Pin. vs. weld vs. oem vs. other?

#46

Rennlist Member

Those pics, I found them while searching for weld examples. Surprised at the supposed vendor who did the welding.

#47

Drifting

Thread Starter

I bought the sharkwerks L shape hoses. I bought the billets from your link-- BBI never got back to me :/ . I'm going to do JBL welding inside AND get aluminum welding done on the outside. The reason for JBL in the inside is because none of these inserts have o-ring gaskets- so using the JBL to fill in between "wall" of the insert/ the casting part.

Sight... over kill but rather be safe then sorry.

Sight... over kill but rather be safe then sorry.

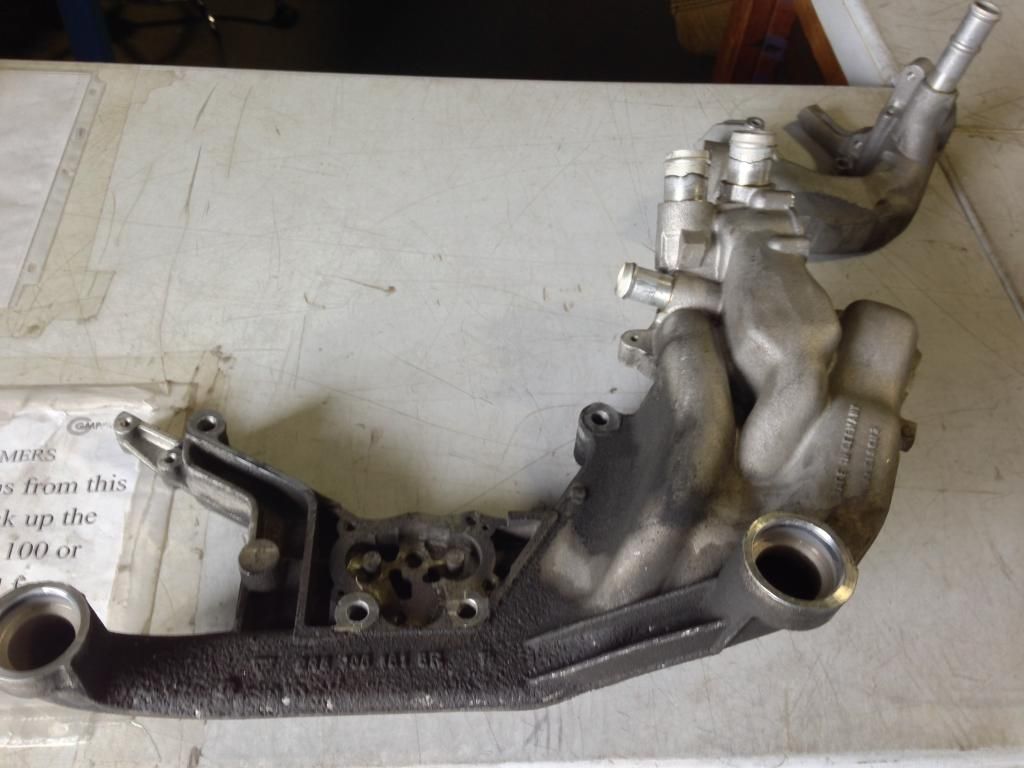

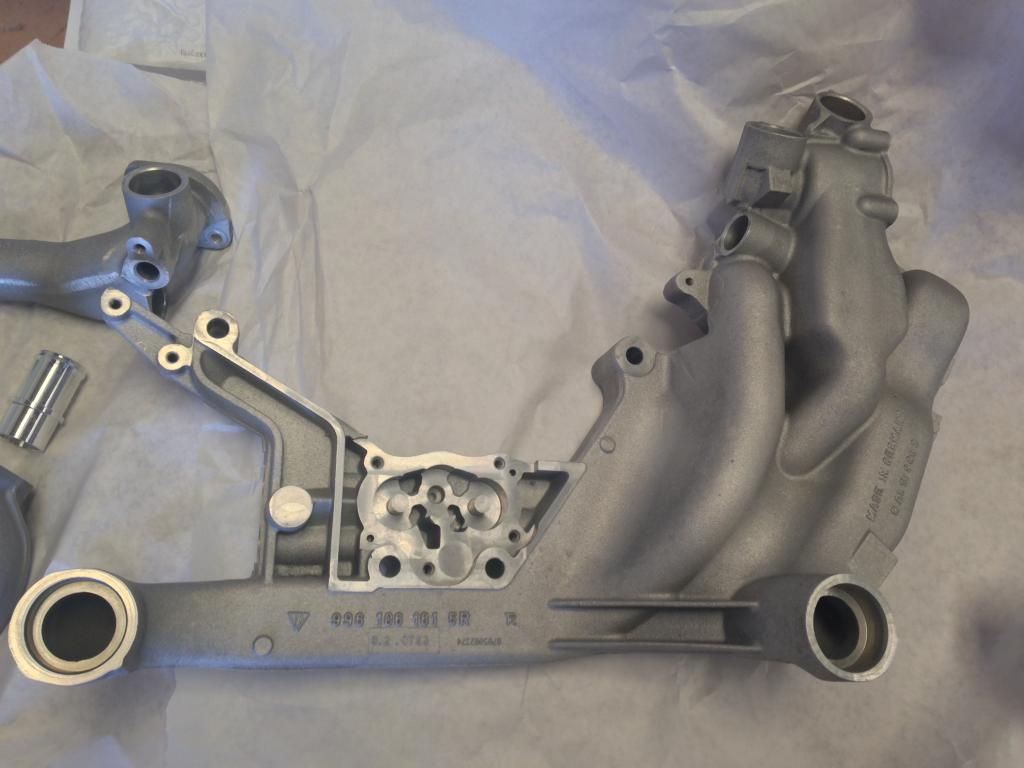

No, 2 different issues. The sharkwerks pipes address a leak that develops on 2 rubber pipes off the oil cooler that carry coolant. It's another one of those while you are in there things as the engine does need to drop to swap these should the begin leaking. These do not blow like the glued fittings.

The billet pipes bbi uses are simply an alternate to the Oem fittings. Feel free to use what you feel is best. When discussing with my shop they prefer theirs, and can use Oem, it's not like they are going to retire selling these pipes. It simply gives more surface to weld due to flange on the pipe. With a great welder the Oem pipes should be fine. Otherwise the method is exactly as gmg posted. Remove old pipes, clean, prep, weld, reassemble.

Sharkwerks pipes: http://www.sharkwerks.com/products.php?pid=386

Location of oil cooler pipes: https://rennlist.com/forums/997-gt2-...gt3-gt3rs.html

Example billet pipes, not bbi but similar concept:

http://nyppd.com/all-parts/nyppd-all...e-911-996-997/

This video shows another method but is good to show in detail what the fittings look like and measurements of hole size and clearances to Oem fittings (there is a big gap): Porsche 996 & 997 Cooling Repair - YouTube

The billet pipes bbi uses are simply an alternate to the Oem fittings. Feel free to use what you feel is best. When discussing with my shop they prefer theirs, and can use Oem, it's not like they are going to retire selling these pipes. It simply gives more surface to weld due to flange on the pipe. With a great welder the Oem pipes should be fine. Otherwise the method is exactly as gmg posted. Remove old pipes, clean, prep, weld, reassemble.

Sharkwerks pipes: http://www.sharkwerks.com/products.php?pid=386

Location of oil cooler pipes: https://rennlist.com/forums/997-gt2-...gt3-gt3rs.html

Example billet pipes, not bbi but similar concept:

http://nyppd.com/all-parts/nyppd-all...e-911-996-997/

This video shows another method but is good to show in detail what the fittings look like and measurements of hole size and clearances to Oem fittings (there is a big gap): Porsche 996 & 997 Cooling Repair - YouTube

#48

Rennlist Member

Sorry bought that betim needs office staff lol. Just got update from shop. Car is back together and great. My pipes just about pulled out with no force. It was time.

#52

Drifting

Thread Starter

#54

Rennlist Member

You're not worried about contaminating the weld with the JB Weld?

#55

Drifting

Thread Starter

Good point Alan. I talked to my welder regarding this. He stated as long as epoxy is present were he is welding, he wont be able to weld bcuz of jb weld. I only want to get JB weld in the inside of the insert so no water goes through the walls of insert / walls of cast part. After i put the jb weld, prior to welding i'm going to b.blast the part so no epoxy residue on the surface where he will be welding.

#57

Drifting

Thread Starter

-- which i hope i wont have to use and i can post for sale.

-- which i hope i wont have to use and i can post for sale. Based on the research, i reached the conclusion best was inserts with o-ring(like 2 supplement sharkwers makes, which i also got). Nothing of that sort on market, and i don't want to get into making more parts (

) - so best case scenario from what i gathered is jb weld inside of insert / weld outside.

) - so best case scenario from what i gathered is jb weld inside of insert / weld outside.

#58

Instructor

"I worked in the Nuclear industry for some time. Although AWS is not in depth as ASME Section 9 / Or NQA 1 i do feel it is sufficient for this application.

I would be hard pressed into agreeing a PIN will last the long haul.. But I am skewed with Failure Analysis type mindset so I error on the side of PROPER welding buy a qualified welder."

Exactly correct. We manufacture pressure vessels for the refrig industry and we routinely Tig and Mig parts that see pressures and heat far and away in excess the Porsche will see.

I would be hard pressed into agreeing a PIN will last the long haul.. But I am skewed with Failure Analysis type mindset so I error on the side of PROPER welding buy a qualified welder."

Exactly correct. We manufacture pressure vessels for the refrig industry and we routinely Tig and Mig parts that see pressures and heat far and away in excess the Porsche will see.

#59

Rennlist Member

Bead blasting will clean the surface. However, I believe you may still have an issue with weld contamination. The depth of the weld pool may still extend into the JB Weld. Another issue may be outgassing from the JB Weld.

#60

Drifting

Thread Starter

"I worked in the Nuclear industry for some time. Although AWS is not in depth as ASME Section 9 / Or NQA 1 i do feel it is sufficient for this application. I would be hard pressed into agreeing a PIN will last the long haul.. But I am skewed with Failure Analysis type mindset so I error on the side of PROPER welding buy a qualified welder." Exactly correct. We manufacture pressure vessels for the refrig industry and we routinely Tig and Mig parts that see pressures and heat far and away in excess the Porsche will see.