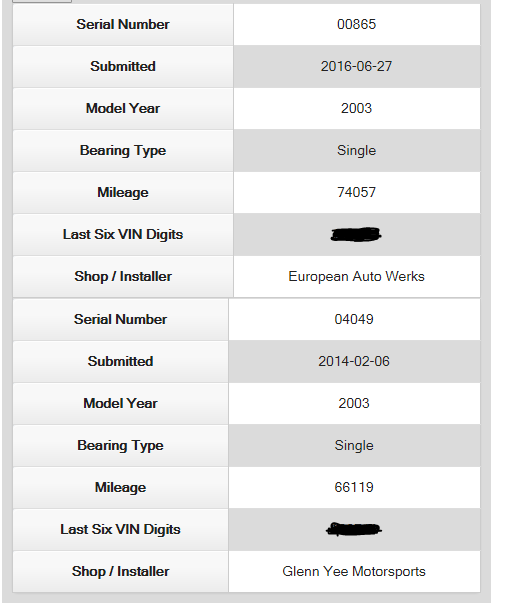

LN engineering IMSB retrofit database

#16

Rennlist Member

I wouldn't trust this as sure fire way to check to see if a car has been updated as I bought a used motor for my roller and installed the new bearing but it's not tagged to my VIN in any way.

#17

Rennlist Member

Based off the feedback we have already received by email and on the forums, we are going to work to add some more data to the database output. Keep the suggestions and feedback coming - it is greatly appreciated.

#18

I had an upgraded LN Engineering bearing fail. When I called them about it, their excuse was that there must of been something wrong with the motor when it was installed that caused the bearing to fail. That is nice as far as it goes, but that is pretty much what Porsche has been saying since this entire thing started. Here is my theory on the bearing.

For years Porsche used a self oiling bearing that could stand up to slight changes in load. When they were looking for ways to make manufacturing easier for the 996, they went to the infamous bearing in the 996 because it was easier to build. The difference was that it could not take changes in load. That didn't bother the engineers because they designed the engine to put a constant load on the bearings. What they didn't know and couldn't have known was that Porsche manufacturing was not uniform enough to make every engine perfect enough to keep the load constant. This wasn't an issue on previous 911s because the oil fed bearings could take variations in loads. So no one noticed that some engines did this if they were not manufactured perfectly.

So here comes the M96 with a bearing that couldn't take really any variance in load. Not a problem if the engine was manufactured on a good day and everything is perfect. If not, a big problem. This is why no could figure out what was causing the bearings to fail and why so many of them didn't. Most of the engines were manufactured to perfect spec. It was only the few that were not that caused the bearing to fail.

If the engine is enough out of whack, it will as was the case with my car and others, kill even an upgraded bearing. What are you getting by upgrading the bearing? Chances are nothing. Chances are overwhelming that there is nothing wrong with the engine or if there is, it be bad enough to kill the upgraded bearing. The bearing upgrade only gets you something if the engine is bad enough to kill the stock bearing but not so bad to kill the upgraded one.

My rebuild has oil fed solution. That is supposed to solve the problem once and for all. I would buy an engine with a solution if I was worried about it. Otherwise, I really don't think the upgrade does you much good.

For years Porsche used a self oiling bearing that could stand up to slight changes in load. When they were looking for ways to make manufacturing easier for the 996, they went to the infamous bearing in the 996 because it was easier to build. The difference was that it could not take changes in load. That didn't bother the engineers because they designed the engine to put a constant load on the bearings. What they didn't know and couldn't have known was that Porsche manufacturing was not uniform enough to make every engine perfect enough to keep the load constant. This wasn't an issue on previous 911s because the oil fed bearings could take variations in loads. So no one noticed that some engines did this if they were not manufactured perfectly.

So here comes the M96 with a bearing that couldn't take really any variance in load. Not a problem if the engine was manufactured on a good day and everything is perfect. If not, a big problem. This is why no could figure out what was causing the bearings to fail and why so many of them didn't. Most of the engines were manufactured to perfect spec. It was only the few that were not that caused the bearing to fail.

If the engine is enough out of whack, it will as was the case with my car and others, kill even an upgraded bearing. What are you getting by upgrading the bearing? Chances are nothing. Chances are overwhelming that there is nothing wrong with the engine or if there is, it be bad enough to kill the upgraded bearing. The bearing upgrade only gets you something if the engine is bad enough to kill the stock bearing but not so bad to kill the upgraded one.

My rebuild has oil fed solution. That is supposed to solve the problem once and for all. I would buy an engine with a solution if I was worried about it. Otherwise, I really don't think the upgrade does you much good.

#19

Rennlist Member

I had an upgraded LN Engineering bearing fail. When I called them about it, their excuse was that there must of been something wrong with the motor when it was installed that caused the bearing to fail. That is nice as far as it goes, but that is pretty much what Porsche has been saying since this entire thing started. Here is my theory on the bearing.

For years Porsche used a self oiling bearing that could stand up to slight changes in load. When they were looking for ways to make manufacturing easier for the 996, they went to the infamous bearing in the 996 because it was easier to build. The difference was that it could not take changes in load. That didn't bother the engineers because they designed the engine to put a constant load on the bearings. What they didn't know and couldn't have known was that Porsche manufacturing was not uniform enough to make every engine perfect enough to keep the load constant. This wasn't an issue on previous 911s because the oil fed bearings could take variations in loads. So no one noticed that some engines did this if they were not manufactured perfectly.

So here comes the M96 with a bearing that couldn't take really any variance in load. Not a problem if the engine was manufactured on a good day and everything is perfect. If not, a big problem. This is why no could figure out what was causing the bearings to fail and why so many of them didn't. Most of the engines were manufactured to perfect spec. It was only the few that were not that caused the bearing to fail.

If the engine is enough out of whack, it will as was the case with my car and others, kill even an upgraded bearing. What are you getting by upgrading the bearing? Chances are nothing. Chances are overwhelming that there is nothing wrong with the engine or if there is, it be bad enough to kill the upgraded bearing. The bearing upgrade only gets you something if the engine is bad enough to kill the stock bearing but not so bad to kill the upgraded one.

My rebuild has oil fed solution. That is supposed to solve the problem once and for all. I would buy an engine with a solution if I was worried about it. Otherwise, I really don't think the upgrade does you much good.

For years Porsche used a self oiling bearing that could stand up to slight changes in load. When they were looking for ways to make manufacturing easier for the 996, they went to the infamous bearing in the 996 because it was easier to build. The difference was that it could not take changes in load. That didn't bother the engineers because they designed the engine to put a constant load on the bearings. What they didn't know and couldn't have known was that Porsche manufacturing was not uniform enough to make every engine perfect enough to keep the load constant. This wasn't an issue on previous 911s because the oil fed bearings could take variations in loads. So no one noticed that some engines did this if they were not manufactured perfectly.

So here comes the M96 with a bearing that couldn't take really any variance in load. Not a problem if the engine was manufactured on a good day and everything is perfect. If not, a big problem. This is why no could figure out what was causing the bearings to fail and why so many of them didn't. Most of the engines were manufactured to perfect spec. It was only the few that were not that caused the bearing to fail.

If the engine is enough out of whack, it will as was the case with my car and others, kill even an upgraded bearing. What are you getting by upgrading the bearing? Chances are nothing. Chances are overwhelming that there is nothing wrong with the engine or if there is, it be bad enough to kill the upgraded bearing. The bearing upgrade only gets you something if the engine is bad enough to kill the stock bearing but not so bad to kill the upgraded one.

My rebuild has oil fed solution. That is supposed to solve the problem once and for all. I would buy an engine with a solution if I was worried about it. Otherwise, I really don't think the upgrade does you much good.

Interestingly enough, Porsche's own IMS replacement is a single row ceramic hybrid bearing, albeit with a grease seal, like the original. Porsche in their own testing must have concluded this was the best way to go. Just we've been able with the years of R&D to come up with options stronger and even permanent, like with the IMS Solution.

What we know for sure is that the engine must be pre-qualified and that the engine is healthy enough to be retrofitted and that many engines are in fact not healthy enough to have the bearing replaced and shops replace them anyways. I know that both our shop and Flat 6 Innovations have disqualified many cars that needed an IMS bearing because the engines needed full rebuilds and some of those cars went to other shops to still be retrofitted. Unfortunately, those cars usually get sold immediately and become another person's problem.

#21

Sorry you had a problem with our products. I am aware of those who have had engines fail after being retrofitted. What I can tell you that we've never had a bearing fail in an engine that was properly pre-qualified and registered with us. Yes, we have had classic single row IMS Retrofit bearings fail, but the subsequent Single Row Pro (dual row bearing) and IMS Solution have had zero failures or problems whatsoever in the years since they were patented and introduced.

Interestingly enough, Porsche's own IMS replacement is a single row ceramic hybrid bearing, albeit with a grease seal, like the original. Porsche in their own testing must have concluded this was the best way to go. Just we've been able with the years of R&D to come up with options stronger and even permanent, like with the IMS Solution.

What we know for sure is that the engine must be pre-qualified and that the engine is healthy enough to be retrofitted and that many engines are in fact not healthy enough to have the bearing replaced and shops replace them anyways. I know that both our shop and Flat 6 Innovations have disqualified many cars that needed an IMS bearing because the engines needed full rebuilds and some of those cars went to other shops to still be retrofitted. Unfortunately, those cars usually get sold immediately and become another person's problem.

Interestingly enough, Porsche's own IMS replacement is a single row ceramic hybrid bearing, albeit with a grease seal, like the original. Porsche in their own testing must have concluded this was the best way to go. Just we've been able with the years of R&D to come up with options stronger and even permanent, like with the IMS Solution.

What we know for sure is that the engine must be pre-qualified and that the engine is healthy enough to be retrofitted and that many engines are in fact not healthy enough to have the bearing replaced and shops replace them anyways. I know that both our shop and Flat 6 Innovations have disqualified many cars that needed an IMS bearing because the engines needed full rebuilds and some of those cars went to other shops to still be retrofitted. Unfortunately, those cars usually get sold immediately and become another person's problem.

The laws of physics do not change from car to car. If something is a design defect, the part will fail under a given set of circumstances, extreme use or some set conditions, every time, not just some of the time. If something has a manufacturing defect, you can predict which parts will fail by looking to see if the part has the defect. Neither of those things are true with the stock bearings. No one has ever come up with a set of circumstances common to all failures or some design defect that can be found in them before they fail. So it must be something else that is causing the parts to fail. And that something else are the things in your five point inspection. Unless there are examples of engines passing this inspection, having their stock bearings reinstalled only to see them fail, I see no reason to believe that any bearing will fail in an engine that passes such an inspection. And as my car shows, any bearing will fail in an engine that doesn't pass your inspection, assuming my would not have.

#22

Former Vendor

Yes, if an engine passes your inspection, it is not going to eat its bearing. But what evidence is there that it would have ate the stock bearing? And you admit that if an engine is predisposed to eat its bearing, it will eat yours as well. The fact that you admit that your product should not be installed installed in an engine that doesn't meet your specifications, it seems to me gives away the game.

The laws of physics do not change from car to car. If something is a design defect, the part will fail under a given set of circumstances, extreme use or some set conditions, every time, not just some of the time. If something has a manufacturing defect, you can predict which parts will fail by looking to see if the part has the defect. Neither of those things are true with the stock bearings. No one has ever come up with a set of circumstances common to all failures or some design defect that can be found in them before they fail. So it must be something else that is causing the parts to fail. And that something else are the things in your five point inspection. Unless there are examples of engines passing this inspection, having their stock bearings reinstalled only to see them fail, I see no reason to believe that any bearing will fail in an engine that passes such an inspection. And as my car shows, any bearing will fail in an engine that doesn't pass your inspection, assuming my would not have.

The laws of physics do not change from car to car. If something is a design defect, the part will fail under a given set of circumstances, extreme use or some set conditions, every time, not just some of the time. If something has a manufacturing defect, you can predict which parts will fail by looking to see if the part has the defect. Neither of those things are true with the stock bearings. No one has ever come up with a set of circumstances common to all failures or some design defect that can be found in them before they fail. So it must be something else that is causing the parts to fail. And that something else are the things in your five point inspection. Unless there are examples of engines passing this inspection, having their stock bearings reinstalled only to see them fail, I see no reason to believe that any bearing will fail in an engine that passes such an inspection. And as my car shows, any bearing will fail in an engine that doesn't pass your inspection, assuming my would not have.

I developed the IMS Retrofit pre- qualification procedure. This was first employed with the vehicles that we were retrofitting before anyone else. After other shops started doing the work, the procedure was shared in our classes, and later online.

Under my roof we’ve installed over 700 IMS retrofits, including the very first one. This is more than double the second biggest Installer, and is more than any facility worldwide.

To date we’ve not experienced a single failure of an LN IMS Retrofit of any version, installed under this roof. Not a single one.

Ensuring every vehicle is qualified is exactly what has attributed to this success. Using the proper judgment, and not just throwing a bearing into anyone’s engine that has the money is the key.

On top of the 700+ that we’ve carried out, another 175 have been disqualified, and were not retrofitted.

I feel very sure that if we would have retrofitted those 175 engines, that we’d probably be sitting on 100 failures right now, rather than a flawless record.

Put simply, the pre- qualification process is effective, if carried out as directed, by a shop that has something to lose. Shops generally don’t care- they just blame the part, as it’s easier to be a victim, than a failure.

#23

Rennlist Member

I had an upgraded LN Engineering bearing fail. When I called them about it, their excuse was that there must of been something wrong with the motor when it was installed that caused the bearing to fail. That is nice as far as it goes, but that is pretty much what Porsche has been saying since this entire thing started. Here is my theory on the bearing.

For years Porsche used a self oiling bearing that could stand up to slight changes in load. When they were looking for ways to make manufacturing easier for the 996, they went to the infamous bearing in the 996 because it was easier to build. The difference was that it could not take changes in load. That didn't bother the engineers because they designed the engine to put a constant load on the bearings. What they didn't know and couldn't have known was that Porsche manufacturing was not uniform enough to make every engine perfect enough to keep the load constant. This wasn't an issue on previous 911s because the oil fed bearings could take variations in loads. So no one noticed that some engines did this if they were not manufactured perfectly.

So here comes the M96 with a bearing that couldn't take really any variance in load. Not a problem if the engine was manufactured on a good day and everything is perfect. If not, a big problem. This is why no could figure out what was causing the bearings to fail and why so many of them didn't. Most of the engines were manufactured to perfect spec. It was only the few that were not that caused the bearing to fail.

If the engine is enough out of whack, it will as was the case with my car and others, kill even an upgraded bearing. What are you getting by upgrading the bearing? Chances are nothing. Chances are overwhelming that there is nothing wrong with the engine or if there is, it be bad enough to kill the upgraded bearing. The bearing upgrade only gets you something if the engine is bad enough to kill the stock bearing but not so bad to kill the upgraded one.

My rebuild has oil fed solution. That is supposed to solve the problem once and for all. I would buy an engine with a solution if I was worried about it. Otherwise, I really don't think the upgrade does you much good.

For years Porsche used a self oiling bearing that could stand up to slight changes in load. When they were looking for ways to make manufacturing easier for the 996, they went to the infamous bearing in the 996 because it was easier to build. The difference was that it could not take changes in load. That didn't bother the engineers because they designed the engine to put a constant load on the bearings. What they didn't know and couldn't have known was that Porsche manufacturing was not uniform enough to make every engine perfect enough to keep the load constant. This wasn't an issue on previous 911s because the oil fed bearings could take variations in loads. So no one noticed that some engines did this if they were not manufactured perfectly.

So here comes the M96 with a bearing that couldn't take really any variance in load. Not a problem if the engine was manufactured on a good day and everything is perfect. If not, a big problem. This is why no could figure out what was causing the bearings to fail and why so many of them didn't. Most of the engines were manufactured to perfect spec. It was only the few that were not that caused the bearing to fail.

If the engine is enough out of whack, it will as was the case with my car and others, kill even an upgraded bearing. What are you getting by upgrading the bearing? Chances are nothing. Chances are overwhelming that there is nothing wrong with the engine or if there is, it be bad enough to kill the upgraded bearing. The bearing upgrade only gets you something if the engine is bad enough to kill the stock bearing but not so bad to kill the upgraded one.

My rebuild has oil fed solution. That is supposed to solve the problem once and for all. I would buy an engine with a solution if I was worried about it. Otherwise, I really don't think the upgrade does you much good.

#24

Pro

In a thread from 2013, then in another thread in 2016......I stated the same thing:

"After reading a 217 posts of this thread, I came to the same conclusion as 3 years ago (post 48 of a thread called "IMS bearing?"......)

The problem is not the bearing.....the problem is something else that causes the bearing to fail......... "

Therefore, if the problem is something else.....regardless whether you install the "LN Engineering" or any other brand.....IT WILL ALSO FAIL.....

I think people were installing bearings for the wrong reason: "because the bearing fails".......

I have read more stories of people stating "the original bearing was perfect" after replacement, than those stating "my old bearing was about to fail"......

"After reading a 217 posts of this thread, I came to the same conclusion as 3 years ago (post 48 of a thread called "IMS bearing?"......)

The problem is not the bearing.....the problem is something else that causes the bearing to fail......... "

Therefore, if the problem is something else.....regardless whether you install the "LN Engineering" or any other brand.....IT WILL ALSO FAIL.....

I think people were installing bearings for the wrong reason: "because the bearing fails".......

I have read more stories of people stating "the original bearing was perfect" after replacement, than those stating "my old bearing was about to fail"......

#27

Track Day

Join Date: Sep 2017

Location: Central Mo USA

Posts: 17

Likes: 0

Received 0 Likes

on

0 Posts

If it wasnt registered when it was done, I doubt you can get on the list. L&N was pretty stringent on that. Mine had to be submitted within 2 weeks or so of the work being done (supposed to be done by the shop) and the wanted the old bearing sent to them too.

I knew my IMS pro wouldn't be in there because the installer didn't register it but I was curious.

I knew my IMS pro wouldn't be in there because the installer didn't register it but I was curious.