Intake concept question?

#16

Professional Hoon

Rennlist Member

Rennlist Member

Join Date: Jan 2010

Location: Melbourne, Australia

Posts: 7,090

Likes: 0

Received 4 Likes

on

4 Posts

I was actually going to just write out the formula from my book, but then found a reference to this website. I would love to build my own intake, if i only knew my cam specs i could follow the formula.

#17

Addict

Rennlist Member

Rennlist Member

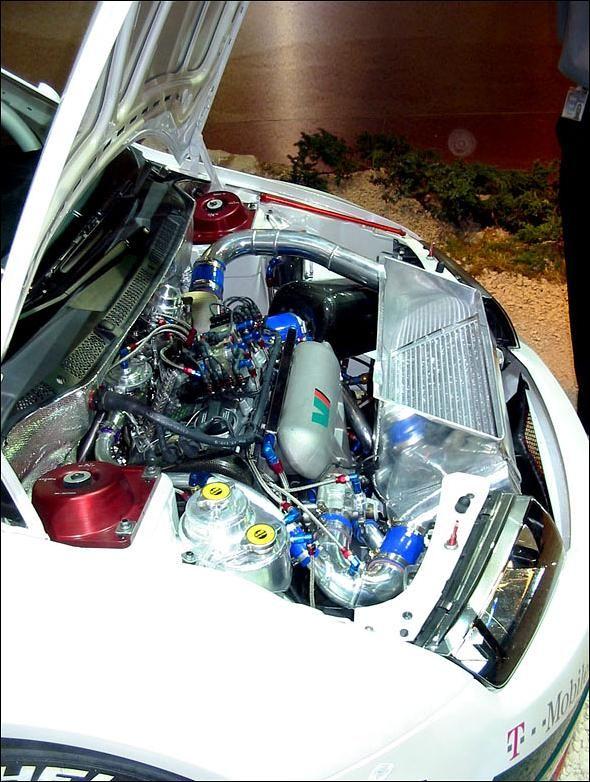

I will design one that will be something between these two. Too bad our brake booster is taking up so much space.

#18

Rennlist Member

Thread Starter

While those intakes are on turbo cars they're on small capacity rally motors which need quick low down acceleration rather than more power up top on a race motor.

Removing your brake booster is an easy decision. Change to a pedal box and be done with it.

Removing your brake booster is an easy decision. Change to a pedal box and be done with it.

#19

Rennlist Member

Join Date: Feb 2015

Location: Louisville

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

After doing some lengthy research, I thought Audi's concept was best and spoke volumes considering the success of the car and engine. Now understanding what the total volume of the plenum needs to be is as important as the shape.

#20

Rennlist Member

Thread Starter

Well volume is another thing that seems to get a lot of different opinions or beliefs. We don't seem to count the pipe from t/body as part of the plenum volume either.

Guess the bottom line is that unless we make and compare intakes we are doing a fair bit of guess work and with tune-able ECUs and knock systems we can work around seemingly pretty agricultural setups (as seen on mostly other modified turbo cars).

Guess the bottom line is that unless we make and compare intakes we are doing a fair bit of guess work and with tune-able ECUs and knock systems we can work around seemingly pretty agricultural setups (as seen on mostly other modified turbo cars).

#22

Addict

Rennlist Member

Rennlist Member

I envy your awesome skills raceboy

#23

Three Wheelin'

Hi Patrick,

The split/tapered plenum is designed to give even flow distribution to all cylinders under all conditions. In my opinion much more important than bellmouthing the runners. Best off-the-shelf manifolds I've seen are the Jenvey ones from the UK. The calculations for the slot dimensions and manifold taper rate should take into account the velocity pressure of the air, something that isn't replicated on the flowbench.

We took a different tack with our motor - dual throttles, one at each end of the manifold. Reduced the issue by 75%, but created some others...

Cheers,

Mike

The split/tapered plenum is designed to give even flow distribution to all cylinders under all conditions. In my opinion much more important than bellmouthing the runners. Best off-the-shelf manifolds I've seen are the Jenvey ones from the UK. The calculations for the slot dimensions and manifold taper rate should take into account the velocity pressure of the air, something that isn't replicated on the flowbench.

We took a different tack with our motor - dual throttles, one at each end of the manifold. Reduced the issue by 75%, but created some others...

Cheers,

Mike

#24

Three Wheelin'

#26

Three Wheelin'

I've used the velocity stacks in my intake as well, i can measure the outside diameter for you Patrick, but i think i'm close to 100mm as well, as we had to make a small dent in the stacks to make them fit.

My intake is actually completely build up like your drawing, except for the fact that is not really getting any smaller on the other side of where the velocity stacks are.

Do you want to measure mine completely? Ofcourse it's for 16v but in big lines it should be similar for 8v!

My intake is actually completely build up like your drawing, except for the fact that is not really getting any smaller on the other side of where the velocity stacks are.

Do you want to measure mine completely? Ofcourse it's for 16v but in big lines it should be similar for 8v!

#27

Rennlist Member

Thread Starter

Hi Patrick,

The split/tapered plenum is designed to give even flow distribution to all cylinders under all conditions. In my opinion much more important than bellmouthing the runners. Best off-the-shelf manifolds I've seen are the Jenvey ones from the UK. The calculations for the slot dimensions and manifold taper rate should take into account the velocity pressure of the air, something that isn't replicated on the flowbench.

We took a different tack with our motor - dual throttles, one at each end of the manifold. Reduced the issue by 75%, but created some others...

Cheers,

Mike

The split/tapered plenum is designed to give even flow distribution to all cylinders under all conditions. In my opinion much more important than bellmouthing the runners. Best off-the-shelf manifolds I've seen are the Jenvey ones from the UK. The calculations for the slot dimensions and manifold taper rate should take into account the velocity pressure of the air, something that isn't replicated on the flowbench.

We took a different tack with our motor - dual throttles, one at each end of the manifold. Reduced the issue by 75%, but created some others...

Cheers,

Mike

Thanks for re posting that Jenvey name. I had looked at these in the past and now wonder how well they'd be suited to our particular motor and of course packaging. Looks like you could run one of their intakes and some velocity stacks. The added attraction of this intake is the cast nature assuming it would resist collapsing. The other aspect we need to consider is location and size of turbo and wanting to keep the intake away from there as much as possible.

http://www.jenvey.co.uk/home/turbo-p...g-70mm-aplc-70

#28

Rennlist Member

Thread Starter

I've used the velocity stacks in my intake as well, i can measure the outside diameter for you Patrick, but i think i'm close to 100mm as well, as we had to make a small dent in the stacks to make them fit.

My intake is actually completely build up like your drawing, except for the fact that is not really getting any smaller on the other side of where the velocity stacks are.

Do you want to measure mine completely? Ofcourse it's for 16v but in big lines it should be similar for 8v!

My intake is actually completely build up like your drawing, except for the fact that is not really getting any smaller on the other side of where the velocity stacks are.

Do you want to measure mine completely? Ofcourse it's for 16v but in big lines it should be similar for 8v!

#30

Three Wheelin'

There are NO issues absolutely with collapsing at all with custom intakes. There may be if the plenums are made of 1mm sheet aluminium, but not when built with common sens of engineering in mind.

We have ran our custom built intakes up to 3 bars of boost (=4 bars of absolute pressure) and no issues whatsoever.

I would suggest not to overthink the ideas, just use your common sense, some math and then some skills and you will get the best result.

We have ran our custom built intakes up to 3 bars of boost (=4 bars of absolute pressure) and no issues whatsoever.

I would suggest not to overthink the ideas, just use your common sense, some math and then some skills and you will get the best result.