Okay I need the masters analisys #2 rod bearing failure & #4 blown HG failure

#61

Thread Starter

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Joined: Dec 2002

Posts: 14,451

Likes: 95

From: California

Well the factory nominated 20w50 for its shear and coking resistance for 1980s oils. You can get those properties today in lower viscosity syns.

Same comment for the "turbo cars thicker oil is better" crowd.

The higher you go in viscosity the lower the flow, the higher the temps, and the more time you'll spend in relief. Dont know why that is "better" if you can minimize that and keep necessary shear and coking resistance.

Same comment for the "turbo cars thicker oil is better" crowd.

The higher you go in viscosity the lower the flow, the higher the temps, and the more time you'll spend in relief. Dont know why that is "better" if you can minimize that and keep necessary shear and coking resistance.

SAE Viscosity Grade Motor Oil: 20W-50

Temperature Conditions: Above 20░ F

Description: Provides maximum protection for high-performance, high-RPM racing engines. Excellent choice for high temperature and heavy loads such as driving in the desert or towing a trailer at high speeds for long periods of time.

http://www.castrol.com/castrol/gener...tentId=7007302

I have yet to experience a rod bearing failure.

#62

Luis, you make a good point about simple maintenance and using quality oil. A lot of 944s, both NA and Turbo were ill-maintained over the years as they passed from owner to owner. Lack of oil changes and low-quality oil will certainly wear out the bearings, and all it would take is one prolonged high RPM one to waste the #2 rod bearing.

That said, most of the failures seem to occur in engines that are used in cars that are tracked frequently. These engines tend to be well-maintained, but a fundamental design flaw is surely to blame.

My own '86 951 has 146K miles, and the engine has never been apart, not even the head! I track it frequently (~10K track miles the last few years), and I run at Willow Springs very often , which has the 8-10 second long turn 2, which is taken at close to 90 MPH. This is a right hand turn, which is supposedly does not cause oil starvation as much as left turns, but I have run at the Roval at Cal Speedway and never had issues. I replaced my original rod bearings last year and they looked almost perfect. The engine has been well maintained since new (I bought the car off the original owner at 88K miles). I do not have any oil pan modifications, but I make sure that the oil level is kept at but not above maximum on the dipstick, and use good oil (Brad Penn or Redline 20W-50). I also make sure I do not go around turns at too high of an RPM level.

I have never had head gasket issues, and I credit that to good cooling system maintenance, but also due to the fact that my engine is 100% bone stock, running the stock turbo at the stock boost level. I will be rebuilding the head soon and doing the gasket preventatively, but I feel that if I had raised the boost levels the gasket would not have lasted as it has. I am not saying that raising the boost guarantees gasket failure, but it likely shortens its lifespan with all else remaining equal. I have installed a steam vent in my stillborn 944 Spec car, but as much for the ease of bleeding the system as for any perceived cooling benefits.

The 928 engine has similar rod bearing issues when raced, which is not surprising given that the crank/rod oiling system is similar in design. I did not cross drill the crank on my 944 Spec engine, but I replaced the bearings. Hopefully it will last!

That said, most of the failures seem to occur in engines that are used in cars that are tracked frequently. These engines tend to be well-maintained, but a fundamental design flaw is surely to blame.

My own '86 951 has 146K miles, and the engine has never been apart, not even the head! I track it frequently (~10K track miles the last few years), and I run at Willow Springs very often , which has the 8-10 second long turn 2, which is taken at close to 90 MPH. This is a right hand turn, which is supposedly does not cause oil starvation as much as left turns, but I have run at the Roval at Cal Speedway and never had issues. I replaced my original rod bearings last year and they looked almost perfect. The engine has been well maintained since new (I bought the car off the original owner at 88K miles). I do not have any oil pan modifications, but I make sure that the oil level is kept at but not above maximum on the dipstick, and use good oil (Brad Penn or Redline 20W-50). I also make sure I do not go around turns at too high of an RPM level.

I have never had head gasket issues, and I credit that to good cooling system maintenance, but also due to the fact that my engine is 100% bone stock, running the stock turbo at the stock boost level. I will be rebuilding the head soon and doing the gasket preventatively, but I feel that if I had raised the boost levels the gasket would not have lasted as it has. I am not saying that raising the boost guarantees gasket failure, but it likely shortens its lifespan with all else remaining equal. I have installed a steam vent in my stillborn 944 Spec car, but as much for the ease of bleeding the system as for any perceived cooling benefits.

The 928 engine has similar rod bearing issues when raced, which is not surprising given that the crank/rod oiling system is similar in design. I did not cross drill the crank on my 944 Spec engine, but I replaced the bearings. Hopefully it will last!

#63

Thread Starter

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Joined: Dec 2002

Posts: 14,451

Likes: 95

From: California

Luis, you make a good point about simple maintenance and using quality oil. A lot of 944s, both NA and Turbo were ill-maintained over the years as they passed from owner to owner. Lack of oil changes and low-quality oil will certainly wear out the bearings, and all it would take is one prolonged high RPM one to waste the #2 rod bearing.

That said, most of the failures seem to occur in engines that are used in cars that are tracked frequently. These engines tend to be well-maintained, but a fundamental design flaw is surely to blame.

My own '86 951 has 146K miles, and the engine has never been apart, not even the head! I track it frequently (~10K track miles the last few years), and I run at Willow Springs very often , which has the 8-10 second long turn 2, which is taken at close to 90 MPH. This is a right hand turn, which is supposedly does not cause oil starvation as much as left turns, but I have run at the Roval at Cal Speedway and never had issues. I replaced my original rod bearings last year and they looked almost perfect. The engine has been well maintained since new (I bought the car off the original owner at 88K miles). I do not have any oil pan modifications, but I make sure that the oil level is kept at but not above maximum on the dipstick, and use good oil (Brad Penn or Redline 20W-50). I also make sure I do not go around turns at too high of an RPM level.

I have never had head gasket issues, and I credit that to good cooling system maintenance, but also due to the fact that my engine is 100% bone stock, running the stock turbo at the stock boost level. I will be rebuilding the head soon and doing the gasket preventatively, but I feel that if I had raised the boost levels the gasket would not have lasted as it has. I am not saying that raising the boost guarantees gasket failure, but it likely shortens its lifespan with all else remaining equal. I have installed a steam vent in my stillborn 944 Spec car, but as much for the ease of bleeding the system as for any perceived cooling benefits.

The 928 engine has similar rod bearing issues when raced, which is not surprising given that the crank/rod oiling system is similar in design. I did not cross drill the crank on my 944 Spec engine, but I replaced the bearings. Hopefully it will last!

That said, most of the failures seem to occur in engines that are used in cars that are tracked frequently. These engines tend to be well-maintained, but a fundamental design flaw is surely to blame.

My own '86 951 has 146K miles, and the engine has never been apart, not even the head! I track it frequently (~10K track miles the last few years), and I run at Willow Springs very often , which has the 8-10 second long turn 2, which is taken at close to 90 MPH. This is a right hand turn, which is supposedly does not cause oil starvation as much as left turns, but I have run at the Roval at Cal Speedway and never had issues. I replaced my original rod bearings last year and they looked almost perfect. The engine has been well maintained since new (I bought the car off the original owner at 88K miles). I do not have any oil pan modifications, but I make sure that the oil level is kept at but not above maximum on the dipstick, and use good oil (Brad Penn or Redline 20W-50). I also make sure I do not go around turns at too high of an RPM level.

I have never had head gasket issues, and I credit that to good cooling system maintenance, but also due to the fact that my engine is 100% bone stock, running the stock turbo at the stock boost level. I will be rebuilding the head soon and doing the gasket preventatively, but I feel that if I had raised the boost levels the gasket would not have lasted as it has. I am not saying that raising the boost guarantees gasket failure, but it likely shortens its lifespan with all else remaining equal. I have installed a steam vent in my stillborn 944 Spec car, but as much for the ease of bleeding the system as for any perceived cooling benefits.

The 928 engine has similar rod bearing issues when raced, which is not surprising given that the crank/rod oiling system is similar in design. I did not cross drill the crank on my 944 Spec engine, but I replaced the bearings. Hopefully it will last!

#64

No I have never used an oil additive of any kind. I feel that if you use a quality oil and change it frequently while limiting the number of cold starts, the bearings will be happy for a long time.

We really only use oil additives at my shop as step 1 in trying to get a sticky hydraulic lifter to pump up if it does not do so through normal means. We use Swepco 502, and normally change the oil afterwards if it is successful in quieting the lifter. This is not to say that oil additives are a bad thing by any means, but I have never felt the need to use one.

We really only use oil additives at my shop as step 1 in trying to get a sticky hydraulic lifter to pump up if it does not do so through normal means. We use Swepco 502, and normally change the oil afterwards if it is successful in quieting the lifter. This is not to say that oil additives are a bad thing by any means, but I have never felt the need to use one.

#65

Thread Starter

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Joined: Dec 2002

Posts: 14,451

Likes: 95

From: California

No I have never used an oil additive of any kind. I feel that if you use a quality oil and change it frequently while limiting the number of cold starts, the bearings will be happy for a long time.

We really only use oil additives at my shop as step 1 in trying to get a sticky hydraulic lifter to pump up if it does not do so through normal means. We use Swepco 502, and normally change the oil afterwards if it is successful in quieting the lifter. This is not to say that oil additives are a bad thing by any means, but I have never felt the need to use one.

We really only use oil additives at my shop as step 1 in trying to get a sticky hydraulic lifter to pump up if it does not do so through normal means. We use Swepco 502, and normally change the oil afterwards if it is successful in quieting the lifter. This is not to say that oil additives are a bad thing by any means, but I have never felt the need to use one.

http://www.archoil.com/index.cfm/general-public/

http://evergreen.cagehosting.com/ind...tion-modifier/

#66

Team Owner

Joined: Oct 2009

Posts: 28,704

Likes: 213

From: one thousand, five hundred miles north of Ft. Lauderdale for the summer.

Bars Leaks Head Gasket Sealer in the large bottle will cure a blown Porsche head gasket on any n/a car.

not sure about your turbos but everyone should try it before pulling the head.

the key is getting 100 % of the antifreeze out of the circuit first, as antifreeze is much more slippery than water.

not sure about your turbos but everyone should try it before pulling the head.

the key is getting 100 % of the antifreeze out of the circuit first, as antifreeze is much more slippery than water.

#67

I have a customer with a 450rwhp race car lots of engine work and a dry sump in his last race @ willow back in April he spun # 2, okay Einstein so much for your answer, I believe there is another thread two other guys with accusump also had #2 failure we know accusump is not as effective as dry sump but still better than stock.

We then ran an accusump, balance shaft delete, catch can and steam vent and used a 951 oil cooler in an external application

Still lost a #2. that was in our second race of 105+ degrees and just over 32 hours on the engine.

We had added an oil temp gauge and pegged it at 280+

We now have added a cross drilled crank, and a crank scraper and a good sized oil cooler on the front

switched to Amsoil Dominator -- while driving the temp gauge hits 280, but immediately drops

to 210 at idle -- we're suspecting its a measurement/gauge issue -- but not sure.

-- we're two races in ~44hours, no issues that we can tell so far -- haven't pulled the bearings out yet to inspect

but will do this summer.

Not a very scientific approach -- but if the kitchen sink works -- then kitchen sink it is... I really don't

care what the minimum set is :-)

I just picked up a 951 -- so I'm even more interested in this topic.

I haven't opened the engine up yet - told it has a cross drilled crank, but not knifed

but that's all I know.

I plan to check the bearings, run a crankscrapper -- go with Dominator oil

Mike

#69

I just noticed the heater gets coolant from the rear of the head. In regards to cyl #4 getting hot and weakening the HG over time, why not just turn the heater on? Or wire the heater valve open? If you don't want to heat the cabin the heater flap under the dash can stay closed. This should improve coolant flow around cyl #4.

#70

We lost a #2 on our 924s chumpcar with just a baffle.

We then ran an accusump, balance shaft delete, catch can and steam vent and used a 951 oil cooler in an external application

Still lost a #2. that was in our second race of 105+ degrees and just over 32 hours on the engine.

We had added an oil temp gauge and pegged it at 280+

We now have added a cross drilled crank, and a crank scraper and a good sized oil cooler on the front

switched to Amsoil Dominator -- while driving the temp gauge hits 280, but immediately drops

to 210 at idle -- we're suspecting its a measurement/gauge issue -- but not sure.

-- we're two races in ~44hours, no issues that we can tell so far -- haven't pulled the bearings out yet to inspect

but will do this summer.

Not a very scientific approach -- but if the kitchen sink works -- then kitchen sink it is... I really don't

care what the minimum set is :-)

I just picked up a 951 -- so I'm even more interested in this topic.

I haven't opened the engine up yet - told it has a cross drilled crank, but not knifed

but that's all I know.

I plan to check the bearings, run a crankscrapper -- go with Dominator oil

Mike

We then ran an accusump, balance shaft delete, catch can and steam vent and used a 951 oil cooler in an external application

Still lost a #2. that was in our second race of 105+ degrees and just over 32 hours on the engine.

We had added an oil temp gauge and pegged it at 280+

We now have added a cross drilled crank, and a crank scraper and a good sized oil cooler on the front

switched to Amsoil Dominator -- while driving the temp gauge hits 280, but immediately drops

to 210 at idle -- we're suspecting its a measurement/gauge issue -- but not sure.

-- we're two races in ~44hours, no issues that we can tell so far -- haven't pulled the bearings out yet to inspect

but will do this summer.

Not a very scientific approach -- but if the kitchen sink works -- then kitchen sink it is... I really don't

care what the minimum set is :-)

I just picked up a 951 -- so I'm even more interested in this topic.

I haven't opened the engine up yet - told it has a cross drilled crank, but not knifed

but that's all I know.

I plan to check the bearings, run a crankscrapper -- go with Dominator oil

Mike

#71

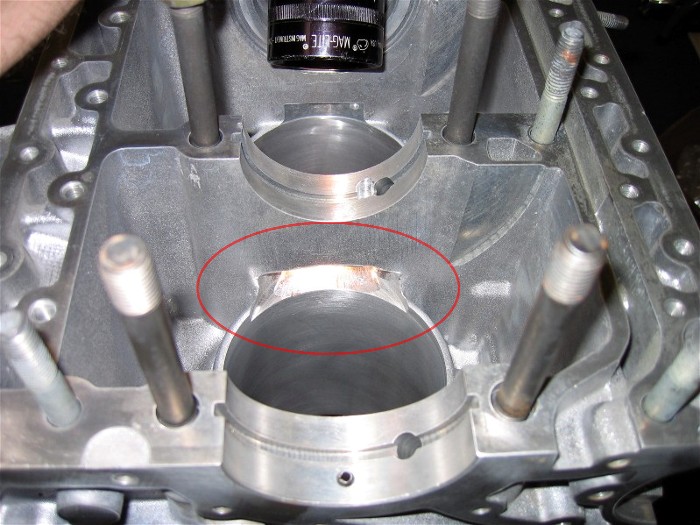

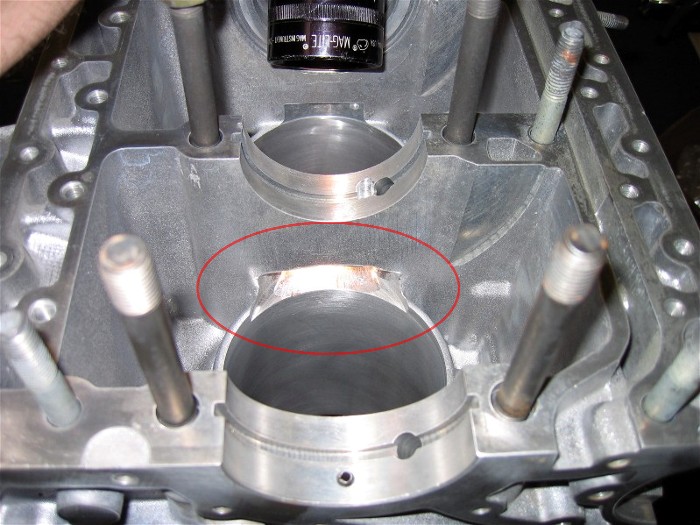

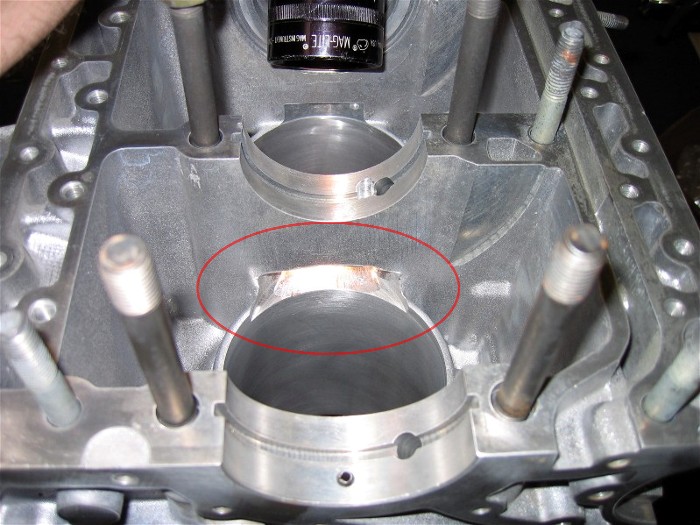

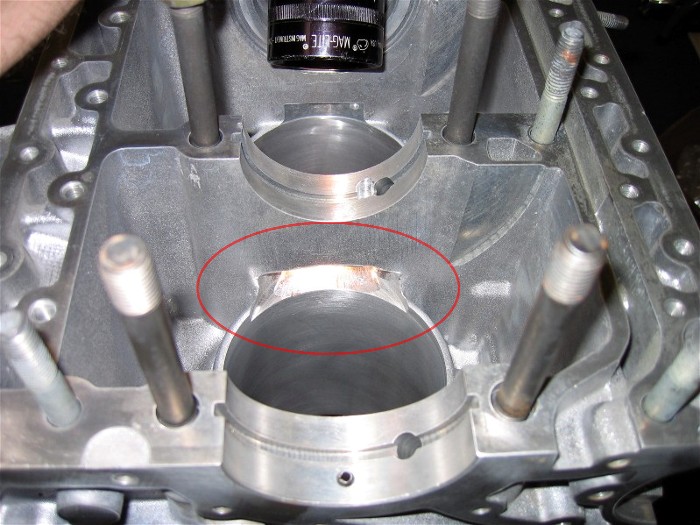

I'm doing this to my block. I'm doing it myself because of where I live, but the info is from Lindsey Racing and I would definitely have them do it if I could. I already ruined one block by making a mistake when programming the CNC milling machine.

From LR HP Letter http://www.lindseyracing.com/hptalk/0808.htm

There is much more if you click the link above.

From LR HP Letter http://www.lindseyracing.com/hptalk/0808.htm

One of the most recent additions to our Machine Work and Engine Services we can perform on your 2.5L engine is what we call our "Windage Port". This can be described as a port or opening at the base of the cylinders. One opening is between the base of cylinders number 1 and 2, and the other is between cylinders 3 and 4.

This wasn't an idea we came up with, but rather Porsche did. You can see it on the '89 2.7L and 3.0L 944S2 and 968 blocks from the factory. What we did was try to understand why they may have added this port to those later years blocks. You would think it was an improvement in either performance or reliability, or both! We refer to it as Cylinder Pumping.

We have noticed that there is a much lower, almost non existent, incidence of rod bearing failure on these 104mm bore blocks. Have you ever heard of a bearing failure on a 968 or 944S2? We don't recall hearing about one. Even one that has been turbo charged and seeing higher bearing loads. Seeing how both the 2.5L and 3.0L engines use the same bearings, oil pump, block oiling passage ways, crank (except stroke length), pick up tube and more, what's the difference? Well... one big difference is the windage port.

This wasn't an idea we came up with, but rather Porsche did. You can see it on the '89 2.7L and 3.0L 944S2 and 968 blocks from the factory. What we did was try to understand why they may have added this port to those later years blocks. You would think it was an improvement in either performance or reliability, or both! We refer to it as Cylinder Pumping.

We have noticed that there is a much lower, almost non existent, incidence of rod bearing failure on these 104mm bore blocks. Have you ever heard of a bearing failure on a 968 or 944S2? We don't recall hearing about one. Even one that has been turbo charged and seeing higher bearing loads. Seeing how both the 2.5L and 3.0L engines use the same bearings, oil pump, block oiling passage ways, crank (except stroke length), pick up tube and more, what's the difference? Well... one big difference is the windage port.

#72

I just noticed the heater gets coolant from the rear of the head. In regards to cyl #4 getting hot and weakening the HG over time, why not just turn the heater on? Or wire the heater valve open? If you don't want to heat the cabin the heater flap under the dash can stay closed. This should improve coolant flow around cyl #4.

At a 50 degrees trackday my stock 951 oil temperatures where getting so high that 10 laps was the maximum before the engine had to cool down. That's about 15 min driving.

#73

Thread Starter

Basic Sponsor

Rennlist

Site Sponsor

Rennlist

Site Sponsor

Joined: Dec 2002

Posts: 14,451

Likes: 95

From: California

Actually this makes a lot of sense, LR sells the steam vent for #4 to help with keeping #4 cooler, but the hose is only a 1/4 hose, the heater vent is at least 1/2 in diameter, so the flow is greater. I bet the secret in a race car is not to delete it, but to send it back to the radiator like a close loop.

#74

I'm doing this to my block. I'm doing it myself because of where I live, but the info is from Lindsey Racing and I would definitely have them do it if I could. I already ruined one block by making a mistake when programming the CNC milling machine.

From LR HP Letter http://www.lindseyracing.com/hptalk/0808.htm

There is much more if you click the link above.

From LR HP Letter http://www.lindseyracing.com/hptalk/0808.htm

There is much more if you click the link above.

#75

I have access to a CNC milling machine. Lindsey charges $350ish for doing it, might be worth a look.

I might consider installing a t-split at the heater outlet going back to the radiator somehow. A second vacuum valve opening the opposite way of the heater core valve would make the system controllable from the cabin. That way i would not have to make the cabin hotter when at the track, it get's hot enough for me already.

I might consider installing a t-split at the heater outlet going back to the radiator somehow. A second vacuum valve opening the opposite way of the heater core valve would make the system controllable from the cabin. That way i would not have to make the cabin hotter when at the track, it get's hot enough for me already.