Cab Clamshell Broken Hinge Arm - (UPDATE w/more pics!)

#16

Three Wheelin'

Thread Starter

Ok, I took the whole business apart this weekend. First of all, the drive mechanism for the clamshell is NOT HYDRAULIC.

It's all mechanical. Good German engineering.

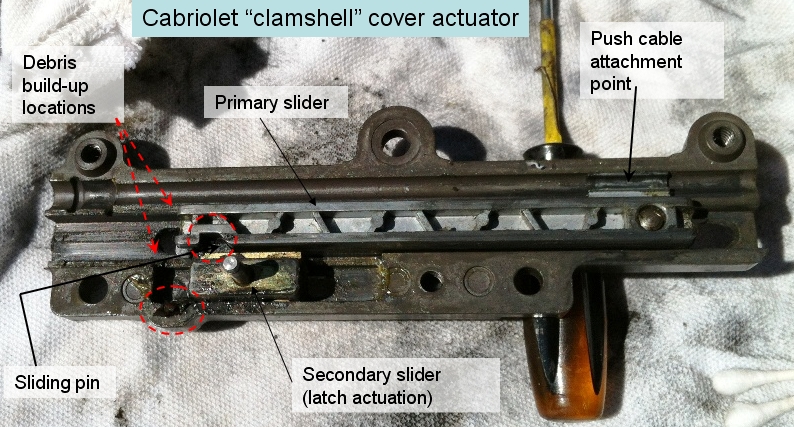

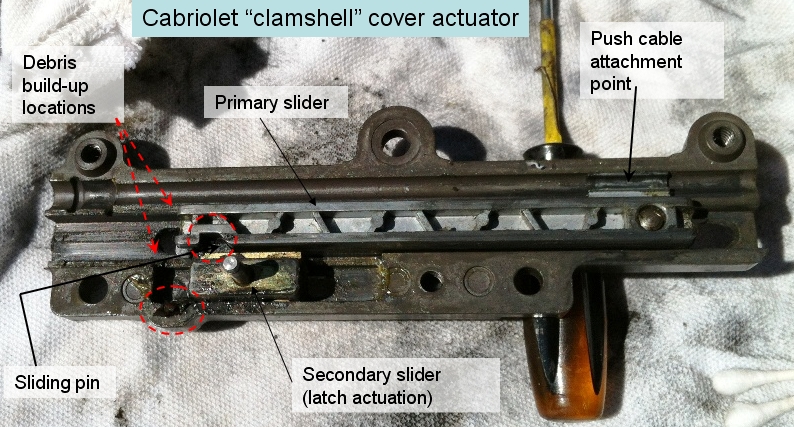

There are sliders inside the "cylinder" that move the clamshell arm, and the latch mechanism. These are driven by cables (think bicycle brake cables), which are in turn driven by a small motor and double-rack and pinion mechanism.

The first thing I did was take apart the slider mechanism. This is a two-slider arrangement: the primary slider moves the clamshell, and the secondary slider is driven by the primary via a movable pin. The secondary slider drives the latch.

I found that the insides of this were gunked up with metal shavings, old grease, and general debris, particularly in the two recesses that house the movable pin. I cleaned this (with a young helper), regreased, and reassembled.

I was hopeful, but after reassembly, the acutator STILL did not move to it's full extent.

Next, I took apart the driving mechanism. The rack-and pinion setup seemed fine, but is a royal PITA to reassemble. I turned my attention to the sliding cable.

The driver's side cable did not slide easily. It took me probably an hour of messing with it to get the cable out of the sleeve. Lo and Behold, the problem...

The cable is a plastic-coated metal braid. The metal is twisted and bunched up, which has caused the plastic to peel. Overall, the cable is slightly too short now due to the bunching, plus it's too fat to fit smoothly inside the sheath.

I tried to remove the excess plastic, and straighten the cable with a vise as neatly as I could thusly:

This acutally worked, briefly. When I reassembled, the actuator worked properly, but once I reassembled the whole car, the added force on the slider to actually move the clamshell and latch caused it to bind once again.

I imagine when I take it apart, I will find that the cable is bent and bunched up once again. I assume the damage was done to the cable when the arm was broken, or from the debris in the slider causing it to bind when moving the clamshell.

Given that Porsche doesn't seem to sell just the cable, but the whole assembly as one piece (item #4 below), and the list price is something like $800, I am seriously considering Macguyvering something. Maybe just replace the cable with a plastic-coated cable of some kind. I'd have to figure out how to attach the ends.

Any other suggestions, let me know.

It's all mechanical. Good German engineering.

There are sliders inside the "cylinder" that move the clamshell arm, and the latch mechanism. These are driven by cables (think bicycle brake cables), which are in turn driven by a small motor and double-rack and pinion mechanism.

The first thing I did was take apart the slider mechanism. This is a two-slider arrangement: the primary slider moves the clamshell, and the secondary slider is driven by the primary via a movable pin. The secondary slider drives the latch.

I found that the insides of this were gunked up with metal shavings, old grease, and general debris, particularly in the two recesses that house the movable pin. I cleaned this (with a young helper), regreased, and reassembled.

I was hopeful, but after reassembly, the acutator STILL did not move to it's full extent.

Next, I took apart the driving mechanism. The rack-and pinion setup seemed fine, but is a royal PITA to reassemble. I turned my attention to the sliding cable.

The driver's side cable did not slide easily. It took me probably an hour of messing with it to get the cable out of the sleeve. Lo and Behold, the problem...

The cable is a plastic-coated metal braid. The metal is twisted and bunched up, which has caused the plastic to peel. Overall, the cable is slightly too short now due to the bunching, plus it's too fat to fit smoothly inside the sheath.

I tried to remove the excess plastic, and straighten the cable with a vise as neatly as I could thusly:

This acutally worked, briefly. When I reassembled, the actuator worked properly, but once I reassembled the whole car, the added force on the slider to actually move the clamshell and latch caused it to bind once again.

I imagine when I take it apart, I will find that the cable is bent and bunched up once again. I assume the damage was done to the cable when the arm was broken, or from the debris in the slider causing it to bind when moving the clamshell.

Given that Porsche doesn't seem to sell just the cable, but the whole assembly as one piece (item #4 below), and the list price is something like $800, I am seriously considering Macguyvering something. Maybe just replace the cable with a plastic-coated cable of some kind. I'd have to figure out how to attach the ends.

Any other suggestions, let me know.

The following users liked this post:

Roofless 1 (01-21-2023)

#17

Three Wheelin'

Thread Starter

For future reference, here is what the inside of the rack and pinion drive for the clamshell looks like.

Update 5/14/2012:

Just an update to document the resolution of this problem... I tried to repair the broken cable but was unsuccessful. I ended up purchasing an entire drive assembly. I found one used, so that saved me quite a bit of money. The drive assembly (996.561.012.03) lists for $778, retails for $563 from Sunset, but I found it used for $325.

After installing the new drive system, I found that the bracket which pushes the clamshell hinge arm was misaligned with the slider pin. (see bracket picture)

Some fiddling with alignment, a small amount of bending and grinding, I corrected the alignment and got things working again. I'm not sure what was the root cause of this cascade of failures, but I'm sure they were all related.

Oh, and I have a partial working drive system for sale. All components are good except the left side drive cable. If your's has other issues, PM me.

Update 5/14/2012:

Just an update to document the resolution of this problem... I tried to repair the broken cable but was unsuccessful. I ended up purchasing an entire drive assembly. I found one used, so that saved me quite a bit of money. The drive assembly (996.561.012.03) lists for $778, retails for $563 from Sunset, but I found it used for $325.

After installing the new drive system, I found that the bracket which pushes the clamshell hinge arm was misaligned with the slider pin. (see bracket picture)

Some fiddling with alignment, a small amount of bending and grinding, I corrected the alignment and got things working again. I'm not sure what was the root cause of this cascade of failures, but I'm sure they were all related.

- Broken hinge arm

- Debris in the sliding mechanism

- Misaligned drive bracket

- Damaged drive cable (bowden cable)

Oh, and I have a partial working drive system for sale. All components are good except the left side drive cable. If your's has other issues, PM me.

Last edited by frisbee91; 05-14-2012 at 04:42 PM. Reason: update

#18

Drifting

Join Date: Sep 2011

Location: Ephrata, PA, USA now. Originally from the UK

Posts: 3,075

Likes: 0

Received 22 Likes

on

17 Posts

OMG you are a wizard. I will keep these pages as a favourite. Thanks a million and bloody well done I say. Please do a complete write up somewhere and let us know where it is. The convertible top is awesome when it is working properly but a real P I T A when its not. I know I have had lots of problems which I had to fix myself with mine. I was going to chip in to help you but you had it solved before I could haha.

#19

Thanks for this awesome write up. I am having some problems after the clip that holds the arm to the latch on the right side of the clamshell fell off. I was able to open the clamshell by prying the latch backwards but I guess having tried to open the clamshell a few times may have taken its toll on the motor or the driving mechanism assembly. Interestingly the whole thing satrted after having been hit from behind (fortunately only killing the bumper) so I'm hoping the other guy's insurance will cover it. If not I'm an avid DIY'er and this will certainly be of help!!

#20

Rennlist Member

Join Date: May 2005

Location: Virginia Beach, VA

Posts: 199

Likes: 0

Received 0 Likes

on

0 Posts

I have the same issue. The top is fully functional and does successfully go all the way up and down without issue. However, not sure how long that will last with the Hinge Bracket broken as in the photo. Anyone think some JBWeld-Steel would hold or should I just leave it until the top faults or purchase hinge assembly and replace the entire deal? EDIT: Thanks go out to Frisbee91 as his write up saved me a $H]T load of time.

Last edited by 4thChild; 04-30-2014 at 12:08 AM.

#21

Three Wheelin'

Thread Starter

I have the same issue. The top is fully functional and does successfully go all the way up and down without issue. However, not sure how long that will last with the Hinge Bracket broken as in the photo. Anyone think some JBWeld-Steel would hold or should I just leave it until the top faults or purchase hinge assembly and replace the entire deal? EDIT: Thanks go out to Frisbee91 as his write up saved me a $H]T load of time.

Given the stresses on this hinge, I doubt JB weld would do the trick, but I haven't tried.

#22

I had my repaired by my upholster. He welded the piece back together. Only bring is he's in Toronto. Not sure where you are.

I have the same issue. The top is fully functional and does successfully go all the way up and down without issue. However, not sure how long that will last with the Hinge Bracket broken as in the photo. Anyone think some JBWeld-Steel would hold or should I just leave it until the top faults or purchase hinge assembly and replace the entire deal? EDIT: Thanks go out to Frisbee91 as his write up saved me a $H]T load of time.

#24

I am seriously considering a 60k '04 996 cabrio in the upcoming days.

I want to sell the complete convertible mechanism and manually open/close the roof '11-'12 Spyder style.

From initial googling I'm seeing these sell for well over $3500, would $1500 be unreasonable to expect:

http://www.autoatlanta.com/porsche-p...section=811-12

http://www.jimellisporscheparts.com/...roduct=3799675

Irrespective of the perceived inconvenience of manually working the roof, would this be a feasible idea to pursue?

I want to sell the complete convertible mechanism and manually open/close the roof '11-'12 Spyder style.

From initial googling I'm seeing these sell for well over $3500, would $1500 be unreasonable to expect:

http://www.autoatlanta.com/porsche-p...section=811-12

http://www.jimellisporscheparts.com/...roduct=3799675

Irrespective of the perceived inconvenience of manually working the roof, would this be a feasible idea to pursue?

#25

Three Wheelin'

Thread Starter

There are 5 motors that operate the top system. The hydraulics that actually move the top could be replicated by simply pulling the top Spyder-style, but the other 4 would still need to be turned somehow. These are:

- The clamshell movement and latching mechanism & motor

- The "wings" operation motors (one on each side)

- The top center latching motor.

Not sure how you would replicate that manually in any practical way. Have you actually observed the operation of a 996 top? I'm curious how you might approach this. Let us know what you end up doing. Best of luck!

#26

Frisbee91 It sounds as if you are the "Expert" and I am chasing my tail....everything worked well until the roof on my 996cab would no longer raise or lower all of a sudden. put fluid in the reservoir and it worked 2 days fine. bought 2 rebuilt actuators the top goes up and down fine but the clam shell "may" not open fully but if so it is very very close (hard to tell). When it goes to close it does not close completely. The top will drive up fine but not latch .....never a problem before. I suspect that the failure to latch is a function of the clamshell not getting to it's right position....I am looking for advice and information like what should the omhs/voltage read on the micro switches if functioning properly?

#27

Burning Brakes

frisbee91, next time get in touch with local motorcycle and/or bicycle indy shops. They either make cables, or have someone who does. I would be willing to bet they could build you a new cable. They may need to use some of your parts, but the cable itself would be all new.

I have had custom cables built for a number of applications.

I have had custom cables built for a number of applications.

#28

Three Wheelin'

Thread Starter

Frisbee91 It sounds as if you are the "Expert" and I am chasing my tail....everything worked well until the roof on my 996cab would no longer raise or lower all of a sudden. put fluid in the reservoir and it worked 2 days fine. bought 2 rebuilt actuators the top goes up and down fine but the clam shell "may" not open fully but if so it is very very close (hard to tell). When it goes to close it does not close completely. The top will drive up fine but not latch .....never a problem before. I suspect that the failure to latch is a function of the clamshell not getting to it's right position....I am looking for advice and information like what should the omhs/voltage read on the micro switches if functioning properly?

That said, I'm not sure that clamshell position dictates if the latch mechanism (that engages at the center of the windshield) can operate. Are you sure it's not just a failure of the latching system?

#29

Thank you for the info....my thought is the synchronization.... it worked extremely well prior to replacing the hydraulic rams. I never had one issue until the fluid leaked out and when I put the fluid in it worked fine for the 2 days. When it failed after the 2 days I had started smelling the fluid in the car. The top was up and I depressed the switch and it unlatched perfectly and the clamshell retracted. After taking the rams out I expressed the remaining fluid and it flowed at will from the seal on one side. after reassembling is the first time the top would not come up far enough for the latch to operate and the clamshell to close. I will try to find and check the voltage on micro-switch that controls the both the latch and clamshell....any other thoughts? I sure the dealer will not over charge to re-synch the system....Lol I almost got that out. thank you for any assistance

#30

@frisbee91

I have nearly the same problem as my clamshell got stuck on the passenger side and the cable in the gear broke, so i bought a new unit for both sides and tried to mount it with the motor.

But the gearwheel wont fit in to the motor, only with beign brutal i could insert it, but when i run a calibration the clamshell does not move.

I can hear the motor working and i can open/close it manually, so i think the problem is the gearwheel which connects the motor with the potentiometer.

I bought spare parts for the motor, but the gearwheel is not in this set, so before buying a new motor maybe you can help me how the gearwheel is mounted on the motor, so that it opens the top like it should?

I have nearly the same problem as my clamshell got stuck on the passenger side and the cable in the gear broke, so i bought a new unit for both sides and tried to mount it with the motor.

But the gearwheel wont fit in to the motor, only with beign brutal i could insert it, but when i run a calibration the clamshell does not move.

I can hear the motor working and i can open/close it manually, so i think the problem is the gearwheel which connects the motor with the potentiometer.

I bought spare parts for the motor, but the gearwheel is not in this set, so before buying a new motor maybe you can help me how the gearwheel is mounted on the motor, so that it opens the top like it should?