951 Cage Build

#16

Three Wheelin'

Join Date: Sep 2005

Location: Fort Worth, TX

Posts: 1,367

Likes: 0

Received 0 Likes

on

0 Posts

There is no set recommendation, it depends on the distance from the seat/Hans to the harness bar.

#17

Addict

Rennlist Member

Rennlist Small

Business Sponsor

Rennlist Member

Rennlist Small

Business Sponsor

#18

Three Wheelin'

Join Date: Sep 2005

Location: Fort Worth, TX

Posts: 1,367

Likes: 0

Received 0 Likes

on

0 Posts

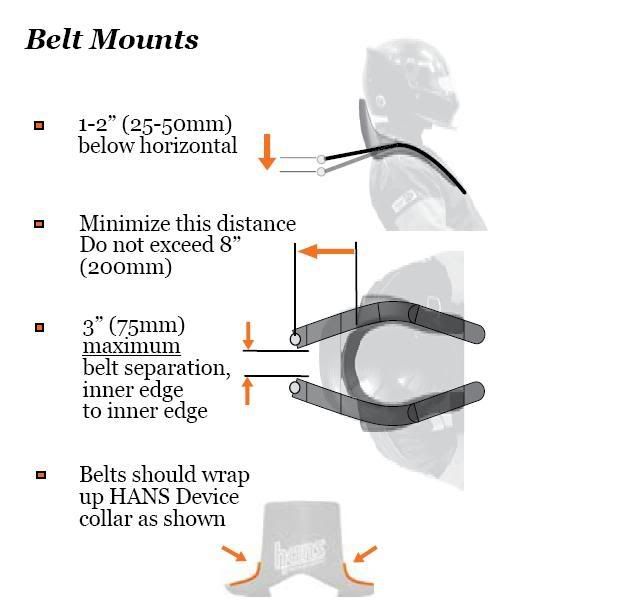

That's the 'quick start guide,' not the full manual. Also that just says 3" maximum....

http://www.hmsmotorsport.com/docs/FIA_HANS_Guide.pdf

http://www.hmsmotorsport.com/docs/FIA_HANS_Guide.pdf

#19

Addict

Rennlist Member

Rennlist Small

Business Sponsor

Rennlist Member

Rennlist Small

Business Sponsor

That's the 'quick start guide,' not the full manual. Also that just says 3" maximum....

http://www.hmsmotorsport.com/docs/FIA_HANS_Guide.pdf

http://www.hmsmotorsport.com/docs/FIA_HANS_Guide.pdf

Regardless. The setup in the first post doens't meet the specs at all.

#20

Rennlist Member

Greg, Its not the fact that they are NASCAR bars, its just the top bar is at the sill of the window, Mine are about where yours are about 5/8-3/4 the way up the door the OP shots make it look about like climbing out the window...hard to do in a 44 due to the rake of the A pillar. Also H&N restraints are manditory in NASA so yea it should be set up for it...

#22

Three Wheelin'

Thread Starter

Getting in does not seem to be a problem, the seat is on sliders, the wheel detaches and I am 5'6" and 145 lbs. After reading all the posts, I will address all of these issues when I go back for detail work. I agree that it is rather......stout, made the wife happy when she saw it. I had a Safety Devices cage seemed spindly compared to this monster.

Painted it this weekend. Same guy who did the cage is fabbing a few other bits for me. I will post as we assemble. Sound like a good idea to approach NASA great lakes for their view.

Painted it this weekend. Same guy who did the cage is fabbing a few other bits for me. I will post as we assemble. Sound like a good idea to approach NASA great lakes for their view.

#23

Addict

Rennlist Member

Rennlist Member

Like I said in post #10, they are too far apart! To make it easy, they should never be wider apart than the HANS collar.

-----------------------------------------------------------------------------------------

-----------------------------------------------------------------------------------------

#24

Whats the verdict on the main hoop brace? I once got excluded from an SCCA event because of a similar sort of issue, my local tech guy passed my cage but at an event at IRP the cage failed tech inspection because the main diagonal was bent for cage clearance around the driver. It well and truly sucked to have to tow the car home 7 hours, so it will pay you big time to fix it now.

I agree the cage "looks" burly, but honestly I dont think its that safe. Please do not take the following as a shot at you or your builder.

The NASCAR style bars look impressive but are not tied into the sill like they should be and can and will collapse inward in a hard impact.

The HALO is simply not right- the middle bar looks cool but does absolutely nothing except add weight up top. A diagonal from behind the drivers head to the passengers front corner with proper gusseting is a better idea.

The main hoop diagonal brace needs to be straight across, because as it sits with that bend there its probably less effective than the Safety Devices you had in there before. The reason I say this is while I doubt a rollover will fold the main hoop, in a side impact the forces transfered through the car can and will push that main hoop in. With the hoop goes your door bars, and your the soft mass in its way.

I see absoltely no gusseting to the cage at all, which is very important IMHO, as the more re-inforcement you have, the better. The more weld area, the better. One important area to beef up to me is the front A-pillar bar, The front corner of a cage is usually its weakest point and can stand some bracing. A simple solution is a bar running from the Halo/downbar corner to the door bar, braced with a diagonal down to the floor plate in front and the sill behind. Yes, this makes it a little harder to get in and out, but the extra strength is worth it.

I agree the cage "looks" burly, but honestly I dont think its that safe. Please do not take the following as a shot at you or your builder.

The NASCAR style bars look impressive but are not tied into the sill like they should be and can and will collapse inward in a hard impact.

The HALO is simply not right- the middle bar looks cool but does absolutely nothing except add weight up top. A diagonal from behind the drivers head to the passengers front corner with proper gusseting is a better idea.

The main hoop diagonal brace needs to be straight across, because as it sits with that bend there its probably less effective than the Safety Devices you had in there before. The reason I say this is while I doubt a rollover will fold the main hoop, in a side impact the forces transfered through the car can and will push that main hoop in. With the hoop goes your door bars, and your the soft mass in its way.

I see absoltely no gusseting to the cage at all, which is very important IMHO, as the more re-inforcement you have, the better. The more weld area, the better. One important area to beef up to me is the front A-pillar bar, The front corner of a cage is usually its weakest point and can stand some bracing. A simple solution is a bar running from the Halo/downbar corner to the door bar, braced with a diagonal down to the floor plate in front and the sill behind. Yes, this makes it a little harder to get in and out, but the extra strength is worth it.

#25

Whats the verdict on the main hoop brace? I once got excluded from an SCCA event because of a similar sort of issue, my local tech guy passed my cage but at an event at IRP the cage failed tech inspection because the main diagonal was bent for cage clearance around the driver. It well and truly sucked to have to tow the car home 7 hours, so it will pay you big time to fix it now.

I agree the cage "looks" burly, but honestly I dont think its that safe. Please do not take the following as a shot at you or your builder.

The NASCAR style bars look impressive but are not tied into the sill like they should be and can and will collapse inward in a hard impact.

The HALO is simply not right- the middle bar looks cool but does absolutely nothing except add weight up top. A diagonal from behind the drivers head to the passengers front corner with proper gusseting is a better idea.

The main hoop diagonal brace needs to be straight across, because as it sits with that bend there its probably less effective than the Safety Devices you had in there before. The reason I say this is while I doubt a rollover will fold the main hoop, in a side impact the forces transfered through the car can and will push that main hoop in. With the hoop goes your door bars, and your the soft mass in its way.

I see absoltely no gusseting to the cage at all, which is very important IMHO, as the more re-inforcement you have, the better. The more weld area, the better. One important area to beef up to me is the front A-pillar bar, The front corner of a cage is usually its weakest point and can stand some bracing. A simple solution is a bar running from the Halo/downbar corner to the door bar, braced with a diagonal down to the floor plate in front and the sill behind. Yes, this makes it a little harder to get in and out, but the extra strength is worth it.

I agree the cage "looks" burly, but honestly I dont think its that safe. Please do not take the following as a shot at you or your builder.

The NASCAR style bars look impressive but are not tied into the sill like they should be and can and will collapse inward in a hard impact.

The HALO is simply not right- the middle bar looks cool but does absolutely nothing except add weight up top. A diagonal from behind the drivers head to the passengers front corner with proper gusseting is a better idea.

The main hoop diagonal brace needs to be straight across, because as it sits with that bend there its probably less effective than the Safety Devices you had in there before. The reason I say this is while I doubt a rollover will fold the main hoop, in a side impact the forces transfered through the car can and will push that main hoop in. With the hoop goes your door bars, and your the soft mass in its way.

I see absoltely no gusseting to the cage at all, which is very important IMHO, as the more re-inforcement you have, the better. The more weld area, the better. One important area to beef up to me is the front A-pillar bar, The front corner of a cage is usually its weakest point and can stand some bracing. A simple solution is a bar running from the Halo/downbar corner to the door bar, braced with a diagonal down to the floor plate in front and the sill behind. Yes, this makes it a little harder to get in and out, but the extra strength is worth it.

You want tubes to be loaded in pure tension/compression as much as possible. Anytime you put an unnecessary bend in a bar or attach it midspan instead of at a "node" - it is no longer loaded in tension and compression.

Now this is not to say that the pictured cage is "unsafe" or in the event of a crash it will certainly fail - but it is far from optimum, especially from a strength to weight perspective.

Their are a lot of very competent fabricators (and this cage looks to be built by one), but it is rare to find one that has both the fab and design skills. These guys are usually very expensive as well. You can save a lot of money and have a great cage if you do a little bit of research and know exactly what you want before you take it to the fabricator.

My 2 cents...

#26

Rennlist

Basic Site Sponsor

Basic Site Sponsor

Seems to me like this should be the guiding principle when designing the major componants of a cage. I have seen too many where it appears that the objective was to line the main hoop up with the B pillar, rather than locate it back far enough so that the diagonals and cross bracing can be absolutely straight.

__________________

Larry Herman

2016 Ford Transit Connect Titanium LWB

2018 Tesla Model 3 - Electricity can be fun!

Retired Club Racer & National PCA Instructor

Past Flames:

1994 RS America Club Racer

2004 GT3 Track Car

1984 911 Carrera Club Racer

1974 914/4 2.0 Track Car

CLICK HERE to see some of my ancient racing videos.

Larry Herman

2016 Ford Transit Connect Titanium LWB

2018 Tesla Model 3 - Electricity can be fun!

Retired Club Racer & National PCA Instructor

Past Flames:

1994 RS America Club Racer

2004 GT3 Track Car

1984 911 Carrera Club Racer

1974 914/4 2.0 Track Car

CLICK HERE to see some of my ancient racing videos.

#27

Race Director

Agree with pretty much everything in here. I have a degree in mechanical engineering and it is always amazing to me to see what cages people are impressed with. Lots of steel is not a substitute for good design. I hate to go on some forum and "bash" some guy's cage that I'm sure he has a lot of money in, but I think the more people understand the design principles the better.

You want tubes to be loaded in pure tension/compression as much as possible. Anytime you put an unnecessary bend in a bar or attach it midspan instead of at a "node" - it is no longer loaded in tension and compression.

Now this is not to say that the pictured cage is "unsafe" or in the event of a crash it will certainly fail - but it is far from optimum, especially from a strength to weight perspective.

Their are a lot of very competent fabricators (and this cage looks to be built by one), but it is rare to find one that has both the fab and design skills. These guys are usually very expensive as well. You can save a lot of money and have a great cage if you do a little bit of research and know exactly what you want before you take it to the fabricator.

My 2 cents...

You want tubes to be loaded in pure tension/compression as much as possible. Anytime you put an unnecessary bend in a bar or attach it midspan instead of at a "node" - it is no longer loaded in tension and compression.

Now this is not to say that the pictured cage is "unsafe" or in the event of a crash it will certainly fail - but it is far from optimum, especially from a strength to weight perspective.

Their are a lot of very competent fabricators (and this cage looks to be built by one), but it is rare to find one that has both the fab and design skills. These guys are usually very expensive as well. You can save a lot of money and have a great cage if you do a little bit of research and know exactly what you want before you take it to the fabricator.

My 2 cents...

I am a mechanical engineer too and agree with all of what you said.

#28

Rennlist Member

Seems to me like this should be the guiding principle when designing the major componants of a cage. I have seen too many where it appears that the objective was to line the main hoop up with the B pillar, rather than locate it back far enough so that the diagonals and cross bracing can be absolutely straight.

I have seen many over the years that feel if they can bend tube and weld then they too are cage builders ! Yes, they can build a cage, but all cages are NOT created equal.

#29

Rennlist

Basic Site Sponsor

Basic Site Sponsor

The cage in my old RSA was a copy of a factory Matter cage, and every tube other than the front cross bar was absolutely straight (diagonal, cross brace, X bars). And the main hoop had exactly 180 of bends (meaning that the legs down to the sill plate were straight). A few pictures of the current cup car cages would be a good "empirical" guideline.

#30

Three Wheelin'

Thread Starter

The wolves are feeding. Some thoughts are well founded, some not so well founded. I appreciate the input, thats why I posted.

1. Fortunately, I have the opportunity to confirm adherence to the respective rules and have them corrected if there is a problem. I have made a list of questions from this list that will help a great deal. Thanks!

2. The person I am dealing with is a true professional, I saw his book of client cars and projects before I sent my car over. The welding and fit work is second to none. It is important to point out that most of his work has been on Corvettes, Vipers and Mustangs. He only takes work by referral, his customer list is impressive. There was a pretty experienced race engineer that consulted with him on the project because he had not done a 944.

4. The build quality, base mounts, welds etc. are much better than the Koni Cup car (black M3) you see in my avatar.

1. Fortunately, I have the opportunity to confirm adherence to the respective rules and have them corrected if there is a problem. I have made a list of questions from this list that will help a great deal. Thanks!

2. The person I am dealing with is a true professional, I saw his book of client cars and projects before I sent my car over. The welding and fit work is second to none. It is important to point out that most of his work has been on Corvettes, Vipers and Mustangs. He only takes work by referral, his customer list is impressive. There was a pretty experienced race engineer that consulted with him on the project because he had not done a 944.

4. The build quality, base mounts, welds etc. are much better than the Koni Cup car (black M3) you see in my avatar.