CV Boot Replacement / PCCB Hardware Question

#1

Rennlist Member

Thread Starter

Well this weekends installation project of H&R Springs on my 12' TTS just got a little more expensive. After finishing the rears (easier than I thought), went to tackle the fronts and realized the both side outer CV joint boots are ripped. My first question is I know I can take apart the CV joint and inspect for damage but I have read some people just recommend replacing the axle with a new (rebuilt) one. I also see where its recommended tp replace both inner / outer boots even if only one is needed. What do you guys think?

Also this will require me to remove the half shafts on both sides and in reading DIY's on removal of the PCCB's with centerlocks I see that it is not recommended to reuse the mounting hardware for the rotors. Is that only the case when replacing the rotors or is this also necessary anytime the rotors come off? Seems like a waste to replace them but I am no Porsche engineer. Should they be replaced? Car has 47,000 ~ miles.

Also this will require me to remove the half shafts on both sides and in reading DIY's on removal of the PCCB's with centerlocks I see that it is not recommended to reuse the mounting hardware for the rotors. Is that only the case when replacing the rotors or is this also necessary anytime the rotors come off? Seems like a waste to replace them but I am no Porsche engineer. Should they be replaced? Car has 47,000 ~ miles.

#2

Rennlist Member

I'm in the process of rebuilding my front axles for the same issue: torn outer front CV boots. I bought inner and outer boot kits and have done one side this weekend, the other side to go. To replace the outer boots you have to remove the inner CV joint. It's really messy, but the good news is that you don't have to mess with the brakes, although I would tape some foam pipe insulation around your expensive rotors - - mine are steel, so no issues. Also, while I don't think my boots were torn for very long, I found no evidence of undue wear - - super tight fit when reassembled and greased - - no play or weird wear patterns on the parts despite 52k miles.

I found the videos in this thread to be invaluable: https://rennlist.com/forums/996-foru...l#post14128076

A couple of notes that weren't expressly covered by the other post:

Tools:

32mm impact socket for the hub nut

24 inch breaker bar and cheater pipe (to retorque the axle nut)

6mm Allen impact socket for the axle bolts

Impact gun and lots of extentions, wobbles, and a universal

Snap ring pliers to remove the CV from the axle shaft

2lb brass hammer to drive out axle stub and reinstall inner CV on the shaft

Large ball joint puller/separator to pop ball joints on suspension and to pull the inner CV race off the axle

Lots of rubber gloves, paper towels, and some rags

Oetiker clamp pliers to bind the CV boot clamps

Torx bits to remove the under car panel

16,17,18mm and 21mm wrenches for suspension bolts

Brass drift/punch

Parts:

I bought Meyle boot kits from eEuroParts (no affiliation). The same kit was available elsewhere. They come with boots, grease, and clamps. Factory is available at greater expense and ordering piecemeal

I would also buy some extra axle bolts - - the Allen heads are easy to round out - - better to put new ones back. Axle bolts are available at ECS and Pelican (no affiliation with either)

Blue loctite for the axle bolts

Copper or Nickel anti sieze for the stub axles

At least one can of brake cleaner per side

Process:

Jack car and secure on jack stands/lift

Remove front under panel (removing such may not be absolutely necessary, but could be helpful and provides different access to the axle bolts)

Remove wheel

Use impact to remove 32mm hub bolt (if doing this manually you have to remove the wheel center cap and use a BF cheater bar with the car/tire on the ground to undo 350lbft torque on the nut)

Cover the edges of your very expensive PCCB rotors with foam pipe insulation or cardboard to protect them -- not necessary if you have iron rotors

Undo tie rod to steering knuckle nut and separate ball joint to free rotation of the steering knuckle

Undo "tuning fork" control arm to lower control arm bolt

Undo lower control arm to chassis/subframe bolt

Push wheel carrier assembly to the side (it will still be supported by the strut)

Use long extensions with a wrench or impact to remove the six axle mounting bolts (or crawl under the car and use a wrench in the limited space between the gas tank and subframe -- if you do this you may want to remove the diagonal brace in that area)

Pull suspension (wheel carrier assembly) upwards and outwards and use brass hammer to drive stub axle through front bearing/hub

Axle should now be free to remove from the car

Clean up messy grease on car, brakes, etc. -- use plenty of brake cleaner and towels. Make sure there's no grease on your brakes.

Rebuilding CVs:

Note: A bench mounted vise is super helpful for these operations -- And while it should go without saying, you really want to make sure you keep the insides of the CVs really clean and free from dirt or other contaminants.

Cut off/remove clamps on original CV boots

Cut/Slide boots off and wipe up grease

Using brass drift, gently knock the inner and outer metal covers off the inner CV joint - - Note: the cover facing the wheel helps hold the joint together - - when you remove it, you can twist/articulate the inner CV joint and cause the bearings to fall out - - that's OK, just be aware before they fall out and track grease all over your garage (ask me how I know)

Remove circlip on inside end of CV joint

Using a puller, or a press, or vice and BFH, remove the inner race of the inner CV joint from the axle -- this is one of the trickiest steps.

Degrease all parts thoroughly (note that outer CV does not disassemble - - use copious brake cleaner to flush it out)

Put boots and clamps on axle shaft in assembly order, but do not install (do not forget to also put on the inner metal cap for the inner CV.

Install the inner race of the inner CV by pounding it on with a brass hammer - - you'll need to use a socket as a spacer for the last little bit.

Install the circlip

Grease the outer CV joint - - squeeze it in there really good and work it around. Put the rest of the grease in the boot.

Slide the outer boot into place to keep the dirt out, but don't clamp it yet

Reassemble the inner CV joint parts on the axle (ie, center and outer races and the six bearings) - - once assembled, don't over articulate the joint or it will fall apart.

Grease the freshly assembled inner CV and boot

Using pliers, a vise, or C-clamps, squeeze the inner and outer metal CV covers onto the inner CV joint being careful to line up the holes and not accidentally disassemble the joint

Install the inner boot and clamps paying attention to the alignment of the clamps -- you don't want the "ear" of the big clamp to block the bolt holes on the inner CV. Clamp the outer boot and line up the clamps with the inner boot to keep the axle balanced.

Wipe up the excess grease

Reassembly:

It's basically the reverse of the disassembly steps above. Once the car is on the ground you can use your body weight at an appropriate distance on a cheater bar to retorque the axle nut to 350ftlbs.

The first one took me 6 hours working slowly. I am optimistic I can rebuild/replace the second one in 3 or four hours. If you're just replacing an axle (no rebuild/regrease/reboot), I'd guess you could do this in under 2 hrs per side -- maybe as little as an hour per side.

I found the videos in this thread to be invaluable: https://rennlist.com/forums/996-foru...l#post14128076

A couple of notes that weren't expressly covered by the other post:

Tools:

32mm impact socket for the hub nut

24 inch breaker bar and cheater pipe (to retorque the axle nut)

6mm Allen impact socket for the axle bolts

Impact gun and lots of extentions, wobbles, and a universal

Snap ring pliers to remove the CV from the axle shaft

2lb brass hammer to drive out axle stub and reinstall inner CV on the shaft

Large ball joint puller/separator to pop ball joints on suspension and to pull the inner CV race off the axle

Lots of rubber gloves, paper towels, and some rags

Oetiker clamp pliers to bind the CV boot clamps

Torx bits to remove the under car panel

16,17,18mm and 21mm wrenches for suspension bolts

Brass drift/punch

Parts:

I bought Meyle boot kits from eEuroParts (no affiliation). The same kit was available elsewhere. They come with boots, grease, and clamps. Factory is available at greater expense and ordering piecemeal

I would also buy some extra axle bolts - - the Allen heads are easy to round out - - better to put new ones back. Axle bolts are available at ECS and Pelican (no affiliation with either)

Blue loctite for the axle bolts

Copper or Nickel anti sieze for the stub axles

At least one can of brake cleaner per side

Process:

Jack car and secure on jack stands/lift

Remove front under panel (removing such may not be absolutely necessary, but could be helpful and provides different access to the axle bolts)

Remove wheel

Use impact to remove 32mm hub bolt (if doing this manually you have to remove the wheel center cap and use a BF cheater bar with the car/tire on the ground to undo 350lbft torque on the nut)

Cover the edges of your very expensive PCCB rotors with foam pipe insulation or cardboard to protect them -- not necessary if you have iron rotors

Undo tie rod to steering knuckle nut and separate ball joint to free rotation of the steering knuckle

Undo "tuning fork" control arm to lower control arm bolt

Undo lower control arm to chassis/subframe bolt

Push wheel carrier assembly to the side (it will still be supported by the strut)

Use long extensions with a wrench or impact to remove the six axle mounting bolts (or crawl under the car and use a wrench in the limited space between the gas tank and subframe -- if you do this you may want to remove the diagonal brace in that area)

Pull suspension (wheel carrier assembly) upwards and outwards and use brass hammer to drive stub axle through front bearing/hub

Axle should now be free to remove from the car

Clean up messy grease on car, brakes, etc. -- use plenty of brake cleaner and towels. Make sure there's no grease on your brakes.

Rebuilding CVs:

Note: A bench mounted vise is super helpful for these operations -- And while it should go without saying, you really want to make sure you keep the insides of the CVs really clean and free from dirt or other contaminants.

Cut off/remove clamps on original CV boots

Cut/Slide boots off and wipe up grease

Using brass drift, gently knock the inner and outer metal covers off the inner CV joint - - Note: the cover facing the wheel helps hold the joint together - - when you remove it, you can twist/articulate the inner CV joint and cause the bearings to fall out - - that's OK, just be aware before they fall out and track grease all over your garage (ask me how I know)

Remove circlip on inside end of CV joint

Using a puller, or a press, or vice and BFH, remove the inner race of the inner CV joint from the axle -- this is one of the trickiest steps.

Degrease all parts thoroughly (note that outer CV does not disassemble - - use copious brake cleaner to flush it out)

Put boots and clamps on axle shaft in assembly order, but do not install (do not forget to also put on the inner metal cap for the inner CV.

Install the inner race of the inner CV by pounding it on with a brass hammer - - you'll need to use a socket as a spacer for the last little bit.

Install the circlip

Grease the outer CV joint - - squeeze it in there really good and work it around. Put the rest of the grease in the boot.

Slide the outer boot into place to keep the dirt out, but don't clamp it yet

Reassemble the inner CV joint parts on the axle (ie, center and outer races and the six bearings) - - once assembled, don't over articulate the joint or it will fall apart.

Grease the freshly assembled inner CV and boot

Using pliers, a vise, or C-clamps, squeeze the inner and outer metal CV covers onto the inner CV joint being careful to line up the holes and not accidentally disassemble the joint

Install the inner boot and clamps paying attention to the alignment of the clamps -- you don't want the "ear" of the big clamp to block the bolt holes on the inner CV. Clamp the outer boot and line up the clamps with the inner boot to keep the axle balanced.

Wipe up the excess grease

Reassembly:

It's basically the reverse of the disassembly steps above. Once the car is on the ground you can use your body weight at an appropriate distance on a cheater bar to retorque the axle nut to 350ftlbs.

The first one took me 6 hours working slowly. I am optimistic I can rebuild/replace the second one in 3 or four hours. If you're just replacing an axle (no rebuild/regrease/reboot), I'd guess you could do this in under 2 hrs per side -- maybe as little as an hour per side.

Last edited by Brainz; 04-10-2019 at 04:18 PM. Reason: Updated to clarify a few steps

The following 2 users liked this post by Brainz:

gsxrjjordan (05-24-2020),

nidlezp (09-11-2022)

#3

Wow, excellent write up! Thank you Brainz. I did mine a couple of weeks ago, driver side only, and had a tough time putting the CV joint back together. The videos you linked help tremendously as I was about to give up.

#4

Three Wheelin'

Check out this video too.

Brainz, that is an excellent write up. Happy to lend a hand next time you need to turn a wrench in Houston.

Brainz, that is an excellent write up. Happy to lend a hand next time you need to turn a wrench in Houston.

#5

[QUOTE=jeebus31;15762960]Check out this video too.

Funny that you mention that, that was me in the video. I hope you guys find it useful. The video is a bit long but I wanted to show some of the obstacles that I ran into.

Funny that you mention that, that was me in the video. I hope you guys find it useful. The video is a bit long but I wanted to show some of the obstacles that I ran into.

The following users liked this post:

nidlezp (09-11-2022)

#6

Rennlist Member

Thread Starter

Brainz, thanks for that post. I was going to tackle the job since I already had the suspension apart for the springs but forgot about my Fidelity Platinum warranty I purchased. I am just going to finish up the spring install tonight and just take the car over to the local Porsche dealership and have them take care of it through warranty. That way if there is actually anything wrong with the CV joint they can just replace the whole axle and I don't have to worry about the cost.

#7

Rennlist Member

sa52: No worries. If you can do it with your warranty, ask to keep the old axles -- they can often be rebuilt and have value. I bought a used axle off eBay for exactly that purpose, but it turned out that mine were rebuildable.

atm4jim: Great video -- I'd not seen yours. You've pretty much filled in a bunch of the more difficult spots that I also encountered. In particular:

1) Separating ball joints (without using a pickle fork) is always tricky. I used the separator you featured in your video for the tie rod ends. Note that I did NOT have to separate any other ball joints including the LCA to steering knuckle joint -- that one is a bear to reach (as you show) -- instead, I just undid the LCA at the chassis and pulled the whole suspension assembly out and away from the center of the car. Using a prybar at the LCA may help, but I was able to do it with a good tug on the brake rotor.

2) Removing the inner race of the inner CV joint was not trivial. I tried 2 different 3-arm gear pullers before finding a different style ball-joint separator that fit perfectly and gave me the leverage to pull on the inner race whilst pushing the end of the axle. When I reinstalled that piece, I used a heat gun to get the inner race hot (probably ~200 degrees F -- near boiling) and used a brass hammer to pound it back on.

POSSIBLY IMPORTANT -- I forgot to mention it, but I also made some scribe marks on the axle and the non-bearing surface of the inner CV race so that I could realign them exactly as they were with respect to the outer CV joint. MAKE YOUR MARKS BEFORE YOU REMOVE THE INNER RACE. I don't know if this really matters, but it would suck to find out later that it did after doing all that work.

3) On reclamping the boots: I'd recommend tightening the clamps as the final step of axle rebuild, starting with the clamps on the inner CV boots first. As you point out in your video, the Oetiker clamp "ear" can interfere with the mounting holes -- you want that ear to be in between two holes. I then offset the ears of the inner clamp 180 degrees out of phase to help keep the axle balanced. On the outer boot, I alternated the alignment of the clamps, i.e., the ear on the big clamp was 180 degrees rotated vs the ear on the big clamp on the inner boot (and vice versa for the smaller clamps). Not sure how much that matters, but it can't hurt. Hope that makes sense.

jeebus31: Thanks for the offer and back at you -- happy to help if you're doing some wrenching, although based on your recent posts you've got an all new suspension, so likely have it covered.

atm4jim: Great video -- I'd not seen yours. You've pretty much filled in a bunch of the more difficult spots that I also encountered. In particular:

1) Separating ball joints (without using a pickle fork) is always tricky. I used the separator you featured in your video for the tie rod ends. Note that I did NOT have to separate any other ball joints including the LCA to steering knuckle joint -- that one is a bear to reach (as you show) -- instead, I just undid the LCA at the chassis and pulled the whole suspension assembly out and away from the center of the car. Using a prybar at the LCA may help, but I was able to do it with a good tug on the brake rotor.

2) Removing the inner race of the inner CV joint was not trivial. I tried 2 different 3-arm gear pullers before finding a different style ball-joint separator that fit perfectly and gave me the leverage to pull on the inner race whilst pushing the end of the axle. When I reinstalled that piece, I used a heat gun to get the inner race hot (probably ~200 degrees F -- near boiling) and used a brass hammer to pound it back on.

POSSIBLY IMPORTANT -- I forgot to mention it, but I also made some scribe marks on the axle and the non-bearing surface of the inner CV race so that I could realign them exactly as they were with respect to the outer CV joint. MAKE YOUR MARKS BEFORE YOU REMOVE THE INNER RACE. I don't know if this really matters, but it would suck to find out later that it did after doing all that work.

3) On reclamping the boots: I'd recommend tightening the clamps as the final step of axle rebuild, starting with the clamps on the inner CV boots first. As you point out in your video, the Oetiker clamp "ear" can interfere with the mounting holes -- you want that ear to be in between two holes. I then offset the ears of the inner clamp 180 degrees out of phase to help keep the axle balanced. On the outer boot, I alternated the alignment of the clamps, i.e., the ear on the big clamp was 180 degrees rotated vs the ear on the big clamp on the inner boot (and vice versa for the smaller clamps). Not sure how much that matters, but it can't hurt. Hope that makes sense.

jeebus31: Thanks for the offer and back at you -- happy to help if you're doing some wrenching, although based on your recent posts you've got an all new suspension, so likely have it covered.

Trending Topics

#8

Rennlist Member

Thread Starter

@Brainz Thanks for all the advice. The local Porsche dealership suggested to Fidelity to replace the passenger axle and a rebuild the driver axle. Fidelity approved the claim and the advisor suggested to replace the inner boot on the rebuilt axle even though Fidelity did not approve it at my cost. They did it at cost for the boot part as the axle was already out and no additional labor was necessary. The Fidelity warranty is already paying off 2 months into buying it.

Also want to mention I was worried that Fidelity would deny the claim as I had just finished lowering the car with H&R springs but even with a inspector coming to look at the car and the parts needed, all was approved. I was also able to keep the old axle as well.

Also want to mention I was worried that Fidelity would deny the claim as I had just finished lowering the car with H&R springs but even with a inspector coming to look at the car and the parts needed, all was approved. I was also able to keep the old axle as well.

Last edited by sa52; 04-17-2019 at 09:27 PM. Reason: Mistake

#9

Rennlist Member

^ So you got Fidelity to cover your torn boots, was this because it was presented as an axle problem? Just curious, because CV boots are specifically listed on the Platinum policy as being excluded.

#10

Rennlist Member

Thread Starter

@saabin I don't believe so but not sure. I brought the car in for the torn boots but I am not sure how they could have presented it to Fidelity. I will say though I have seen it mentioned before that the cv boots are on the exclusionary list. From what I was sent as of the 2019 list in my contract, I don't see it listed. Also, here it is from their website:

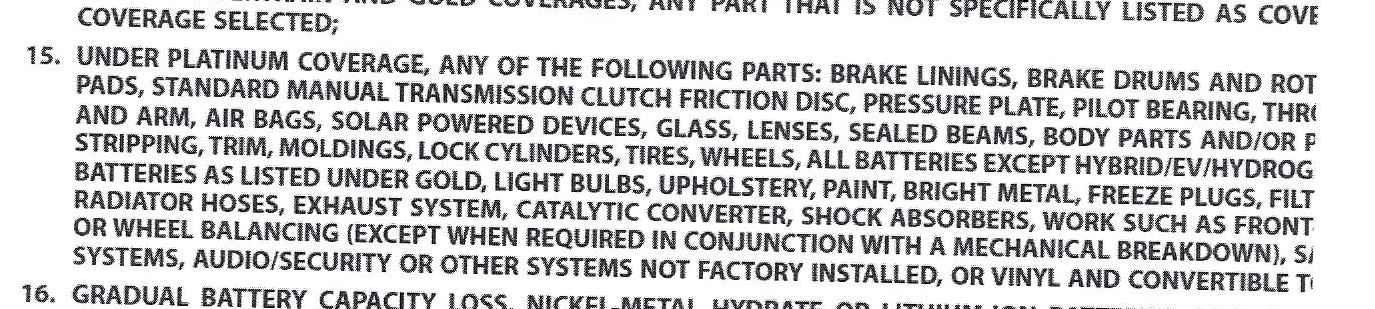

PLATINUM EXCLUSIONS:

Brake linings, brake drums and rotors, disc brake pads, standard manual transmission clutch friction disc, pressure plate, pilot bearing, throw-out bearing and arm, air bags, solar powered devices, glass, lenses, sealed beams, body parts and/or panels, weather stripping, trim, moldings, lock cylinders, tires, wheels, all batteries except Hybrid/EV/Hydrogen High Voltage batteries as listed under Gold Coverage, light bulbs, upholstery, paint, bright metal, freeze plugs, filters, heater and radiator hoses, exhaust system, catalytic converter, shock absorbers, work such as front-end alignment or wheel balancing (except when required in conjunction with a mechanical breakdown), safety restraint systems, audio/security or other systems not factory installed, or vinyl and convertible tops.

#13

Rennlist Member

Just did this. Two additions to the excellent info from the guys above and charlieaf92 (linked above)

Scott

- I couldn't get the inner cv joint inner race off of the axle shaft. After breaking a gear puller and failing even using heat from a torch and a bigger gear puller, I went to my local Euro auto shop for help thinking he had a hydraulic press to pull if off . Instead he used a vice and 3-lb hammer to knock the outer cv joint off which is held on by a spring steel circlip inside the outer axle shaft/cv joint splined joint. He showed me how to use a zip tie to compress the circlip into the shaft groove so that the cv joint spline can be tapped into place while displacing the zip tie out of the way. Ingenious.

- I couldn't slide the Oeliker clamps into place. charlieaf92 has a video that shows a pliers/coin technique to open the clamps then compress them to catch the tangs so that they can be crimped. I failed. I purchased stainless worm style hose clamps and was about to install when it occurred to me that I might have success compressing the Oeliker using the worm clamp. I opened a worm clamp, installed and tightened it over the Oeliker then removed it and TO MY AMAZEMENT, it beautifully compressed the Oeliker and caught the tangs. Now crimping was easy and fast.

Scott

#14

Rennlist Member

I couldn't get the inner cv joint inner race off of the axle shaft. After breaking a gear puller and failing even using heat from a torch and a bigger gear puller, I went to my local Euro auto shop for help thinking he had a hydraulic press to pull if off . Instead he used a vice and 3-lb hammer to knock the outer cv joint off which is held on by a spring steel circlip inside the outer axle shaft/cv joint splined joint. He showed me how to use a zip tie to compress the circlip into the shaft groove so that the cv joint spline can be tapped into place while displacing the zip tie out of the way. Ingenious.