rpm specific fuel cut

#46

#47

Drifting

#49

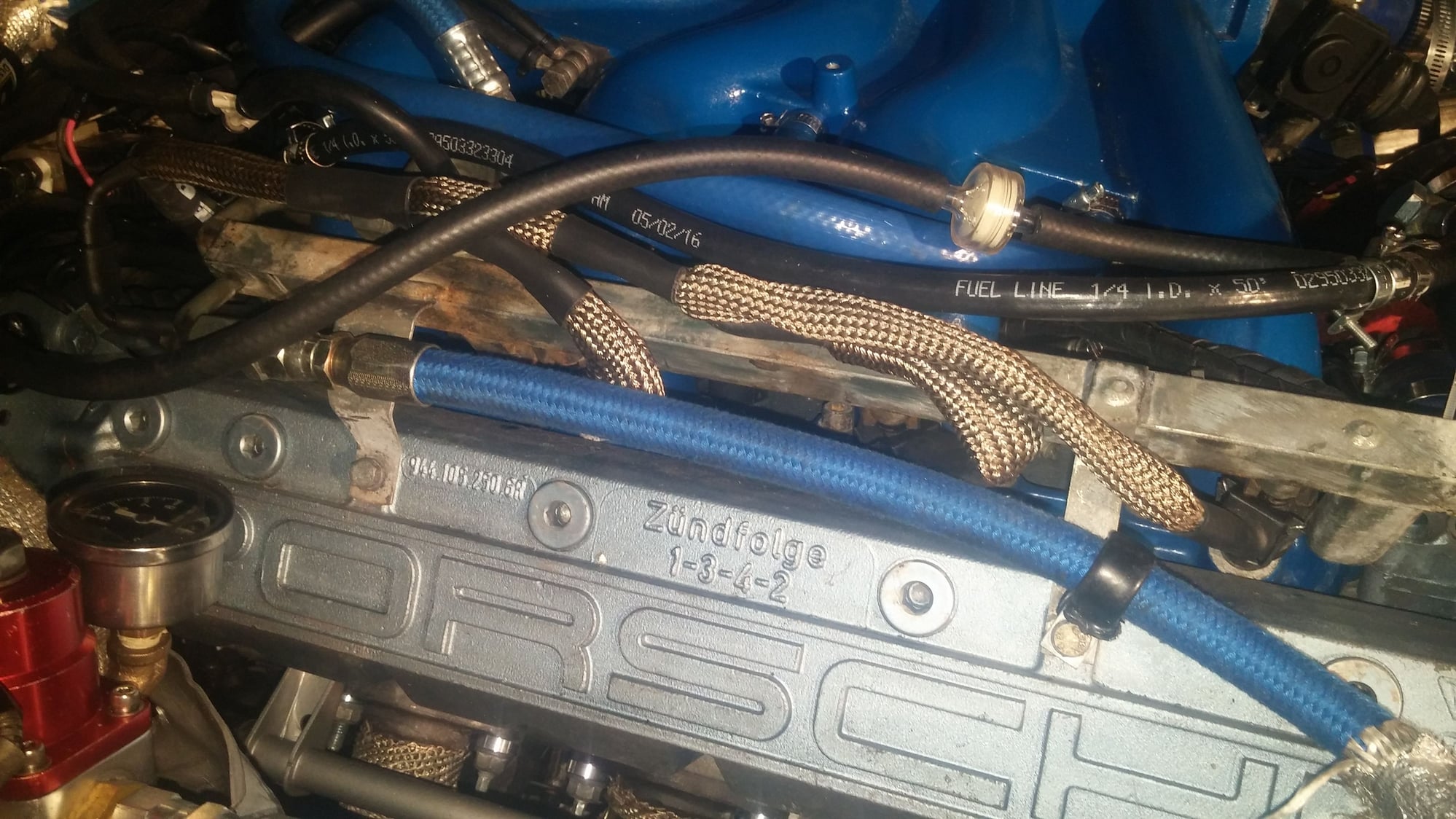

Managed to go for test drive with refurbished plug wires.

Seems to run a little better, but still having same symptom, going lean, hitting brief flat spot between 2500 and 3000rpm. Im wondering if my alternator is causing issues. I know maf is very sensitive to voltage. When im running lights and blower belt squeals and when fans kick on voltage drops briefly causing afrs to go low/high. Belt is new and very very tight but still wants to slip under load even with belt dressing.

Also checked out dme connector it looks like injector connectors, exposed and corroded. So I ordered all of the connectors to do the temperature connector and reference sensors knock sensor idle valve and TPS. I'm also going to remove as much as the heat shrink as I can to inspect the wires and rewrap.

Yes I cleaned my grounds

May be excuse to do quest alternator.

I should be getting new plug wires and sensor connectors soon as well as injector resistors.

Also opened klr, it all looks good.

#50

Drifting

Ok now change your distributor cap/rotor and spark plugs, fuel filter, air filter. Basically tune up your car then if the problem still exist then start digging into other items. Change your oil while your at it. And check your DME coolant temp sensor and IAT sensor to see if there in range.

#51

Ok now change your distributor cap/rotor and spark plugs, fuel filter, air filter. Basically tune up your car then if the problem still exist then start digging into other items. Change your oil while your at it. And check your DME coolant temp sensor and IAT sensor to see if there in range.

#52

Rennlist Member

Update

Managed to go for test drive with refurbished plug wires.

Seems to run a little better, but still having same symptom, going lean, hitting brief flat spot between 2500 and 3000rpm. Im wondering if my alternator is causing issues. I know maf is very sensitive to voltage. When im running lights and blower belt squeals and when fans kick on voltage drops briefly causing afrs to go low/high. Belt is new and very very tight but still wants to slip under load even with belt dressing.

Also checked out dme connector it looks like injector connectors, exposed and corroded. So I ordered all of the connectors to do the temperature connector and reference sensors knock sensor idle valve and TPS. I'm also going to remove as much as the heat shrink as I can to inspect the wires and rewrap.

Yes I cleaned my grounds

May be excuse to do quest alternator.

I should be getting new plug wires and sensor connectors soon as well as injector resistors.

Also opened klr, it all looks good.

Managed to go for test drive with refurbished plug wires.

Seems to run a little better, but still having same symptom, going lean, hitting brief flat spot between 2500 and 3000rpm. Im wondering if my alternator is causing issues. I know maf is very sensitive to voltage. When im running lights and blower belt squeals and when fans kick on voltage drops briefly causing afrs to go low/high. Belt is new and very very tight but still wants to slip under load even with belt dressing.

Also checked out dme connector it looks like injector connectors, exposed and corroded. So I ordered all of the connectors to do the temperature connector and reference sensors knock sensor idle valve and TPS. I'm also going to remove as much as the heat shrink as I can to inspect the wires and rewrap.

Yes I cleaned my grounds

May be excuse to do quest alternator.

I should be getting new plug wires and sensor connectors soon as well as injector resistors.

Also opened klr, it all looks good.

Checking the harness connectors and heat-shrunk connections is definitely time well spent too.

If the starter motor cranks strong without needing to be externally charged, your charging system is not a likely cause of this issue.

#53

What is a refurbished spark plug wire? I'd get brand new, right out of the box, wires before chasing other things -- especially if wrapping them in electrical tape or whatever seemed to help a little. It's money well spent whether or not the cause of your current issue.

Checking the harness connectors and heat-shrunk connections is definitely time well spent too.

If the starter motor cranks strong without needing to be externally charged, your charging system is not a likely cause of this issue.

Checking the harness connectors and heat-shrunk connections is definitely time well spent too.

If the starter motor cranks strong without needing to be externally charged, your charging system is not a likely cause of this issue.

#54

12 volt on one side 10 on other for all 4

Should i be getting any continuity between injectors 1/2 and 3/4? Are signal and ground wires seperated for the pairs do they share a common anything? I read somewhere on here someone had same voltage readings i think he had wires grounded out inside the snorkel boot