PS Intermediate shaft converted to manual

#18

I'm still boggled by the lengths you guys go through to put in a slower response manual rack. I love my power rack that is now a manual. The feel is fantastic. But.. then again.. I work out. LOL. J/K. it's easy to turn. It was also easy to turn when the car weighed 2800lbs. It last weighted 2300, so that also makes a bit of difference.

#19

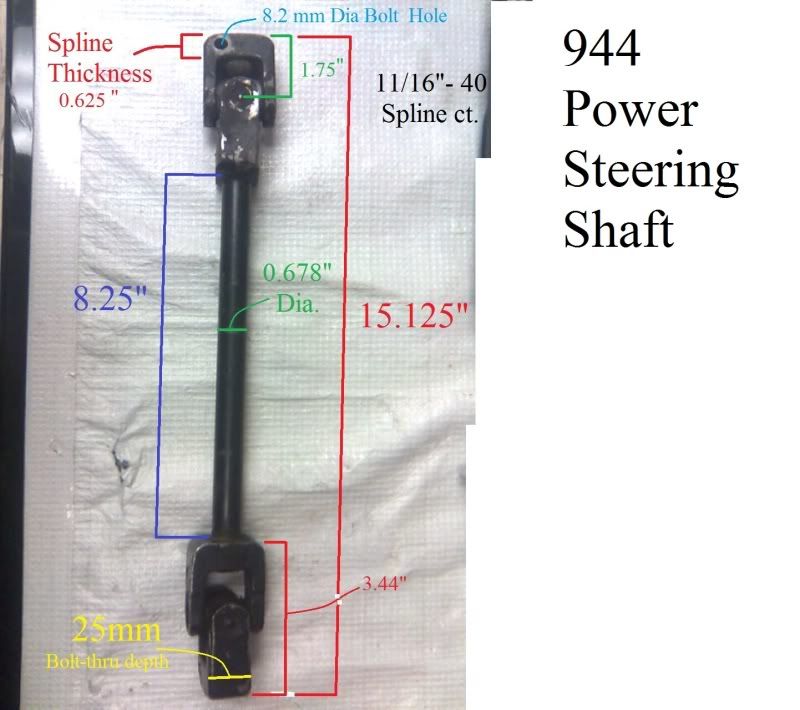

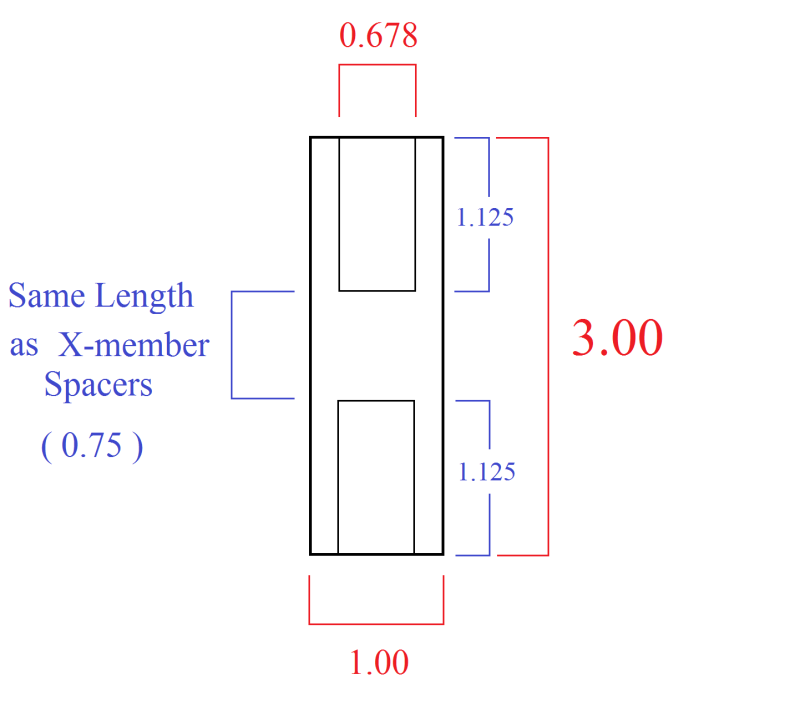

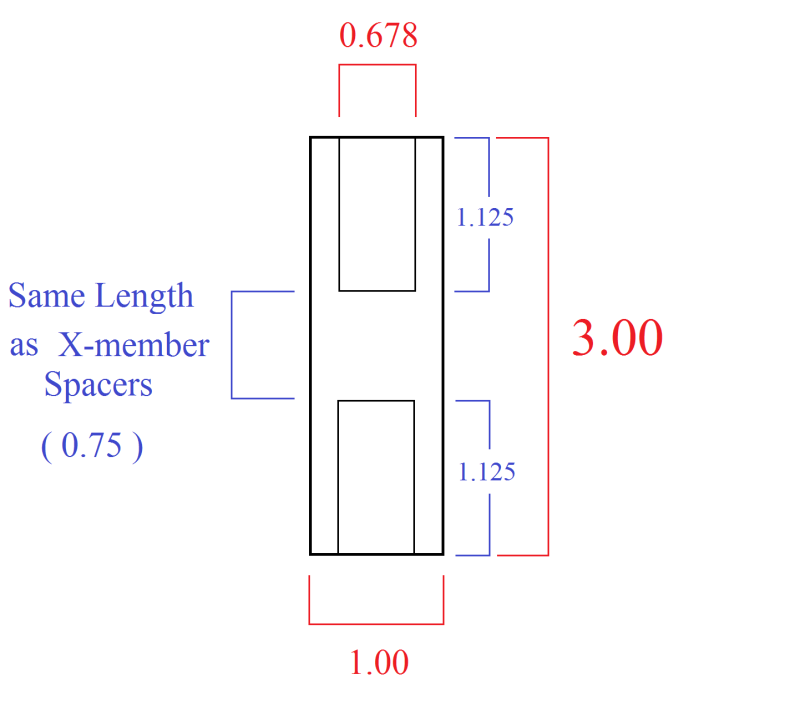

Hey 95ONE, this mod is for a Power Steering Shaft lengthened to 3/4" for my V8 swap kit (3/4" drop) and Van's method worked like a charm. I put the shaft in a torsional device after I welded it and air-cooled and it isn't budging. To make life simpler, I'm going to build the shafts to spec now that it is confirmed that the Manual shaft is exactly 1" (25mm) longer between the U-joints.... With Borgeson part # 014928 the sky's the limit.... But you guys can mod your own, just adjust the 0.75" dimension to your needs....

#22

That is good to know as well, but I'm talking about the angle of the U-joints as they snake down from the steering whell column, then from the midshaft to the rack splines. It would have to be measured with the X-member and rack installed. I will note the 10* rotation though...great trivia question. I always wondered why Porsche had the shafts clocked wrong from factory and why only the 10* clock.

The Borgeson joints are 35* max operating angle......

and I clocked my custom shaft per Borgeson's suggestion....

The Borgeson joints are 35* max operating angle......

and I clocked my custom shaft per Borgeson's suggestion....

#24

Rennlist Member

That is good to know as well, but I'm talking about the angle of the U-joints as they snake down from the steering whell column, then from the midshaft to the rack splines. It would have to be measured with the X-member and rack installed. I will note the 10* rotation though...great trivia question. I always wondered why Porsche had the shafts clocked wrong from factory and why only the 10* clock.

The Borgeson joints are 35* max operating angle......

and I clocked my custom shaft per Borgeson's suggestion....

The Borgeson joints are 35* max operating angle......

and I clocked my custom shaft per Borgeson's suggestion....

I measured that by reaching into the engine compartment... but I think it's pretty accurate.

#25

Van, My Borgeon joints have been operating flawlessly, unclocked, at 1.25" extended length (PS rack) on my swap. I recently made a couple shafts and set them up for the factory 10 degrees clocking. The chop and weld method is a pain and I won't be doing those any more... 4140 steel rod is the way to go with adjustability at the DD ends.....

#27

Your 10 degrees was right on the money. I just tossed a manual shaft because the bearings were totally shot. On my swap kit the 3/4" X-member drop modification only requires 1/2" steering shaft extension, so a custom shaft has to be done. The Borgeson joints will be a quick way to mod up a different ratio manual rack with different input splines as well