More Accurate: Wasted Spark v Sequential Ignition

#1

I'm interested to hear if there's a downside to running sequential ignition on a standalone rather than wasted spark.

Is a Hall sensor on the cam going to give less accurate timing than retaining the stock flywheel trigger set-up & going with wasted spark?

Tim

Is a Hall sensor on the cam going to give less accurate timing than retaining the stock flywheel trigger set-up & going with wasted spark?

Tim

#2

The down side to a wasted spark is that it can ignite unburned fuel in your exhaust if the timing is a little off. As far as sensors on your cam, I am running both my reference and sync off of the cam gear, and as such are tied together. By going with one on the fly wheel / crank and the other to the cam you are adding the variable of your timing belt between the two.

#3

No real downsides (unless you want to get into installing four coils, the wiring, etc as downsides). Sequential setups use an additional trigger on the camshaft. It will depend on your standalone, but you would use your existing crank trigger and add a hall sensor or similar to your camshaft. Some people do move to cam only triggering but there is no need to do that specifically. For the cam trigger you really just need a single point on the cam shaft to somehow trigger off of.

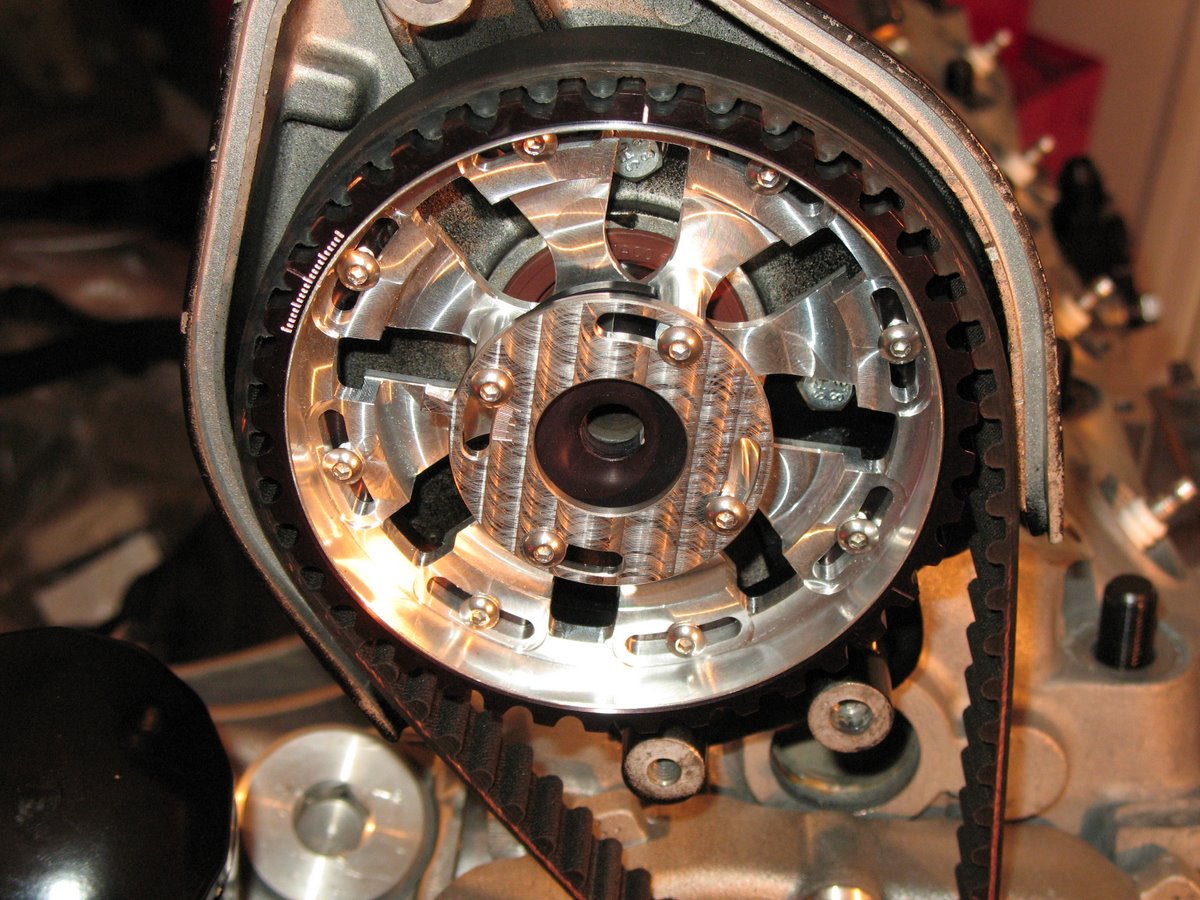

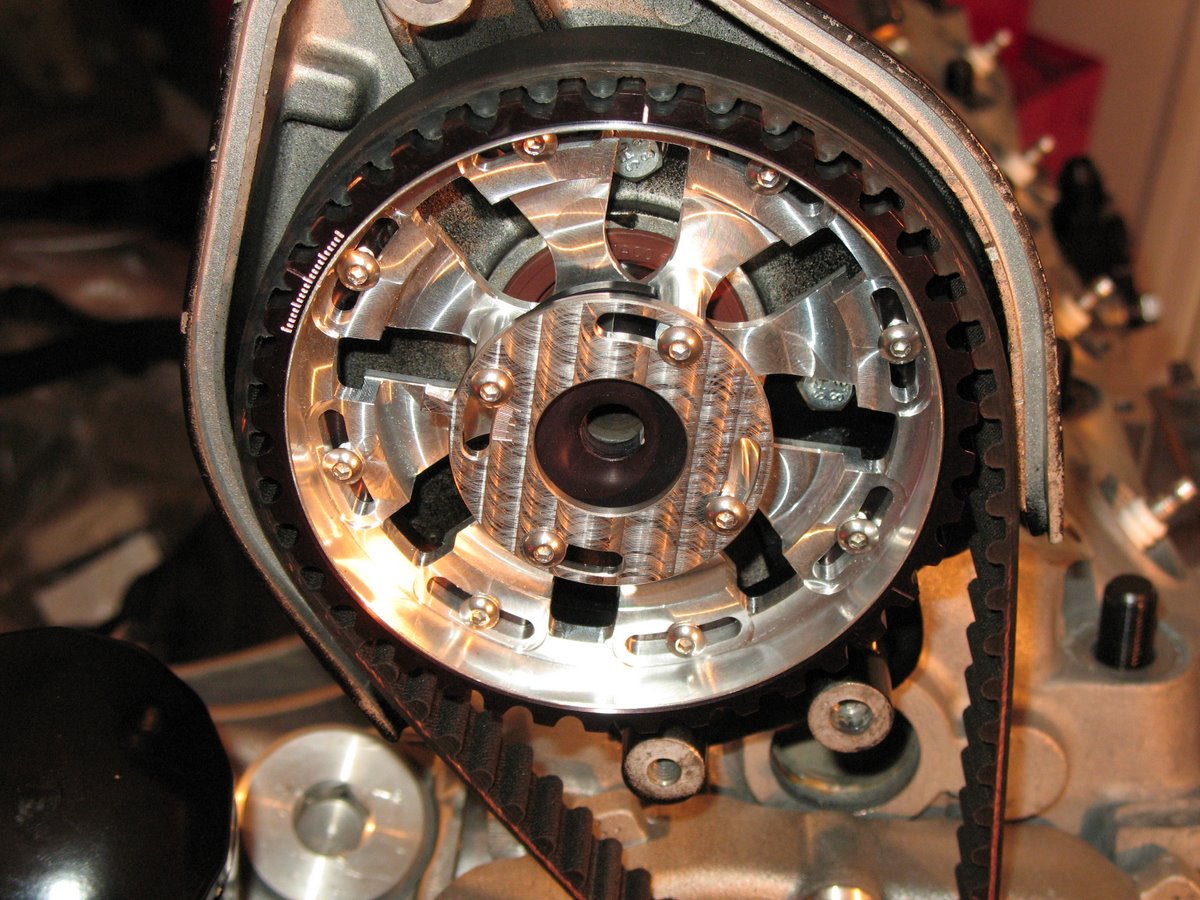

I have (and really like) the CEP products. I bought two trigger wheels, one is 24-1 and the other is just a single tooth for use with my 60-2 on my flywheel. These are what the parts look like. The CEP front cover has a hole for a hall sensor that lines up. I plan on using my 60-2 flywheel and the single tooth on the camshaft. I bought the 24-1 wheel for the camshaft as a backup/second option/etc.

Theoretically keeping your crankshaft triggers is more accurate (more teeth, crank speed vs cam shafts half speed, no belt stretch between crank and cam, etc). Realistically, there are many cars working on just a few triggers on the cam shaft running at half speed.... So it just depends.

I have (and really like) the CEP products. I bought two trigger wheels, one is 24-1 and the other is just a single tooth for use with my 60-2 on my flywheel. These are what the parts look like. The CEP front cover has a hole for a hall sensor that lines up. I plan on using my 60-2 flywheel and the single tooth on the camshaft. I bought the 24-1 wheel for the camshaft as a backup/second option/etc.

Theoretically keeping your crankshaft triggers is more accurate (more teeth, crank speed vs cam shafts half speed, no belt stretch between crank and cam, etc). Realistically, there are many cars working on just a few triggers on the cam shaft running at half speed.... So it just depends.

#4

Got this when reducing ignition timing below a certain point. Not good when it happens! That wasn't on a 951 though.

Since sequential spark allows for using one coil per cylinder it should allow for a higher spark power, assuming a coil pack will never be as powerful as single coil (but I have not checked all coil packs and coils available).

Sequential ignition should make for smoother engine operation under knock events, at least when using a proper anti-knock device.

Since a sequential ignition set up should allow sequential fuel injection, this will allow varying injection timing, good for fine tuning fuel efficiency and avoid knock by reducing intake valve temp depending on when BTDC fuel is injected.

My set up supplied from Pauertuning runs on all stock sensors + a cam angle sensor supplied that fits on the stock cam pulley and cover.

Last edited by Thom; 05-29-2013 at 02:36 PM.

#5

+1.

Got this when reducing ignition timing below a certain point. Not good when it happens! That wasn't on a 951 though.

Since sequential spark allows for using one coil per cylinder it should allow for a higher spark power, assuming a coil pack will never be as powerful as single coil (but I have not checked all coil packs and coils available).

Sequential ignition should make for smoother engine operation under knock events, at least when using a proper anti-knock device.

Since a sequential ignition set up should allow sequential fuel injection, this will allow varying injection timing, good for fine tuning fuel efficiency and avoid knock by reducing intake valve temp depending on when BTDC fuel is injected.

My set up supplied from Pauertuning runs on all stock sensors + a cam angle sensor supplied that fits on the stock cam pulley and cover.

Got this when reducing ignition timing below a certain point. Not good when it happens! That wasn't on a 951 though.

Since sequential spark allows for using one coil per cylinder it should allow for a higher spark power, assuming a coil pack will never be as powerful as single coil (but I have not checked all coil packs and coils available).

Sequential ignition should make for smoother engine operation under knock events, at least when using a proper anti-knock device.

Since a sequential ignition set up should allow sequential fuel injection, this will allow varying injection timing, good for fine tuning fuel efficiency and avoid knock by reducing intake valve temp depending on when BTDC fuel is injected.

My set up supplied from Pauertuning runs on all stock sensors + a cam angle sensor supplied that fits on the stock cam pulley and cover.