Looking for contacts in the racing world

#1

Rennlist Member

Thread Starter

Hi all,

I know that this is a little off topic, but I figure this is the best place to find the folks I would like to contact.

I was watching the races this weekend and I had seen delays in the pits because of stuck wheel nuts. I may have a solution to this problem.

The company that I work for, Nova Machine Products, a division of Curtiss Wright, has a coating that reduces friction and nearly eliminates the opportunity for galling. The trade name of the coating is Plasmabond.

Nova Machine Products is a specialty fastener company that has been in business for over 20 years supplying threaded fasteners and fastener based services to the nuclear power industry.

PlasmaBond is an engineered surface that is applied using a vacuum deposition process that applies a thin, soft metal layer to the fastener in order to counteract the potential for galling. It is applied at ambient temperature, so it does not change the original properties of the base material. Also, it is a very thin layer (< .001mm) so it does not dimensionally change the part as well.

PlasmaBond was originally created and developed by Comanche Peak Nuclear Power Plant to solve the problem of reactor head stud galling. They estimate that a stuck head stud costs them $1.5 million. They used the process for 10 years before bringing it to market. They developed two mobile units for the purpose of applying the product at the nuclear sites as well as two stationary units that are permanently located at a facility. Recently, however, the parent company decided that Plasmabond was not part of the core business of making power, so the process was sold to Nova earlier this year.

Plasmabond is better than over conventional thread lubricants because the liquid lubricants migrate from the contact area over time and they evaporate under higher operating temperatures. Plasmabond is a semi-permanent coating that holds up for 10 or more torqued applications. It can be applied to new or existing threaded fasteners. (or non-fastener applications as well. Comanche Peak used it on everything and anything including power breakers and electronic door latches)

Here are some links to more information about the process.

http://www.txucorp.com/power/generat...d/default.aspx

http://www.westinghousenuclear.com/d...august2005.pdf

http://www.nova-nsa.com/cgi-local/CSVXtra/NovaNews.pl

http://www.cwfc.com/Power/spokes/7_EngServices.htm

I am also an avid racer. I have a Porsche 911 that I compete in the NASA GTS series and with Porsche Club. I am also the Northern Ohio Porsche Club of America president and chair one of the drivers education events for the club. I am an engineer for Nova and I am the person who was tasked with transitioning the program from Texas up to Cleveland.

This process is focused on the nuclear industry, but we would be open to commercial sales as well. I have plans to coat my transmission gears this winter as well as some other items in my car.

Thanks

Ed

I know that this is a little off topic, but I figure this is the best place to find the folks I would like to contact.

I was watching the races this weekend and I had seen delays in the pits because of stuck wheel nuts. I may have a solution to this problem.

The company that I work for, Nova Machine Products, a division of Curtiss Wright, has a coating that reduces friction and nearly eliminates the opportunity for galling. The trade name of the coating is Plasmabond.

Nova Machine Products is a specialty fastener company that has been in business for over 20 years supplying threaded fasteners and fastener based services to the nuclear power industry.

PlasmaBond is an engineered surface that is applied using a vacuum deposition process that applies a thin, soft metal layer to the fastener in order to counteract the potential for galling. It is applied at ambient temperature, so it does not change the original properties of the base material. Also, it is a very thin layer (< .001mm) so it does not dimensionally change the part as well.

PlasmaBond was originally created and developed by Comanche Peak Nuclear Power Plant to solve the problem of reactor head stud galling. They estimate that a stuck head stud costs them $1.5 million. They used the process for 10 years before bringing it to market. They developed two mobile units for the purpose of applying the product at the nuclear sites as well as two stationary units that are permanently located at a facility. Recently, however, the parent company decided that Plasmabond was not part of the core business of making power, so the process was sold to Nova earlier this year.

Plasmabond is better than over conventional thread lubricants because the liquid lubricants migrate from the contact area over time and they evaporate under higher operating temperatures. Plasmabond is a semi-permanent coating that holds up for 10 or more torqued applications. It can be applied to new or existing threaded fasteners. (or non-fastener applications as well. Comanche Peak used it on everything and anything including power breakers and electronic door latches)

Here are some links to more information about the process.

http://www.txucorp.com/power/generat...d/default.aspx

http://www.westinghousenuclear.com/d...august2005.pdf

http://www.nova-nsa.com/cgi-local/CSVXtra/NovaNews.pl

http://www.cwfc.com/Power/spokes/7_EngServices.htm

I am also an avid racer. I have a Porsche 911 that I compete in the NASA GTS series and with Porsche Club. I am also the Northern Ohio Porsche Club of America president and chair one of the drivers education events for the club. I am an engineer for Nova and I am the person who was tasked with transitioning the program from Texas up to Cleveland.

This process is focused on the nuclear industry, but we would be open to commercial sales as well. I have plans to coat my transmission gears this winter as well as some other items in my car.

Thanks

Ed

#4

Rennlist Member

Trending Topics

#8

Guru

Lifetime Rennlist

Member

Rennlist Small

Business Sponsor

Lifetime Rennlist

Member

Rennlist Small

Business Sponsor

Yes, this is an ever evolving problem with centerlock type fastening systems. The trouble we have is from material transfer or pickup from wheel to wheel nut. A lot of this is due to our wheel and nut both being of aluminum, for cost savings mostly.

Dow Corning 321 dry lube spray is what seems to be popular by our teams to help prevent this, but teams still spend an hour a day preparing wheel nuts and wheel seats.

Here are some examples

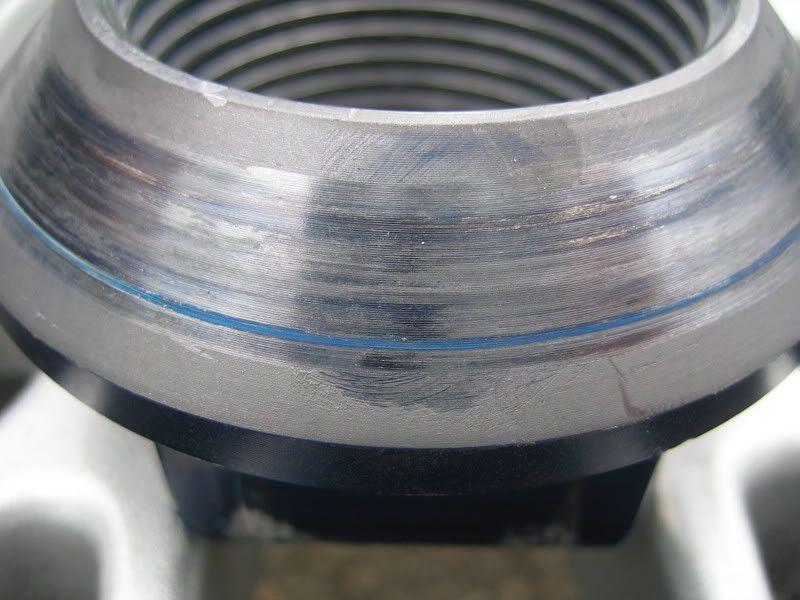

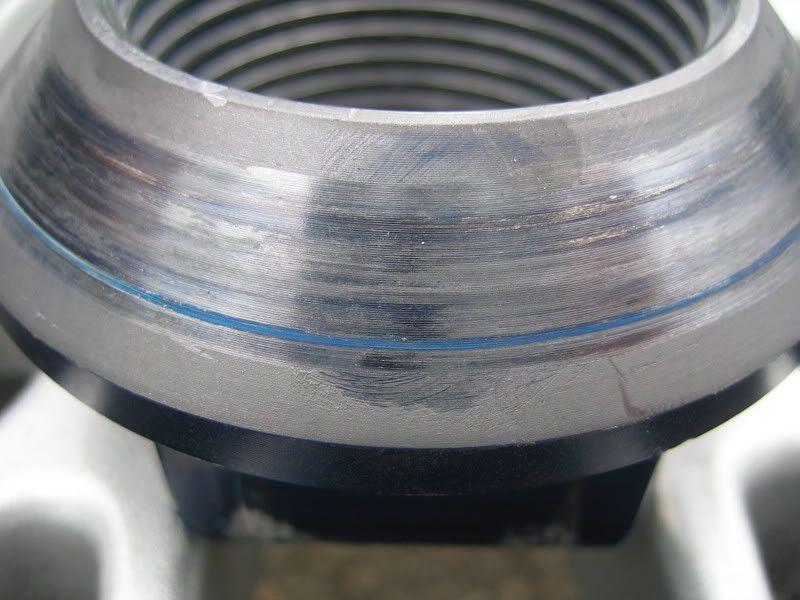

Treated:

Without periodic maintenance:

You can see the material pickup from the wheel.

For the big cars, steel wheel nuts are used on magnesium wheels, so prep involves just a wire brushing, then brake fluid on the threads, nothing on the seating surfaces. There is a natural lubricity trait in magnesium.

Naturally, yes - I am always interested in friction reducing methods!!

Dow Corning 321 dry lube spray is what seems to be popular by our teams to help prevent this, but teams still spend an hour a day preparing wheel nuts and wheel seats.

Here are some examples

Treated:

Without periodic maintenance:

You can see the material pickup from the wheel.

For the big cars, steel wheel nuts are used on magnesium wheels, so prep involves just a wire brushing, then brake fluid on the threads, nothing on the seating surfaces. There is a natural lubricity trait in magnesium.

Naturally, yes - I am always interested in friction reducing methods!!

#9

Drifting

We use a dry moly spray lube on the engines we assemble at work, but once things are assembled they should stay that way for a few years so the requirements are different. Components that see a lot of deflection and thermal growth get anti-wear coatings. What is the max temperature your coating can withstand?

Racecar Engineering magazine has a "racer database" in the back of every issue, several pages of racecar and component manufacturers are listed with contact info. You can get the magazine at Barnes and Noble.

Racecar Engineering magazine has a "racer database" in the back of every issue, several pages of racecar and component manufacturers are listed with contact info. You can get the magazine at Barnes and Noble.