88 transmission protection switch leak,... FIX

#16

I'm going to guess that the difficult part will be getting the existing threads straightened out.

And them being the "ever common" 27 x 1.5mm threads means some hunting to find a shop with that tap.

Maybe you can grind a notch in the broken switch and use it a thread chaser?

You should be able to grab the "barrel" with a pair of "broad nose" pliers...that's how I get them out.

And then you need a switch.

And them being the "ever common" 27 x 1.5mm threads means some hunting to find a shop with that tap.

Maybe you can grind a notch in the broken switch and use it a thread chaser?

You should be able to grab the "barrel" with a pair of "broad nose" pliers...that's how I get them out.

And then you need a switch.

I tried to hand tighten the switch into the hole after I got the barrel out just to see. If goes in to exactly the same place so Iím not too sure itís damaged. Seems like no difference from the first time. Anyone else have issues screwing In the switch? With no barrel it should go right in right? Any thoughts on the condition of the threads and why this bugger wonít screw in?

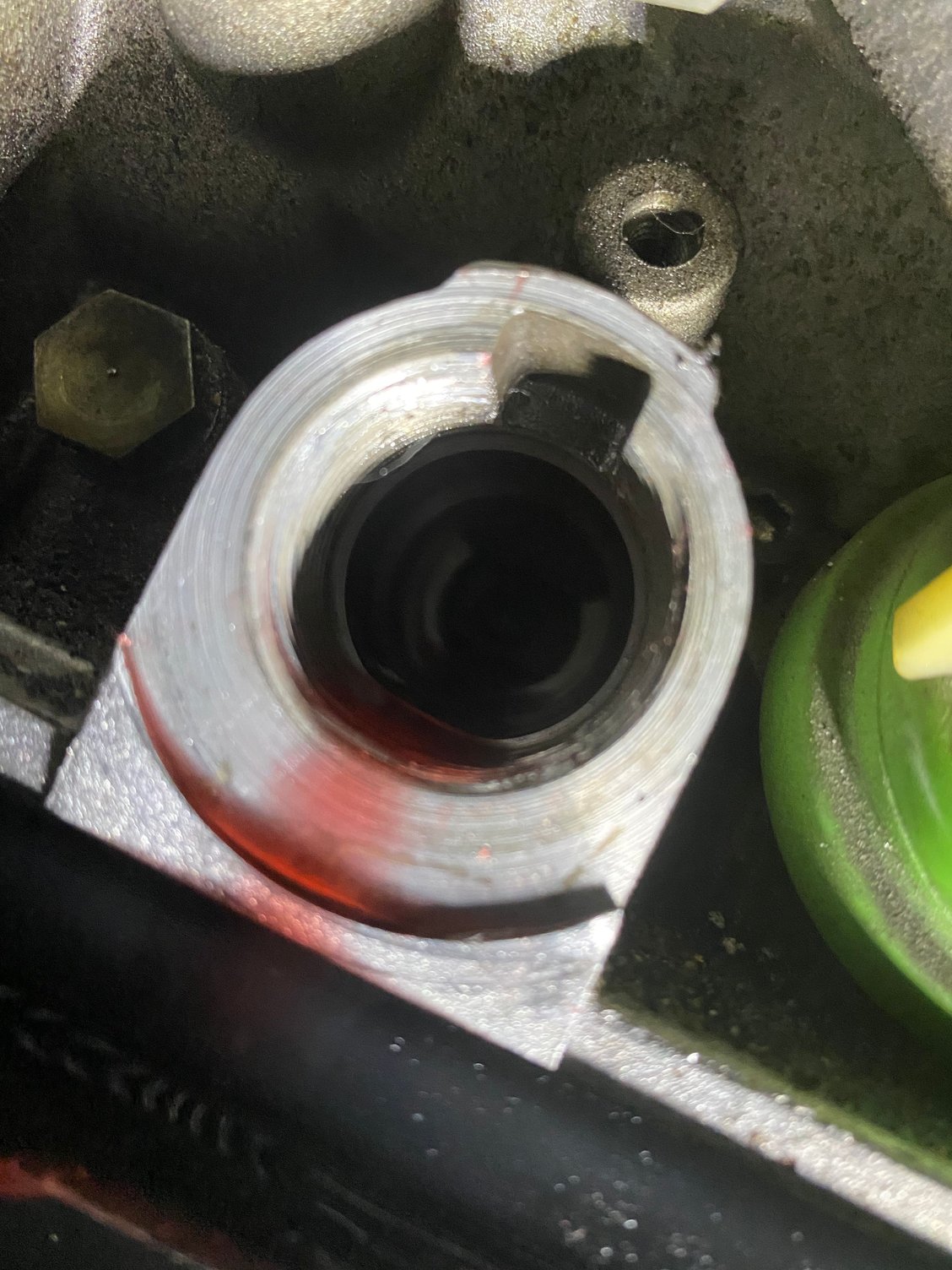

oops forgot the pics. When I took the switch out initially without problems I stuffed a rag into the hole to prevent debris from getting in as I opened and closed the garage door. The next day the rag was a little damp. Is there any way the barrel could have damaged the hole causing a leak? As you can see thereís ATF in the pic. You guys also mentioned the size of the transmission hole. Thatís standard on all 928ís / an 89? 27 x 1.5mm threads?

I tired my best to show the threads. Not sure if thatís helpful but thanks again for following the saga of the switch!

Last edited by Rexxus; 12-14-2021 at 08:55 PM. Reason: Pics

#17

Former Vendor

Yeah, those threads are not very "pretty".

Since there is no seal or O-ring on that switch and there is that deep rectangular cut through the threads (leaving a very narrow sealing surface), it has to sit perfectly square to the threads, in order to seal.

Which means the threads have to be good enough to make sure the switch is perpendicular.

And once you've put a wrench onto cross threaded threads, they are not particularly easy to straighten back out.

The good news is that there's a whole bunch of "smarts" on this forum, who excel in figuring out how to fix messed up things, on the cheap.

Someone will have a genius idea!

Since there is no seal or O-ring on that switch and there is that deep rectangular cut through the threads (leaving a very narrow sealing surface), it has to sit perfectly square to the threads, in order to seal.

Which means the threads have to be good enough to make sure the switch is perpendicular.

And once you've put a wrench onto cross threaded threads, they are not particularly easy to straighten back out.

The good news is that there's a whole bunch of "smarts" on this forum, who excel in figuring out how to fix messed up things, on the cheap.

Someone will have a genius idea!

The following users liked this post:

Rexxus (12-14-2021)

#18

Team Owner

Thread Starter

I like Greg's idea to use the old part to chase the threads,

I would cut 3 even slots into the old broken switch,

you can line the cuts with 3 alternating flats where the wrench would fit.

I use the side edge of the grinding wheel;

cut in about 2 to 3 threads about 3 MM deep, this will act like a tap, put grease on the threads to catch any shavings .

Dont force anything and you might have to remove the rear half of exhaust system and heat shields to get a better perspective.

Based on what your reporting,

you put the switch into the trans at an angle and continued to force it in this snapped off the tip and cross threaded the switch bore

\ what part of the instructions do you think you did not follow?

Maybe I need to add more info to the install procedure so this doesn't happen again.

I think I made a warning to not force anything,

everything with this assembly should fit easily.

are you working on a lift or on jack stands?

maybe the car is not high enough off the floor?

I would cut 3 even slots into the old broken switch,

you can line the cuts with 3 alternating flats where the wrench would fit.

I use the side edge of the grinding wheel;

cut in about 2 to 3 threads about 3 MM deep, this will act like a tap, put grease on the threads to catch any shavings .

Dont force anything and you might have to remove the rear half of exhaust system and heat shields to get a better perspective.

Based on what your reporting,

you put the switch into the trans at an angle and continued to force it in this snapped off the tip and cross threaded the switch bore

\ what part of the instructions do you think you did not follow?

Maybe I need to add more info to the install procedure so this doesn't happen again.

I think I made a warning to not force anything,

everything with this assembly should fit easily.

are you working on a lift or on jack stands?

maybe the car is not high enough off the floor?

The following users liked this post:

Rexxus (12-15-2021)

#19

I like Greg's idea to use the old part to chase the threads,

I would cut 3 even slots into the old broken switch,

you can line the cuts with 3 alternating flats where the wrench would fit.

I use the side edge of the grinding wheel;

cut in about 2 to 3 threads about 3 MM deep, this will act like a tap, put grease on the threads to catch any shavings .

Dont force anything and you might have to remove the rear half of exhaust system and heat shields to get a better perspective.

Based on what your reporting,

you put the switch into the trans at an angle and continued to force it in this snapped off the tip and cross threaded the switch bore

\ what part of the instructions do you think you did not follow?

Maybe I need to add more info to the install procedure so this doesn't happen again.

I think I made a warning to not force anything,

everything with this assembly should fit easily.

are you working on a lift or on jack stands?

maybe the car is not high enough off the floor?

I would cut 3 even slots into the old broken switch,

you can line the cuts with 3 alternating flats where the wrench would fit.

I use the side edge of the grinding wheel;

cut in about 2 to 3 threads about 3 MM deep, this will act like a tap, put grease on the threads to catch any shavings .

Dont force anything and you might have to remove the rear half of exhaust system and heat shields to get a better perspective.

Based on what your reporting,

you put the switch into the trans at an angle and continued to force it in this snapped off the tip and cross threaded the switch bore

\ what part of the instructions do you think you did not follow?

Maybe I need to add more info to the install procedure so this doesn't happen again.

I think I made a warning to not force anything,

everything with this assembly should fit easily.

are you working on a lift or on jack stands?

maybe the car is not high enough off the floor?

youíre too kind amending your instructions lol. Iím new and thought this would be an easier fix. I broke a cardinal rule and forced something and will have to pay for the mistake.

for what itís worth though here are my thoughts on the instructions;

- more detail on what the seated barrel looks like. Maybe a picture. I couldnít really tell so I used my mirror to try and see if the tab on the barrel was flush with the transmission hole. Seemed like it was

- then add a sentence that explains you should be able to hand tighten the switch to whatever. Flush? An 1/8 of an inch from the bore?

- I guess add a warning not to be a **** and tighten a crooked switch

I actually backed the car up on wedges so Iíd have more space. I have jack stands but they werenít high enough for me to be able to work well. So wedgesÖ I canít imagine that created the issue though because I was able to loosen the switch no prob

#20

Yeah, those threads are not very "pretty".

Since there is no seal or O-ring on that switch and there is that deep rectangular cut through the threads (leaving a very narrow sealing surface), it has to sit perfectly square to the threads, in order to seal.

Which means the threads have to be good enough to make sure the switch is perpendicular.

And once you've put a wrench onto cross threaded threads, they are not particularly easy to straighten back out.

The good news is that there's a whole bunch of "smarts" on this forum, who excel in figuring out how to fix messed up things, on the cheap.

Someone will have a genius idea!

Since there is no seal or O-ring on that switch and there is that deep rectangular cut through the threads (leaving a very narrow sealing surface), it has to sit perfectly square to the threads, in order to seal.

Which means the threads have to be good enough to make sure the switch is perpendicular.

And once you've put a wrench onto cross threaded threads, they are not particularly easy to straighten back out.

The good news is that there's a whole bunch of "smarts" on this forum, who excel in figuring out how to fix messed up things, on the cheap.

Someone will have a genius idea!

could you elaborate on the tap dimensions? So id be looking for a 27mm tap with thread spacing of 1.55m? So when you search for taps, I search for 27mm first and then comb through for 1.55mm spacing? My mechanic said he can machine the needed parts so hopefully he knows the tighter spacing heís into.

if he machines the tap, do you think thereís any interest in the community for me to buy it and share it if needed? Or is the bore hole like the only one of its size on the car?

lastly, given your comment about how the seal has to be perfect, does it make sense in general whenever anyone does this maintenance to put thread locker?