Trouble removing Strut bolts/nuts

#16

#17

Rennlist Member

Thread Starter

Ooops! They're not 85 mm long, they're only 70mm so I should be able to get them without too much trouble. That said, I still can't get the damn thing out... It turns, but won't back out

#19

Rennlist Member

Thread Starter

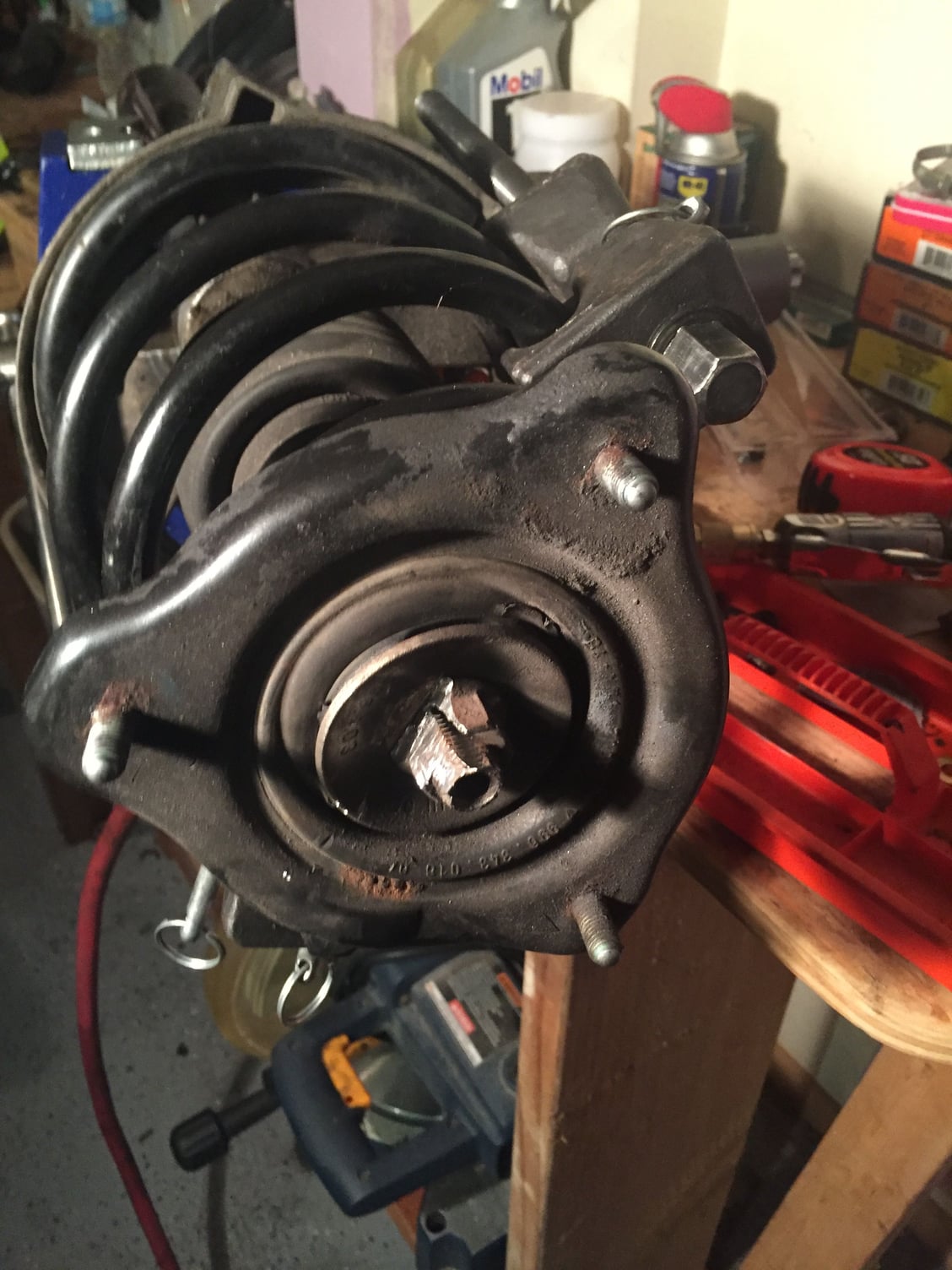

This one! Wheel carrier to strut. As u can see, the nut is off, but I can't get the bolt out of the carrier. 😳

#20

I suspect it's the rusted rectangular piece grabbing the threads in the middle of the bolt. Can you spray more pb or kroil into the hole and hammer the rectangular piece at different directions to loosen up all the rust a bit?

May also try to pry around the crack between that piece and the aluminum carrier carefully.

May also try to pry around the crack between that piece and the aluminum carrier carefully.

#21

Rennlist Member

Thread Starter

I followed these instructions and did not have the problems you mention: http://www.pelicanparts.com/techarti...nd_Springs.htm

Is something different?

Is something different?

#22

Rennlist Member

Thread Starter

I suspect it's the rusted rectangular piece grabbing the threads in the middle of the bolt. Can you spray more pb or kroil into the hole and hammer the rectangular piece at different directions to loosen up all the rust a bit?

May also try to pry around the crack between that piece and the aluminum carrier carefully.

May also try to pry around the crack between that piece and the aluminum carrier carefully.

Last edited by dporto; 03-19-2016 at 09:09 AM.

#23

Rennlist Member

Join Date: Apr 2010

Location: Ormond Beach, FL

Posts: 5,811

Likes: 0

Received 1,091 Likes

on

701 Posts

Thread a nut on there, three or four threads, heat it red hot (the bolt) with a propane torch and then hammer it hard. It will come out, just stuck due to corrosion. Be careful you fully support the aluminum wheel carrier housing perhaps with a large socket directly under the bolt. You don't want it to crack.

#25

If PB Blaster doesn't loosen it after a liberal soaking overnight and you don't have readily access to Kroil, try putting some ATF on it. This is the old school formula for loosening nuts and bolts before Kroil came along. Some say Kroil is based on an ATF derivative.

Good luck and keep at it. If it makes you feel any better, it took me over a week to replace my rear suspension on my old Civic due to rust and many frozen bolts.

#26

Rennlist Member

Thread Starter

So, I got the first one out of the wheel carrier today - After 3 days soaking with PB's and beating the hell out of it with a drift and a big ball peen hammer!!! It came out - I guess it's just the steel bolt in the aluminum carrier...big pain, but everything is progressing now. Good thing I ordered new top-mounts (Tarrertt adjustable camber mono-ball) as mine were toast. I'll post some photo's later...

As you can see, the top mount was shot!

New strut, just waiting for camber plates to reinstall

Last edited by dporto; 03-20-2016 at 02:10 PM.

#27

Rennlist Member

Thread Starter

Now that I've gotten one of the front struts out and am working on the other, next question... Upon pulling the wheel carrier off the end of the axle, I noticed a little play in the wheel bearings. There isn't a lot of play, but it is noticeable (maybe 1/16" ?). This wasn't noticeable with the wheels on, but once they were off and the hub was exposed it feels a little loose/wobbly. I figure that now's the time to replace them as I don't want take this all apart again. I've already ordered the bearings and they should arrive this week. My plan is to use a screw type bearing extractor as I don't have a press readily available. My question is this: Using the screw type bearing extractor, would it be easier if the wheel carrier was back in it's installed position in the car (mounted on the strut) or loose/on the bench? It seems to me that I should mount everything back up and then extract/install the new bearings - I just want to check with those who've done it.

#28

Rennlist Member

Join Date: Nov 2008

Location: Mooresville, IN (Life Long Cheesehead)

Posts: 5,815

Likes: 0

Received 54 Likes

on

35 Posts

My question is this: Using the screw type bearing extractor, would it be easier if the wheel carrier was back in it's installed position in the car (mounted on the strut) or loose/on the bench? It seems to me that I should mount everything back up and then extract/install the new bearings - I just want to check with those who've done it.

#29

Rennlist Member

Thread Starter

#30

Rennlist Member

Thread Starter

I've been working on the second strut for three days now - Soaking with PB blaster and hammering with a drift. I've also used a bit of heat (heat gun) but I'm very hesitant to use too much on the aluminum casting... I can't even get this bolt to turn, whereas the other one turned, it just wouldn't back out... Man, what a pain in the ***! I'm thinking I may need to bring the whole carrier/strut assembly to a shop with a press and have them press it out...