not hold? Perhaps it is a bit of both but relaxation of the pack with temperature increase is a mechanical fact- different materials exhibiting different characteristics and that is why the pack orientation is critical.

#37

Electron Wrangler

Lifetime Rennlist

Member

Lifetime Rennlist

Member

The Belleville pack has to have a function and as I understand from the research I did some time ago, that function is to apply a correction based on operating temperature of the pack- as it gets hotter the washers go flatter and the piston retracts slightly. Thus why some folks refer to the thing as a "de-tensioner" but that can only apply to the Bellevile pack itself not the thing as a whole that is most definitely a tensioning device....

...relaxation of the pack with temperature increase is a mechanical fact- different materials exhibiting different characteristics and that is why the pack orientation is critical...

...relaxation of the pack with temperature increase is a mechanical fact- different materials exhibiting different characteristics and that is why the pack orientation is critical...

My gut just says it doesn't happen.

I agree it would be a wonderful thing - and makes sense why it would be nice if it worked that way. But it also seems totally illogical from a physical perspective.

I believe the function of the Belleville washers is simply to act as a spring - in that mode it certainly does de-tension the belt (Vs the case where there is no spring) under excessive loads (e.g. driven by the block & head expansions under working temps).

Show me the sources for any significant temperature effect - I just can't find them. You seem take it as a given - but I don't.

Alan

#38

Inventor

Rennlist Member

Rennlist Member

I measure ~2mm squish at ~90F (32C) with the Belleville pack removed from my old '85 at ~120K mile (190K km) between hand pressure and compressed in a vice.

It did not take much effort to compress the first ~1mm. I imagine the 32V tension spec would take least this much.

I put the pack in the freezer to check the cold spec, later.

Someone could do a much better job with more accurate measurements...Rob?

It did not take much effort to compress the first ~1mm. I imagine the 32V tension spec would take least this much.

I put the pack in the freezer to check the cold spec, later.

Someone could do a much better job with more accurate measurements...Rob?

Last edited by PorKen; 08-26-2017 at 08:09 PM. Reason: tensioner year

#39

Rennlist Member

If its a mechanical fact that there is a very significant temperature effect - show me the sources for this - I'll believe it when I see it.

My gut just says it doesn't happen.

I agree it would be a wonderful thing - and makes sense why it would be nice if it worked that way. But it also seems totally illogical from a physical perspective.

I believe the function of the Belleville washers is simply to act as a spring - in that mode it certainly does de-tension the belt (Vs the case where there is no spring) under excessive loads (e.g. driven by the block & head expansions under working temps).

Show me the sources for any significant temperature effect - I just can't find them. You seem take it as a given - but I don't.

Alan

My gut just says it doesn't happen.

I agree it would be a wonderful thing - and makes sense why it would be nice if it worked that way. But it also seems totally illogical from a physical perspective.

I believe the function of the Belleville washers is simply to act as a spring - in that mode it certainly does de-tension the belt (Vs the case where there is no spring) under excessive loads (e.g. driven by the block & head expansions under working temps).

Show me the sources for any significant temperature effect - I just can't find them. You seem take it as a given - but I don't.

Alan

In trying to understand something, a good engineer theorises about what might be going on and then looks for hard evidence to support the theory before proposing such to his peers for endorsement.

You asked for something to support the notion that there is a significant temperature effect so I enclose a screen shot from a website I studied that states how Belleville washers perform as a function of temperature with a very clear diagram indicating the effect of temperature for different materials. All the materials shown show a clear degradation of modulus with increasing temperature and thus as temperature increases, the ability of the Bellville pack to resist the tension induced by thermal expansion reduces and the assembly contracts. The amount of contraction is controlled by the design of the Bellville pack in terms of how many washers are in parallel and how many are in series and thus why it is critical that the Porsche assembly instructions are followed.

What Ken alluded to [as I understand] was that as far as belt tension is concerned in pure compression terms the Belleville pack is effectively non compressible [thus why he implied it was not working as a spring] and thus it is the action of temperature that causes the pack to relax due to reduced spring rate. Thus with more washers configured back to back, there is more de-tensioning movement available and this has been carefully determined by Porsche..

Whether this is a complete explanation remains to be seen but at the moment it is the best explanation I could find to date.

#40

Electron Wrangler

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Fred

So this shows a load reduction (max) of ~10% for 250C variation, and a modulus in elasticity variation of maybe 7% for 250C variation. To me this is NOT a very significant change.

And this is certainly more than the temperature variation range we are talking of for the tensioner body.

Ken measures 2mm manual compression @32C (so clearly it IS a spring) but we'd be talking about very small delta movements due to temp.

I never doubted there was some small temperature effect - just that its really not very material overall.

I don't know why you keep repeating this - I'm not disagreeing with you - In fact I think it is PRIMARILY just a spring and that any temperature effect while beneficial is a very distinctly second order effect.

Alan

So this shows a load reduction (max) of ~10% for 250C variation, and a modulus in elasticity variation of maybe 7% for 250C variation. To me this is NOT a very significant change.

And this is certainly more than the temperature variation range we are talking of for the tensioner body.

Ken measures 2mm manual compression @32C (so clearly it IS a spring) but we'd be talking about very small delta movements due to temp.

I never doubted there was some small temperature effect - just that its really not very material overall.

Alan

#41

Inventor

Rennlist Member

Rennlist Member

No change in uncompressed stack height at 60F (15C), ~44mm, but increased to ~44.5mm at 32F (0C).

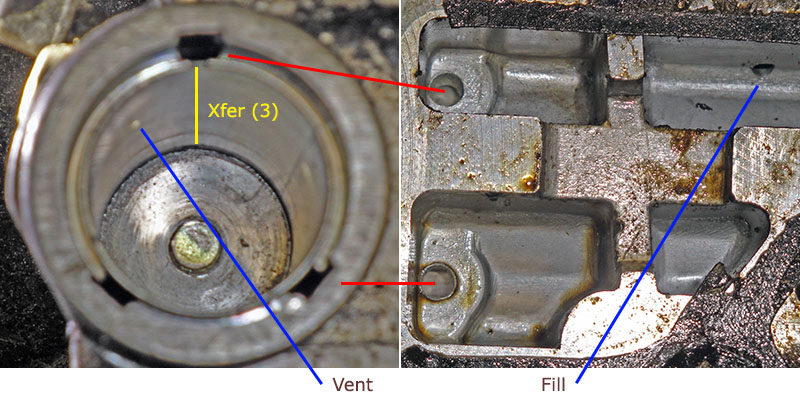

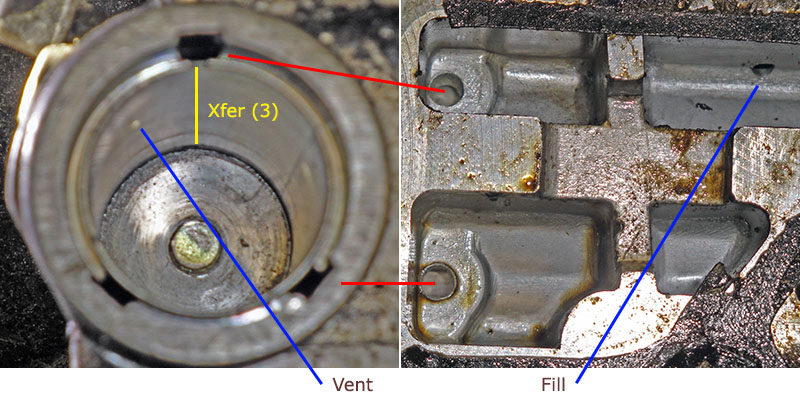

Looking at the tensioner body it's clear now that any damping would come from oil flowing around the upper 'piston'. The (o-ringed) valve body never moves.

Looking at the oil passages, the fill port injects into the engine block space, oil then goes through into two of the three transfer passages which connect the space above the piston to below the valve body. The vent port is right in the middle of the piston. The fill and vent ports do NOT connect to any of the transfer passages. (Hard to see in photo, but the upper passage is notched at the piston area for some reason.)

Looking at the tensioner body it's clear now that any damping would come from oil flowing around the upper 'piston'. The (o-ringed) valve body never moves.

Looking at the oil passages, the fill port injects into the engine block space, oil then goes through into two of the three transfer passages which connect the space above the piston to below the valve body. The vent port is right in the middle of the piston. The fill and vent ports do NOT connect to any of the transfer passages. (Hard to see in photo, but the upper passage is notched at the piston area for some reason.)

Last edited by PorKen; 08-26-2017 at 10:13 PM.

#42

Inventor

Rennlist Member

Rennlist Member

According to my bad measuring, generously speaking, it looks like there's ~2mm possible movement under tension for heat contraction and cold dampening (▒ for age/mileage).

Note the washers did not spring back immediately to their full temperature-dependent size after being fully compressed. It took a short time to get the same measurement (or possibly, I was doing it wrong).

Regarding low oil level tripping the light, if that is a thing, I could imagine that when the oil level gets low, vibration could compress air behind the piston (or even the whole assembly), itself sealed with a film of oil? (The primary path to ground is through the washer pack and bolt?)

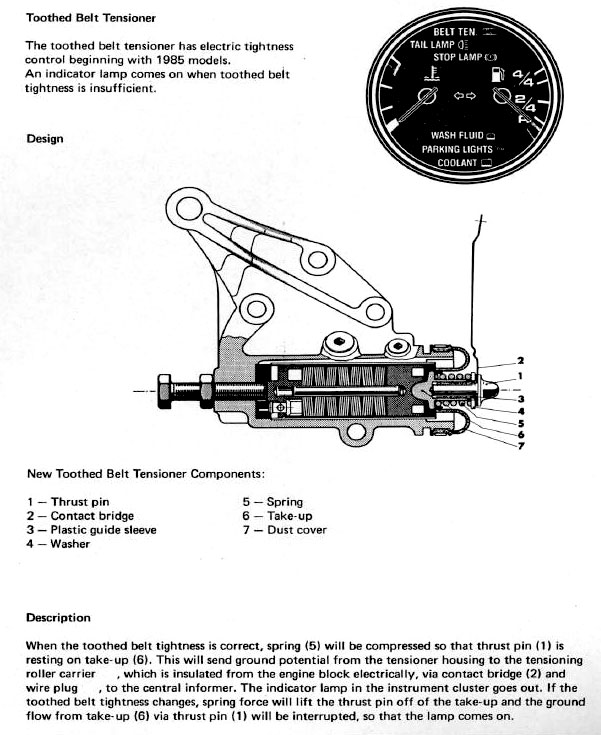

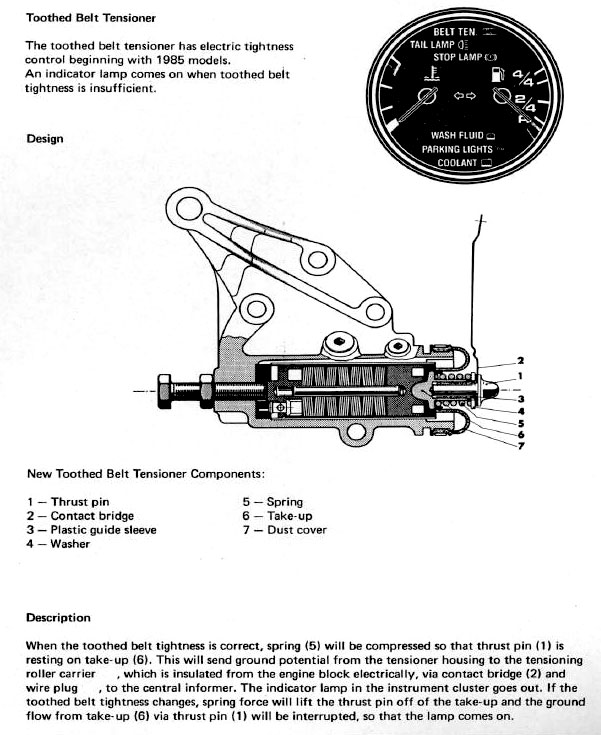

Sidebar: this may be obvious when said but the tension light spring can't help with tensioning - if the spring moved the light would go on.

Note the washers did not spring back immediately to their full temperature-dependent size after being fully compressed. It took a short time to get the same measurement (or possibly, I was doing it wrong).

Regarding low oil level tripping the light, if that is a thing, I could imagine that when the oil level gets low, vibration could compress air behind the piston (or even the whole assembly), itself sealed with a film of oil? (The primary path to ground is through the washer pack and bolt?)

Sidebar: this may be obvious when said but the tension light spring can't help with tensioning - if the spring moved the light would go on.

Last edited by PorKen; 08-27-2017 at 02:56 AM. Reason: more info

#43

Rennlist Member

It seems to me that where we differ in view point is in percpetion of the significance of the change due to temperature. In reading these graphs I looked at what was happening assuming the temperature of the tensioner was around 100C and generates a 3% change in the modulus. I figured that if the length of the Belleville pack were to change by 1mm to 2mm then it was significant in the context of the discussion.

The only reason I even looked into this was that when I did my first TB/WP job a few years ago I dismantled the tensioner and was intrigued by the Belleville pack. Why was it there? I did not see any evidence to support the notion that is was some kind of damper and if there was an elastic reaction why would it be needed when the belt does the very same thing. Rightly or wrongly I also figured that the Bellevile pack could not respond quickly enough to be of any value as a damper thus I could not figure out initially why it was present.

I knew that there was a delay for arming of the alarm and that was obviously to let the system settle thermally and some of our more knowledgable friends had talked about the system being a "de-tensioner" but this seemed strange to me. Porsche clearly understood that the alarm will trigger during the warm up phase so they temporarily disengaged it. I then started to wonder whether the Belleville pack was designed to absorb excess tension but I concluded that if that were the case and the systems were in dynamic balance then winding the tensioner bolt in would simply result in the Belleville pack being compressed and at some point there would be no further increase in belt tension so I discarded that.

Now, in Greg's post yesterday on the other current belt thread he talks very clearly about being able to over tension lower spec belts to the point that they plastically deform- if the Belleville pack was truly compressible then surely that could not happen? Thus when other possibilities are eliminated you are left with whatever else is in play which as I could visualise only left the concept of thermal contraction.

It is of no great consequence to me whether my perception is right or wrong - I simply like to understand how things work and what exactly they do. Thus the notion that the Belleville pack acts as a cold spring opposing the belt tension did not make sense to me whereas the thermal correction did.

The truth is out there!

#44

Electron Wrangler

Lifetime Rennlist

Member

Lifetime Rennlist

Member

...

Regarding low oil level tripping the light, if that is a thing, I could imagine that when the oil level gets low, vibration could compress air behind the piston (or even the whole assembly), itself sealed with a film of oil? (The primary path to ground is through the washer pack and bolt?)

Regarding low oil level tripping the light, if that is a thing, I could imagine that when the oil level gets low, vibration could compress air behind the piston (or even the whole assembly), itself sealed with a film of oil? (The primary path to ground is through the washer pack and bolt?)

I have a stock tensioner hanging around - maybe I'll do some experiments too. Based on Ken's measurements above it seem seems there may be more temperature effect that I expected - but I still can't really understand why at these temperature differentials.

Alan

#45

Inventor

Rennlist Member

Rennlist Member

Hmmm...how about filling the tensioner with thick oil and replacing the stack with a machined (valve) spring...self adjusting (after the initial bolt adj) with momentary damping...wait...I should shut up, now!

*Compare to the PKT with >2mm of damping range and an ~11mm total travel range to adapt to belt length regardless of temperature.

Last edited by PorKen; 08-28-2017 at 03:22 PM. Reason: just one spring