Distributor timing - off one tooth?

#16

Rennlist Member

Thread Starter

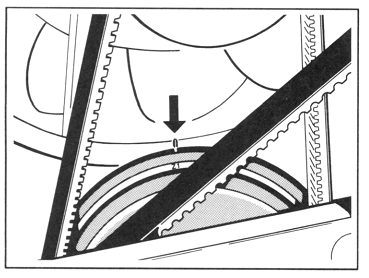

Pic of crank pulley with mark at TDC. Pic of primary distributor with rotor 30deg (1 tooth) past #1 (exactly in between #1 and #6)

The car runs with this set up.

When I rotated the distributor back one tooth, and the rotor pointing at the #1 mark, it would not run.

Like everyone else, I have installed distributors in all kinds of other engines (mostly older ones where the dist did everything), and timing the dist is pretty straightforward; but this one has me confused. And now I am obsessed with it.

Now for a theory - is it possible for the crank pulley to be installed 180 deg off? The dist is off by 30deg, which is 60deg crank position, or also 180deg crank position. I notice that the harmonic balancer (and pulley?) is bolted on - can this be rotated 180deg. If this was true, it would all fall into logic.

The car runs with this set up.

When I rotated the distributor back one tooth, and the rotor pointing at the #1 mark, it would not run.

Like everyone else, I have installed distributors in all kinds of other engines (mostly older ones where the dist did everything), and timing the dist is pretty straightforward; but this one has me confused. And now I am obsessed with it.

Now for a theory - is it possible for the crank pulley to be installed 180 deg off? The dist is off by 30deg, which is 60deg crank position, or also 180deg crank position. I notice that the harmonic balancer (and pulley?) is bolted on - can this be rotated 180deg. If this was true, it would all fall into logic.

#17

Instructor

Join Date: Oct 2003

Location: Maumelle, AR

Posts: 109

Likes: 0

Received 0 Likes

on

0 Posts

Is there a Z1 marking at this position just opposite of the timing mark on the pulley? There is glare in the pic and I can't see it. When you are at TDC, you should see the Z1 on the outside of the inner pulley aligned with the timing mark on the inside of the pulley. I don't know about the pulley being bolted on, I haven't had one apart that far to tell!

#18

Rennlist Member

Thread Starter

Is there a Z1 marking at this position just opposite of the timing mark on the pulley? There is glare in the pic and I can't see it. When you are at TDC, you should see the Z1 on the outside of the inner pulley aligned with the timing mark on the inside of the pulley. I don't know about the pulley being bolted on, I haven't had one apart that far to tell!

This is taking way too much energy - there has to be a simple answer to this. In the end, all I want to know is if this apparent misalignment is causing a performance issue.

(it also suggests that doing a valve adjustment is going to be difficult/strange).

#19

Nordschleife Master

Pull the top plug from cylinder number one .

With a coat hanger wire that is folded over , no raw end ,

feel the piston come up to the top of the stroke .

To make sure you are on the compression stroke ,

put your finger onto the empty spark plug hole .

If its on the compression stroke it will blow air passed your finger .

If its on the exhaust stroke , the exhaust valve will be open and no air will be blown past your finger .

Or if you want to get fancy ,

do a positive stop to find you "real" top dead center .

With a coat hanger wire that is folded over , no raw end ,

feel the piston come up to the top of the stroke .

To make sure you are on the compression stroke ,

put your finger onto the empty spark plug hole .

If its on the compression stroke it will blow air passed your finger .

If its on the exhaust stroke , the exhaust valve will be open and no air will be blown past your finger .

Or if you want to get fancy ,

do a positive stop to find you "real" top dead center .

#20

Addict

Rennlist Member

Rennlist Member

#21

Rennlist Member

there could be 3 things that could cause this.

1) whoever installed the belt on the distributor installed the gear 180 out. i believe it goes on a certain way but can be installed wrong.

2) someone removed the front pulley via the 10 or so small bolts instead of the large center one and installed it one hole off.

3) some one installed the front pulley and it sheared the dowel locating pin and the pulley is not in the right place on the crank, that is the purpose of the holding tool porsche makes to be used at the pulley side when tighting the nut, some argue its not needed.

i would find true top dead center as suggested and see if its on the pulley end and if its not i would go straight ot the gear on the distibutor.

1) whoever installed the belt on the distributor installed the gear 180 out. i believe it goes on a certain way but can be installed wrong.

2) someone removed the front pulley via the 10 or so small bolts instead of the large center one and installed it one hole off.

3) some one installed the front pulley and it sheared the dowel locating pin and the pulley is not in the right place on the crank, that is the purpose of the holding tool porsche makes to be used at the pulley side when tighting the nut, some argue its not needed.

i would find true top dead center as suggested and see if its on the pulley end and if its not i would go straight ot the gear on the distibutor.

#22

Rennlist Member

i left one out

4) someone removed the fan housing and its not installed correctly, it too has a locating dowel to position before the strap is tightened. the fan housing provides the timing reference mark that you are aligning the pulley Z1 to.

although this might not be the culprit this 4 things can lead to the problem your having.

4) someone removed the fan housing and its not installed correctly, it too has a locating dowel to position before the strap is tightened. the fan housing provides the timing reference mark that you are aligning the pulley Z1 to.

although this might not be the culprit this 4 things can lead to the problem your having.

#23

Racer

Join Date: May 2006

Location: Altamonte Springs, Florida

Posts: 423

Likes: 0

Received 0 Likes

on

0 Posts

Darrell, I recently had my engine out for gasket and clutch replacement. When I was adjusting the valves, I discovered the Z1 timing mark was not at #1 TDC. The pulley is attached to the hub by several bolts, it could have been installed any number of ways making the mark useless. The hub can only go on one way. I verified #1 TDC and re-instaled the pulley on the hub correctly. My Z1 mark is now correct. Before I removed the distributor, (after the valve adjustment and pully correction) the marks lined up correctly. Had I not had my engine out adjusting the valves, I may not have discovered it and would have been scratching my head when I tried to check the distributor timing.

#25

Rennlist Member

Thread Starter

Darrell, I recently had my engine out for gasket and clutch replacement. When I was adjusting the valves, I discovered the Z1 timing mark was not at #1 TDC. The pulley is attached to the hub by several bolts, it could have been installed any number of ways making the mark useless. The hub can only go on one way. I verified #1 TDC and re-instaled the pulley on the hub correctly. My Z1 mark is now correct. Before I removed the distributor, (after the valve adjustment and pully correction) the marks lined up correctly. Had I not had my engine out adjusting the valves, I may not have discovered it and would have been scratching my head when I tried to check the distributor timing.

I would have Really been scratching my head when trying to adjust the valves, or remove/install the distributor.

Will I be able to unbolt and re-install the pulley, without a full engine drop?

THANKS for everyone's suggestions

#26

Rennlist Member

yes you can, you will need to support rear of engine and remove the rear engine hangar ( black piece) . use some medium strenghth locktite , its blue in color when installing the 10 or so bolts, do not use the red high strenghth!

#27

Aren't there three marks on the pulley? Each 120 degrees apart?

Have you verified TDC by removing a spark plug on #1 and checking?

No offense intended, I'm just having trouble visualizing this issue.

Have you verified TDC by removing a spark plug on #1 and checking?

No offense intended, I'm just having trouble visualizing this issue.

#28

Nordschleife Master

The pully can only go on the crankshaft one way. There is a centering locating pin. Just have them reinsert the distributor in the correct orientation and you should be fine.

#29

Rennlist Member

Thread Starter

The pully can only go on the crankshaft one way. There is a centering locating pin. Just have them reinsert the distributor in the correct orientation and you should be fine.

Aren't there three marks on the pulley? Each 120 degrees apart?

Have you verified TDC by removing a spark plug on #1 and checking?

No offense intended, I'm just having trouble visualizing this issue.

Aren't there three marks on the pulley? Each 120 degrees apart?

Have you verified TDC by removing a spark plug on #1 and checking?

No offense intended, I'm just having trouble visualizing this issue.

No offense taken. I am trying to find a logical answer to this confusion.

The key bit of info here is that the car Runs in the current configuration.

I need to draw a picture.

There are 3 marks on the pulley, 120deg apart. Currently Z1 is at the bottom, pointing down, when the rotors point to #1. There is even a crude punch/chisel mark on the pulley that would correspond to TDC.

If I were to go by the Z1 mark at the top pointer, install the distributor with the rotors pointing to #1, I guarantee you that the car would Not run. The crank would be 180 degrees away from where it is now, and #1 would be at the bottom of the stroke. If another mark was used, the crank would be 60 degs off, and the car would not run (This is actually a scenario that I tried - moving the dist by one tooth=30deg dist rotation=60deg crank rotation, and the engine would not run)

Freds964's comments confirmed my suspicion that the pulley can be separated from the hub (the hub can go onto the crank only one way, per Fred and Geoffrey), and bolted back on in other positions. (I counted ten bolts with my fingers squeezed down there.)

The way that the pulley is mounted currently, None of the cylinders will be at TDC when any of the three pulley marks are pointing up. This would make valve adj impossible.

I am satisfied with the answer, per Freds964, that the pulley has been bolted back on incorrectly. The real question is - WHY?

This all started with my chasing down a lack of power increase when my dist belt was replaced. I am going to continue with that quest.

Let's close this discussion.

Unless, someone out there has an engine out of the car, wants to take a picture of the pulley and hub, remove the bolts, and show whether the pulley can be removed from the hub and rotated. Then we can close it.

Unless, someone out there has an engine out of the car, wants to take a picture of the pulley and hub, remove the bolts, and show whether the pulley can be removed from the hub and rotated. Then we can close it.

#30

Nordschleife Master

If I were in your place , I would not pull anything apart .

I would put the marks onto the pulley .

One red dot for TDC on cylinder #1

Two red dots that are list to the left and right of the marker at 120 .

Three red dots at 240 .

I would put the marks onto the pulley .

One red dot for TDC on cylinder #1

Two red dots that are list to the left and right of the marker at 120 .

Three red dots at 240 .