RS shift rod - thoughts?

#47

I'm gonna be under the car tonight replacing O2 sensors. Maybe I'll try to take a look at that bushing and see if I can fab something up with very basic tools to replace it with something a little harder.

#50

Just did my O2 sensors. What a cinch, definitely the easiest job I've done on this car. While down there, I checked out the bushing on my shift rod. It looked terrible. So I will look for one of those cheap poly cutting boards or something .5" in thickness, take out the old bushing, trace it on the new poly stock, cut, drill and replace.

#51

Originally Posted by hidden impact

i personally went this route, but many have indicated the same effect by replacing the washers on the bolts holding the rod like TroyN said. the difference was well worth the effort.

#52

I could not make this work today. The cutting board was about .05" too thin and it did make too much difference. Those weird bolts with the rubber on them do not fit snug in the coupler and even tightened down with washers, there's still slop in there. I put it together with the cutting board chunk, but my shifter is slightly worse now, not better. I don't know what do here. I can't see how hidden impact's set up would keep those large bolts from still flopping around inside the coupler.

#53

Those 'large bolts' are shoulder bolts ..... ie., they have a shoulder cut at ~5/8" above the rubber face on the head which meets the two eared flange of the rear shift rod - so replacement with any material of similar thickness will not reduce the play, but may transmit more vibration. It is this feature that permits the play for vibration dampening against the 1/2" spacer and molded rubber under the bolt heads.

This is why I installed additional hard rubber spacers between the shift rod and the thick spacer ... to effectively take up the slack, but still allow some dampening.

This is why I installed additional hard rubber spacers between the shift rod and the thick spacer ... to effectively take up the slack, but still allow some dampening.

#54

I wonder if I can get some rubber O-rings to fit onto the 5/8" shoulders and inside the coupler holes. That should take the slop out, though I wonder how long they would hold up. It seems to me that, unless some rubber parts are there, there would always be slop, as there is a tiny space between the bolt shoulders and coupler holes they go through. I guess the old piece of rubber dampened it, but I don't want to reinstall that.

#55

Originally Posted by Rick Lee

I could not make this work today. The cutting board was about .05" too thin and it did make too much difference.

#56

Originally Posted by Rick Lee

I wonder if I can get some rubber O-rings to fit onto the 5/8" shoulders and inside the coupler holes. That should take the slop out, though I wonder how long they would hold up. It seems to me that, unless some rubber parts are there, there would always be slop, as there is a tiny space between the bolt shoulders and coupler holes they go through. I guess the old piece of rubber dampened it, but I don't want to reinstall that.

You mean somewhat like this? At great expense, you can import from Gerrmany zwei schlauchunterlegscheiben, or for a mere quarter, go to the nearest hardware store and pick up a couple of garden hose washers ... same thing

#57

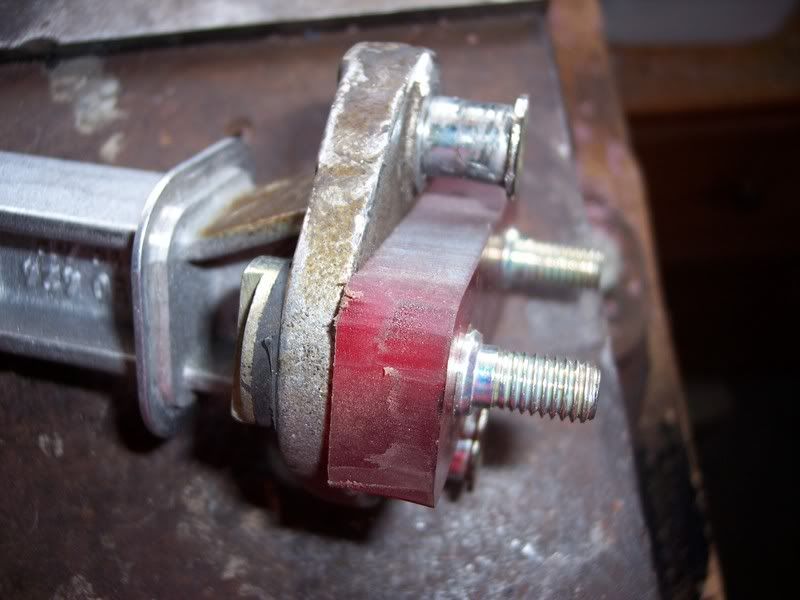

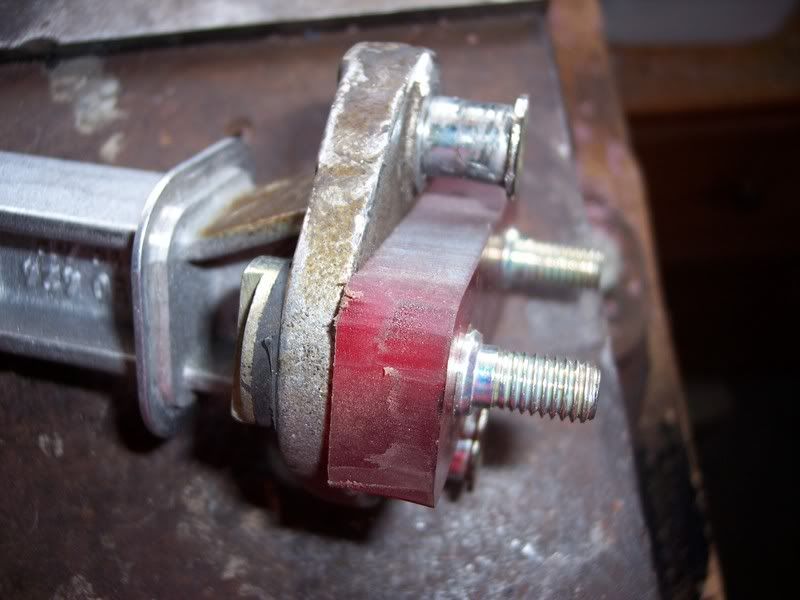

there was zero slop in those bolts when i installed them.

notice the space in the bolts before the threads in the second photo.

washers installed after the red plastic piece are necessary because without them, the rod bracket would push the bolts through causing the slop.

notice the space in the bolts before the threads in the second photo.

washers installed after the red plastic piece are necessary because without them, the rod bracket would push the bolts through causing the slop.

.

.