Krikit Belt Tension Tool - LOOK WHAT GATES RUBBER HAS TO SAY

#46

Instructor

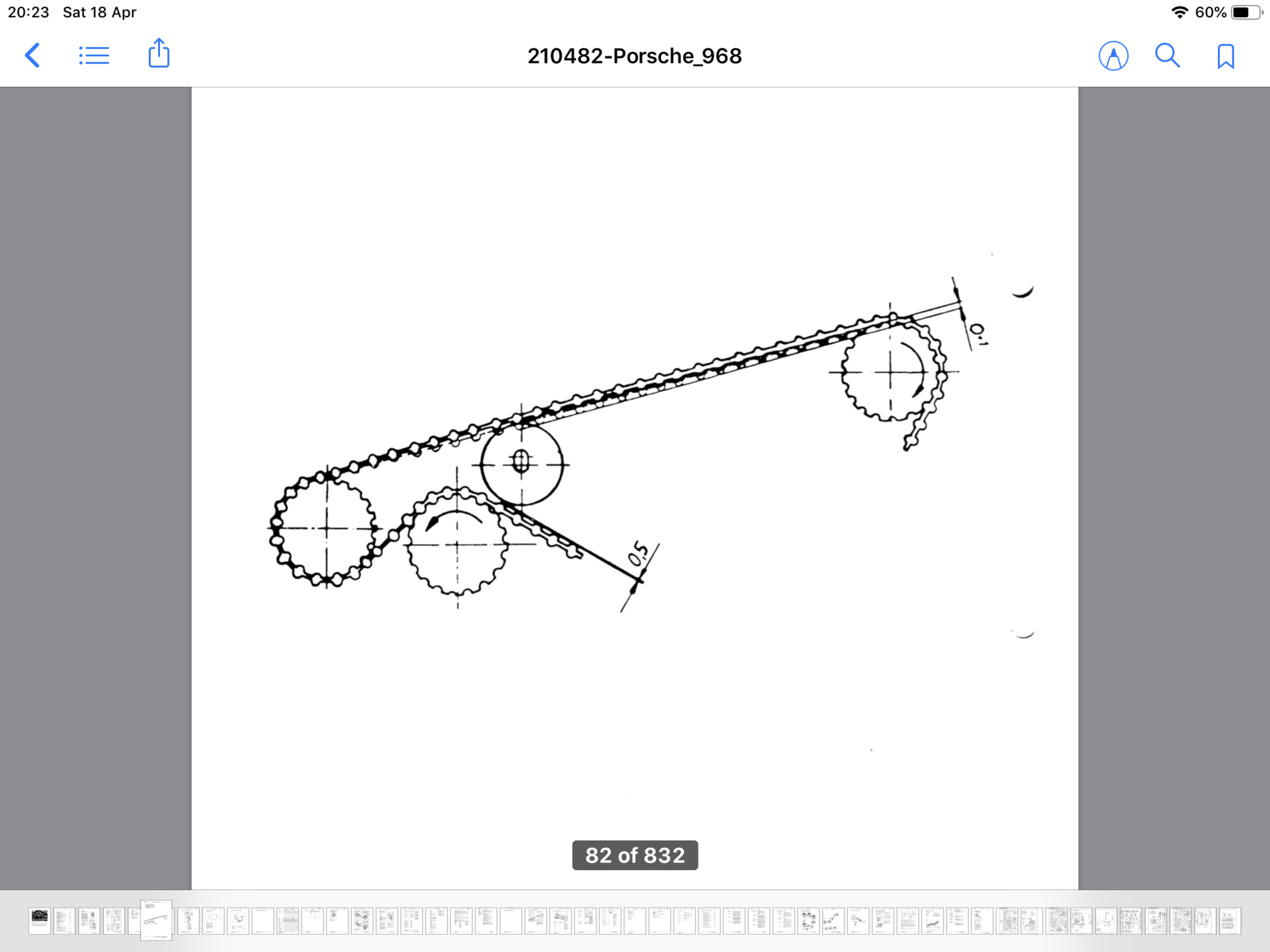

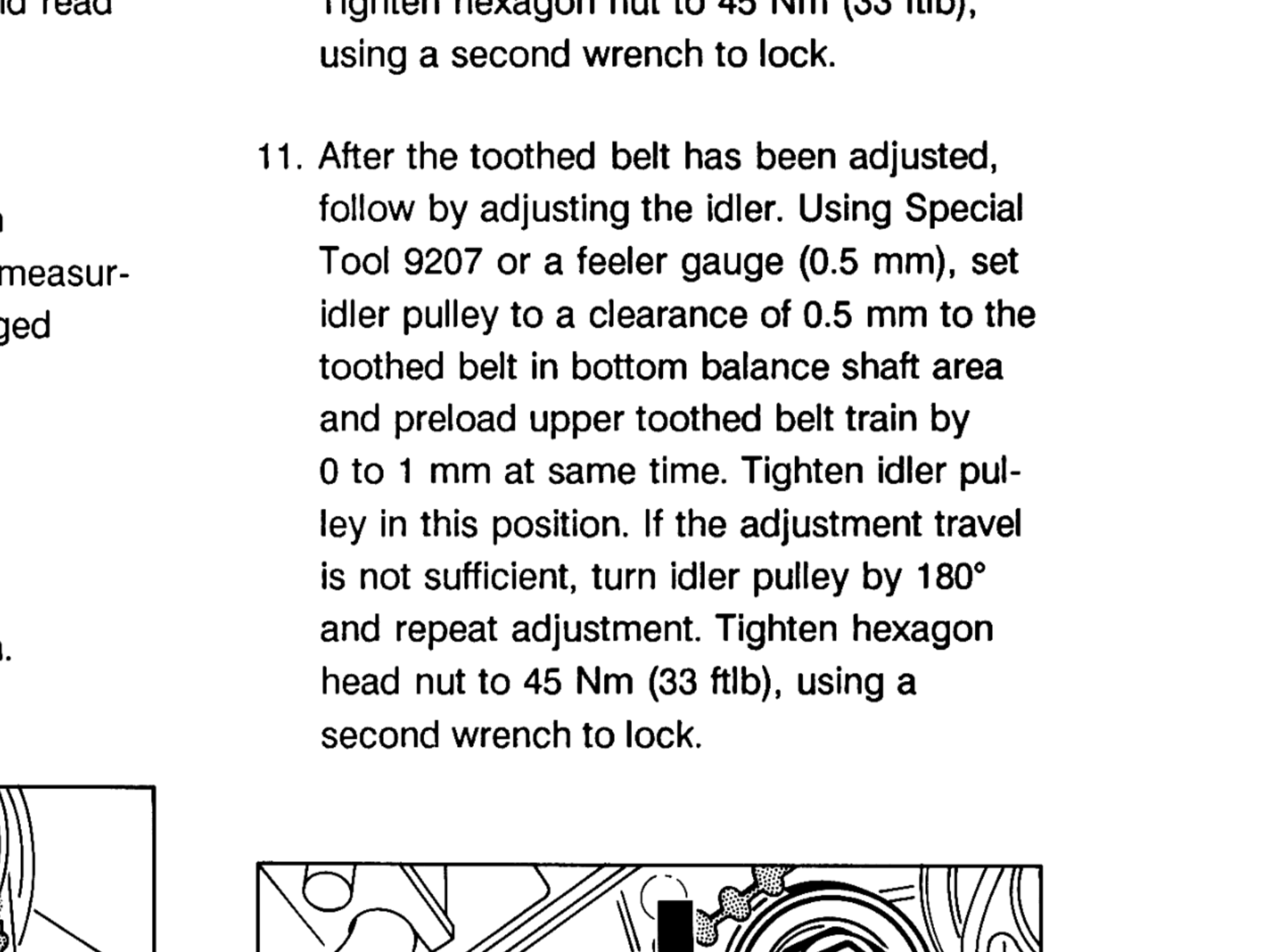

It appears your balance shaft belt is touching the idler roller in the picture (below and to the left of the gauge). It is supposed to have 0.7mm space between the belt and the roller. This is why people have the whine on their belt assembly as the roller is not made to turn all the time. This is not common knowledge as I have seen shops that charge $100+/hour doing the same thing.

Steve

#47

Race Car

To keep it all simple, my understanding is that the idler roller for the balance shaft belt is to keep the face of the balance belt from moving less than 0.7mm and was something I read more than 25 years ago so I don't even remember exactly where. The tension is set with the tension pulley and the idler is to keep from deflection of more than 0.7mm but not spinning all the time. This has worked well for the belts I have done in the past, which numbers in the 100s without any premature failure so it's a practice I stuck with. The belt roller whine will magically disappear every time. I don't believe a 0.7mm gap will do any damage to the balance shaft belt more than a 0 gap causing the idler roller bearing to wear out and seize. The idler bearing is smaller and weaker than the other bearings in the belt assembly also convinces me that it is not meant to spin all the time.

Last edited by Legoland951; 04-18-2020 at 05:32 PM.

#48

Instructor

To keep it all simple, my understanding is that the idler roller for the balance shaft belt is to keep the face of the balance belt from moving less than 0.7mm and was something I read more than 25 years ago so I don't even remember exactly where. The tension is set with the tension pulley and the idler is to keep from deflection of more than 0.7mm but not spinning all the time. This has worked well for the belts I have done in the past, which numbers in the 100s without any premature failure so it's a practice I stuck with. The belt roller whine will magically disappear every time. I don't believe a 0.7mm gap will do any damage to the balance shaft belt more than a 0 gap causing the idler roller bearing to wear out and seize. The idler bearing is smaller and weaker than the other bearings in the belt assembly also convinces me that it is not meant to spin all the time.

Steve

#49

Instructor

To keep it all simple, my understanding is that the idler roller for the balance shaft belt is to keep the face of the balance belt from moving less than 0.7mm and was something I read more than 25 years ago so I don't even remember exactly where. The tension is set with the tension pulley and the idler is to keep from deflection of more than 0.7mm but not spinning all the time. This has worked well for the belts I have done in the past, which numbers in the 100s without any premature failure so it's a practice I stuck with. The belt roller whine will magically disappear every time. I don't believe a 0.7mm gap will do any damage to the balance shaft belt more than a 0 gap causing the idler roller bearing to wear out and seize. The idler bearing is smaller and weaker than the other bearings in the belt assembly also convinces me that it is not meant to spin all the time.

#50

Race Car

I know this is the official method. I have seen too many belt whines from doing it. The idler does nothing to add tension at 0mm clearance and the only thing it does is to control deflection. I rather have a slight more deflection and less bearing wear/whine, which could cause the roller to seize, which is something I have seen. Then the belt will rub on a non spinning roller possibly causing belt breakage. In a car I bought in the past, the balance shaft belt broke causing the timing belt to derail resulting in bent valves. The idler roller was seized.

#51

Instructor

I know this is the official method. I have seen too many belt whines from doing it. The idler does nothing to add tension at 0mm clearance and the only thing it does is to control deflection. I rather have a slight more deflection and less bearing wear/whine, which could cause the roller to seize, which is something I have seen. Then the belt will rub on a non spinning roller possibly causing belt breakage. In a car I bought in the past, the balance shaft belt broke causing the timing belt to derail resulting in bent valves. The idler roller was seized.

Steve