Mount Subs to Floor?

#31

Cows-4-Rent

Rennlist Member

Rennlist Member

Okay. This is a pretty serious topic and I don't really want to read through all the little jokes to find real answers...some of us really driver and are concerned and interested about these types of things.

#34

Addict

Rennlist Member

Rennlist Member

Thread Starter

Originally Posted by Red

That looks like very nice work, John. How come you did not mount the lap belts in double shear?

That's an interesting point, Mark. Frankly it did not occur to me. I guess that is because every manufacturer under the sun does them single. Seems to work pretty good.

The position of the tabs on the edge of their side sills renders the load in shear, So I am not afraid of the mount itself. The bolt is rated for something in the 5-figures PSI worth of shear strength. I'm fairly confident!

#35

King of Cool

Rennlist Member

Rennlist Member

Originally Posted by Mike Buck

That looks like a nice way to add ballast real real low. Thanks for the idea Joe.

No no no, I did it for safety!

I will mount the subs with one plate (~1ft x 1.5ft, say 5-10 mm thick) for each two mount instead of the two big washers I now have. Only for safety!

#36

Race Director

Originally Posted by Flying Finn

+1

I will mount the subs with one plate (~1ft x 1.5ft, say 5-10 mm thick) for each two mount instead of the two big washers I now have. Only for safety!

I will mount the subs with one plate (~1ft x 1.5ft, say 5-10 mm thick) for each two mount instead of the two big washers I now have. Only for safety!

Lets just say... when in doubt add more metal.

#37

Rennlist Member

Originally Posted by David K.

Per the PCA Club Racing Rules:

"14. Five or six point competition harnesses, properly mounted, are required as detailed in Appendix B. Harnesses cannot be mounted to seat or seat rail. Mounting must be to the chassis backed by large diameter washers or to the roll bar. No two harness straps can be attached to a single mounting bolt."

My sub-belt has always been mounted with a cross bar to the sliders, I now need to mount it to floor per the rules. I could trap the 6-point sub-belts between the seat and the floor using the front seat bolt as the anchor point. This would put the mounting point for the sub-belt to far forward. See below per Schroth. Any suggestion?

"14. Five or six point competition harnesses, properly mounted, are required as detailed in Appendix B. Harnesses cannot be mounted to seat or seat rail. Mounting must be to the chassis backed by large diameter washers or to the roll bar. No two harness straps can be attached to a single mounting bolt."

My sub-belt has always been mounted with a cross bar to the sliders, I now need to mount it to floor per the rules. I could trap the 6-point sub-belts between the seat and the floor using the front seat bolt as the anchor point. This would put the mounting point for the sub-belt to far forward. See below per Schroth. Any suggestion?

Is there some different PCA CR rule for GT3 seats and Schroth than is in the book?

#38

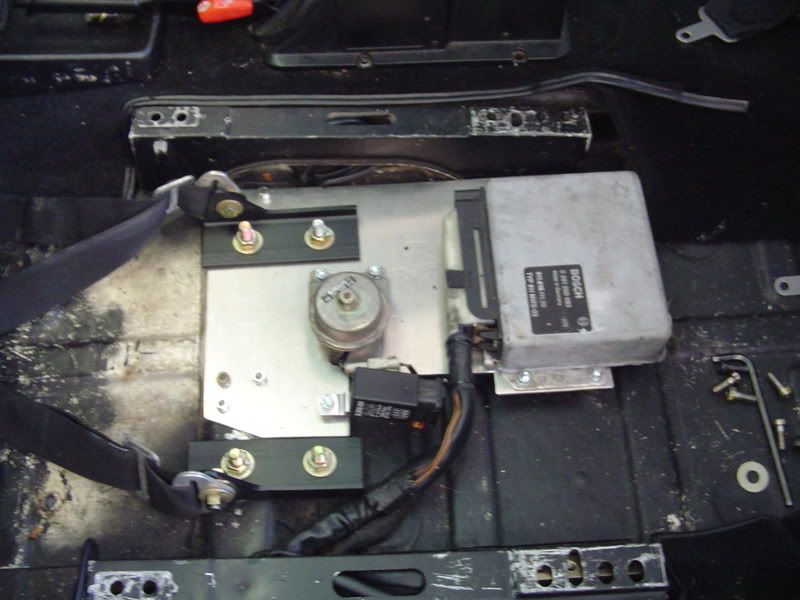

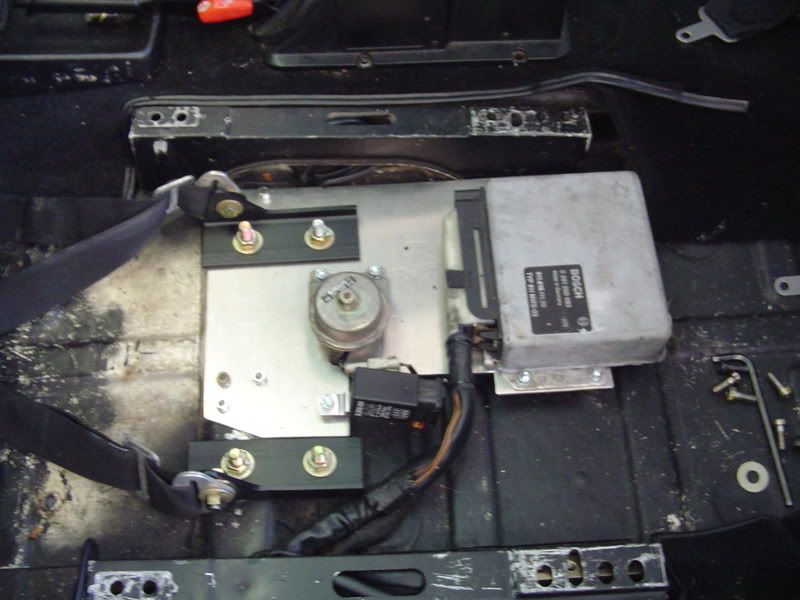

Here's what I did to my 88 911. I wanted something that was removable because I really did not want to cut up my car but didn't want to compromise on safety. My car is used for occasional street use and a few De's per year. I wanted to keep my stock seats and throw in my Momo's with my 6 pt harness for De's My car already had a cage so the shoulder strips were no problem.

I made these mounts out a piece of 2X2X 1/4 angle. I drilled it so it mounts to the factory location where the stock seats mount. I cut some of the excess material away with a 4 1/2" grinder so it would look neater but not loose strength. It attaches to the stock seat location with the stock bolt into the stock backing plates that the factory used to mount the seats. These bolts also hold the sliders in place, in other words the 2x2 angle is sandwiched between the seat slider and the frame. The round piece sticking out the side is where the lap belt mounts and is held in place with grade 8 hardware.

The belts are made by Simpson, so I logged on the their site and downloaded their instructions so I would get all the angles correct. I had to make an alum plate to remount the DME, in order to mount the sub straps per Simpsons specs but that was no big deal.

I only have large fender washers under the car holding the sub belts. This thread has inspired (shamed) me into making something more substantial.

Dan.

I made these mounts out a piece of 2X2X 1/4 angle. I drilled it so it mounts to the factory location where the stock seats mount. I cut some of the excess material away with a 4 1/2" grinder so it would look neater but not loose strength. It attaches to the stock seat location with the stock bolt into the stock backing plates that the factory used to mount the seats. These bolts also hold the sliders in place, in other words the 2x2 angle is sandwiched between the seat slider and the frame. The round piece sticking out the side is where the lap belt mounts and is held in place with grade 8 hardware.

The belts are made by Simpson, so I logged on the their site and downloaded their instructions so I would get all the angles correct. I had to make an alum plate to remount the DME, in order to mount the sub straps per Simpsons specs but that was no big deal.

I only have large fender washers under the car holding the sub belts. This thread has inspired (shamed) me into making something more substantial.

Dan.

#39

Addict

Rennlist Member

Rennlist Member

Thread Starter

Originally Posted by Phokaioglaukos

Is there some different PCA CR rule for GT3 seats and Schroth than is in the book?

Definitely a case of The Curse of Knowledge. We know so much about safety systems and how they work that it just isn't easy any more. This old worn-out has-been sub belt rule is perfect evidence of that. However, to try and write a new rule to cover the infinite number of parameters contained in mounting the sub properly might be virtually impossible.

When faced with such conundrums, I start looking at percentages & likelyhoods. They don't want any belt mounted along with the seat, and I understand the thinking here. RedlineMan says which is more likely to happen; 1) a properly mounted seat to come adrift, or 2) the floor to bend (using the rule quoted)? Clearly there are not a lot of seats coming loose, and so the more common occurrence would be degredation of sub perfomance from the mount (floor) bending. I therefore would be inclined to back-track on that rule to try and improve the performance of the system. In that light, a Brey-Krause type of solution is more palatable to me.

A question I would ask someone in charge is what do you do when you have a car with two drivers of significantly different size? All the other belts accommodate this just fine, but not the sub. What to do if you have an essentially non-adjustable sub?

That's why mine is indeed mounted to my seat! One setting works for me at 6'5", and my girlfriend who is 5'7". A compromise, yes, but a sound one in my opinion.

#40

Addict

Rennlist Member

Rennlist Member

Thread Starter

No Shame, Dan;

What this thread points out is the extreme difficulty the sub belt presents. Not only is it the demon belt in terms of mounting, and critical to system performance, but it is very hard to render on ANY car, be it full race (where you can do anything you want) or dual purpose (where you can't).

You've got some nice fab skills going on there!

I'm curious about two things.

1) Why did you need to move the lap belt mounts?

2) And in what direction do those sub belts run?

What this thread points out is the extreme difficulty the sub belt presents. Not only is it the demon belt in terms of mounting, and critical to system performance, but it is very hard to render on ANY car, be it full race (where you can do anything you want) or dual purpose (where you can't).

You've got some nice fab skills going on there!

I'm curious about two things.

1) Why did you need to move the lap belt mounts?

2) And in what direction do those sub belts run?

#41

Rennlist Member

Thanks, John. I'm with you, Porsche/Schroth and HMS Motorsports and will keep my subs and lap belts mounted to the seat. It is more convenient, but I think it's also better than the alternatives.

I would not pay attention to the PCA CR rules, but the thought crossed my mind about club racing this car. If I add a base plate to the legs of the DAS Sport roll bar it should be good. And with a single mass flywheel I would be in A Stock, I think, and maybe the only car there!

I would not pay attention to the PCA CR rules, but the thought crossed my mind about club racing this car. If I add a base plate to the legs of the DAS Sport roll bar it should be good. And with a single mass flywheel I would be in A Stock, I think, and maybe the only car there!

#42

Mr. Excitement

Rennlist Member

Rennlist Member

Perhaps one reason the seats tend not to come loose as we are not using them as part of the harness system with after market installs. It would be easy to weld in some angle under the seat that runs tunnel to rocker and the subs mount to that. This would give a good mount point that is less likely to bend or tear away at 1500 pounds pull force. This would also comply with PCA and other race rules.

Your pictures dont show any conection from the frame to the car other than at the tunnel and rocker. If this were my car I would weld the angle iron to the floor of the car and have a stronger less flexable structure, as now the forces run all the way to the tunnel or rocker. Yes the floor is not real strong but it added in with the frame you built produces some more geometric strenght value. Its there, why not put it to work?

Your pictures dont show any conection from the frame to the car other than at the tunnel and rocker. If this were my car I would weld the angle iron to the floor of the car and have a stronger less flexable structure, as now the forces run all the way to the tunnel or rocker. Yes the floor is not real strong but it added in with the frame you built produces some more geometric strenght value. Its there, why not put it to work?

#43

John,

Thanks for the kind words.

I moved the lap belt location for 2 main reasons. One is that there is not a mounting point on the inboard side of the seat (tunnel) and second is that the lap belts would not be at Simpsons recommended angle given the location of the opening in the Momo seats. I first got the seat located where it is comfortable for me and located the harness from there. I like to sit very close to the wheel.

To answer your second question, as a reference, the DME is re mounted to the rear of the car and the straps are laying toward the front.

Dan

Thanks for the kind words.

I moved the lap belt location for 2 main reasons. One is that there is not a mounting point on the inboard side of the seat (tunnel) and second is that the lap belts would not be at Simpsons recommended angle given the location of the opening in the Momo seats. I first got the seat located where it is comfortable for me and located the harness from there. I like to sit very close to the wheel.

To answer your second question, as a reference, the DME is re mounted to the rear of the car and the straps are laying toward the front.

Dan

#44

Addict

Rennlist Member

Rennlist Member

Thread Starter

Dan;

Good show on the first point. It's refreshing to see someone who has done their homework -vs- just going with what was easy or what the herd has done, all completed with style!

Now, as for the sub. It looks to me like this was an over-the-front-of-a-stock-seat install. I don't get the wide and forward positioning of the mounts. The angle at which they are fixed also looks odd, and the fact that they are indeed fixed instead of floating. These are the points I was looking for clarification on.

Not trying to be critical. Just trying to provoke thought... possibly to avert future shame.

Good show on the first point. It's refreshing to see someone who has done their homework -vs- just going with what was easy or what the herd has done, all completed with style!

Now, as for the sub. It looks to me like this was an over-the-front-of-a-stock-seat install. I don't get the wide and forward positioning of the mounts. The angle at which they are fixed also looks odd, and the fact that they are indeed fixed instead of floating. These are the points I was looking for clarification on.

Not trying to be critical. Just trying to provoke thought... possibly to avert future shame.

#45

Addict

Rennlist Member

Rennlist Member

Thread Starter

Originally Posted by kurt M

Perhaps one reason the seats tend not to come loose as we are not using them as part of the harness system with after market installs. It would be easy to weld in some angle under the seat that runs tunnel to rocker and the subs mount to that. This would give a good mount point that is less likely to bend or tear away at 1500 pounds pull force. This would also comply with PCA and other race rules.

Your pictures dont show any conection from the frame to the car other than at the tunnel and rocker. If this were my car I would weld the angle iron to the floor of the car and have a stronger less flexable structure, as now the forces run all the way to the tunnel or rocker. Yes the floor is not real strong but it added in with the frame you built produces some more geometric strenght value. Its there, why not put it to work?

Your pictures dont show any conection from the frame to the car other than at the tunnel and rocker. If this were my car I would weld the angle iron to the floor of the car and have a stronger less flexable structure, as now the forces run all the way to the tunnel or rocker. Yes the floor is not real strong but it added in with the frame you built produces some more geometric strenght value. Its there, why not put it to work?

It would be an assumption at this point to wonder why I was not going to tie the floor in. Boy, I wish I had a strain gauge. I'm betting that a simple test would show the floor pan to have no meaningful strength whatsoever (relative to the task at hand), beyond keeping your boots off the pavement.

Your idea for another transverse beam to mount subs to works fine, of course... but only for one position. Mine - running front-to-back - allows for multiple sub locations as possibly needed in the future.