Cosworth engines done...finally

#31

Rennlist Member

#32

Drifting

Join Date: May 2003

Location: Charlotte, NC

Posts: 2,585

Likes: 0

Received 0 Likes

on

0 Posts

They always talk about CAD computers, 3-D etc. but in the end, whether CAD or some other computer aided design method, in the end, it is just a pen (I work in design and for some of the work, use CAD).

Makes designing in many cases (not all), easier and more accurate etc. but it doesn't mean "computer has designed it" and it now has no errors.

Makes designing in many cases (not all), easier and more accurate etc. but it doesn't mean "computer has designed it" and it now has no errors.

The beauty of the computer is precisely that it can consider and look at a lot more factors than you can in a much shorter amount of time. The days of using a computer as a glorified electronic piece of pen and paper are hopefully long behind us.

#33

King of Cool

Rennlist Member

Rennlist Member

It depends on what field and what software you're talking about. I work within the "design software" field for a startup company (www.siteops.com) and we have optimization software that very much replaces the idea that CAD is just an electronic pen and paper..."CAD with a Brain!" is the company's registered trademark. Running genetic algorithms that look at billions of options in just a few hours and then spitting out an optimized 2D building/parking/street/sidewalk layout and 3D grading and drainage plan for a real estate development site. I can only assume that if we're applying such principles to something like moving dirt, that similar things have been done within aerospace and F1 for years.

The beauty of the computer is precisely that it can consider and look at a lot more factors than you can in a much shorter amount of time. The days of using a computer as a glorified electronic piece of pen and paper are hopefully long behind us.

The beauty of the computer is precisely that it can consider and look at a lot more factors than you can in a much shorter amount of time. The days of using a computer as a glorified electronic piece of pen and paper are hopefully long behind us.

I agree and some of the high tech stuff F1 teams do (did you see that molding machine that creates molds from "nothing" by building them up?) are really amazing.

I was more talking about the conventional method when they're drawing the parts by using CAD and then marketing folks try to make you believe it's something magical.

#34

Drifting

Join Date: May 2003

Location: Charlotte, NC

Posts: 2,585

Likes: 0

Received 0 Likes

on

0 Posts

If we want to talk technology, let's talk about the Dr's at Wake Forest University who are creating organs (a beating heart valve, working bladder, blood vessels) using the guts of an old HP ink jet printer, building them up one layer of cells at a time in 3D. Cool stuff from the ole' alma mater:

http://www.time.com/time/health/arti...679115,00.html

#35

Guru

Lifetime Rennlist

Member

Rennlist Small

Business Sponsor

Lifetime Rennlist

Member

Rennlist Small

Business Sponsor

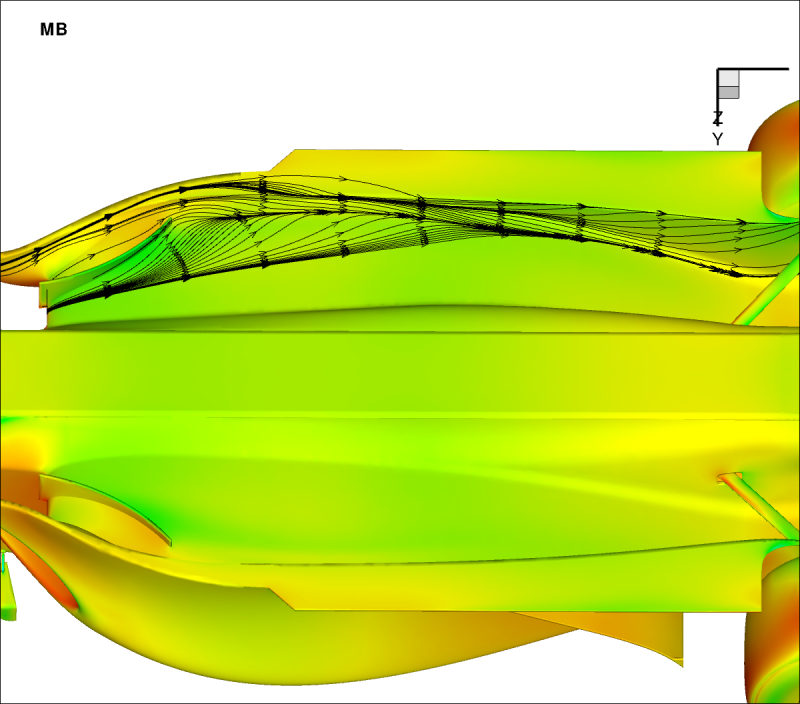

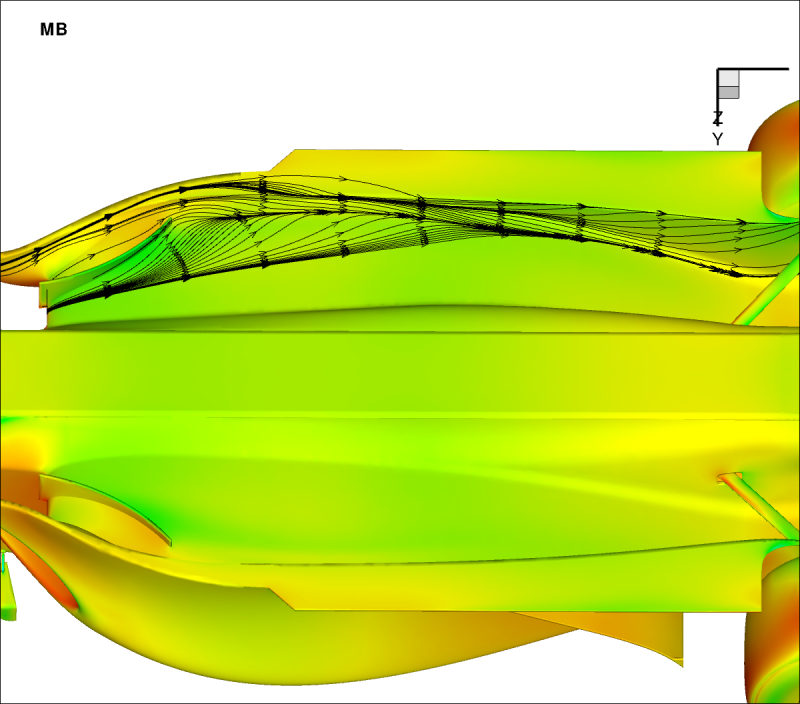

The simulation systems that are being advanced each day are truly impressive, even rendering programs are becoming more and more realistic

Aero sim programs too -- here is a sim and real world flow visualization

Car wake simulation

http://www.youtube.com/watch?v=tNoSf0zA-_A

Aero sim programs too -- here is a sim and real world flow visualization

Car wake simulation

http://www.youtube.com/watch?v=tNoSf0zA-_A

#36

King of Cool

Rennlist Member

Rennlist Member

Assuming we're talking about something similar, I've seen that technology used in rapid prototyping and for creating 3D architectural structures and topography maps. I guess making molds would just be rapid prototyping in reverse.

If we want to talk technology, let's talk about the Dr's at Wake Forest University who are creating organs (a beating heart valve, working bladder, blood vessels) using the guts of an old HP ink jet printer, building them up one layer of cells at a time in 3D. Cool stuff from the ole' alma mater:

http://www.time.com/time/health/arti...679115,00.html

If we want to talk technology, let's talk about the Dr's at Wake Forest University who are creating organs (a beating heart valve, working bladder, blood vessels) using the guts of an old HP ink jet printer, building them up one layer of cells at a time in 3D. Cool stuff from the ole' alma mater:

http://www.time.com/time/health/arti...679115,00.html

Basically it was a container with some white liquid in it and then the computer started to do "something" and little by little the part they were doing started to "grow" from nothing.

Kinda like reversed milling where you have a block and you remove stuff to create a part, in this case they started from nothing and the part just "showed up", hard to explain.

#37

Three Wheelin'

Join Date: Apr 2008

Location: Sarasota, FL. Home of Florida Man.

Posts: 1,268

Likes: 0

Received 2 Likes

on

2 Posts

wow, i think we all sort of agree and are having a discussion. did something happen to this forum?

all you have to do is look at boeing's 787 and realize that "computer designed with exotic materials" doesn't always work out as planned. there, the wing fit, but, well, it wouldn't exactly stay on. doh!

all you have to do is look at boeing's 787 and realize that "computer designed with exotic materials" doesn't always work out as planned. there, the wing fit, but, well, it wouldn't exactly stay on. doh!

#38

Drifting

Join Date: May 2003

Location: Charlotte, NC

Posts: 2,585

Likes: 0

Received 0 Likes

on

0 Posts

It was shown on one segment of "Racing Per Matchett" on Speed where he visited Red Bull's factory.

Basically it was a container with some white liquid in it and then the computer started to do "something" and little by little the part they were doing started to "grow" from nothing.

Kinda like reversed milling where you have a block and you remove stuff to create a part, in this case they started from nothing and the part just "showed up", hard to explain.

Basically it was a container with some white liquid in it and then the computer started to do "something" and little by little the part they were doing started to "grow" from nothing.

Kinda like reversed milling where you have a block and you remove stuff to create a part, in this case they started from nothing and the part just "showed up", hard to explain.

#39

Guru

Lifetime Rennlist

Member

Rennlist Small

Business Sponsor

Lifetime Rennlist

Member

Rennlist Small

Business Sponsor

SLA - stereolithography, FDM, 3D printing -- essentially the same technology, only using different materials to 'grow' the parts as we tend to call it.

We have this capability here, and its it really cool stuff.

We have this capability here, and its it really cool stuff.

#40

Drifting

They can do this with metal these days, not just plastic. "Rapid Manufacturing" not just prototyping. Look up Direct Metal Laser Sintering. You can go from cad model to complex 3 dimensional titanium parts in a matter of hours. It's pretty amazing..

But I still don't agree that everything will fit pefectly the first time because it does in CAD. That assumes manufacturing will produce a nominal part everytime and this just isn't the case in the real world. Especially when you have complicated assemblies, tight schedules, and unique parts. Is USF1 going to scrap a bunch of parts that violate a few tolerances? What if they don't have any other parts to use?

But I still don't agree that everything will fit pefectly the first time because it does in CAD. That assumes manufacturing will produce a nominal part everytime and this just isn't the case in the real world. Especially when you have complicated assemblies, tight schedules, and unique parts. Is USF1 going to scrap a bunch of parts that violate a few tolerances? What if they don't have any other parts to use?

#41

Rennlist

Basic Site Sponsor

Basic Site Sponsor

It certainly will be interesting to see what happens when they actually get the car running.

I have always operated under the motto that to err is human, but to really screw things up you need a computer. Allows you to make exponentially more mistakes a lot faster.

Maybe that is why USF1 has spent so very much time on the CAD design end, trying to get it as close as possible rather than chance that a highly critical item has been mis-designed.

I have always operated under the motto that to err is human, but to really screw things up you need a computer. Allows you to make exponentially more mistakes a lot faster.

Maybe that is why USF1 has spent so very much time on the CAD design end, trying to get it as close as possible rather than chance that a highly critical item has been mis-designed.

__________________

Larry Herman

2016 Ford Transit Connect Titanium LWB

2018 Tesla Model 3 - Electricity can be fun!

Retired Club Racer & National PCA Instructor

Past Flames:

1994 RS America Club Racer

2004 GT3 Track Car

1984 911 Carrera Club Racer

1974 914/4 2.0 Track Car

CLICK HERE to see some of my ancient racing videos.

Larry Herman

2016 Ford Transit Connect Titanium LWB

2018 Tesla Model 3 - Electricity can be fun!

Retired Club Racer & National PCA Instructor

Past Flames:

1994 RS America Club Racer

2004 GT3 Track Car

1984 911 Carrera Club Racer

1974 914/4 2.0 Track Car

CLICK HERE to see some of my ancient racing videos.

#43

It was shown on one segment of "Racing Per Matchett" on Speed where he visited Red Bull's factory.

Basically it was a container with some white liquid in it and then the computer started to do "something" and little by little the part they were doing started to "grow" from nothing.

Kinda like reversed milling where you have a block and you remove stuff to create a part, in this case they started from nothing and the part just "showed up", hard to explain.

Basically it was a container with some white liquid in it and then the computer started to do "something" and little by little the part they were doing started to "grow" from nothing.

Kinda like reversed milling where you have a block and you remove stuff to create a part, in this case they started from nothing and the part just "showed up", hard to explain.

#45

Guru

Lifetime Rennlist

Member

Rennlist Small

Business Sponsor

Lifetime Rennlist

Member

Rennlist Small

Business Sponsor

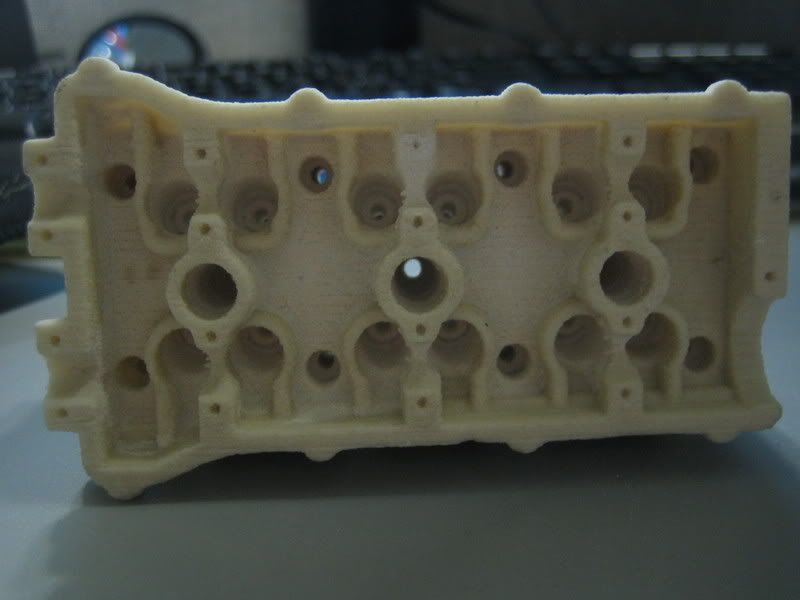

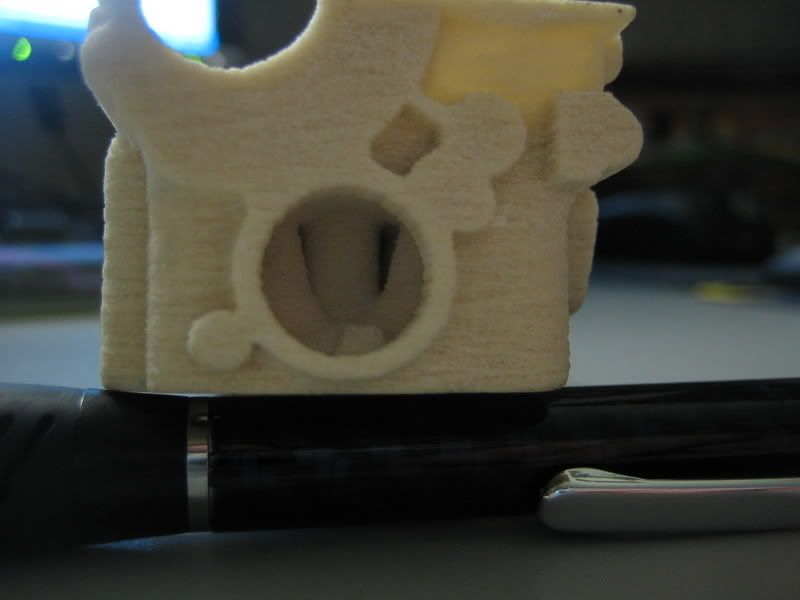

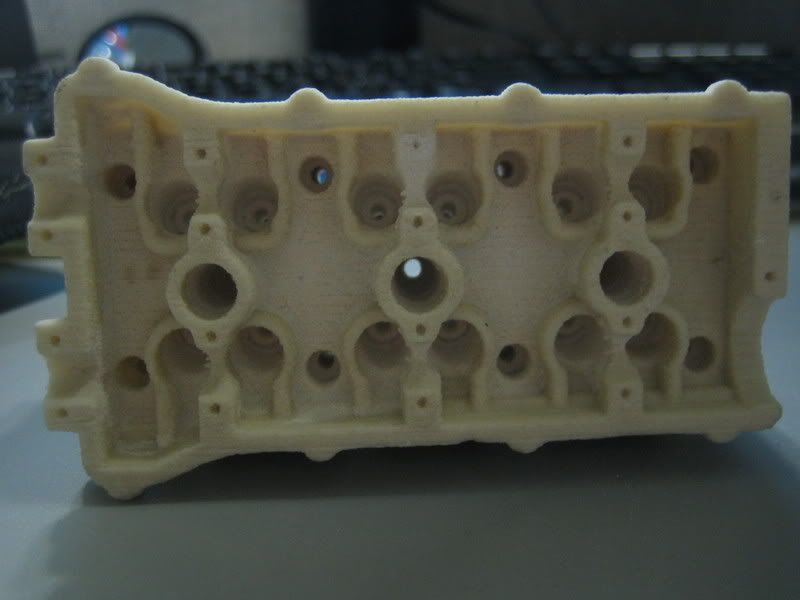

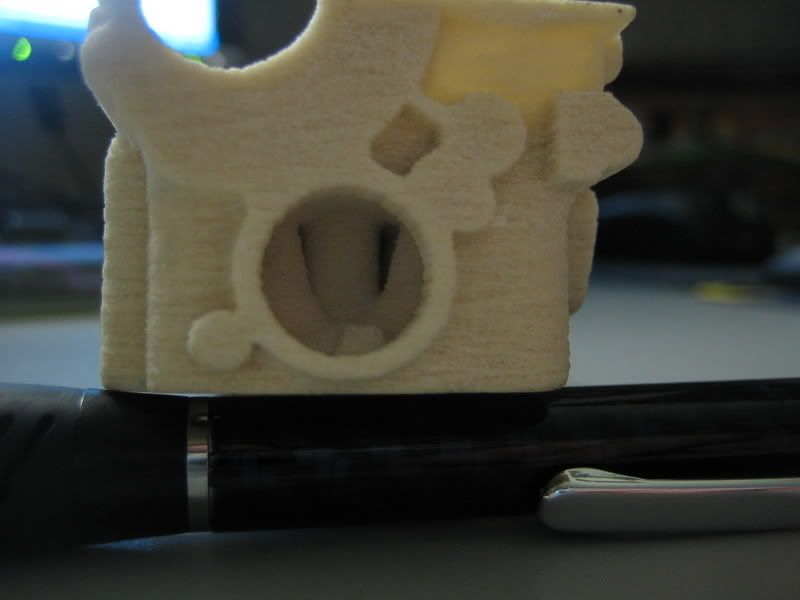

Here is an example of rapid prototyping with the cookie-dough machine

Then a header collector, full scale

Cylinder head

Then a header collector, full scale

Cylinder head