Longevity concern using block fill on 2.5 liter hybrud

#16

Race Car

It's not the expansion that is the issue. Filling a 2.5L block half way holds the cylinder walls better and it helps from the cylinder walls egg shaping from the pistons rocking which results in piston slap. That's why a 3.0L block is preferred over a 2.5L block on high HP builds. On the 3.0L block the cylinders are connected, not floating like the 2.5L block, and the block is already cast with half the depth of the coolant valley from the 2.5L block.

It seems that if the fill material allows no movement, then by the same token, it can't allow for expansion. If this were true, the cylinder and sleeve will still expand but the force would be turned to closing piston to cylinder clearance, creating high pressure points on the piston, sleeve warping etc.

If the filler expands with the cylinder and sleeve on initial hot run cycle, then it's useless in it's original intent unless the degree of expansion and contraction of the filler is near or equal to that of aluminum, not just in maximum degree but of rate also..

Refined piston pin location can fix piston rock.

T

#17

Addict

Rennlist Member

Rennlist Member

I think he means pouring and curing at ambient temp, having the filler harden, then later the remaining aluminum block, cylinder and/or sleeve expanding in a space with no room for expansion.

It seems that if the fill material allows no movement, then by the same token, it can't allow for expansion. If this were true, the cylinder and sleeve will still expand but the force would be turned to closing piston to cylinder clearance, creating high pressure points on the piston, sleeve warping etc.

If the filler expands with the cylinder and sleeve on initial hot run cycle, then it's useless in it's original intent unless the degree of expansion and contraction of the filler is near or equal to that of aluminum, not just in maximum degree but of rate also..

Refined piston pin location can fix piston rock.

T

It seems that if the fill material allows no movement, then by the same token, it can't allow for expansion. If this were true, the cylinder and sleeve will still expand but the force would be turned to closing piston to cylinder clearance, creating high pressure points on the piston, sleeve warping etc.

If the filler expands with the cylinder and sleeve on initial hot run cycle, then it's useless in it's original intent unless the degree of expansion and contraction of the filler is near or equal to that of aluminum, not just in maximum degree but of rate also..

Refined piston pin location can fix piston rock.

T

Exactly, mimicking material's temperature expansion/contraction properties with other material is not very easy thing to do. (HardBlok is cement with iron particles for instance. Neither is even close to expansion or heat conductivity rate of aluminum)

So expecting some generic filler that ''works in all blocks'' to expand and contract dimensionally correct and at same speed as very specific aluminum silica alloy is a bit optimistic in my opinion.

Maybe it works with iron sleeves and bigger piston/cyl clerance, but on stock piston/cyl/clerance between 0.008mm and 0.032mm , I would be worried.

0.008mm won't forgive much.

Last edited by Voith; 08-10-2017 at 11:37 AM.

#18

Race Car

Exactly, mimicking material's temperature expansion/contraction properties with other material is not very easy thing to do. (HardBlok is cement with iron particles for instance. Neither is even close to expansion or heat conductivity rate of aluminum)

So expecting some generic filler that ''works in all blocks'' to expand and contract dimensionally correct and at same speed as very specific aluminum silica alloy is a bit optimistic in my opinion.

Maybe it works with iron sleeves and bigger piston/cyl clerance, but on stock piston/cyl/clerance measured in thousands of mm, I would be worried.

So expecting some generic filler that ''works in all blocks'' to expand and contract dimensionally correct and at same speed as very specific aluminum silica alloy is a bit optimistic in my opinion.

Maybe it works with iron sleeves and bigger piston/cyl clerance, but on stock piston/cyl/clerance measured in thousands of mm, I would be worried.

I don't know which one of us should be more concerned about that...

T

#19

Addict

Rennlist Member

Rennlist Member

#20

Rainman

Rennlist Member

Rennlist Member

Exactly, mimicking material's temperature expansion/contraction properties with other material is not very easy thing to do. (HardBlok is cement with iron particles for instance. Neither is even close to expansion or heat conductivity rate of aluminum)

So expecting some generic filler that ''works in all blocks'' to expand and contract dimensionally correct and at same speed as very specific aluminum silica alloy is a bit optimistic in my opinion.

Maybe it works with iron sleeves and bigger piston/cyl clerance, but on stock piston/cyl/clerance between 0.008mm and 0.032mm , I would be worried.

0.008mm won't forgive much.

So expecting some generic filler that ''works in all blocks'' to expand and contract dimensionally correct and at same speed as very specific aluminum silica alloy is a bit optimistic in my opinion.

Maybe it works with iron sleeves and bigger piston/cyl clerance, but on stock piston/cyl/clerance between 0.008mm and 0.032mm , I would be worried.

0.008mm won't forgive much.

#21

Addict

Rennlist Member

Rennlist Member

Or even better, make a plate and machine something like this out of it for instant NA -> turbo CR and fixation of cylinders.

http://speedstar-racing.com/store/ca...roducts_id=470

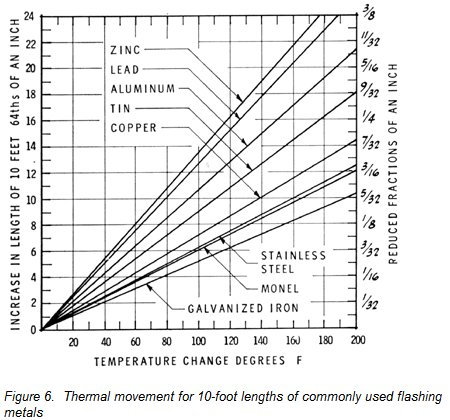

This chart should also be here, didn't check the accuracy of it but appears to be about right..

#23

Rennlist Member

I guess we better take all these motors we built back into the shop because they won't work

We are running 0.005" piston to wall clearance, calculate the actual thermal expansion numbers and you will see why they are not a problem. I think block twist is far more significant. Seriously, this works. We have a lot of history. The 2.85L hybrid stroker works if you stick to the formula that is documented. It is a great way to build a very cheap, fairly big power motor.

We are running 0.005" piston to wall clearance, calculate the actual thermal expansion numbers and you will see why they are not a problem. I think block twist is far more significant. Seriously, this works. We have a lot of history. The 2.85L hybrid stroker works if you stick to the formula that is documented. It is a great way to build a very cheap, fairly big power motor.

#24

Instructor

Thread Starter

I guess we better take all these motors we built back into the shop because they won't work

We are running 0.005" piston to wall clearance, calculate the actual thermal expansion numbers and you will see why they are not a problem. I think block twist is far more significant. Seriously, this works. We have a lot of history. The 2.85L hybrid stroker works if you stick to the formula that is documented. It is a great way to build a very cheap, fairly big power motor.

We are running 0.005" piston to wall clearance, calculate the actual thermal expansion numbers and you will see why they are not a problem. I think block twist is far more significant. Seriously, this works. We have a lot of history. The 2.85L hybrid stroker works if you stick to the formula that is documented. It is a great way to build a very cheap, fairly big power motor.

I measured the approximate thickness of the original cylinder at about 8mm. If it is bored in half to 4mm thickness as an example and then the sleeve is installed, in theory the wall would be half aluminum block and half iron liner so contraction of the walls with the block filler may be more akin to an iron block on the sleeve side. I hope that was clear?

As an alternative to block fill, I could fill the water jackets with aluminum foil and tamp it in and then run with it lean to melt the foil and form it to the water passages. As a side benefit, the aliens would have a difficult time reading my engine tune since it will be covered in aluminum foil

#25

Rennlist Member

Thank you Shawn for your continued help with this build. As a side note, how much of the original cylinder is removed when the iron sleeve is installed? Is the block heated and the sleeves frozen to fit together?

I measured the approximate thickness of the original cylinder at about 8mm. If it is bored in half to 4mm thickness as an example and then the sleeve is installed, in theory the wall would be half aluminum block and half iron liner so contraction of the walls with the block filler may be more akin to an iron block on the sleeve side. I hope that was clear?

As an alternative to block fill, I could fill the water jackets with aluminum foil and tamp it in and then run with it lean to melt the foil and form it to the water passages. As a side benefit, the aliens would have a difficult time reading my engine tune since it will be covered in aluminum foil

I measured the approximate thickness of the original cylinder at about 8mm. If it is bored in half to 4mm thickness as an example and then the sleeve is installed, in theory the wall would be half aluminum block and half iron liner so contraction of the walls with the block filler may be more akin to an iron block on the sleeve side. I hope that was clear?

As an alternative to block fill, I could fill the water jackets with aluminum foil and tamp it in and then run with it lean to melt the foil and form it to the water passages. As a side benefit, the aliens would have a difficult time reading my engine tune since it will be covered in aluminum foil