87 951 VEMS Install

#256

Three Wheelin'

I have had same issue since I got VEMS. Usually by second or 3rd start it runs properly. I am wondering if it's either voltage related or maybe sensor gap on speed and ref sensors. Car runs great when it clicks over and is clean. I have 3 br, FPR, 80lb injectors, reasonably new fuel filter, so doubtful it is fuel delivery. I have also removed ICV now, no change, although car idels properly when I get clean start. Nothing I have done has made any difference so have just got used to having to start it a few timees. Very annoying considering how well it runs when its running cleanly

Same thing for the power side; check for voltage drops at all of the junction points from the battery (starter, bellhousing, alternator, etc). Make sure the sensors are getting a full 5V reference.

Surprised to know that someone else with the same issue. What have you done so far to correct issue?I thought about speed reference sensor gap and quality. Then interference and kickback comes to mind. Did you notch the bell housing by any chance or have the older type speed reference sensor bracket without the updated sleeve?I've notch my bell housing when I rebuild my motor a few years back and believe I have the bracket without sleeve.

#258

Three Wheelin'

You might be confusing the fact that jumpering the connector in the engine compartment is no longer used to set base idle---you have to use the VEMS software to deactivate the ISV to do that.

#259

Three Wheelin'

It's not using idle contact in factory TPS, only uses variable resistance part of the TPS (3 pins).

Regarding starting or not, you should observe/log the injector pw when idling and then adjust cranking enrichment and/or starting VE so that it is close to what engine likes when idling. Obviously something is off when it does not want to start, you should check the injector pw then also.

Regarding starting or not, you should observe/log the injector pw when idling and then adjust cranking enrichment and/or starting VE so that it is close to what engine likes when idling. Obviously something is off when it does not want to start, you should check the injector pw then also.

#261

Rennlist Member

I have no idea about the VEMS but always wondered if the separate switch was simply a function of limited processing power in the old 8051-driven DME's. With ample processing power, how hard would it be to set a flag in software when the pot reaches the idle area?

#262

Racer

Thread Starter

Thatís what VEMS does, when itís at 0% throttle itís in idle mode, and will show the Idle indication. Doesnít need a separate switch to tell it that after the TPS is calibrated.

#263

Rennlist Member

I was able to get my low speed and cruize semi dialed in with autotune. As of now I'm not able to decipher how to set up the ebc config in VEMS. If someone could provide a screenshot of their settings I would greatly appreciate it. I plan on running about 16psi. So for now I plan on using a MBC. Also wondering how you guys are using autotune to set fueling under boost? Autotune requires that the cell being tuned remain constant for about ~2 sec. Thanks for the help.

#264

Racer

Thread Starter

If using MBC then it doesnít matter what EBC settings are in VEMS since it wonít be doing anything. Auto tune in boost you just need to drive it a bunch, after itís got enough samples for a given cell it will make a change. Doesnít need to be continuous time in the Cel, just over time total in Cel.

#266

Three Wheelin'

I was able to get my low speed and cruize semi dialed in with autotune. As of now I'm not able to decipher how to set up the ebc config in VEMS. If someone could provide a screenshot of their settings I would greatly appreciate it. I plan on running about 16psi. So for now I plan on using a MBC. Also wondering how you guys are using autotune to set fueling under boost? Autotune requires that the cell being tuned remain constant for about ~2 sec. Thanks for the help.

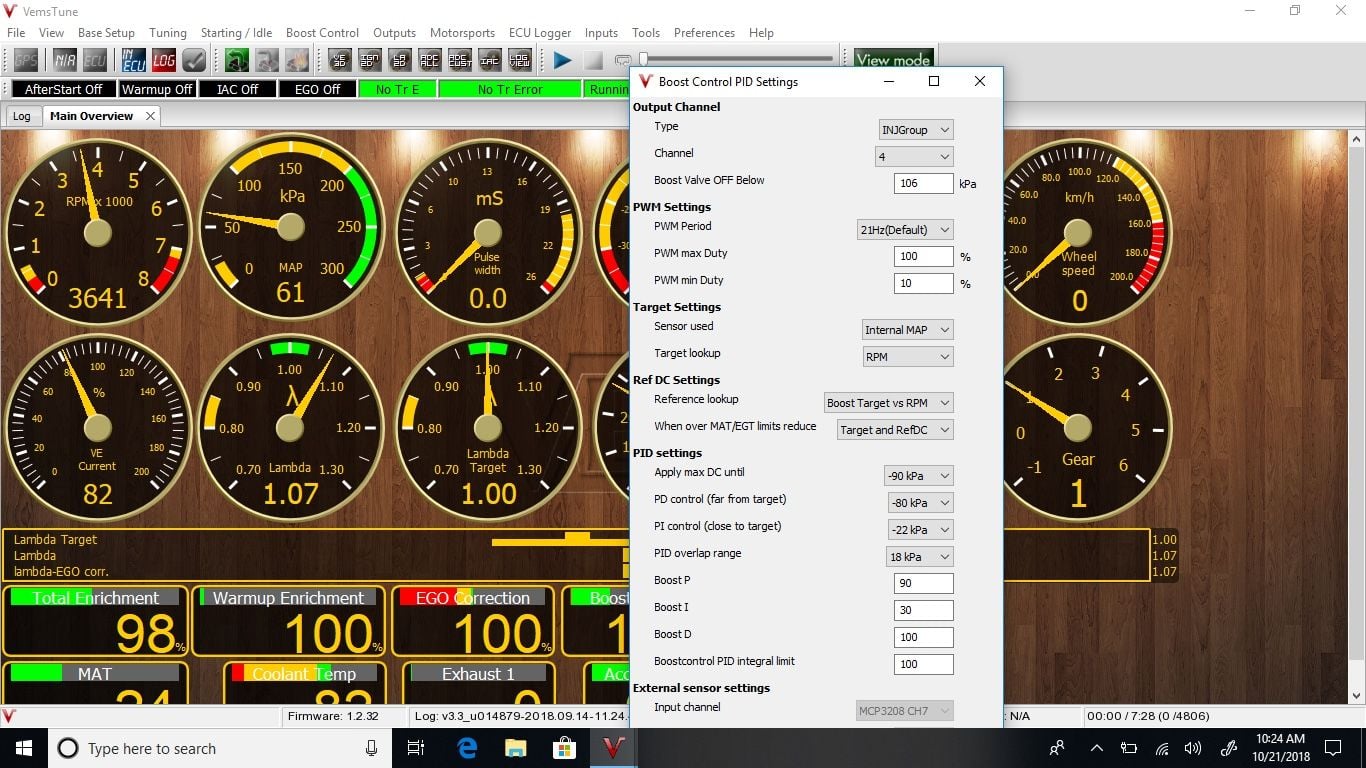

My VEMS wasn't configured correctly for EBC when I first got it. Peep changed it for me after I sent a config file to him. Use the factory cycling valve wires, and in the "output channels" menu of VEMStune, set the boost control channel to "Injector output 4 (7A) Grounding, InjGroup." Then set your boost curve how you want it. The PID boost control works great.

Let me know if you need advice about plumbing the boost control solenoid (I assume you have a dual-port wastegate).

#267

Rennlist Member

For EBC, you will need to install an aftermarket boost control solenoid like this (factory cycling valve won't work):

https://www.amazon.com/MAC-35A-AAA-D.../dp/B00YBN3DRO

My VEMS wasn't configured correctly for EBC when I first got it. Peep changed it for me after I sent a config file to him. Use the factory cycling valve wires, and in the "output channels" menu of VEMStune, set the boost control channel to "Injector output 4 (7A) Grounding, InjGroup." Then set your boost curve how you want it. The PID boost control works great.

Let me know if you need advice about plumbing the boost control solenoid (I assume you have a dual-port wastegate).

https://www.amazon.com/MAC-35A-AAA-D.../dp/B00YBN3DRO

My VEMS wasn't configured correctly for EBC when I first got it. Peep changed it for me after I sent a config file to him. Use the factory cycling valve wires, and in the "output channels" menu of VEMStune, set the boost control channel to "Injector output 4 (7A) Grounding, InjGroup." Then set your boost curve how you want it. The PID boost control works great.

Let me know if you need advice about plumbing the boost control solenoid (I assume you have a dual-port wastegate).

#268

Three Wheelin'

Here ya go. Make sure you change the boost control output setting to injector output 4 as I posted above.

Then set your boost control target vs RPM table and have fun! The PID boost control quickly learns the optimum boost curve.

#269

Rennlist Member

Had to put off messing around with the car today, found a screw in the work truck tire. Heading out to see the Thunderbirds off the coast of Huntington Beach

#270

Rennlist Member

It's not using idle contact in factory TPS, only uses variable resistance part of the TPS (3 pins).

Regarding starting or not, you should observe/log the injector pw when idling and then adjust cranking enrichment and/or starting VE so that it is close to what engine likes when idling. Obviously something is off when it does not want to start, you should check the injector pw then also.

Regarding starting or not, you should observe/log the injector pw when idling and then adjust cranking enrichment and/or starting VE so that it is close to what engine likes when idling. Obviously something is off when it does not want to start, you should check the injector pw then also.

My car runs great, when it gets a good start But it takes a few cranks to get that good start. If I run the car on a bad start, it seems like it's running lean. Please see video I posted will try and get better videos of problem. Another person is also experiencing the same exact problem as me.