Some Mods, Short Shift, 3rd Gear Chirps, Shifter knob vibration SOLVED

#47

Drifting

"As you can see there are joints available that have studs instead of the through bolt hole. By using those someone without a machine shop could remove the spherical ball off the end of the shifter and reaction plate and drill a hole that they will attach to."

Rick,

Do you have some part numbers, right now thanks to Mike (MB965) I have the following parts: The rod ends are from McMaster Carr part number 2988K14, M10 x1.5 stainless steel male thread, right hand (both ends).

The SS are $41 the zinc coated are $9.

Going this route requires removing both ball ends which is how Mike did it I believe but if these other type joints can be obtained as you describe, that would be perfect.

Also, you and Chris talk about spinning the bearing to loosen them up. What is the procedure for this and how long and fast do you spin the bearing? I'm guessing you put a bolt thru the hole, lock it with a nut them mount the bolt in the drill chuck?

Rick,

Do you have some part numbers, right now thanks to Mike (MB965) I have the following parts: The rod ends are from McMaster Carr part number 2988K14, M10 x1.5 stainless steel male thread, right hand (both ends).

The SS are $41 the zinc coated are $9.

Going this route requires removing both ball ends which is how Mike did it I believe but if these other type joints can be obtained as you describe, that would be perfect.

Also, you and Chris talk about spinning the bearing to loosen them up. What is the procedure for this and how long and fast do you spin the bearing? I'm guessing you put a bolt thru the hole, lock it with a nut them mount the bolt in the drill chuck?

#48

Instructor

Cway27, I don’t know about the Weltmeister kit. Did look at it on their site and you can see they have a rodend and attachment for it at the shifter but as pointed out no idea what’s at the other end. I would like to think they have a rodend there too.

PRSHGUY, I don’t have McMaster part numbers for anything specific since I have a lot of this hardware on hand. Nice thing about their catalog is that you can shop by picture for your design. Some might use the stud type some may use a through bolt, sort of depends on what you have as equipment to support your project. For sizes I think that 3/8” is ideal. Even though a good quality ╝” joint has the strength the 3/8” rodend has good surface area for the spherical and will give good service life. Seems with all the stories of the factory ball socket failures the system seems more wear than one would assume. I am sure the stock ball socket suffers pretty heavy every time it sees the forces of removal as well.

The big problem I see for the DYI group is the tube and how to get the rodends attached to it. Easy with fab shop access to turn up a couple of thread receivers and weld them on but not available resources for everyone. They do make rodends with a plus one-thread size stem. In other words a 3/8” end will have a 7/16” stem. This may allow you to tap the inside of a tube to accept. Not my favorite way to do the attachment but if done properly will certainly be strong enough. Companies like The Chassis Shop sell tubing, receivers and joints. Also have tubing sized for threading the ID. They do Mail Order. Good resource for DYI guys.

The spinning of the bearing with a drill is to prematurely wear it out, (in a controlled manor). The PTFE or Teflon lined ends have quite a bit of preload when new. This would be hard to over come with a shift linkage. Sometimes when these joints are used on suspension arms even those loads notice the stickiness.

Specific speed I don’t know, I spin them pretty slow a 75 rpm and keep an eye on it. The key as pointed out by Chris is to keep the cool.

Rick

PRSHGUY, I don’t have McMaster part numbers for anything specific since I have a lot of this hardware on hand. Nice thing about their catalog is that you can shop by picture for your design. Some might use the stud type some may use a through bolt, sort of depends on what you have as equipment to support your project. For sizes I think that 3/8” is ideal. Even though a good quality ╝” joint has the strength the 3/8” rodend has good surface area for the spherical and will give good service life. Seems with all the stories of the factory ball socket failures the system seems more wear than one would assume. I am sure the stock ball socket suffers pretty heavy every time it sees the forces of removal as well.

The big problem I see for the DYI group is the tube and how to get the rodends attached to it. Easy with fab shop access to turn up a couple of thread receivers and weld them on but not available resources for everyone. They do make rodends with a plus one-thread size stem. In other words a 3/8” end will have a 7/16” stem. This may allow you to tap the inside of a tube to accept. Not my favorite way to do the attachment but if done properly will certainly be strong enough. Companies like The Chassis Shop sell tubing, receivers and joints. Also have tubing sized for threading the ID. They do Mail Order. Good resource for DYI guys.

The spinning of the bearing with a drill is to prematurely wear it out, (in a controlled manor). The PTFE or Teflon lined ends have quite a bit of preload when new. This would be hard to over come with a shift linkage. Sometimes when these joints are used on suspension arms even those loads notice the stickiness.

Specific speed I don’t know, I spin them pretty slow a 75 rpm and keep an eye on it. The key as pointed out by Chris is to keep the cool.

Rick

#49

Seared

Rennlist Member

Rennlist Member

Rick,

Great info - I'm following this thread with a great deal of interest. I noticed a number of pre-threaded tubes in steel or aluminum on the Speedway site that was posted earlier.

Andreas

Great info - I'm following this thread with a great deal of interest. I noticed a number of pre-threaded tubes in steel or aluminum on the Speedway site that was posted earlier.

Andreas

#50

Rennlist Member

Just talked to Sunset and the RS shift rod is $368!! Guess that'll have to wait. I'm wondering if there is a way to adapt a small universal joint of some kind. I'm reasonably proficient at fabricating/welding and there has to be a way. First thought here is a universal from a small displacement shaft-drive motorcycle, any ideas out there?

#51

Instructor

Here for reference are some parts from The Chassis Shop. Go to the tubing adapter PDF in the catalog section. (They have rodends and a lot of different hardware in other sections). Depends what your after but either 5/8" or 3/4" .058" wall will work. 3/8"-24 thread. You can get one end left hand thread on right hand if you choose. Get the adpter with a hex to allow you to counter torque the jam nut. If you buy their safety washers that could act as a spacer for the rodend and allow you to bolt to the shifter and reaction plate. The tube adapter "could" be held into the tube with a small cross screws or a roll pin and some structural expoxy IF there was no way to weld it. Loads are low but I like welds. Even though the next time you fly commercially it's the adhesives that are keeping that baby in the air these days.

Rick

http://www.chassisshop.com/

Rick

http://www.chassisshop.com/

#52

Drifting

I had that same thought too. I like the idea of a lubricated joint rather than plain surface. But haven't found a source yet. Thought about hitting the local PicnPull junk yard for a Volvo unit or something similiar. Mike, who has been helpful with info on this topic had a neat looking universal that I'm trying to get more info on and will update when I hear.

#53

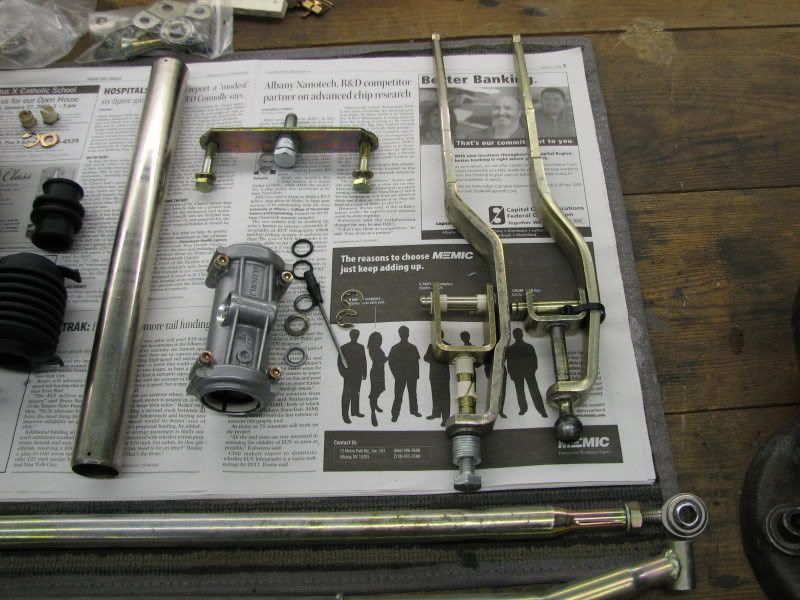

I will try to post a few photos of my modified shifter rods when I get home tonight.

The Weltmister front shift rod does have rod end on both end and includes a new rod. However their kit costs $250 and includes the factory short shifter kit. I did not want to spend that much and I already had the short shift kit.

You need to get a metric rod end if you want to replace the factory ball cup.

The front shift rod is only about .06" wall so you can not just tap it. I made a solid plug, welded it to the rod and then threaded it for the rod end.

No issues with the tightness of the teflon lined rod ends I got from McMaster Carr.

For the rear rod I got a universal joint from Pegasis (sp?, I'll check the part number), bored the transmission end to match the transmission shift rod and welded an extension to the shift rod and then welded the universal to the extension.

If you can weld and have a small lathe the project should not cost more $150 to do both rods. If you have to pay someone to do all of the fabrication work it might come close to the cost of buying the available kits.

Mike

The Weltmister front shift rod does have rod end on both end and includes a new rod. However their kit costs $250 and includes the factory short shifter kit. I did not want to spend that much and I already had the short shift kit.

You need to get a metric rod end if you want to replace the factory ball cup.

The front shift rod is only about .06" wall so you can not just tap it. I made a solid plug, welded it to the rod and then threaded it for the rod end.

No issues with the tightness of the teflon lined rod ends I got from McMaster Carr.

For the rear rod I got a universal joint from Pegasis (sp?, I'll check the part number), bored the transmission end to match the transmission shift rod and welded an extension to the shift rod and then welded the universal to the extension.

If you can weld and have a small lathe the project should not cost more $150 to do both rods. If you have to pay someone to do all of the fabrication work it might come close to the cost of buying the available kits.

Mike

#54

Drifting

I will try to post a few photos of my modified shifter rods when I get home tonight.

The Weltmister front shift rod does have rod end on both end and includes a new rod. However their kit costs $250 and includes the factory short shifter kit. I did not want to spend that much and I already had the short shift kit.

You need to get a metric rod end if you want to replace the factory ball cup.

The front shift rod is only about .06" wall so you can not just tap it. I made a solid plug, welded it to the rod and then threaded it for the rod end.

No issues with the tightness of the teflon lined rod ends I got from McMaster Carr.

For the rear rod I got a universal joint from Pegasis (sp?, I'll check the part number), bored the transmission end to match the transmission shift rod and welded an extension to the shift rod and then welded the universal to the extension.

If you can weld and have a small lathe the project should not cost more $150 to do both rods. If you have to pay someone to do all of the fabrication work it might come close to the cost of buying the available kits.

Mike

The Weltmister front shift rod does have rod end on both end and includes a new rod. However their kit costs $250 and includes the factory short shifter kit. I did not want to spend that much and I already had the short shift kit.

You need to get a metric rod end if you want to replace the factory ball cup.

The front shift rod is only about .06" wall so you can not just tap it. I made a solid plug, welded it to the rod and then threaded it for the rod end.

No issues with the tightness of the teflon lined rod ends I got from McMaster Carr.

For the rear rod I got a universal joint from Pegasis (sp?, I'll check the part number), bored the transmission end to match the transmission shift rod and welded an extension to the shift rod and then welded the universal to the extension.

If you can weld and have a small lathe the project should not cost more $150 to do both rods. If you have to pay someone to do all of the fabrication work it might come close to the cost of buying the available kits.

Mike

How did you attach the rod end to the shifter?

#55

I did the same as for the front rod end; cut off the ball, threaded the shifter and used a spacer and bolt.

I got the rear rod universal end from Pegasus Auto Racing, p.n.1494-.75. They also have the universal that Chris showed but I wasn't sure I could weld it without getting the boot too hot.

Sorry but I tried to post or link my photos but they are too big and I am not sure how to reduce them.

Mike

I got the rear rod universal end from Pegasus Auto Racing, p.n.1494-.75. They also have the universal that Chris showed but I wasn't sure I could weld it without getting the boot too hot.

Sorry but I tried to post or link my photos but they are too big and I am not sure how to reduce them.

Mike

#56

Drifting

I did the same as for the front rod end; cut off the ball, threaded the shifter and used a spacer and bolt.

I got the rear rod universal end from Pegasus Auto Racing, p.n.1494-.75. They also have the universal that Chris showed but I wasn't sure I could weld it without getting the boot too hot.

Sorry but I tried to post or link my photos but they are too big and I am not sure how to reduce them.

Mike

I got the rear rod universal end from Pegasus Auto Racing, p.n.1494-.75. They also have the universal that Chris showed but I wasn't sure I could weld it without getting the boot too hot.

Sorry but I tried to post or link my photos but they are too big and I am not sure how to reduce them.

Mike

#57

The rod end with the stud might work but the nut on the stud is going to limit your adjustment on how close you can get the rod end to the shifter end, which could cause the rod end to be closer to the tunnel cover. You are going to need the part in hand to make it work as there are several places were you are clearance limited. I prefered the bolt and spacer as I could use washers during the fit up to make the adjustments.

Mike

Mike

#59

Seared

Rennlist Member

Rennlist Member

#60

Drifting

I remember when I got my 965 a couple of years back that the PO had installed a short shift kit and it was hitting the tunnel cover. I went back to stock but then I heard the installing the kit required reversing a mounting or pivot point?