BBi Autosport Mahle Motorsports 964 3.6L TO 3.8L Engine Build Thread

#1

Thread Starter

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Joined: Jul 2015

Posts: 4,290

Likes: 553

From: Huntington Beach, California

Attachment 1344394

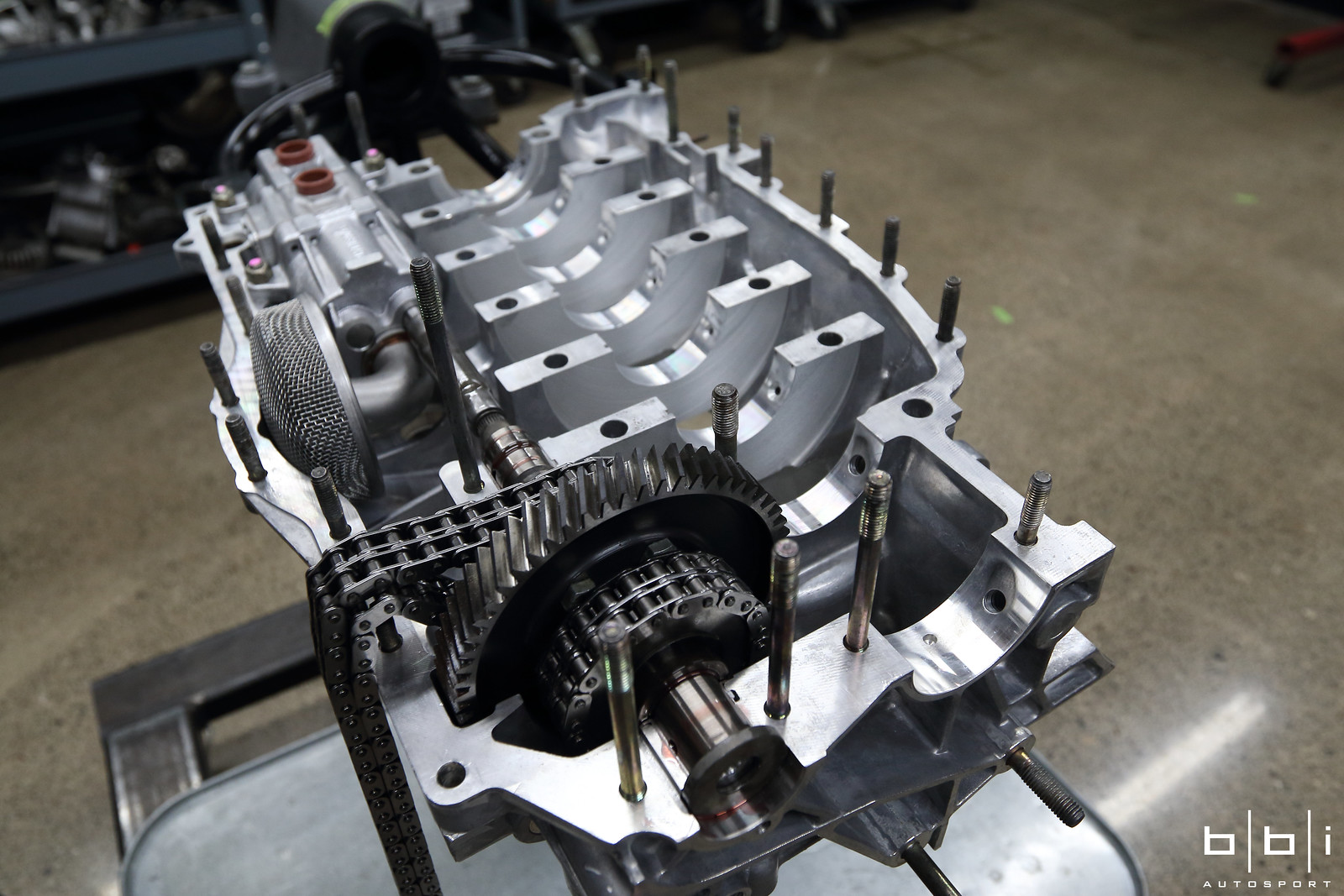

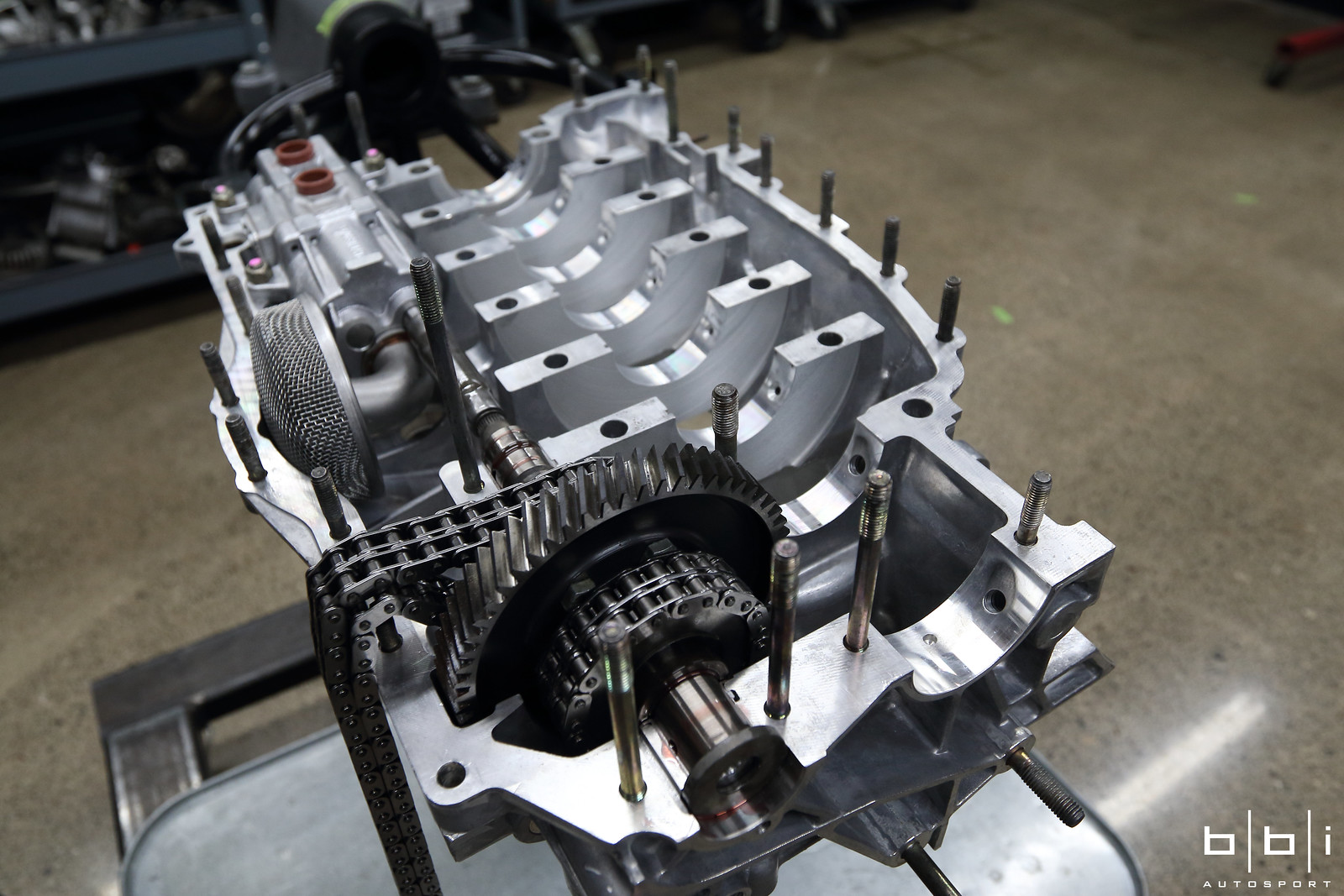

BBi Autosport Mahle Motorsports 964 3.6L TO 3.8L Engine Build

(Click for higher resolution images)

While known for building high powered water-cooled Porsche engines, BBi Autosport also builds equally impressive air-cooled engines. Our engine design and development constantly strives to raise the bar by developing proven and reliable engines for all types of applications. Our program has produced some of the most powerful Porsche engines reaching up to 1,500 horsepower reliably for competition use.

For a Porsche 964 restomod project, we took a milder approach for this engine build pictured here and used off the shelf parts from our trusted partners Mahle Motorsport and CP Carillo. Built to the same pedigree as its high powered counterparts, BBi Autosport takes pride in the quality, and every engine undergoes an the extensive process to ensure optimum power delivery and long term reliabilty. With proper tools and industry leading partners, we have all the resources to precisely measure clearances of engine components with extreme acccuracy and able to build extremely reliable high performance engines. Here are pictures of this build from start to finish that we would like to share.

Engine Specifications:

- Jerry@BBiautosport.com

BBi Autosport Mahle Motorsports 964 3.6L TO 3.8L Engine Build

(Click for higher resolution images)

While known for building high powered water-cooled Porsche engines, BBi Autosport also builds equally impressive air-cooled engines. Our engine design and development constantly strives to raise the bar by developing proven and reliable engines for all types of applications. Our program has produced some of the most powerful Porsche engines reaching up to 1,500 horsepower reliably for competition use.

For a Porsche 964 restomod project, we took a milder approach for this engine build pictured here and used off the shelf parts from our trusted partners Mahle Motorsport and CP Carillo. Built to the same pedigree as its high powered counterparts, BBi Autosport takes pride in the quality, and every engine undergoes an the extensive process to ensure optimum power delivery and long term reliabilty. With proper tools and industry leading partners, we have all the resources to precisely measure clearances of engine components with extreme acccuracy and able to build extremely reliable high performance engines. Here are pictures of this build from start to finish that we would like to share.

Engine Specifications:

- BBi Autosport Mahle Motorsports 964 3.6L TO 3.8L Engine Build Thread

- Mahle Motorsports 964 3.6L TO 3.8L NA Piston & Cylinder Set Slip Fit

- CP Carillo 964 Rods CARR Multiphase bolts

- Lightened Crankshaft

- 993 Turbo Head Studs

- Jerry@BBiautosport.com

__________________

Bringing Passion, Artistry, Craft to the Porsche Tuning Industry

Southern California's Porsche Performance Tuning, Engine Development,

ECU Software Tuning, Custom Fabrication, Race Preparation & Factory Service Center

Website: www.bbiautosport.com Email: sales@bbiautosport.com Phone: (714) 843-0200

Follow Us On: Facebook & Instagram

Bringing Passion, Artistry, Craft to the Porsche Tuning Industry

Southern California's Porsche Performance Tuning, Engine Development,

ECU Software Tuning, Custom Fabrication, Race Preparation & Factory Service Center

Website: www.bbiautosport.com Email: sales@bbiautosport.com Phone: (714) 843-0200

Follow Us On: Facebook & Instagram

#4

Thread Starter

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Joined: Jul 2015

Posts: 4,290

Likes: 553

From: Huntington Beach, California

- Jerry@BBiAutosport.com

#5

Trending Topics

#8

Someone please explain bore in to me and Jerry what crank did you lighten?

I'm not an engine man but I've designed quite a few carbon bits fitted to V10, V8 and V6 turbo engines so can appreciate the precision and testing that goes into making a reliable high power engine.

Looking forward to following this thread, please keep the posts and pictures coming

I'm not an engine man but I've designed quite a few carbon bits fitted to V10, V8 and V6 turbo engines so can appreciate the precision and testing that goes into making a reliable high power engine.

Looking forward to following this thread, please keep the posts and pictures coming

#9

Thread Starter

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Joined: Jul 2015

Posts: 4,290

Likes: 553

From: Huntington Beach, California

Someone please explain bore in to me and Jerry what crank did you lighten?

I'm not an engine man but I've designed quite a few carbon bits fitted to V10, V8 and V6 turbo engines so can appreciate the precision and testing that goes into making a reliable high power engine.

Looking forward to following this thread, please keep the posts and pictures coming

I'm not an engine man but I've designed quite a few carbon bits fitted to V10, V8 and V6 turbo engines so can appreciate the precision and testing that goes into making a reliable high power engine.

Looking forward to following this thread, please keep the posts and pictures coming

Good questions!

The bore in cylinders have to be machined into the crankcase to accept larger cylinder liners.

In comparison, the slip in cylinders utilizes thinner walls to slide into case.

For this particular project, we used slip in as it is not turbocharged or high powered race engine.

We used the stock factory 964 crankshaft. It has been knife-edged and balanced, and lightened as a result.

(Click on images for higher resolution)

- Jerry@BBiAutosport.com

#11

Great looking engine and nice photography skills.

I'm really interested in this as I've asked the question a few times and the last time I asked a reputable source I was told that 'the slip-in cylinders go out of round within 10K miles, regardless how the car is used and its reflected in the leakdown values. One finds uncontrolled blowby and there is really nothing one can do beyond replacement'.

I asked my engine builder and he said I read too much 'stuff' on the the internet so there is certainly difference of opinion out there.

I can understand the thinking behind the smaller wall thickness causing ovality in the cylinders but at the same time it's something I would love to do but not if it will cause me tears further down the road!!

Can I ask if you have an opinion on this and why you didn't just machine the case seeing as it was all apart anyway?

Thanks

I'm really interested in this as I've asked the question a few times and the last time I asked a reputable source I was told that 'the slip-in cylinders go out of round within 10K miles, regardless how the car is used and its reflected in the leakdown values. One finds uncontrolled blowby and there is really nothing one can do beyond replacement'.

I asked my engine builder and he said I read too much 'stuff' on the the internet so there is certainly difference of opinion out there.

I can understand the thinking behind the smaller wall thickness causing ovality in the cylinders but at the same time it's something I would love to do but not if it will cause me tears further down the road!!

Can I ask if you have an opinion on this and why you didn't just machine the case seeing as it was all apart anyway?

Thanks

#13

I know a few of their guys have PMNA experience, and it really showed through in the cars that I saw. It was OEM level of detail.

#14

Thread Starter

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Joined: Jul 2015

Posts: 4,290

Likes: 553

From: Huntington Beach, California

Here are pictures and a feature of BBi Project King Kong, our Shift-S3ctor air-strip race car

http://blog.powerblocktv.com/king-ko...turbo-porsche/

- Jerry@BBiAutosport.com

now this is more like it

now this is more like it