Brake ducts - HELP!!

#1

Ok folks... I am completely baffled by this puzzle. First I thought it was impossible and gave up, saying: adding “real” brake ducts to a 993 is a farce. Then I see that Kelly Moss offers carbon fiber duct shrouds, so it seems they have figured this out, but they are out of my league (>1k for the shrouds alone), so anyone know how they did it?

First some ground rules:

1) The surface area of the “hose” opening must remain relatively consistent (no crips)

2) Wheels must be able to turn lock to lock (turning radius is bad enough as-is)

3) Exit of “hose” must vent into the center of the rotor, not just in the “vicinity”

I’ve seen several solutions that break one or more of these “rules”, never one that “does it right”. To solve 1 and 2, I’ve seen some folks bring the “hose” into the frame rail and use the frame rail as part of the pathway. Seems like a great solution, however, I have concerns ducting rain water into the rails. Any thoughts on that?

Where I am truly stuck though, is problem #3…. It does not seem there is any open space available on the backside of the rotor to connect the hose, even if I were to fabricate a shroud. Anyone figured out this piece of origami? See the pic of backside mockup…

http://i429.photobucket.com/albums/q...993Upright.jpg

Looking forward to your suggestions….

First some ground rules:

1) The surface area of the “hose” opening must remain relatively consistent (no crips)

2) Wheels must be able to turn lock to lock (turning radius is bad enough as-is)

3) Exit of “hose” must vent into the center of the rotor, not just in the “vicinity”

I’ve seen several solutions that break one or more of these “rules”, never one that “does it right”. To solve 1 and 2, I’ve seen some folks bring the “hose” into the frame rail and use the frame rail as part of the pathway. Seems like a great solution, however, I have concerns ducting rain water into the rails. Any thoughts on that?

Where I am truly stuck though, is problem #3…. It does not seem there is any open space available on the backside of the rotor to connect the hose, even if I were to fabricate a shroud. Anyone figured out this piece of origami? See the pic of backside mockup…

http://i429.photobucket.com/albums/q...993Upright.jpg

Looking forward to your suggestions….

#2

It’s funny how just talking about a problem, spurs a solution….. Right after posting this thread, I had a epiphany, and may have my own answer. A quick mockup with some cardboard and scrap aluminum, I think this will work… any thoughts?

http://i429.photobucket.com/albums/q...uctMockup1.jpg

http://i429.photobucket.com/albums/q...uctMockup2.jpg

http://i429.photobucket.com/albums/q...uctMockup1.jpg

http://i429.photobucket.com/albums/q...uctMockup2.jpg

#3

I just wonder whether the stock deflector on the front part of the a-arm feeds more air to the rotor than anything we can come up with.... I guess the question is, how much will this additional airflow (very nice BTW  ) help?

) help?

) help?

) help?

#4

Just to throw a spanner in the works....

IIRC for the ducts to be truly effective -the dia must be larger than than 100mm - and must be in the +ve pressure area... ie like Ram Air on some sport bikes. Not sure if these two are mutually exclusive or not....

There is a thread on it somewhere....

Scoops = prob better...?

Simon

IIRC for the ducts to be truly effective -the dia must be larger than than 100mm - and must be in the +ve pressure area... ie like Ram Air on some sport bikes. Not sure if these two are mutually exclusive or not....

There is a thread on it somewhere....

Scoops = prob better...?

Simon

#5

This would be my bet as well.. I really like the a-arm solution that the 996 models use.. Just use the front ducts for additional cold air to the oil cooler..

#6

My real goal is to extend the life of the rotors. Ive been running doubled "scoops" for years, and they do do a great job, but they are just keeping air flowing through the wheel opening. They dont do a good job of venting the vanes of the rotor. So the duct would be used to suplement not replace the scoops (although my car is so low now I have to go back to the stock scoops)

#7

Trending Topics

#8

However...... In a 993 the control arm is over an inch thick and the scoops mount to the top of it, so one option is to simply move the scoop to the bottom of the control arm for added effect.... I took that one step further and bought a second scoop, mounted it to the bottom, leaving the stock on top, and grafted the two together to form one larger scoop.... Unfortunately I broke these off in my wreck and did not replace them... so no picture to show....

#9

I run a duct under the front diff cover that splits to run a 3 inch duct to each rotor. This setup works VERY well but only works if you have 2wd as the ducts run essentially where the front driveshafts would go. I used the CF brake duct hose connections for turner motorsports and fabbed them to fit with my 380mm bbk

I can tell you where to buy the ducts if you are interested

I can tell you where to buy the ducts if you are interested

#10

Because of the upright design in the area of the axle there's no way to duct to the eye, you can use dual 993 scoops or adapt Cup or GT3 scoops to the 993 arms, or make your own.

Of course you could also have some custom uprights fabricated too,

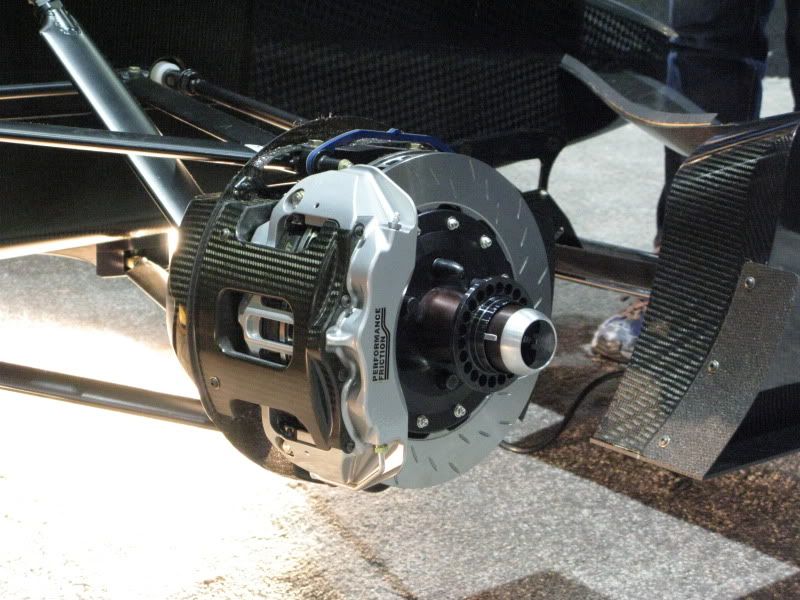

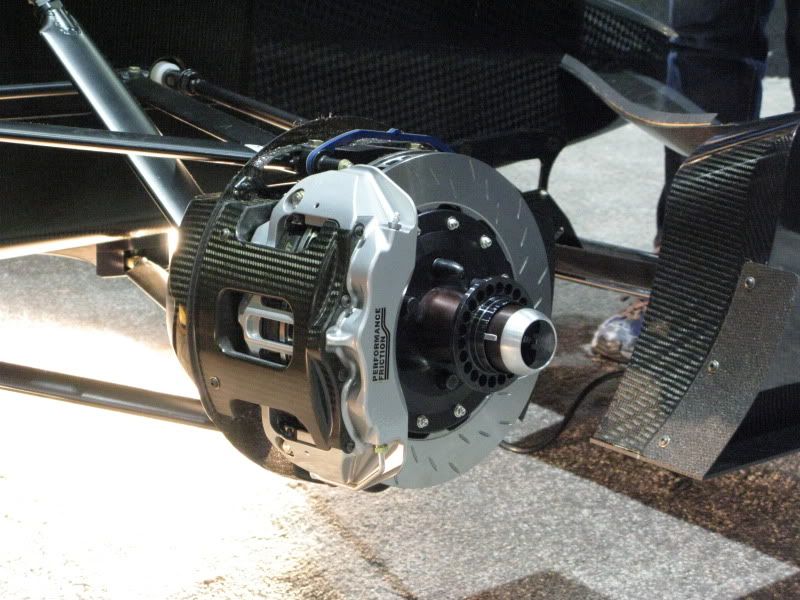

something like Robert Lintens Gem shown here, shouldn't set you back more than a few decades of spare change

Of course you could also have some custom uprights fabricated too,

something like Robert Lintens Gem shown here, shouldn't set you back more than a few decades of spare change

#11

Because of the upright design in the area of the axle there's no way to duct to the eye, you can use dual 993 scoops or adapt Cup or GT3 scoops to the 993 arms, or make your own.

Of course you could also have some custom uprights fabricated too,

something like Robert Lintens Gem shown here, shouldn't set you back more than a few decades of spare change

Of course you could also have some custom uprights fabricated too,

something like Robert Lintens Gem shown here, shouldn't set you back more than a few decades of spare change

#12

I run a duct under the front diff cover that splits to run a 3 inch duct to each rotor. This setup works VERY well but only works if you have 2wd as the ducts run essentially where the front driveshafts would go. I used the CF brake duct hose connections for turner motorsports and fabbed them to fit with my 380mm bbk

I can tell you where to buy the ducts if you are interested

I can tell you where to buy the ducts if you are interested

#14

Guru

Lifetime Rennlist

Member

Rennlist Small

Business Sponsor

Lifetime Rennlist

Member

Rennlist Small

Business Sponsor

Joined: Aug 2001

Posts: 15,748

Likes: 102

From: yorba linda, ca

What Bill says is right on -- you want to feed the eye of the rotor, not so much to face cool the inboard face of the rotor. Rotor core cooling is much preferred over face cooling.

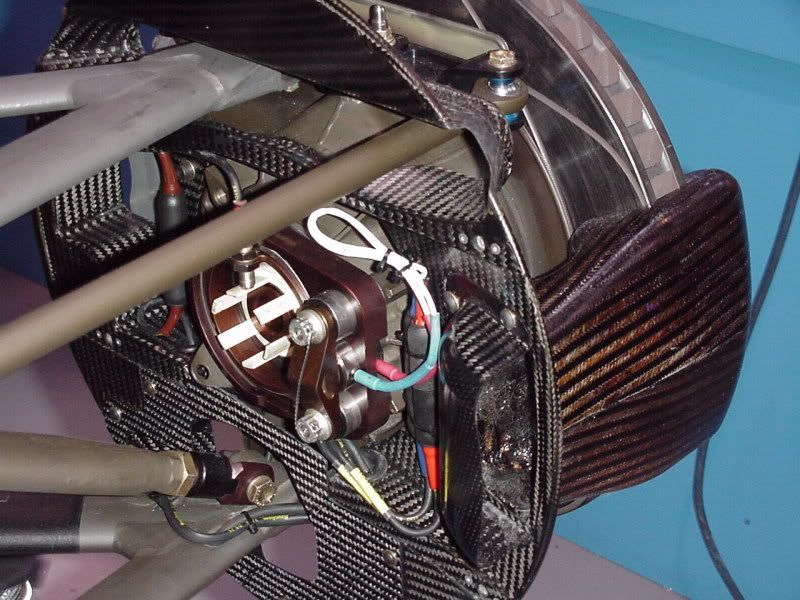

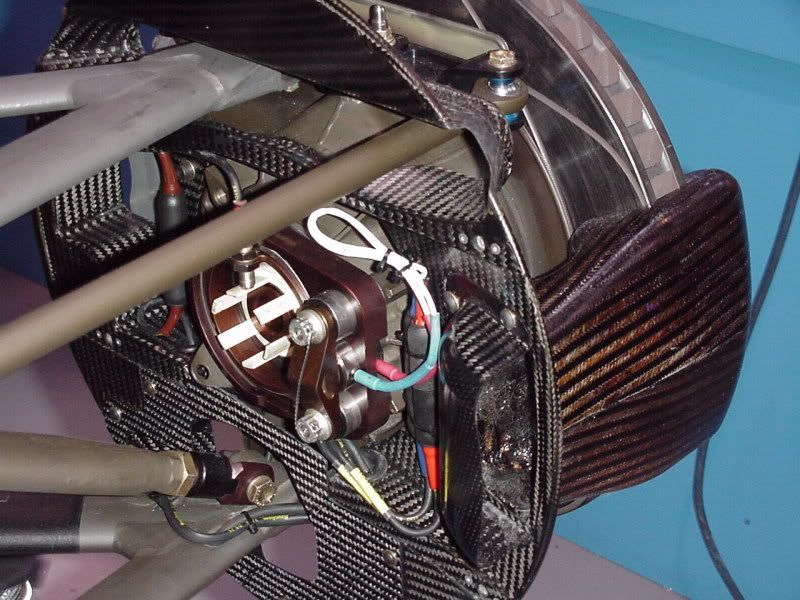

If core cooling isnt enough, face cooling both sides of the rotor is the next step. This is commonly done by way of a rotor glove like this. Obviously this isnt a road car but merely some examples of how to get air to the source of the heat. Also in these images are pad cooling ducts. We've found the outboard pad to require more cooling than the inboard pad.

Other examples

If core cooling isnt enough, face cooling both sides of the rotor is the next step. This is commonly done by way of a rotor glove like this. Obviously this isnt a road car but merely some examples of how to get air to the source of the heat. Also in these images are pad cooling ducts. We've found the outboard pad to require more cooling than the inboard pad.

Other examples

#15

Here is the nicest 964/993 setup I have ever seen, I believe that this was done by Pro Systems in NC

Intakes in trunk floor, blowers in trunk

wiring

spindle duct for a 328mm Brembo NASCAR rotor, 322 would be similar but compromised by reduced space

wheel well ducting, this was for the stock 964 brakes

Intakes in trunk floor, blowers in trunk

wiring

spindle duct for a 328mm Brembo NASCAR rotor, 322 would be similar but compromised by reduced space

wheel well ducting, this was for the stock 964 brakes