Re-Cap on Max-Jax...

#1

Racer

Thread Starter

Join Date: Apr 2011

Location: Alexandria Ont.

Posts: 437

Likes: 0

Received 0 Likes

on

0 Posts

This is at the request of a fellow RL'er who had some problems with the installation of his MaxJax, specifically the concrete anchors supplied with the unit.

I initially attempted to utilize the Wej-it anchors that came with the MaxJax and found after repeated attempts to attain the recommended torque values that they just were not grabbing the concrete the way they were supposed to, and consequently the anchors were just turning in the hole, and never taking a 'set'.

Sooo, I was able to pound those anchors down into the gravel under the floor and utilize another product from Wej-it, called 'chemical anchors'...basically an anchor using a very special epoxy to 'anchor' the anchors.

This worked well, however a caveat here...when I 'sealed' the bottom of the hole with styrofoam sheeting, bunched up and stuffed down the hole until I couldn't get any more in there, what I didn't realize was that the epoxy reacted with the styrofoam and created a cavity, extending the bottom of the hole so when I pushed, ( hammered ) the new anchors into place it displaced some of the epoxy downward instead of up the sides of the anchors. Consequently 2 of my new anchors pulled up...and out of the hole. I bought more epoxy ( special 2 stage epoxy, $35.00 per tube! ), and re-did the 2 anchors this time putting a liberal amount of material up and down the sides of the anchor before putting them down the opening. I also used new grade 8 bolts instead of the utility grade supplied with the MaxJax.

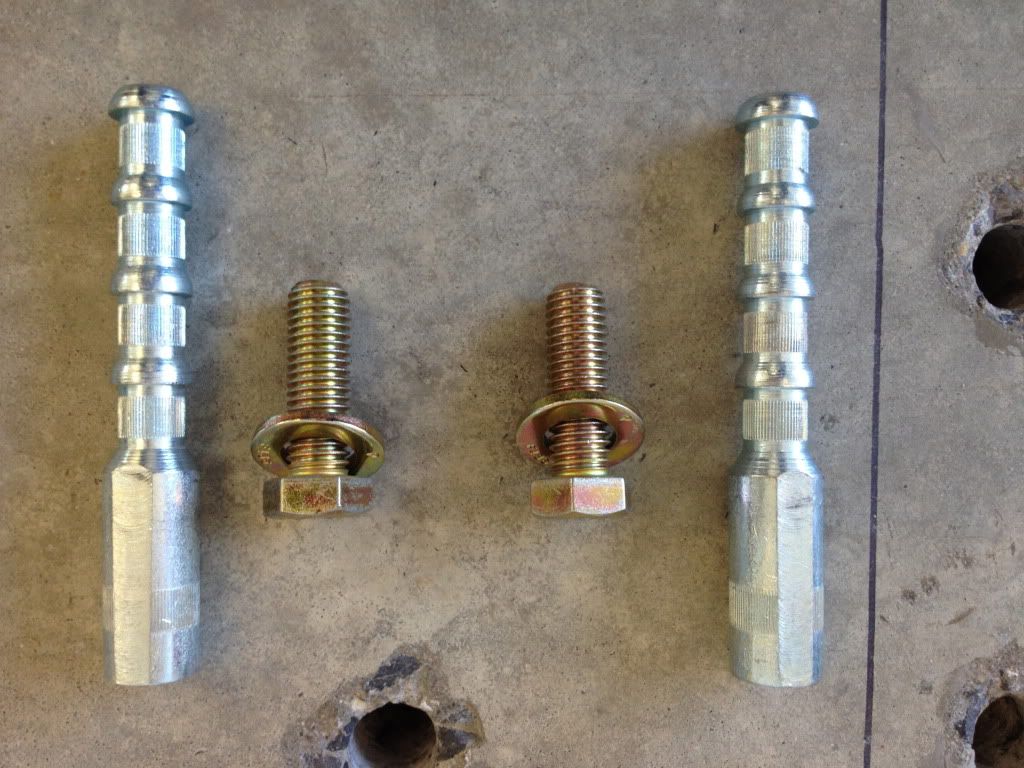

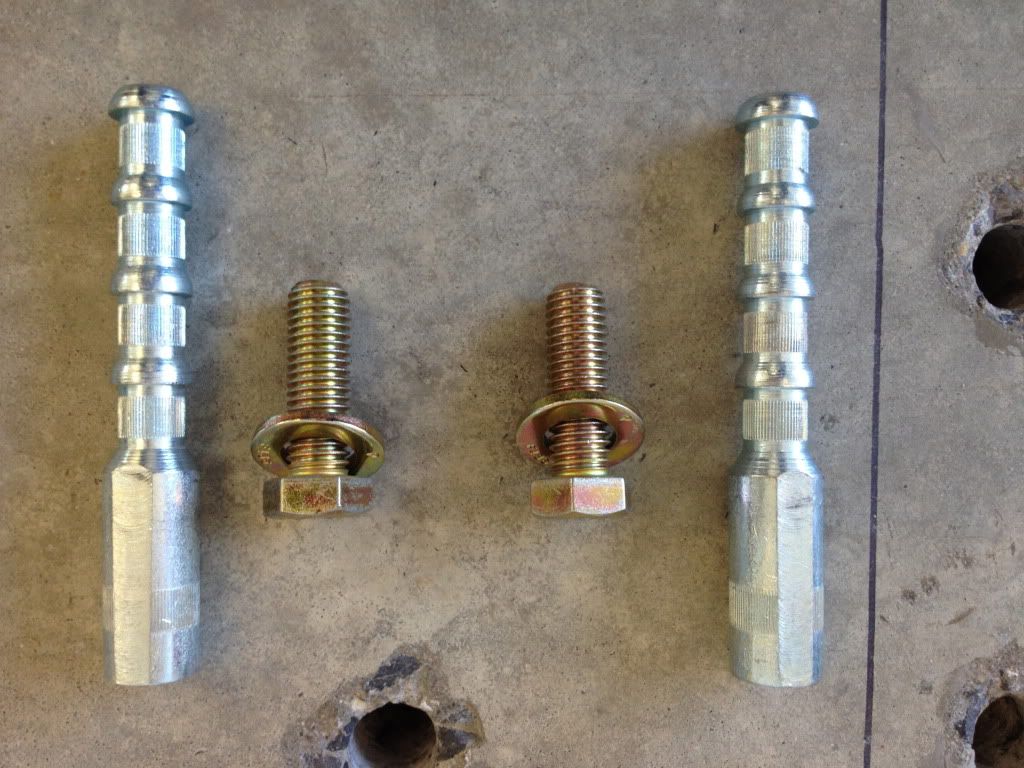

Now all my bolts take repeated 100ft/lbs of torque, no problem! Here are some photos...

I initially attempted to utilize the Wej-it anchors that came with the MaxJax and found after repeated attempts to attain the recommended torque values that they just were not grabbing the concrete the way they were supposed to, and consequently the anchors were just turning in the hole, and never taking a 'set'.

Sooo, I was able to pound those anchors down into the gravel under the floor and utilize another product from Wej-it, called 'chemical anchors'...basically an anchor using a very special epoxy to 'anchor' the anchors.

This worked well, however a caveat here...when I 'sealed' the bottom of the hole with styrofoam sheeting, bunched up and stuffed down the hole until I couldn't get any more in there, what I didn't realize was that the epoxy reacted with the styrofoam and created a cavity, extending the bottom of the hole so when I pushed, ( hammered ) the new anchors into place it displaced some of the epoxy downward instead of up the sides of the anchors. Consequently 2 of my new anchors pulled up...and out of the hole. I bought more epoxy ( special 2 stage epoxy, $35.00 per tube! ), and re-did the 2 anchors this time putting a liberal amount of material up and down the sides of the anchor before putting them down the opening. I also used new grade 8 bolts instead of the utility grade supplied with the MaxJax.

Now all my bolts take repeated 100ft/lbs of torque, no problem! Here are some photos...

#4

Racer

Join Date: Dec 2010

Location: King of Prussia Pa Area

Posts: 272

Likes: 0

Received 0 Likes

on

0 Posts

I just installed my Max jack 2 weeks ago, after drilling a 7/8 hole I installed my anchors but they had to be pounded in by hammer until they reached the proper depth. After using the lift a few times I noticed the bolts were a little loose (washers could move) so I re-torqued the bolts and all seams fine. I was concerned that my bolts were pulling up but they re-torqued fine. I am not sure why they loosened and I will keep an eye on this. Has anyone else had problems with lose or pulling up bolts??

#6

Rennlist Member

About half of my bolts (outboard) had to be re-torqued when I dropped it down the first time. The anchors hadn't moved at all. Hasn't happened again.

#7

Racer

Join Date: Dec 2010

Location: King of Prussia Pa Area

Posts: 272

Likes: 0

Received 0 Likes

on

0 Posts

Andreas; I was told to have a Concrete depth of 5.5 inches.

Thanks 963K993 I was worried that each time I use the lift I will have to re-torque the bolts. I am glade after the first re-torque they have held tight for you, I hope I have the same experience

Thanks 963K993 I was worried that each time I use the lift I will have to re-torque the bolts. I am glade after the first re-torque they have held tight for you, I hope I have the same experience

Trending Topics

#9

Race Director

98% positive it's 4" of 3,000 lb concrete.

I know mine's not much more than 4"

Edit: Direct from MaxJax's FAQ's

See: http://www.maxjaxusa.com/faqs/installation.html

I know mine's not much more than 4"

Edit: Direct from MaxJax's FAQ's

Do I need a special floor or foundation to support my lift?

Most residential or commercial foundations are strong enough to support a MaxJax™ lift. The minimum requirements are 2500-3000 PSI 4" thick concrete. Be sure to check your floor on the possibility of it being a post tension slab. In this case contact the building architect before drilling. Visually inspect the site where the lift is to be installed and verify the concrete is in good condition. If your concrete has cracks or other defects, please consult with a certified contractor before proceeding to install the MaxJax™ lift.

Most residential or commercial foundations are strong enough to support a MaxJax™ lift. The minimum requirements are 2500-3000 PSI 4" thick concrete. Be sure to check your floor on the possibility of it being a post tension slab. In this case contact the building architect before drilling. Visually inspect the site where the lift is to be installed and verify the concrete is in good condition. If your concrete has cracks or other defects, please consult with a certified contractor before proceeding to install the MaxJax™ lift.

#10

Racer

Thread Starter

Join Date: Apr 2011

Location: Alexandria Ont.

Posts: 437

Likes: 0

Received 0 Likes

on

0 Posts

Sorry Alex, I have no idea on parts #'s for the 90 degree fittings...I just walked into the local AutoPak store here in town and they put the fittings on the hyd hose while I waited. Took 10 minutes max. Cost was about $30.00 for everything as I recall.

Jim

Jim

#11

Rennlist Member

There seems to be two requirements. MaxJax's 4" minimum concrete thickness for their lift and a minimum hole depth as specified by the Installation Instructions that came with my Wej-It PD58 anchors...which they state as 5 1/2". That has me wondering how I get a hole depth of 5 1/2" with a concrete slab of 4"or more. I'm using a different installation method and just curious about the Wej-It anchors.

Power-Drop Drop-In Anchor Specifications

Power-Drop Drop-In Anchor Specifications

#12

Racer

Join Date: Dec 2010

Location: King of Prussia Pa Area

Posts: 272

Likes: 0

Received 0 Likes

on

0 Posts

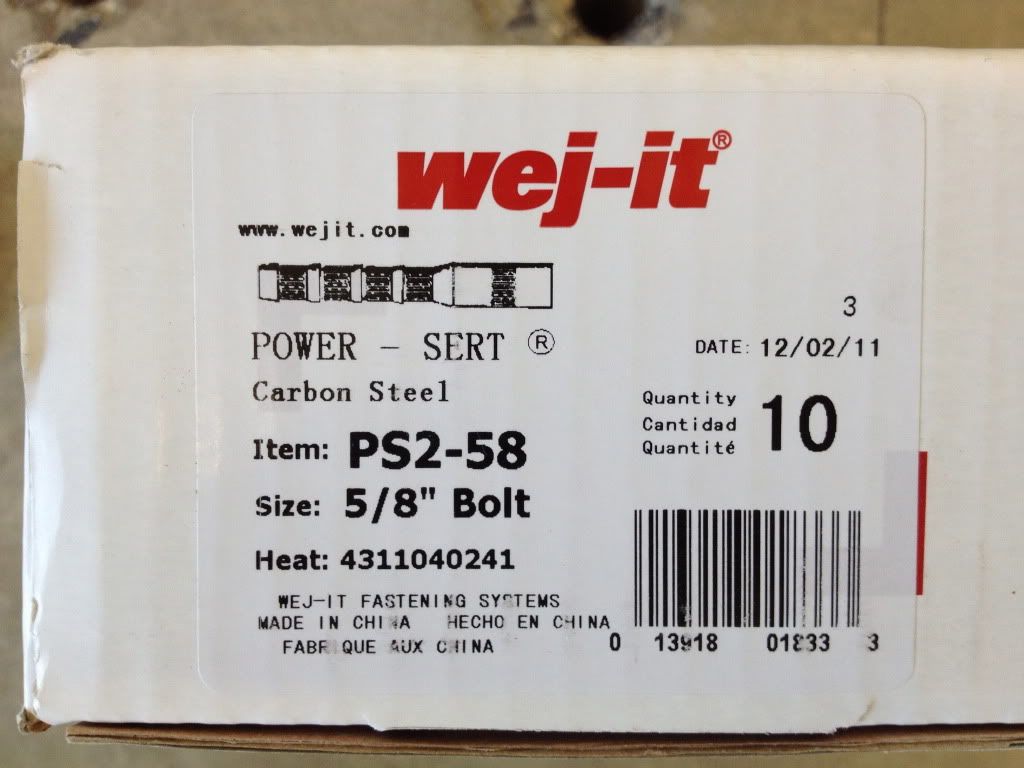

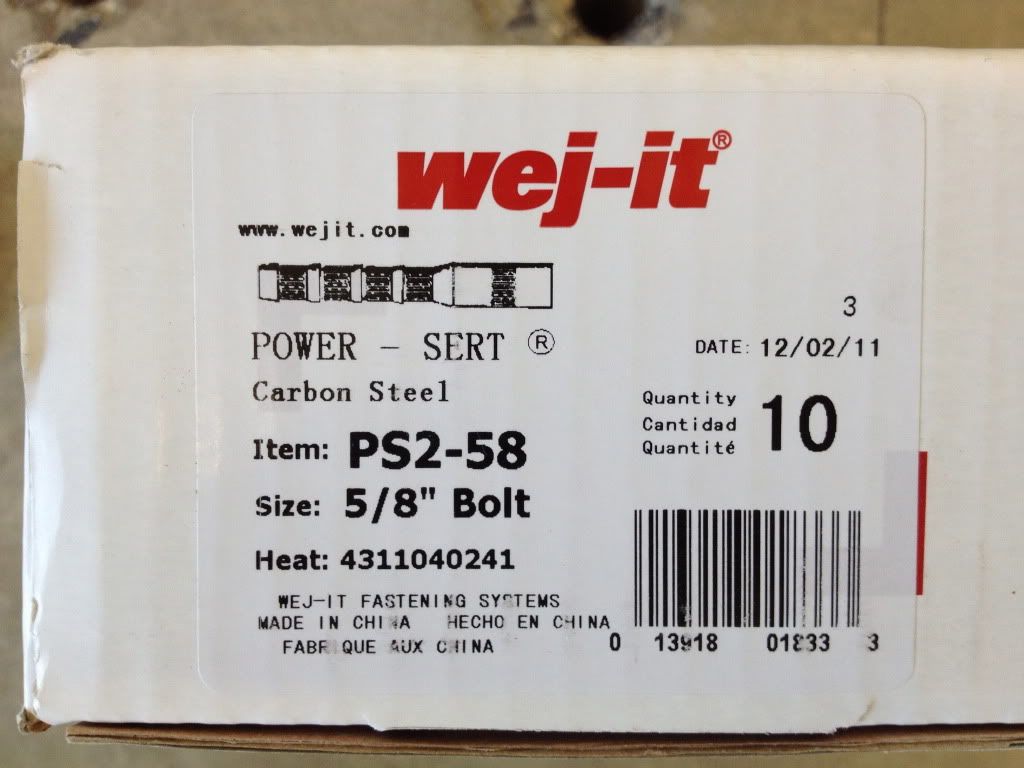

It looks like the depth is dependent on the size of the anchor. The op shows 5/8 inch anchor which requires a 4 inch hole. My Max Jack came with 7/8 inch anchors which require a 5 inch hole. (As per Alex’s spec sheet he attached in his post.)

Why does the max jack sometimes come with 5/8 as shown in op and sometimes come with 7/8 anchors as mine came with??? Also why does it say in manual to drill a 5 Ż inch hole??

Why does the max jack sometimes come with 5/8 as shown in op and sometimes come with 7/8 anchors as mine came with??? Also why does it say in manual to drill a 5 Ż inch hole??

#13

Rennlist Member

The part number on my Wej-It box is PD58. I assume the 58 refers to the 5/8" bolt thread. Were yours listed as PD78?

#14

Racer

Join Date: Dec 2010

Location: King of Prussia Pa Area

Posts: 272

Likes: 0

Received 0 Likes

on

0 Posts

I am out of town until Monday so I cannot look at the box for the product number. But I am sure the box says 7/8 anchors (using a 5/8 inch bolt) (are we talking about the same thing?) and I used a 7/8 drill for the holes, the anchors had to be pounded in the hole with a hammer using some force.

The OP said the anchors were not seating and turning in the hole, that is why I thought if he used a 5/8 anchor and drilled a 7/8 hole he would not be able to set the anchors.

Also one of the posts said that 4 inch was the minimum depth (that is the spec for the 5/8 anchors. The 7/8 anchors require a 5 inch deep hole. So I made the assumption that some max jacks were delivered with 5/8 anchors. (you know what happens when you assume)

Lastly I would recommend that you check the bolts after you use the lift the first time, as I posted earlier mine loosened after the first use.

Alex what method of securing the lift will you be using if you are not using the wej it anchors??

The OP said the anchors were not seating and turning in the hole, that is why I thought if he used a 5/8 anchor and drilled a 7/8 hole he would not be able to set the anchors.

Also one of the posts said that 4 inch was the minimum depth (that is the spec for the 5/8 anchors. The 7/8 anchors require a 5 inch deep hole. So I made the assumption that some max jacks were delivered with 5/8 anchors. (you know what happens when you assume)

Lastly I would recommend that you check the bolts after you use the lift the first time, as I posted earlier mine loosened after the first use.

Alex what method of securing the lift will you be using if you are not using the wej it anchors??

#15

Race Director

I've had my MaxJax for almost 2 yrs. The anchors supplied with mine were a different style WejIt than the ones pictured. About half of them were loose to very loose when I tried to install them. I wound up cutting out 2 squares of concrete, making a template of the hole spacing needed by the MaxJax, placing the anchors in the template and having rebar welded to the bottom of the anchors in such a way as the rebar extended under the existing concrete slab. I then poured new concrete around the rebar'ed anchors and forced it under the existing concrete slab (after digging out several buckets of rock base) and let it cure for over a week. It was a real PITA!

If I had to do it again, with what I know now, I would use anchors like the ones in the OP and use a HIGH QUALITY concrete epoxy to secure them in the holes. It wouldn't matter to me if I had to use 5 tubes of the epoxy to get it done it's still much easier than cutting out the concrete (and would look much better in the end).

I also use 1/4 steel plate (w/ holes cut for the anchor bolts) between the MaxJax base and the concrete floor. The steel plate extends beyond the newly poured concrete by apx 3", for added piece of mind.

Personally, I see no need to torque the bolts to the floor. What are the bolts doing? They're only to hold the MaxJax to the floor, there is no vibration where they have a chance to back out. I snug the bolts down with a 1/2 in. drive ratchet/socket set, I've never had one of the bolts loosen up. If one of the bolts comes up it's because the anchor came up.

If I had to do it again, with what I know now, I would use anchors like the ones in the OP and use a HIGH QUALITY concrete epoxy to secure them in the holes. It wouldn't matter to me if I had to use 5 tubes of the epoxy to get it done it's still much easier than cutting out the concrete (and would look much better in the end).

I also use 1/4 steel plate (w/ holes cut for the anchor bolts) between the MaxJax base and the concrete floor. The steel plate extends beyond the newly poured concrete by apx 3", for added piece of mind.

Personally, I see no need to torque the bolts to the floor. What are the bolts doing? They're only to hold the MaxJax to the floor, there is no vibration where they have a chance to back out. I snug the bolts down with a 1/2 in. drive ratchet/socket set, I've never had one of the bolts loosen up. If one of the bolts comes up it's because the anchor came up.