CV joint disassembly tips please!

#17

Technical Guru

Rennlist Member

Rennlist Member

Autozone rents a 5-ton puller (the arms on the 2-ton are too short) for a $40USD (fully refundable) deposit. On a lot of driveshafts the joint won't just pop off the shaft so the alternative is wacking it with a hammer which can damage the outer bearing cage. The Autozone band-it jr. clamp strap compressor is useless so you might need new clamps in addition to the boots ($4USD at EBSRacing, part #POR052856) and 16oz of grease (Swepco - $9USD, Optimoly NR - $16USD, Krytox GPL-217 - $200USD).

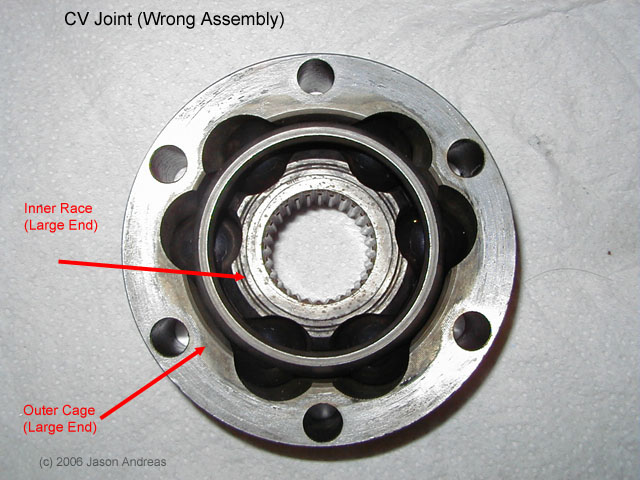

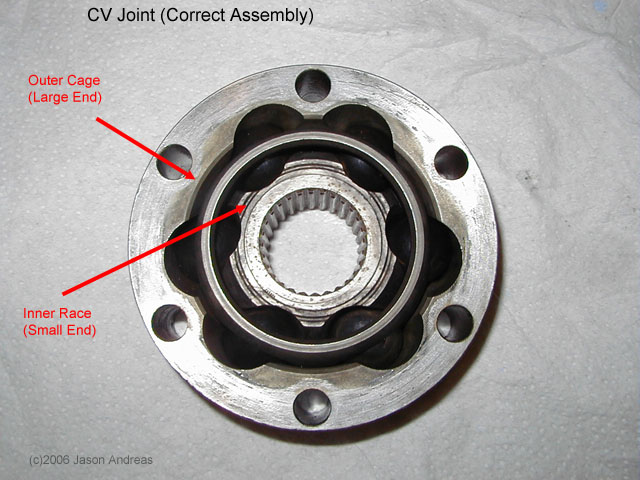

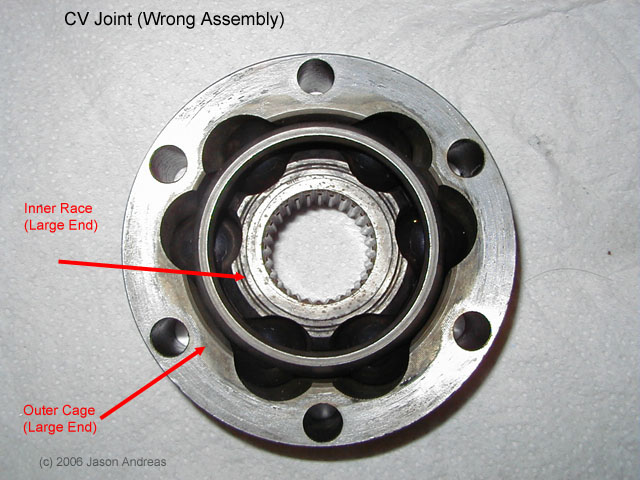

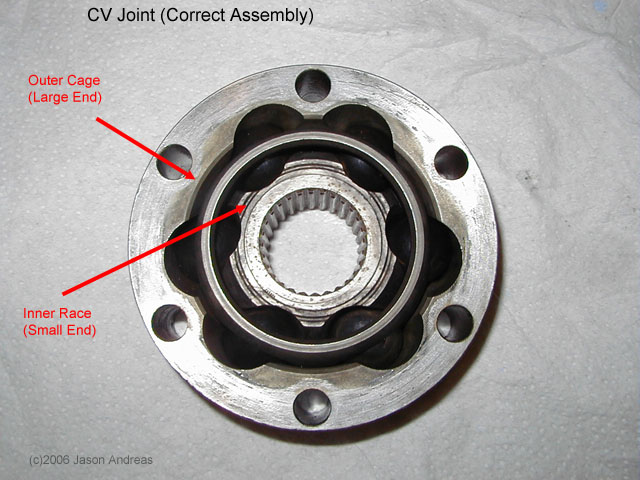

If you completely disassemble the CV joint (not necessary) for cleaning

than there are two ways to put it back together. The easy way:

and the slightly more difficult way:

And when it comes to reassembly (before you put the inner race back onto the driveshaft) you must lube the driveshaft spline with Optimoly HT (copper grease). The threaded portion of the CV joint bolts should also be lubed but don't get anything on the flange cover. The torque spec for the driveshaft panhead screws of size (M8) are 42 Nm (31 ft.lb) or for (M10) 80 Nm (59 ft.lb).

If you completely disassemble the CV joint (not necessary) for cleaning

than there are two ways to put it back together. The easy way:

and the slightly more difficult way:

And when it comes to reassembly (before you put the inner race back onto the driveshaft) you must lube the driveshaft spline with Optimoly HT (copper grease). The threaded portion of the CV joint bolts should also be lubed but don't get anything on the flange cover. The torque spec for the driveshaft panhead screws of size (M8) are 42 Nm (31 ft.lb) or for (M10) 80 Nm (59 ft.lb).

Last edited by JasonAndreas; 11-06-2006 at 03:35 AM. Reason: autozone band-it clamp compressor is too large

#19

Drifting

I followed this DIY this weekend, things went well, but I have a few additional tips:

1) I needed the puller for sure. You might want to go get one ahead of time per Jason's advice/pics.

2) As Garrett points out, there is no need to take off both sides of the drive shaft, just go ahead and do the inboard side. Don't even mess with the wheel nut if you don't have to.

3) When you have the CV joint off the transmission, it's hard to understand how to get the 'cap' off the back of the CV joint so you can see the grease inside the joint. The trick was to put a blunt-end screwdriver against the lip, then just 'pop' it once with a mallet. It's just pushed on once you have the CV off the car.

4) This is a messy mucky job. Gloves, floor covering, coveralls, you will need them all. This is not that hard of a procedure, just take your time.

5) I had zip-ties holding my boots on except for one side. I checked them, and I believe that zip-ties will be OK for holding on the boots. They seemed more secure to me than the metal straps frankly. So I used them on re-install. Your mileage may vary.

1) I needed the puller for sure. You might want to go get one ahead of time per Jason's advice/pics.

2) As Garrett points out, there is no need to take off both sides of the drive shaft, just go ahead and do the inboard side. Don't even mess with the wheel nut if you don't have to.

3) When you have the CV joint off the transmission, it's hard to understand how to get the 'cap' off the back of the CV joint so you can see the grease inside the joint. The trick was to put a blunt-end screwdriver against the lip, then just 'pop' it once with a mallet. It's just pushed on once you have the CV off the car.

4) This is a messy mucky job. Gloves, floor covering, coveralls, you will need them all. This is not that hard of a procedure, just take your time.

5) I had zip-ties holding my boots on except for one side. I checked them, and I believe that zip-ties will be OK for holding on the boots. They seemed more secure to me than the metal straps frankly. So I used them on re-install. Your mileage may vary.

#20

Drifting

I am laughing out loud. I couldn't remember how to get the cap off the transmission side of the CV joint, and I searched, and then found all this, and at the end, was my own post! hahaha.

#24

I've just been told I have a split gaiter on the rear driveshaft (outer, by the wheel). But unless I've misunderstood, it looks like I may need a puller - and I don't have one, so it looks like it's probably a job for a mechanic?

#25

Addict

Rennlist Member

Rennlist Member

When you re-assemble after doing this, how do you secure the boot to the axle shaft? Do you use a zip tie only or does the metal band clamp function well enough once it is forced back on...?

The stock grease doesn't last long for track use (it can liquify in as few as 3 hours of track time - ask me how I know). The recommended grease, based on a post in the Racing forum, is Neo which is available from HRP Racing. Krytox is excellent stuff but extremely toxic when it's very hot (the fumes).

The stock grease doesn't last long for track use (it can liquify in as few as 3 hours of track time - ask me how I know). The recommended grease, based on a post in the Racing forum, is Neo which is available from HRP Racing. Krytox is excellent stuff but extremely toxic when it's very hot (the fumes).

#26

Three Wheelin'

Join Date: Jul 2007

Location: Helotes, TX

Posts: 1,307

Likes: 0

Received 0 Likes

on

0 Posts

Let me know when you find that torque wrench with the 339 ft lbs reading. Meanwhile do what another Rennlister suggested: One 169 1/2 lb man standing on the end of a 2 ft long breaker bar = 339 ft lbs

Helpful Hint: I'm getting ready to replace the two right side boots as the outer on my '88 911 Targa has a slit in it. Today I broke two tools trying to break the stub axle nut loose. Then my buddy suggested applying heat to the nut and axle. After heating the pair sufficiently, the nut came off with a breaker bar with no problem. That's the helpful hint. Now I have to figure out how to retorque the thing to 339 ft-lb when I reassemble it!!!

#27

When I used the cheater bar I lowered my full weight down onto it without jumping and trying not to introduce too much dynamic loading. I guess I got lucky!

#28

Rennlist Member

Join Date: May 2007

Location: Highland Park, IL (Chicagoland)

Posts: 1,019

Likes: 0

Received 0 Likes

on

0 Posts

#29

Rennlist Member

Join Date: May 2007

Location: Highland Park, IL (Chicagoland)

Posts: 1,019

Likes: 0

Received 0 Likes

on

0 Posts

If you are incline are to DIY, you should buy a puller. They cost less than an hour of shop time. You can do the repair without removing the wheel nut but you will have to remove both CV joints. Go ahead and plan on replacing both boots (gaiters) if you go that route. They are easy to rip when removing.

#30

OK, I might give it a go.

The only thing that makes me hesitate is that although there are useful pics in this thread, it still didn't make it obvious to me quite what I should be removing.

I can actually do most car things if I put my mind to it, but I've never tried removing a drive shaft before.

The only thing that makes me hesitate is that although there are useful pics in this thread, it still didn't make it obvious to me quite what I should be removing.

I can actually do most car things if I put my mind to it, but I've never tried removing a drive shaft before.