Pedal box rebuild checklist.

#1

Three Wheelin'

Thread Starter

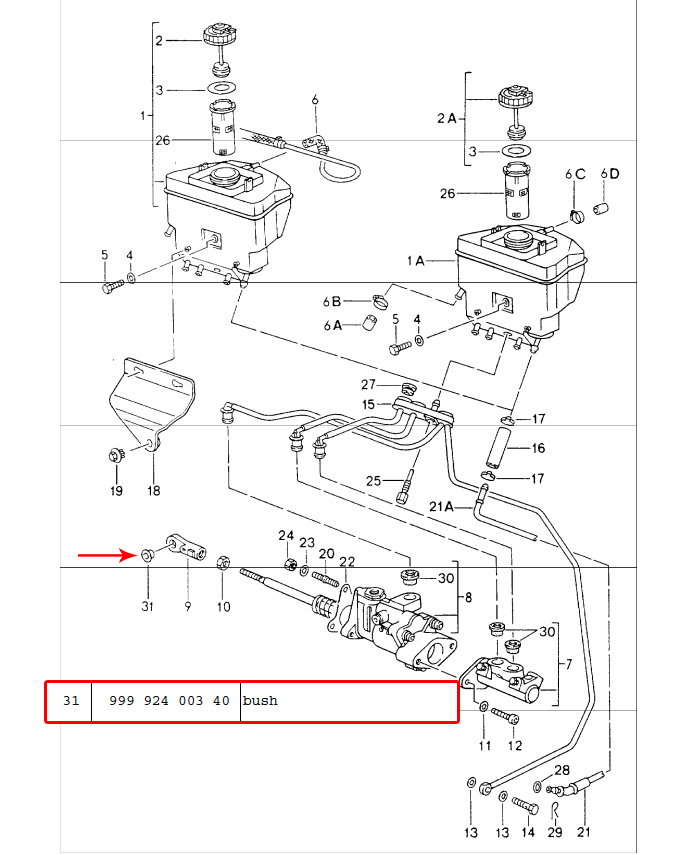

In the past week my clutch pedal has been a bit tougher to operate smoothy to get rolling. Pressing it fast it feels fine, but when you're letting it out slow it is a bit hesitant like its rubbing at some spots. I shot some WD90 around the first clutch bushing and it seemed to help. So I assume I'm in for a pedal box rebuild. But what does that require exactly? Circled in the first diagram is the stuff I 'assume' needs replacing.

But what about the second diagram? Do I really need to swap the clutch master cylinder and its lines?

Also, what lube to use?

But what about the second diagram? Do I really need to swap the clutch master cylinder and its lines?

Also, what lube to use?

#2

Race Car

I can't see the pics for some reason...

Superlube is safe for the plastic bushings in the pedal box. You don't have to replace the master and lines unless you want to.

Keep in mind that the new brake bushings Porsche supplies are going to leave a lot of play in your brake pedal. So those may not feel as tight as even your old worn bushings. The clutch bushings will likely feel better.

You can get super lube at harbor freight, Napa, maybe even Home Depot. But if you can't find that, go to a bike shop and get any good synthetic Teflon grease that's ok for plastics.

It's an easy job. First time I did it was on my kitchen counter. Car was in an open parking lot and I was done in maybe an hour. You don't need to disconnect the clutch master from the lines. Unbolt it from the box and leave it in there. A decent set of 1/4 13mm socket with some wobble extensions will be your friends to get the two clutch master nuts out and in. And then wiggle the box out and do the build. Wiggle it back in and put the nuts back on the master and bolt it all down and done.

Make sure the brake switch and clutch micro switch function after the install and before you put the floor board back.

Also. The reason why we break rollpins is because of the clutch pedal stop design. The pedal stop must be the stop for the pedal. If the pedal stops by hitting the end of the master cylinder travel, then you will quickly break the rollpin. So make sure the pedal travel is stopped by the adjustment plate on the floorboard before the end of the travel inside the master. It'll make sense when you see it.

Superlube is safe for the plastic bushings in the pedal box. You don't have to replace the master and lines unless you want to.

Keep in mind that the new brake bushings Porsche supplies are going to leave a lot of play in your brake pedal. So those may not feel as tight as even your old worn bushings. The clutch bushings will likely feel better.

You can get super lube at harbor freight, Napa, maybe even Home Depot. But if you can't find that, go to a bike shop and get any good synthetic Teflon grease that's ok for plastics.

It's an easy job. First time I did it was on my kitchen counter. Car was in an open parking lot and I was done in maybe an hour. You don't need to disconnect the clutch master from the lines. Unbolt it from the box and leave it in there. A decent set of 1/4 13mm socket with some wobble extensions will be your friends to get the two clutch master nuts out and in. And then wiggle the box out and do the build. Wiggle it back in and put the nuts back on the master and bolt it all down and done.

Make sure the brake switch and clutch micro switch function after the install and before you put the floor board back.

Also. The reason why we break rollpins is because of the clutch pedal stop design. The pedal stop must be the stop for the pedal. If the pedal stops by hitting the end of the master cylinder travel, then you will quickly break the rollpin. So make sure the pedal travel is stopped by the adjustment plate on the floorboard before the end of the travel inside the master. It'll make sense when you see it.

#3

Three Wheelin'

Thread Starter

The photos show for me but I'l try to upload them to photobucket. This really sucks to hear that the new bushings could be more sloppy, and that there are no other options. Maybe I should just change that one clutch pedal one [12] and be done with it? And the roll pin while I'm there for good measure. What do you think? My clutch master boot has a little tear but I see that quite a few people have the same thing with no issues thus far.

This was my original rebuild plan:

But I see from this thread this guy went the extra mile with the roll pins, and I'm somewhat curious to try the same.

This was my original rebuild plan:

But I see from this thread this guy went the extra mile with the roll pins, and I'm somewhat curious to try the same.

And rather than try to fit another shoulder bolt, I've got these, which are imperia-sized industrial rollpins.

The big 1/4in one hammers in snugly, and fits nice and tight with no slop.

And to make it a bit more secure, I drive in a second 5/32in rollpin, which will make the whole combination stronger, and also spread the outer pin harder against the sides of the hole.

The big 1/4in one hammers in snugly, and fits nice and tight with no slop.

And to make it a bit more secure, I drive in a second 5/32in rollpin, which will make the whole combination stronger, and also spread the outer pin harder against the sides of the hole.

#4

Race Car

I wouldn't bother going nuts on rollpins. Just be sure to adjust the pedal stop properly and done.

As to the stuff to buy to rebuild. As long as there are no cracks in the plastic pivots for the clutch return spring assembly, all you need is a rollpin, two clutch bushings, two brake bushings, and two throttle arm bushings...

Simple enough

As to the stuff to buy to rebuild. As long as there are no cracks in the plastic pivots for the clutch return spring assembly, all you need is a rollpin, two clutch bushings, two brake bushings, and two throttle arm bushings...

Simple enough

#6

Three Wheelin'

Thread Starter

After Rob mentioning the new brake pedal bushings might give a bit of slop I think I might leave those for now.

On the diagram which is the bushing for the master? 5?

I see there is a brass bushing option for the throttle pedal for a buck more

On the diagram which is the bushing for the master? 5?

I see there is a brass bushing option for the throttle pedal for a buck more