968 Oil Squirters Part Number?

#46

Nordschleife Master

25 years in the automatic transmission business, servicing everything from government contract, police all the way to Fire Trucks, school buses, etc. to 8 second 1/4 drag race stuff and the normal public in between. Cooling can help keep viscosity on thrust components and keep plastic washers from melting ( ) but does little holding force of clamped clutch discs that I can bend with 2 fingers laid over the edge of a table.LOL, the clutch material is probably held onto a steel based spline disc with adhesive like most other automatics.....

) but does little holding force of clamped clutch discs that I can bend with 2 fingers laid over the edge of a table.LOL, the clutch material is probably held onto a steel based spline disc with adhesive like most other automatics.....

) but does little holding force of clamped clutch discs that I can bend with 2 fingers laid over the edge of a table.LOL, the clutch material is probably held onto a steel based spline disc with adhesive like most other automatics.....

) but does little holding force of clamped clutch discs that I can bend with 2 fingers laid over the edge of a table.LOL, the clutch material is probably held onto a steel based spline disc with adhesive like most other automatics.....

#47

Race Car

MmKay, I got nothing better going on at the moment.

Up until the introduction of electronic pressure control, which is pulse width modulation of the pump's output after the already mechanically limited spool valve vs spring pressure in hydraulic circuitry, cars pre-1995 were using a "TV Cable" which manipulated throttle pressure in direct correlation to throttle bellcrank operation and/or vacuum modulators that increased line pressure linked in much the same way, to increase transmission clamping pressure when vacuum was less, meaning, more open throttle.

This is how antiquated things were before the ability to control everything via electronics.

This is why an ECU reflash can change shift point, increase line pressure etc on modern vehicles.

Before that, you are limited to the intended design and just like in modern times, in the past, requiring the pump to make unnecessary pressure output for part throttle and idle duty is a waste of power and fuel so even back in the analog days where centrifugal governors were used, your clamping force on any given clutch pack is manipulated to be limited to only the pressure required.

So, if you go from 200hp/200trq at 3/4 throttle to 400hp/400trq without the ability to electronically change the curve at which pressure increases proportional to throttle, you are stuck with the original design's pressure output per throttle opening.

What it boils down to from there is square inch surface area of the clutch frictions and the pressure applied to them to clamp to a theoretical direct drive, discounting the fluid coupling slippage of the torque converter.

Could there have been a 300% headroom built into a 928 automatic that allows it to withstand 3x the original design parameters of 300hp/300trq...?

I guess it's possible but by the looks of the internal components, the clutch frictions (not to mention that breakthroughs in disc material since 1995 like "high energy" frictions) have 1/2 the surface area of modern transmission that have friction discs 2 and 3 times larger in surface area and are finely controlled with, by 1995 comparison, guided missile technology.

You have no idea wither you have a decouple from direct drive clamping of you fwd drive disc.

The only way for you to tell data wise is to know what the input speed is vs the output shaft.

Next time you dyno, if the 928 allows (would usually be a dipstick tube on conventional unit), remove the filler cap and look for smoke puffing out of it.

Other than that, if you add a known quantifiable power increase from where you are now, say 2 more psi boost should equal xx gain on dyno, and you see nothing or less than expected, it's a sure bet that you have internal slippage.

Modern cars would recognize this and default to a single range like 3rd gear and inhibit automatic shifting until either the error is cleared or a repair is made.

It's self preservation software to protect the manufacturer from eating catastrophic failure warranty.

If modern, way more advanced automatics have the ability to discriminate a 2-300rpm input/output slippage, what do you think the chances are that an early 90s cable/vacuum pressure regulated automatic isn't experiencing component slippage at 300% past it's design parameters...?

This is my field.

I was a child prodigy and was a fully certified transmission master tech through General Motors at age 21.

Repaired and improved nearly every automatic known to man in the space of 25 years post dealer.

T

Up until the introduction of electronic pressure control, which is pulse width modulation of the pump's output after the already mechanically limited spool valve vs spring pressure in hydraulic circuitry, cars pre-1995 were using a "TV Cable" which manipulated throttle pressure in direct correlation to throttle bellcrank operation and/or vacuum modulators that increased line pressure linked in much the same way, to increase transmission clamping pressure when vacuum was less, meaning, more open throttle.

This is how antiquated things were before the ability to control everything via electronics.

This is why an ECU reflash can change shift point, increase line pressure etc on modern vehicles.

Before that, you are limited to the intended design and just like in modern times, in the past, requiring the pump to make unnecessary pressure output for part throttle and idle duty is a waste of power and fuel so even back in the analog days where centrifugal governors were used, your clamping force on any given clutch pack is manipulated to be limited to only the pressure required.

So, if you go from 200hp/200trq at 3/4 throttle to 400hp/400trq without the ability to electronically change the curve at which pressure increases proportional to throttle, you are stuck with the original design's pressure output per throttle opening.

What it boils down to from there is square inch surface area of the clutch frictions and the pressure applied to them to clamp to a theoretical direct drive, discounting the fluid coupling slippage of the torque converter.

Could there have been a 300% headroom built into a 928 automatic that allows it to withstand 3x the original design parameters of 300hp/300trq...?

I guess it's possible but by the looks of the internal components, the clutch frictions (not to mention that breakthroughs in disc material since 1995 like "high energy" frictions) have 1/2 the surface area of modern transmission that have friction discs 2 and 3 times larger in surface area and are finely controlled with, by 1995 comparison, guided missile technology.

You have no idea wither you have a decouple from direct drive clamping of you fwd drive disc.

The only way for you to tell data wise is to know what the input speed is vs the output shaft.

Next time you dyno, if the 928 allows (would usually be a dipstick tube on conventional unit), remove the filler cap and look for smoke puffing out of it.

Other than that, if you add a known quantifiable power increase from where you are now, say 2 more psi boost should equal xx gain on dyno, and you see nothing or less than expected, it's a sure bet that you have internal slippage.

Modern cars would recognize this and default to a single range like 3rd gear and inhibit automatic shifting until either the error is cleared or a repair is made.

It's self preservation software to protect the manufacturer from eating catastrophic failure warranty.

If modern, way more advanced automatics have the ability to discriminate a 2-300rpm input/output slippage, what do you think the chances are that an early 90s cable/vacuum pressure regulated automatic isn't experiencing component slippage at 300% past it's design parameters...?

This is my field.

I was a child prodigy and was a fully certified transmission master tech through General Motors at age 21.

Repaired and improved nearly every automatic known to man in the space of 25 years post dealer.

T

#49

Nordschleife Master

The about 1000 rwhp turbo-nitrous-E85 928 S4 on racing tires has the S4 automatic transmission that was originally made by Daimler for Porsche. He's been in it, but not because of reliability. He wanted to change the stall speed, I've understood. It is in my opinion possible that Daimler's transmission is sized 3x the 928 torque, if the cooling needs are met.

I've studied a little bit about engines over the last years, but know next to nothing about automatic transmissions.

#50

Race Car

I've got a manual transmission and foot operated clutch in a street car with street tires. I haven't broken anything yet, but have a spare tranny in the garage. The clutch is aftermarket unit with 750 lbf-ft torque limit, so that probably needs to be upgraded at some point. Frankly, I don't know where it will break on street, there's a good chance that street tires will keep it healthy.

The about 1000 rwhp turbo-nitrous-E85 928 S4 on racing tires has the S4 automatic transmission that was originally made by Daimler for Porsche. He's been in it, but not because of reliability. He wanted to change the stall speed, I've understood. It is in my opinion possible that Daimler's transmission is sized 3x the 928 torque, if the cooling needs are met.

I've studied a little bit about engines over the last years, but know next to nothing about automatic transmissions.

The about 1000 rwhp turbo-nitrous-E85 928 S4 on racing tires has the S4 automatic transmission that was originally made by Daimler for Porsche. He's been in it, but not because of reliability. He wanted to change the stall speed, I've understood. It is in my opinion possible that Daimler's transmission is sized 3x the 928 torque, if the cooling needs are met.

I've studied a little bit about engines over the last years, but know next to nothing about automatic transmissions.

T

#51

Nordschleife Master

Plus the number of actually truly 500 hp 928 motors that are driven on track is very small, a factor to take into account when searching the Internet.

#52

Race Car

My opinion (not a fact) is that this limit is possibly the case if the car doesnít have additional transmission cooling and is driven on track with slicks. If you add cooling and donít drive to minimize the lap time, I believe itíll hold a lot more. The transmission doesnít like the rear slicks catching air, picking up rpm, and landing hard to instant deceleration.

Plus the number of actually truly 500 hp 928 motors that are driven on track is very small, a factor to take into account when searching the Internet.

) but for the life of me, I can't understand why anyone wants/needs a street car on slippery tires @ 700 lbft of torque.

) but for the life of me, I can't understand why anyone wants/needs a street car on slippery tires @ 700 lbft of torque.I'm sure you have your goals and reasons though.

We used to run across Abby Short and his 928 from time to time around a few tracks in the south but hadn't seen him in a while.

That thing's sound was so distinctive and loud I'm almost certain I could see the leaves on the trackside trees wilt as he went by....

T

#54

Nordschleife Master

#55

Rennlist Member

The correct PN for 968 squirters is 944-101-018-01. They probably need to come from Germany, but they are available. If installed properly they will NOT cause an OP loss since there will be no significant leak in the oil system. I use an old 968 block to set up the mill at the correct angle and position. Once set up, the machining is simple. Porsche installs the squirters with a sealant to ensure no leakage around the squirters.

Like other modifications, it's all in proper application and accurate machining.

Like other modifications, it's all in proper application and accurate machining.

#56

Nordschleife Master

The correct PN for 968 squirters is 944-101-018-01. They probably need to come from Germany, but they are available. If installed properly they will NOT cause an OP loss since there will be no significant leak in the oil system. I use an old 968 block to set up the mill at the correct angle and position. Once set up, the machining is simple. Porsche installs the squirters with a sealant to ensure no leakage around the squirters. Like other modifications, it's all in proper application and accurate machining.

#57

Rennlist Member

I know little about a 928 V8. Logic asks why wouldn't you use the early 928 squirters since they were designed for that engine? If the stroke is the same as your S4 engine, the squirter placement should be the same. The bore is not nearly as relevant.

#58

Nordschleife Master

I don't think the early 1987 928 S4 oil squirters are available. The closest thing to those that's available is 944 101 018 01, I think.

#59

Rennlist Member

I stopped looking at the 928 engine once I determined it wouldn't fit between the strut towers on my race car. But since it's the big brother to the 944 series, I can offer what I know about high RPM. I ran my own cars to 8000 and ran wet sump engines to 7600 on the dyno.

You have indicated you will reduce piston weight which suggests a good set of custom pistons designed for a boosted application. The crown on these will be thicker than a NA piston, and will tolerate more heat. Further, they'll easily be much lighter than your factory slugs. You didn't mention connecting rods. The Porsche rods are way too soft for a high RPM application. They will deform at the big end at TDC and even BDC and squeeze out the oil cushion. What follows is rod bearing failure and then a broken rod due to heat generated. You'll need a more durable rod bearing too.

The other consideration is moving your power band up so the extra 1000 RPM is useful. I haven't seen your dyno sheets, but you'll likely need more duration on both I and E lobes. If you're using hydraulic lifters I know they are okay to very close to your RPM goal. What are your valve sizes? Increasing at least the intake diameter will increase intake flow, and you can go a little bigger on the exhaust too. Is your head ported? Find a cylinder head guy that really knows these heads, not the guy that tells you he does. Beware of head work that hurts the power, or doesn't provide any gains.

Don't order pistons until your valve diameters are finalized. Further, your dish should allow a quench area.

Don't forget the exhaust. If your allowing more air in, you have to allow it to get out.

I can add detail to my comments via PM if you want.

MM

You have indicated you will reduce piston weight which suggests a good set of custom pistons designed for a boosted application. The crown on these will be thicker than a NA piston, and will tolerate more heat. Further, they'll easily be much lighter than your factory slugs. You didn't mention connecting rods. The Porsche rods are way too soft for a high RPM application. They will deform at the big end at TDC and even BDC and squeeze out the oil cushion. What follows is rod bearing failure and then a broken rod due to heat generated. You'll need a more durable rod bearing too.

The other consideration is moving your power band up so the extra 1000 RPM is useful. I haven't seen your dyno sheets, but you'll likely need more duration on both I and E lobes. If you're using hydraulic lifters I know they are okay to very close to your RPM goal. What are your valve sizes? Increasing at least the intake diameter will increase intake flow, and you can go a little bigger on the exhaust too. Is your head ported? Find a cylinder head guy that really knows these heads, not the guy that tells you he does. Beware of head work that hurts the power, or doesn't provide any gains.

Don't order pistons until your valve diameters are finalized. Further, your dish should allow a quench area.

Don't forget the exhaust. If your allowing more air in, you have to allow it to get out.

I can add detail to my comments via PM if you want.

MM

#60

Nordschleife Master

I stopped looking at the 928 engine once I determined it wouldn't fit between the strut towers on my race car. But since it's the big brother to the 944 series, I can offer what I know about high RPM. I ran my own cars to 8000 and ran wet sump engines to 7600 on the dyno.

You have indicated you will reduce piston weight which suggests a good set of custom pistons designed for a boosted application. The crown on these will be thicker than a NA piston, and will tolerate more heat. Further, they'll easily be much lighter than your factory slugs. You didn't mention connecting rods. The Porsche rods are way too soft for a high RPM application. They will deform at the big end at TDC and even BDC and squeeze out the oil cushion. What follows is rod bearing failure and then a broken rod due to heat generated. You'll need a more durable rod bearing too.

The other consideration is moving your power band up so the extra 1000 RPM is useful. I haven't seen your dyno sheets, but you'll likely need more duration on both I and E lobes. If you're using hydraulic lifters I know they are okay to very close to your RPM goal. What are your valve sizes? Increasing at least the intake diameter will increase intake flow, and you can go a little bigger on the exhaust too. Is your head ported? Find a cylinder head guy that really knows these heads, not the guy that tells you he does. Beware of head work that hurts the power, or doesn't provide any gains.

Don't order pistons until your valve diameters are finalized. Further, your dish should allow a quench area.

Don't forget the exhaust. If your allowing more air in, you have to allow it to get out.

I can add detail to my comments via PM if you want.

MM

You have indicated you will reduce piston weight which suggests a good set of custom pistons designed for a boosted application. The crown on these will be thicker than a NA piston, and will tolerate more heat. Further, they'll easily be much lighter than your factory slugs. You didn't mention connecting rods. The Porsche rods are way too soft for a high RPM application. They will deform at the big end at TDC and even BDC and squeeze out the oil cushion. What follows is rod bearing failure and then a broken rod due to heat generated. You'll need a more durable rod bearing too.

The other consideration is moving your power band up so the extra 1000 RPM is useful. I haven't seen your dyno sheets, but you'll likely need more duration on both I and E lobes. If you're using hydraulic lifters I know they are okay to very close to your RPM goal. What are your valve sizes? Increasing at least the intake diameter will increase intake flow, and you can go a little bigger on the exhaust too. Is your head ported? Find a cylinder head guy that really knows these heads, not the guy that tells you he does. Beware of head work that hurts the power, or doesn't provide any gains.

Don't order pistons until your valve diameters are finalized. Further, your dish should allow a quench area.

Don't forget the exhaust. If your allowing more air in, you have to allow it to get out.

I can add detail to my comments via PM if you want.

MM

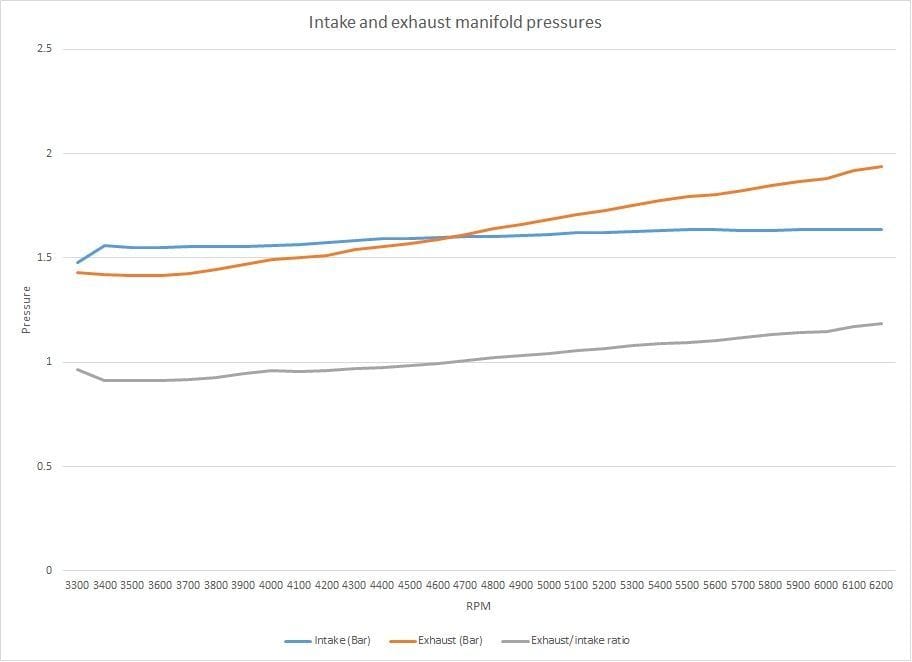

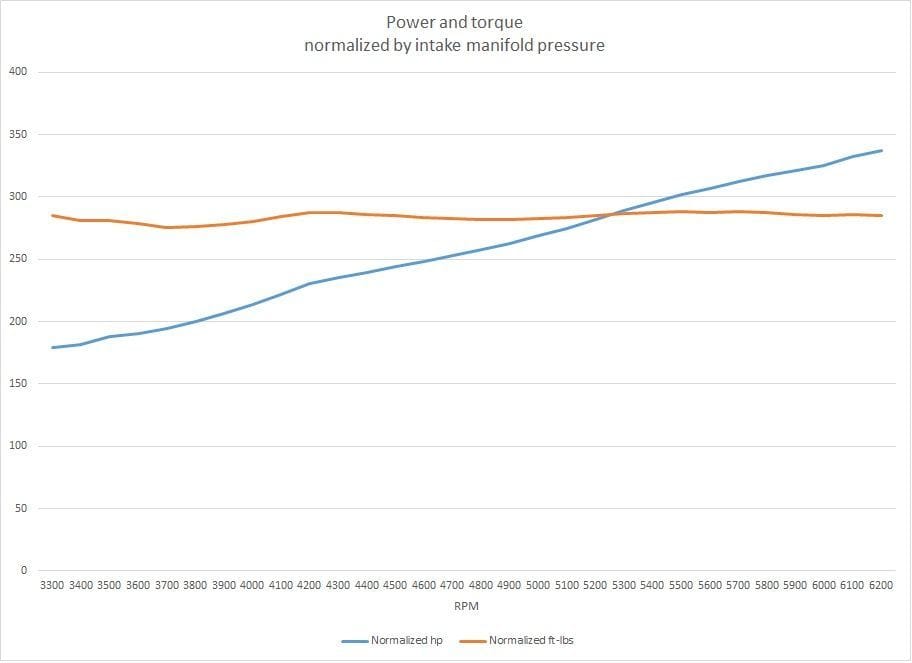

Thanks for your comments. We didnít get a clean run of the latest version before the transmission broke down. For what itís worth, here are the data from the low boost shakedown (0.6bar / 10 psi constant boost) run:

The engine runs like a champ between 3500-6000 rpm. Because the log exhaust manifolds are the only ones that fit, the 90-degree exhaust interference causes cylinders 1 and 6 to knock at above 6000 rpm. So weíre only looking to keep the power up close to that level above 6000 rpm and letting the torque fall. This still means that the rotating assembly needs to be reliable at those higher rpms.