Decoding GT3 Cup sequential

#1

Addict

Rennlist Member

Rennlist Member

Thread Starter

When I decided to get a GT3 Cup car the biggest mystery to me was the sequential gearbox. What do I know about it? Almost nothing. I know motorcycle and race car use them and that's about it. I also know GT3 Cup need gearbox rebuild more often than engine for some reason. I was happy to learn my gearbox was "rebuild" with zero hour when I bought it. That's all I know. Well, after driving for two years and 40-50 hours my sequential gave up it's ghost. Granted I was not kind to the tranny when I first learn how to drive a Cup it lasted for a good while. The cost of this repair was very expensive and I like to share my experience for those of you that may entertained a Cup car in the future or currently owns one so you may know what to look out for.

First, a basic sequential transmission 101 from Wikipedia:

A sequential manual transmission (or sequential manual gearbox) is a type of manual transmission used on motorcycles and high-performance cars for auto racing, where gears are selected in order, and direct access to specific gears is not possible.

With traditional manual transmissions, the driver can move from gear to gear, by moving the shifter to the appropriate position. This type of transmission is often referred to as a H-pattern because of the path that the shift lever takes as it selects the various gears. A clutch must be disengaged before the new gear is selected, to disengage the running engine from the transmission, thus stopping all torque transfer. In auto racing, this process is slow and prone to human error; hence the development of the sequential transmission. A true sequential transmission will very often use dog clutch engagement rather than the more usual synchromesh as fitted to a normal H-pattern road car gearbox. Engagement using dogs only requires a very brief interruption of engine torque to complete a shift into any adjacent gear. This allows shifting between gears without the use of the clutch. The clutch would normally be used only for standing starts.

That's the basic about sequential transmission and why it's used in road racing cars to help extract every last horsepower from the drivetrain. So now you got your eyes on a nice 997 Cup and the seller tell you the gearbox has just been refreshed vs rebuild vs rebuild and sealed vs lightly used vs "I only race it couple times". What does all that mean and is there a way to measure the health of a sequential gearbox? Let's take a look at my sequential gearbox repair and it will help shed light on the matter.

The problem I encounter recently was that my sequential did not engage gear from 4th to 3rd and rattle around like crazy. Loud rattle become prominent when clutch was released as shown by video below.

Similar issue happened once before going from 5th to 4th but no loud noise after gears re-engaged. I felt pretty confident about the gearbox thinking it must be robust since it's been rebuild by the race shop and continue to use it for another 20 hours. I drain tranny oil both times and no large mental fragments.

So now the gearbox has to be serviced. After much research I decided to have it repair by Bill Rader motorsports. I chose Bill because he is a Porsche gearbox specialist with years of experience servicing GT3 Cup sequential for various race teams. He was upfront on the phone with repair process and cost and provide detail photo journal to document diagnostic and repair process so customer like myself know exactly what's going on. After diagnosing the problem I was presented with a list of repair options taken into consideration of cost and race purpose. Another good thing is that Bill can arrange expedited freight shipping and deal with my shop directly for FedEx pick up and drop off . It took Bill 2 days to rebuild the gearbox, dyno and ship back to my shop - that is really fast!

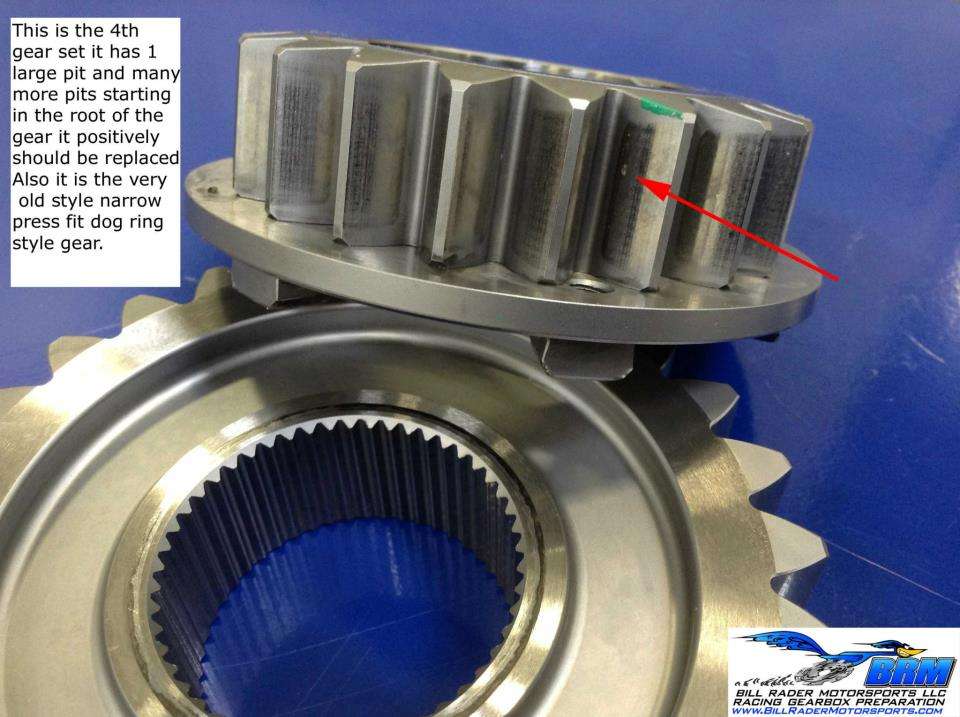

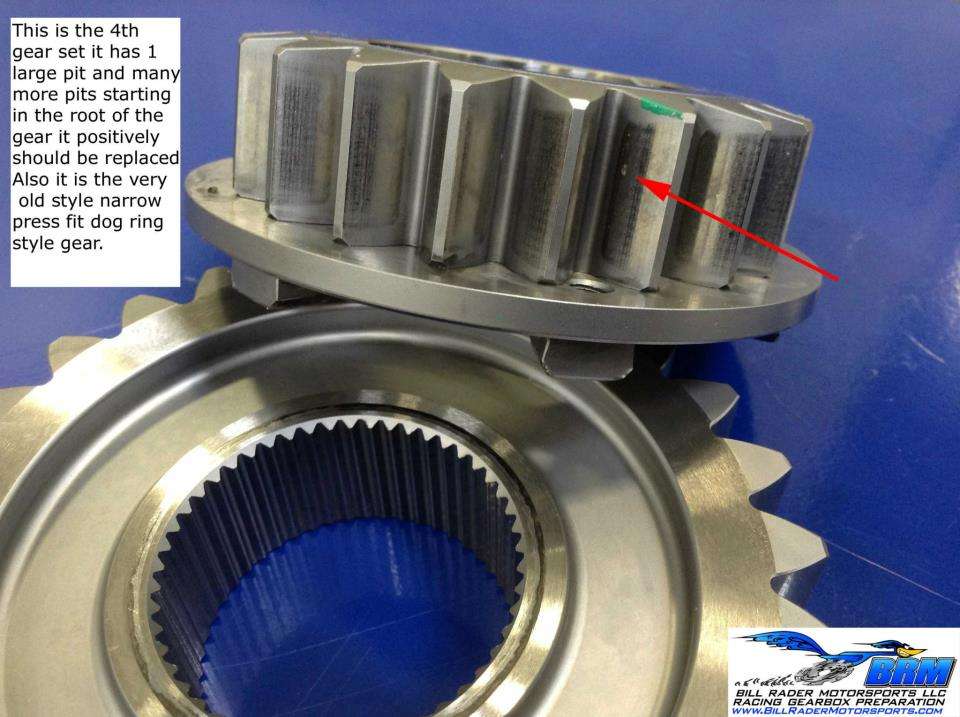

Here is what Bill found when he open the gearbox illustrated with photo journal:

I felt sick to learn that majority of the damage was done by two $18 nut that was not replaced and properly secured when it was "rebuild" two years ago. This goes to show the importance of using an experienced gearbox expert to have it done right the first time. The report also pointed out that the only thing that was updated in this gearbox was the 3rd/4th shift fork and the rest of the components are old and dated. It is amazing that the gearbox has lasted this long . It helps that I only DE and club race which kept the damage to a minimum - it will never survive endurance race condition. Now when you look at a shiny GT3 Cup and the seller tells you the gearbox has been rebuild or refreshed you need to ask to see the repair parts list and speak with the repair shop directly and ask to see pictures if available. Without detail documentation like what Bill Rader offer you can not determine the true health and durability of a sequential gearbox.

So, what's my repair options? I want to fix the clunky noise but how about the rest such as cracked first gear dog teeth and the claw collar? I could just replaced the damaged first gear set and be done with only spending $3000 ... but that's not addressing all other issues and the gearbox will not last and the next repair will be even more expensive. Here is what Bill proposed:

I decided to go with option 2 and use Guard gears and components which are stronger than OEM Porsche parts and proven in 24 hours endurance race condition. Guard gears are not as wide as the 2012 super wide OEM Porsche gears shown above but it has the "middle of the road" 2011 wider width which help reduce friction. Guard use stronger manufacture metallurgy which means it does not need the extra width for strength. All this means more power is transfer to the rear wheels with stronger gear set and internals. The other obvious benefit of Guard gears sets is that they are about $1000 less per gear set compare with OEM Porsche parts. Stronger, better mechanical efficiency and price conscious wins every time.

Now let's take a look at the repair process

Here is a video of the sequential gearbox dyno run after repair and assembly

https://www.facebook.com/photo.php?v...type=2&theater

I also took the opportunity when my gearbox are out to replace both rear drive axle and also central bolts on each wheels. Shad at driving ambition did a great job in getting everything done in a timely manner and woke everyone up when he test drove my Cup near his shop

Wheel central bolt for the center lock

996 TT rear axles

Engine view with tranny removed

Bad boy is home after a wild ride at Vegas and ready to go back to work!

So what's the cost of repair? I called PMNA to find out how much a brand new 2012 sequential gearbox cost and they can have it ship directly from Germany for $40K. Wow ... not cheap. A new Quaife QBE85G 997 sequential cost about 1/2 as much at $21K but I decided to use original gearbox and strengthen the internal and make it stronger and more efficient that should last another 40-50 hours before next refresh. Total parts cost for this repair is about the price of a new Honda civic. 1 day expedited freight shipping of gearbox from Northern California to Las Vagas cost $150 each way. Total labor cost both shops combine are about $2500. It was a hard lesson learned and I wish I could have known better ... but how could I if I have not experienced it first hand.

I was eager to try out the new gearbox to feel the difference. Now I know 3rd and 4th gears are the weakest link because most high speed compression gear change on track involves 3rd and 4th gears and that's where all my miss shifts happens. When I fly down a fast straight to a high compression braking zone I have to brake hard - but not hard enough to lock up the brakes which means my right hand also react like my right foot with a slight hesitancy when I push the lever forward to down shift. This lead to not getting gears in from 5th to 4th or 4th to 3rd and I hate that grinding sound.

One thing I immediately noticed when I start up the car with refreshed gearbox is that the engine does not die easily like before when cold and I don't have to crazy rev to engine to 4K RPM to get her going from first gear or reverse. I also notice the engine spool up super fast on the track - so fast I kept on hitting redline before I react to upshift. My ears and reactions times are train to the old gearbox and now the new gearbox is super fast and I had to retrain my muscle memory. Gone are the clunky gear change and now replace with smooth shift which minimize excessive drivetrain movement. All this translate to faster lap time, so fast that I beat my previous best time by 3 seconds under the same track condition - and this was done in traffic with older scrub slicks! 3 seconds is huge for a 2.86 mile track. This is equivalent to more than 50 horsepower gain.

This has been a very trying experience but with a satisfying result. I hope by sharing my experience can help you avoid some of the pitfall when it comes to purchsing a Cup car and servicing sequential gearbox

First, a basic sequential transmission 101 from Wikipedia:

A sequential manual transmission (or sequential manual gearbox) is a type of manual transmission used on motorcycles and high-performance cars for auto racing, where gears are selected in order, and direct access to specific gears is not possible.

With traditional manual transmissions, the driver can move from gear to gear, by moving the shifter to the appropriate position. This type of transmission is often referred to as a H-pattern because of the path that the shift lever takes as it selects the various gears. A clutch must be disengaged before the new gear is selected, to disengage the running engine from the transmission, thus stopping all torque transfer. In auto racing, this process is slow and prone to human error; hence the development of the sequential transmission. A true sequential transmission will very often use dog clutch engagement rather than the more usual synchromesh as fitted to a normal H-pattern road car gearbox. Engagement using dogs only requires a very brief interruption of engine torque to complete a shift into any adjacent gear. This allows shifting between gears without the use of the clutch. The clutch would normally be used only for standing starts.

That's the basic about sequential transmission and why it's used in road racing cars to help extract every last horsepower from the drivetrain. So now you got your eyes on a nice 997 Cup and the seller tell you the gearbox has just been refreshed vs rebuild vs rebuild and sealed vs lightly used vs "I only race it couple times". What does all that mean and is there a way to measure the health of a sequential gearbox? Let's take a look at my sequential gearbox repair and it will help shed light on the matter.

The problem I encounter recently was that my sequential did not engage gear from 4th to 3rd and rattle around like crazy. Loud rattle become prominent when clutch was released as shown by video below.

Similar issue happened once before going from 5th to 4th but no loud noise after gears re-engaged. I felt pretty confident about the gearbox thinking it must be robust since it's been rebuild by the race shop and continue to use it for another 20 hours. I drain tranny oil both times and no large mental fragments.

So now the gearbox has to be serviced. After much research I decided to have it repair by Bill Rader motorsports. I chose Bill because he is a Porsche gearbox specialist with years of experience servicing GT3 Cup sequential for various race teams. He was upfront on the phone with repair process and cost and provide detail photo journal to document diagnostic and repair process so customer like myself know exactly what's going on. After diagnosing the problem I was presented with a list of repair options taken into consideration of cost and race purpose. Another good thing is that Bill can arrange expedited freight shipping and deal with my shop directly for FedEx pick up and drop off . It took Bill 2 days to rebuild the gearbox, dyno and ship back to my shop - that is really fast!

Here is what Bill found when he open the gearbox illustrated with photo journal:

I felt sick to learn that majority of the damage was done by two $18 nut that was not replaced and properly secured when it was "rebuild" two years ago. This goes to show the importance of using an experienced gearbox expert to have it done right the first time. The report also pointed out that the only thing that was updated in this gearbox was the 3rd/4th shift fork and the rest of the components are old and dated. It is amazing that the gearbox has lasted this long . It helps that I only DE and club race which kept the damage to a minimum - it will never survive endurance race condition. Now when you look at a shiny GT3 Cup and the seller tells you the gearbox has been rebuild or refreshed you need to ask to see the repair parts list and speak with the repair shop directly and ask to see pictures if available. Without detail documentation like what Bill Rader offer you can not determine the true health and durability of a sequential gearbox.

So, what's my repair options? I want to fix the clunky noise but how about the rest such as cracked first gear dog teeth and the claw collar? I could just replaced the damaged first gear set and be done with only spending $3000 ... but that's not addressing all other issues and the gearbox will not last and the next repair will be even more expensive. Here is what Bill proposed:

- This one is the bare minimum I would recommend doing to it to make it a good reliable box, this one will use Guard gears, and I have put in an option by using a perfectly good RSR style main shaft and a Guard slide on 1st gear set. With this one I would clean up the dogs on 2nd gear and we would reuse the old original 5th and 6th.

- This one is the best option and will make it a great reliable box that will be fully updated to 2011 specs with Guard gears

- This one is the same as #1 except will use Factory 2012 super wide 3rd and 4th gears. To do that conversion it would also need to use a standard style 1st gear set so there is a different price for that in the quote.

- This one is to fully update everything in the box to 2012 specs

I decided to go with option 2 and use Guard gears and components which are stronger than OEM Porsche parts and proven in 24 hours endurance race condition. Guard gears are not as wide as the 2012 super wide OEM Porsche gears shown above but it has the "middle of the road" 2011 wider width which help reduce friction. Guard use stronger manufacture metallurgy which means it does not need the extra width for strength. All this means more power is transfer to the rear wheels with stronger gear set and internals. The other obvious benefit of Guard gears sets is that they are about $1000 less per gear set compare with OEM Porsche parts. Stronger, better mechanical efficiency and price conscious wins every time.

Now let's take a look at the repair process

Here is a video of the sequential gearbox dyno run after repair and assembly

https://www.facebook.com/photo.php?v...type=2&theater

I also took the opportunity when my gearbox are out to replace both rear drive axle and also central bolts on each wheels. Shad at driving ambition did a great job in getting everything done in a timely manner and woke everyone up when he test drove my Cup near his shop

Wheel central bolt for the center lock

996 TT rear axles

Engine view with tranny removed

Bad boy is home after a wild ride at Vegas and ready to go back to work!

So what's the cost of repair? I called PMNA to find out how much a brand new 2012 sequential gearbox cost and they can have it ship directly from Germany for $40K. Wow ... not cheap. A new Quaife QBE85G 997 sequential cost about 1/2 as much at $21K but I decided to use original gearbox and strengthen the internal and make it stronger and more efficient that should last another 40-50 hours before next refresh. Total parts cost for this repair is about the price of a new Honda civic. 1 day expedited freight shipping of gearbox from Northern California to Las Vagas cost $150 each way. Total labor cost both shops combine are about $2500. It was a hard lesson learned and I wish I could have known better ... but how could I if I have not experienced it first hand.

I was eager to try out the new gearbox to feel the difference. Now I know 3rd and 4th gears are the weakest link because most high speed compression gear change on track involves 3rd and 4th gears and that's where all my miss shifts happens. When I fly down a fast straight to a high compression braking zone I have to brake hard - but not hard enough to lock up the brakes which means my right hand also react like my right foot with a slight hesitancy when I push the lever forward to down shift. This lead to not getting gears in from 5th to 4th or 4th to 3rd and I hate that grinding sound.

One thing I immediately noticed when I start up the car with refreshed gearbox is that the engine does not die easily like before when cold and I don't have to crazy rev to engine to 4K RPM to get her going from first gear or reverse. I also notice the engine spool up super fast on the track - so fast I kept on hitting redline before I react to upshift. My ears and reactions times are train to the old gearbox and now the new gearbox is super fast and I had to retrain my muscle memory. Gone are the clunky gear change and now replace with smooth shift which minimize excessive drivetrain movement. All this translate to faster lap time, so fast that I beat my previous best time by 3 seconds under the same track condition - and this was done in traffic with older scrub slicks! 3 seconds is huge for a 2.86 mile track. This is equivalent to more than 50 horsepower gain.

This has been a very trying experience but with a satisfying result. I hope by sharing my experience can help you avoid some of the pitfall when it comes to purchsing a Cup car and servicing sequential gearbox

Last edited by mikymu; 05-04-2013 at 05:20 AM.

#2

Rennlist Member

Cool Thread. A "zero" hour box can mean many things. Like you stated, a rebuild can be anything from replacing a few damaged parts to a complete upgrade. These transmissions can be very expensive when upgrading the early versions.

Other common issues with these (and the syncro boxes as well) include the ring and pinion, the early cast diff housing and the bearing races on the bell housing. The ring and pinions are definitely a wear item and start to pit at the base of the pinion gears. The early cast diff housings are also prone to failure. The flange that the ring gear mounts on can break free from the rest of the housing and cause a mess. The bearing race in the bell housing for the pinion shaft will get loose and spin in the housing. The small 4-point bearing on the input shaft will also start to spin and wear away the seating surface on the bell housing which causes longitudinal play in the input shaft and can cause the dreaded "2 gears at once" which will destroy the transmission. We have seen one transmission split from front to rear with a crack in all 3 housings due to this.

There are many things to look out for in these transmissions. Upgrading the early year models can be very costly. (part of the reason the 05-07's are normally cheaper) Ask for a parts list when discussing what was done during a "rebuild".

If you ever hear a new noise while engaged in any gear quit driving the car. If the tranny makes a sporadic tick, scrape or clack noise when in neutral it needs to be looked at. If you find any large pieces in the oil don't run the car. If you see pitting in the pinion gear when you have the diff out don't drive the car. If you see brass or copper color shavings in the gear oil, don't drive the car. Paying attention and not ignoring the warning signs could significantly lower the repair cost. A poor shifting issue isn't the only tell that something needs to be done.

Other common issues with these (and the syncro boxes as well) include the ring and pinion, the early cast diff housing and the bearing races on the bell housing. The ring and pinions are definitely a wear item and start to pit at the base of the pinion gears. The early cast diff housings are also prone to failure. The flange that the ring gear mounts on can break free from the rest of the housing and cause a mess. The bearing race in the bell housing for the pinion shaft will get loose and spin in the housing. The small 4-point bearing on the input shaft will also start to spin and wear away the seating surface on the bell housing which causes longitudinal play in the input shaft and can cause the dreaded "2 gears at once" which will destroy the transmission. We have seen one transmission split from front to rear with a crack in all 3 housings due to this.

There are many things to look out for in these transmissions. Upgrading the early year models can be very costly. (part of the reason the 05-07's are normally cheaper) Ask for a parts list when discussing what was done during a "rebuild".

If you ever hear a new noise while engaged in any gear quit driving the car. If the tranny makes a sporadic tick, scrape or clack noise when in neutral it needs to be looked at. If you find any large pieces in the oil don't run the car. If you see pitting in the pinion gear when you have the diff out don't drive the car. If you see brass or copper color shavings in the gear oil, don't drive the car. Paying attention and not ignoring the warning signs could significantly lower the repair cost. A poor shifting issue isn't the only tell that something needs to be done.

The following users liked this post:

The Mick (06-29-2023)

#4

Addict

Rennlist Member

Rennlist Member

Thread Starter

Cool Thread. A "zero" hour box can mean many things. Like you stated, a rebuild can be anything from replacing a few damaged parts to a complete upgrade. These transmissions can be very expensive when upgrading the early versions.

Other common issues with these (and the syncro boxes as well) include the ring and pinion, the early cast diff housing and the bearing races on the bell housing. The ring and pinions are definitely a wear item and start to pit at the base of the pinion gears. The early cast diff housings are also prone to failure. The flange that the ring gear mounts on can break free from the rest of the housing and cause a mess. The bearing race in the bell housing for the pinion shaft will get loose and spin in the housing. The small 4-point bearing on the input shaft will also start to spin and wear away the seating surface on the bell housing which causes longitudinal play in the input shaft and can cause the dreaded "2 gears at once" which will destroy the transmission. We have seen one transmission split from front to rear with a crack in all 3 housings due to this.

There are many things to look out for in these transmissions. Upgrading the early year models can be very costly. (part of the reason the 05-07's are normally cheaper) Ask for a parts list when discussing what was done during a "rebuild".

If you ever hear a new noise while engaged in any gear quit driving the car. If the tranny makes a sporadic tick, scrape or clack noise when in neutral it needs to be looked at. If you find any large pieces in the oil don't run the car. If you see pitting in the pinion gear when you have the diff out don't drive the car. If you see brass or copper color shavings in the gear oil, don't drive the car. Paying attention and not ignoring the warning signs could significantly lower the repair cost. A poor shifting issue isn't the only tell that something needs to be done.

Other common issues with these (and the syncro boxes as well) include the ring and pinion, the early cast diff housing and the bearing races on the bell housing. The ring and pinions are definitely a wear item and start to pit at the base of the pinion gears. The early cast diff housings are also prone to failure. The flange that the ring gear mounts on can break free from the rest of the housing and cause a mess. The bearing race in the bell housing for the pinion shaft will get loose and spin in the housing. The small 4-point bearing on the input shaft will also start to spin and wear away the seating surface on the bell housing which causes longitudinal play in the input shaft and can cause the dreaded "2 gears at once" which will destroy the transmission. We have seen one transmission split from front to rear with a crack in all 3 housings due to this.

There are many things to look out for in these transmissions. Upgrading the early year models can be very costly. (part of the reason the 05-07's are normally cheaper) Ask for a parts list when discussing what was done during a "rebuild".

If you ever hear a new noise while engaged in any gear quit driving the car. If the tranny makes a sporadic tick, scrape or clack noise when in neutral it needs to be looked at. If you find any large pieces in the oil don't run the car. If you see pitting in the pinion gear when you have the diff out don't drive the car. If you see brass or copper color shavings in the gear oil, don't drive the car. Paying attention and not ignoring the warning signs could significantly lower the repair cost. A poor shifting issue isn't the only tell that something needs to be done.

You are welcome and it's nice to have something interesting to read in a raining day

#6

Addict

Rennlist Member

Rennlist Member

Thread Starter

Trending Topics

#8

Nordschleife Master

Thanks for sharing this Mike.

Now, why the increased performance? And why is it easier to start from a stop?

Did you change ratios, or does everything just work better?

Now, why the increased performance? And why is it easier to start from a stop?

Did you change ratios, or does everything just work better?

#9

Burning Brakes

Good post, thanks for sharing!

Here's the first 3rd gear I broke in a Cup (i keep it on my desk as a reminder.. and paper weight):

I've had very good experiences w/ Guard parts and local rebuilds (JWE) when I'm not worried about having to run a sealed gearbox (testing, etc).

I wouldn't get too used to it sounding and feeling nice and smooth. It's going to get chunky and sound like crap.. it's just the way these gearboxes work (unless you do a bunch more fancy stuff inside, which isn't legal in most series). Have fun! :-)

-mike

Here's the first 3rd gear I broke in a Cup (i keep it on my desk as a reminder.. and paper weight):

I've had very good experiences w/ Guard parts and local rebuilds (JWE) when I'm not worried about having to run a sealed gearbox (testing, etc).

I wouldn't get too used to it sounding and feeling nice and smooth. It's going to get chunky and sound like crap.. it's just the way these gearboxes work (unless you do a bunch more fancy stuff inside, which isn't legal in most series). Have fun! :-)

-mike

#10

Rennlist

Basic Site Sponsor

Basic Site Sponsor

Join Date: Jun 2008

Location: Durham, NC and Virginia International Raceway

Posts: 19,079

Received 3,237 Likes

on

1,856 Posts

Great post, thanks for putting it up. This is the way every build should be documented.

__________________

-Peter Krause

www.peterkrause.net

www.gofasternow.com

"Combining the Art and Science of Driving Fast!"

Specializing in Professional, Private Driver Performance Evaluation and Optimization

Consultation Available Remotely and at VIRginia International Raceway

-Peter Krause

www.peterkrause.net

www.gofasternow.com

"Combining the Art and Science of Driving Fast!"

Specializing in Professional, Private Driver Performance Evaluation and Optimization

Consultation Available Remotely and at VIRginia International Raceway

#11

Addict

Rennlist Member

Rennlist Member

Thread Starter

Cheers

your avitar is sooo funny! Hope that's not you in real life

I did not change gear ratio. I suspect the much improved performance came from corrected gear geometry and reduce friction with Guard gearset. It is like having no weight on the flywheel. Engine spool up so fast it's fantastic!!

Hey Mike, that is one nasty crack and I am sure it sounded really nice in your gearbox. Even after the rebuild these gearbox is still super noise at idle and scream bloody hell at speed. I saw your race at Long Beach ... you should talk to those Lizard guys and tell them quit hitting your ***

Without clear documentation like this you can't determine the health and durability of a gearbox

your avitar is sooo funny! Hope that's not you in real life

Good post, thanks for sharing!

Here's the first 3rd gear I broke in a Cup (i keep it on my desk as a reminder.. and paper weight):

I've had very good experiences w/ Guard parts and local rebuilds (JWE) when I'm not worried about having to run a sealed gearbox (testing, etc).

I wouldn't get too used to it sounding and feeling nice and smooth. It's going to get chunky and sound like crap.. it's just the way these gearboxes work (unless you do a bunch more fancy stuff inside, which isn't legal in most series). Have fun! :-)

-mike

Here's the first 3rd gear I broke in a Cup (i keep it on my desk as a reminder.. and paper weight):

I've had very good experiences w/ Guard parts and local rebuilds (JWE) when I'm not worried about having to run a sealed gearbox (testing, etc).

I wouldn't get too used to it sounding and feeling nice and smooth. It's going to get chunky and sound like crap.. it's just the way these gearboxes work (unless you do a bunch more fancy stuff inside, which isn't legal in most series). Have fun! :-)

-mike

Without clear documentation like this you can't determine the health and durability of a gearbox

#12

Nordschleife Master

Mike,

Thanks for the write up and as always you were a pleasure to work with on this. Here's wishing you many hours of fun with your new trans...

#13

Rennlist Member

Hey Mike!

Thank you for sharing this! Our 2008 is going to have the engine (currently ~70h) and the box (~40h, 2009 spec) rebuilt and updated to latest spec @ Porsche Motorsport in Weissach next winter.

The parts still feel nice and sound good and healthy but we want to have maximum security and lower cost then repairing a broken trans or engine...

Loose-fit is already much better then '06 & '07 but 2012 gears are the way to go if you want to get the sealing on the engine to keep the car legal for the Sports Cup or GT3 Cup-Challenge here in Germany. That's why we can't go for aftermarket-parts like Guard or others even if we'd like to...

Thank you for sharing this! Our 2008 is going to have the engine (currently ~70h) and the box (~40h, 2009 spec) rebuilt and updated to latest spec @ Porsche Motorsport in Weissach next winter.

The parts still feel nice and sound good and healthy but we want to have maximum security and lower cost then repairing a broken trans or engine...

Loose-fit is already much better then '06 & '07 but 2012 gears are the way to go if you want to get the sealing on the engine to keep the car legal for the Sports Cup or GT3 Cup-Challenge here in Germany. That's why we can't go for aftermarket-parts like Guard or others even if we'd like to...

#15

Addict

Rennlist Member

Rennlist Member

Thread Starter

And moving over to the newer billet "RSR" housing on the later Cups hasn't solved the problem. Not going to name names, but there were 2 Cup Cars that DNF'd at the 24 Hours of Daytona this year because the billet LSD housing broke in the exact same way that the cast ones used to...

Mike,

Thanks for the write up and as always you were a pleasure to work with on this. Here's wishing you many hours of fun with your new trans...

Mike,

Thanks for the write up and as always you were a pleasure to work with on this. Here's wishing you many hours of fun with your new trans...

I knew the rebuild gearbox will be better but I was not prepared for an easy 3 seconds shot in the arm

I guess one of your GT LSD will be in my wish list next. What kind of LSD ratio does Cup car use?