Higher RPM Research : Lifter Dimensions / Specs?

#1

Racer

Thread Starter

Ok, I need to know more about lifters - I've done a bit of reading and found.

Exhibit A: a dissection of the 944s lifter showing cross-section

http://forums.pelicanparts.com/porsc...s-lifters.html

Exhibit B: a rebuild of a nissan hydraulic lifter showing a fairly good process

http://www.gtrpwr.com/showthread.php?t=726

Exhibit C: cheap lightweight VW lifters -

http://www.bahnbrenner.com/vw_audi/p...draulic_Lifter

So - does anyone have the dimensions / any other technical specifications of the 944 lifter?

I'm thinking that losing a little weight here could be a good idea - and coupled with a stronger valve spring might safely give an increased redline.

I'm looking for the VW lifter specs too, to see if there's a possibility of a drop-in. From what I've read the new INA have had failures with a heavier cam, the original INA are expensive, and the solid lifter option is really hard to set up - requiring machining of valve tips, incredibly sensitive lash adjustment, and a steel cam-tower gasket etc.

Exhibit A: a dissection of the 944s lifter showing cross-section

http://forums.pelicanparts.com/porsc...s-lifters.html

Exhibit B: a rebuild of a nissan hydraulic lifter showing a fairly good process

http://www.gtrpwr.com/showthread.php?t=726

Exhibit C: cheap lightweight VW lifters -

http://www.bahnbrenner.com/vw_audi/p...draulic_Lifter

So - does anyone have the dimensions / any other technical specifications of the 944 lifter?

I'm thinking that losing a little weight here could be a good idea - and coupled with a stronger valve spring might safely give an increased redline.

I'm looking for the VW lifter specs too, to see if there's a possibility of a drop-in. From what I've read the new INA have had failures with a heavier cam, the original INA are expensive, and the solid lifter option is really hard to set up - requiring machining of valve tips, incredibly sensitive lash adjustment, and a steel cam-tower gasket etc.

#3

Racer

Thread Starter

This I know, but for the reasons above solid lifters aren't really for everyone. I'm wondering if we can find an improved hydraulic lifter - or failing that improve the ones we have - e.g. maybe drilling another oil fill hole.

There is anecdotal evidence of the stock lifters supporting higher rpm - but I'm looking for specs to see if there's a vw equivalent from more modern cars that could perform better.

There is anecdotal evidence of the stock lifters supporting higher rpm - but I'm looking for specs to see if there's a vw equivalent from more modern cars that could perform better.

The following users liked this post:

Dwizle (12-11-2020)

#4

Proprietoristicly Refined

Rennlist Member

Rennlist Member

#6

Racer

Thread Starter

Now I found the site below - looks like the stock lifters are 38mm diameter. Wonder if this company would make an order of lifters in a lighter material / improved design.

www.chinazhenglong.net/?m=product&part=&make=PO

www.chinazhenglong.net/?m=product&part=&make=PO

#7

Rennlist Member

If you do in fact replace the lifters to gain greater RPMs, do post your solution and your experiences. I'm interested, but at this point, not committed to doing something about it. I figure with the excellent engine balancing mine has, a few more revs wouldn't hurt the bottom end, if the top end could keep up.

Trending Topics

#8

Racer

Thread Starter

Ok, so at present it looks like the 38mm NA lifters don't have any off-the-shelf equivalent. Custom made lifters could be the only way to go to shed weight here - although you could have the housings made (quite a simple part) and use the piston assembly from the stock lifter.

Two modifications seem common in other vehicles with similar lifters. 1) Improved oil flow - another fill hole or a groove around the lifter. 2) An improved check valve - I think a stronger spring could help here, but at the moment that's speculation and it's not the sort of thing people share.

The 35mm diameter 16v lifters do share a VW equivalent, and are available in a lighter format (see the link that John posted) - so your S, S2, 968 are all able to benefit here. The weight difference is not known exactly at this stage, but seems to be about 20 or 30 grams. So, a fair bit of weight to resist the valve spring / cam.

One other notable improvment is DLC coating - Diamond Like Carbon - although to get the most benefit from this the coating needs to be applied over a polished finish, then a substrate layer. There are shops providing this service springing up and it's not too expensive for lifters - but I'd quiz them on the prep they give the piece before coating. Look up DLC on the 928 forum for more details.

From the Michael Mount build thread, you get the important info that solid lifters and big cams can lead to cracking on the 16v heads due to the extra load from the cams back on to the head - so for hobby builds or for weekend track builds it would seem that avoiding solid lifters is good for reliability reasons on top of the difficulty of setting the valve lash.

On 8V NA engines, it seems Turbo valve springs would be a good budget upgrade (higher rate), although the cost of high performance springs seems reasonable (even the Lindsey Racing ones).

I've had a bite on the S2 for 2.7 head swap that I've been trying to arrange - if that deal goes ahead, personally I'll be trying the lightweight lifters in the S2 head (DLC coated), a moderate cam (TBC), and uprated valvesprings. Stock valves to start with. Much more research to be done before then.

Two modifications seem common in other vehicles with similar lifters. 1) Improved oil flow - another fill hole or a groove around the lifter. 2) An improved check valve - I think a stronger spring could help here, but at the moment that's speculation and it's not the sort of thing people share.

The 35mm diameter 16v lifters do share a VW equivalent, and are available in a lighter format (see the link that John posted) - so your S, S2, 968 are all able to benefit here. The weight difference is not known exactly at this stage, but seems to be about 20 or 30 grams. So, a fair bit of weight to resist the valve spring / cam.

One other notable improvment is DLC coating - Diamond Like Carbon - although to get the most benefit from this the coating needs to be applied over a polished finish, then a substrate layer. There are shops providing this service springing up and it's not too expensive for lifters - but I'd quiz them on the prep they give the piece before coating. Look up DLC on the 928 forum for more details.

From the Michael Mount build thread, you get the important info that solid lifters and big cams can lead to cracking on the 16v heads due to the extra load from the cams back on to the head - so for hobby builds or for weekend track builds it would seem that avoiding solid lifters is good for reliability reasons on top of the difficulty of setting the valve lash.

On 8V NA engines, it seems Turbo valve springs would be a good budget upgrade (higher rate), although the cost of high performance springs seems reasonable (even the Lindsey Racing ones).

I've had a bite on the S2 for 2.7 head swap that I've been trying to arrange - if that deal goes ahead, personally I'll be trying the lightweight lifters in the S2 head (DLC coated), a moderate cam (TBC), and uprated valvesprings. Stock valves to start with. Much more research to be done before then.

#10

Racer

Thread Starter

Well, it's not a case of the lifters lasting, but reducing the three forces counter to the valve spring closing the valve - friction, the mass of the valve, and the mass of the lifter. Reducing friction in the lifter bore is good, and DLC coating is marginally better than TiN. Reduced wear from the constant contact with the cam is a nice bonus.

As I understand it the problem with the oil pump is cavitation at higher RPM. I caught a pithy Special Tool post that points to the pump being a gerotor type fixed at a 1:1 ratio (I assume with respect to RPM) - and so I guess he had encountered this problem and looked to solve it the same way I initially thought - by under-driving the pump by 1/5th or so to delay the onset of cavitation.

I've yet to look into this aspect of the problem in depth, but any info backed up with a thread or some evidence would be good. Also, any thoughts on a solution you have would be good to share too.

All said, there are a few stories of people pulling to higher RPM - someone must have encountered / dealt with this problem. Perhaps they just added extra air oil separators etc and didn't sustain high RPM long enough to worry.

Dry sump is a great solution to the mechanical issue - just not my other constraint of a "hobby" budget. There must be a compromise solution to this, given some creative engineering.

As I understand it the problem with the oil pump is cavitation at higher RPM. I caught a pithy Special Tool post that points to the pump being a gerotor type fixed at a 1:1 ratio (I assume with respect to RPM) - and so I guess he had encountered this problem and looked to solve it the same way I initially thought - by under-driving the pump by 1/5th or so to delay the onset of cavitation.

I've yet to look into this aspect of the problem in depth, but any info backed up with a thread or some evidence would be good. Also, any thoughts on a solution you have would be good to share too.

All said, there are a few stories of people pulling to higher RPM - someone must have encountered / dealt with this problem. Perhaps they just added extra air oil separators etc and didn't sustain high RPM long enough to worry.

Dry sump is a great solution to the mechanical issue - just not my other constraint of a "hobby" budget. There must be a compromise solution to this, given some creative engineering.

#12

Racer

Thread Starter

Ok, have done some digging in the archives - these topics seem relevant.

1) Port matching oil returns from the head.

https://rennlist.com/forums/924-931-...-in-block.html

At higher RPM engines can end up with oil backing up in the head, unable to drain down to where we know it's needed.

Following this logic on, without drysumping, you could try an "active" wet sump - scavenging the return from the head, back to the pan, possibly via an AOS mechanism.

2) Air oil separators are cheap to build / install - it would seem that this is a good place to start looking for a solution if you have limited funds.

3) Some detailed oil pump pics here: http://forums.pelicanparts.com/porsc...ml#post6804162

Looks like the stock pump could be disassembled for improvements if necessary, but I'm guessing that any cavitation is from the temperature of the oil - and a lack of supply at the pickup tube.

I think the best summary post on the oiling issues in the 944 is to be found in eohrnberger's first post here, and some of the responses.

https://rennlist.com/forums/924-931-...n-problem.html

Thread is partially OT now - reckon I've answered the lifter question to about 85% satisfaction for now.

1) Port matching oil returns from the head.

https://rennlist.com/forums/924-931-...-in-block.html

At higher RPM engines can end up with oil backing up in the head, unable to drain down to where we know it's needed.

Following this logic on, without drysumping, you could try an "active" wet sump - scavenging the return from the head, back to the pan, possibly via an AOS mechanism.

2) Air oil separators are cheap to build / install - it would seem that this is a good place to start looking for a solution if you have limited funds.

3) Some detailed oil pump pics here: http://forums.pelicanparts.com/porsc...ml#post6804162

Looks like the stock pump could be disassembled for improvements if necessary, but I'm guessing that any cavitation is from the temperature of the oil - and a lack of supply at the pickup tube.

I think the best summary post on the oiling issues in the 944 is to be found in eohrnberger's first post here, and some of the responses.

https://rennlist.com/forums/924-931-...n-problem.html

Thread is partially OT now - reckon I've answered the lifter question to about 85% satisfaction for now.

#13

Rennlist Member

Is there a way to either bore out a cam box to the next size lifters? 40mm maybe? I doubt sleeving is an option, unless smaller diameter valve springs are used, because I think the spring "nests" in the lifter a little.

What does something like an S2000 use? Solid or hydraulic?

What does something like an S2000 use? Solid or hydraulic?

#14

Rainman

Rennlist Member

Rennlist Member

http://www.ebay.com/itm/Gambler-4-St...sories&vxp=mtr

http://www.ebay.com/itm/Peterson-Dry..._Parts&vxp=mtr

Alternatively, what are the odds that an electric diesel fuel pump (like off a 7.3 Ford) would have enough flow for oil? Or even a fuel lift pump? They are capable of moving diesel fuel and ATF and veggie oil or whatever else people use...

#15

Racer

Thread Starter

Is there a way to either bore out a cam box to the next size lifters? 40mm maybe? I doubt sleeving is an option, unless smaller diameter valve springs are used, because I think the spring "nests" in the lifter a little.

What does something like an S2000 use? Solid or hydraulic?

What does something like an S2000 use? Solid or hydraulic?

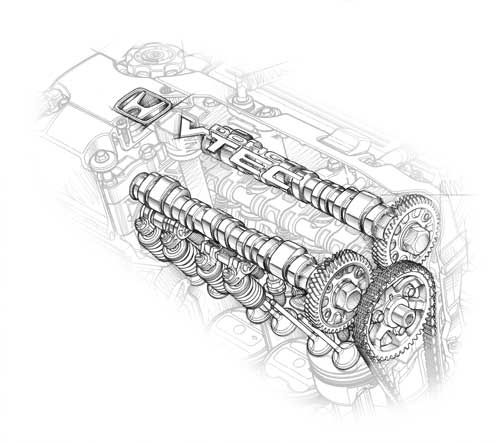

In this pic you can see the screw adjustment on top of the followers - used to set the lash for each valve I think.

Perhaps it's within the realm of possibility to build something like this on top of the 8v to replace the existing cam tower - but I think it might be a bit extreme!

I hadn't thought of boring out the lifter space - but it looks like our lifters are the biggest size around, and we really want to lose weight/size if possible. I had thought about sleeving down to 35mm, but you'd need to be sure the valve spring didn't bind laterally when under compression, and that the cam still ran on the top surface correctly - and the oil feed was accommodated somehow.

Alternatively, what are the odds that an electric diesel fuel pump (like off a 7.3 Ford) would have enough flow for oil?

I'm looking for a good oiling diagram to help me visualise the problem - but my working idea is using one of these, or the type of pumps linked to, to enhance the wet sump system - returning oil from the head drains to the deep part of the sump.

It also just occured to me to "force feed" the oil pickup tube - adding a T, and feeding the pickup directly.

Another piece of tech I've noticed is the way Honda integrates an AOS labyrinth into the head -

http://www.google.com/patents?id=dbT...page&q&f=false

Seems like a good idea - and if pumping oil back down to the sump it could be redirected via a good AOS.