clutch fork installation - still need help!!!

#16

Drifting

Thread Starter

OK, so I've pulled everything back apart.

Turns out I had the TO bearing on properly (except for the toothed ring being upside down), so that's not the cause of the problem.

Oddly though, on the pic below of the PP installed, the PP forks are nearly flat. Got me wondering so I took it off..

You can see in the side view pic below of the old and new pressure plates how the end of the TO bearing is above the edge of the old PP (on the right). However, the forks of the new PP (a KEP light-duty; stamped 240) are angled downward much more toward the centerline of the PP, putting the edge of the TO bearing below the edge of the PP by a couple mm.

You can also see in the side view closeup of the KEP and 930 disk that the clutch disk is somewhat above the PP edge that mounts to the flywheel (this is why I had such a pain bolting the PP on).

So, can anyone tell me what is going on?

Did KEP send me the wrong PP?

The side of the disk marked "gearbox side" goes against the PP surface, correct?

I'm concerned that even if I reinstall it, the PP force is so strong the clutch fork won't last more than couple pulls before snapping...

Yes, I did use an alignment tool when mounting the PP to ensure the disk was aligned properly.

Thanks,

Jerome

Turns out I had the TO bearing on properly (except for the toothed ring being upside down), so that's not the cause of the problem.

Oddly though, on the pic below of the PP installed, the PP forks are nearly flat. Got me wondering so I took it off..

You can see in the side view pic below of the old and new pressure plates how the end of the TO bearing is above the edge of the old PP (on the right). However, the forks of the new PP (a KEP light-duty; stamped 240) are angled downward much more toward the centerline of the PP, putting the edge of the TO bearing below the edge of the PP by a couple mm.

You can also see in the side view closeup of the KEP and 930 disk that the clutch disk is somewhat above the PP edge that mounts to the flywheel (this is why I had such a pain bolting the PP on).

So, can anyone tell me what is going on?

Did KEP send me the wrong PP?

The side of the disk marked "gearbox side" goes against the PP surface, correct?

I'm concerned that even if I reinstall it, the PP force is so strong the clutch fork won't last more than couple pulls before snapping...

Yes, I did use an alignment tool when mounting the PP to ensure the disk was aligned properly.

Thanks,

Jerome

#18

Rennlist Member

I've never used the KEP PP so am afraid I can't help. I can confirm that on the Sach's PP's I've used that were modified for more force, the TOB sits a few mm's deeper, but in both cases it still stood higher than the rest of the PP. Maybe start a new thread to attract the attention of KEP users...

I'd agree "gearbox side" goes toward PP.

I'd agree "gearbox side" goes toward PP.

#19

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Thanks Tom. I appreciate the pics and description. I definitely put it upside down. What a way to start 2010.

Karl, there were no shims other than shown in the pics by Tom. The bearing is one purchased from the dealer and didn't come w/ any shims. Should I be concerned? I did notice that my old bearing had no shims and was a little loose.

Karl, there were no shims other than shown in the pics by Tom. The bearing is one purchased from the dealer and didn't come w/ any shims. Should I be concerned? I did notice that my old bearing had no shims and was a little loose.

#20

Drifting

Thread Starter

My kit came w/ everything but one of the thinner washers.

When I assemble the bearing w/ the teeth angled with the PP forks, the bearing has quite a bit of play (probably 1mm or more). When I turn the teeth of the ring against the PP forks (so that the toothed ring acts as a spring washer) then the bearing is tight.

Which is correct?

I could re-use the thin washer that holds the toothed ring on, but it isn't very thick.

Another thing I just noticed. In looking at pics of factory flywheels (as on Paragon's website), there is a step from where the PP bolts to where the clutch disk mates. However, my disk is perfectly flat all the way across. Is my disk bad??? Without the clutch mating area being lower than the PP surface, I can see why I had trouble compressing the PP to bolt it on.

#22

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Thanks Karl,

My kit came w/ everything but one of the thinner washers.

When I assemble the bearing w/ the teeth angled with the PP forks, the bearing has quite a bit of play (probably 1mm or more). When I turn the teeth of the ring against the PP forks (so that the toothed ring acts as a spring washer) then the bearing is tight.

Which is correct?

I could re-use the thin washer that holds the toothed ring on, but it isn't very thick.

Another thing I just noticed. In looking at pics of factory flywheels (as on Paragon's website), there is a step from where the PP bolts to where the clutch disk mates. However, my disk is perfectly flat all the way across. Is my disk bad??? Without the clutch mating area being lower than the PP surface, I can see why I had trouble compressing the PP to bolt it on.

My kit came w/ everything but one of the thinner washers.

When I assemble the bearing w/ the teeth angled with the PP forks, the bearing has quite a bit of play (probably 1mm or more). When I turn the teeth of the ring against the PP forks (so that the toothed ring acts as a spring washer) then the bearing is tight.

Which is correct?

I could re-use the thin washer that holds the toothed ring on, but it isn't very thick.

Another thing I just noticed. In looking at pics of factory flywheels (as on Paragon's website), there is a step from where the PP bolts to where the clutch disk mates. However, my disk is perfectly flat all the way across. Is my disk bad??? Without the clutch mating area being lower than the PP surface, I can see why I had trouble compressing the PP to bolt it on.

#23

Drifting

Thread Starter

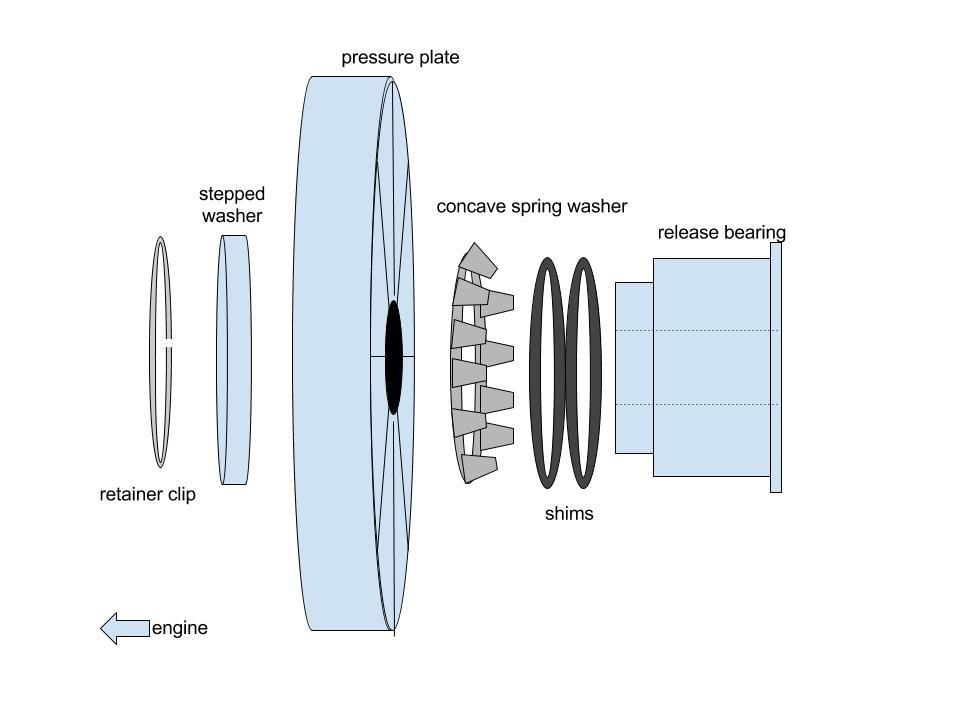

If you lay the release bearing on the table, slide on a shim or two, place the toothed washer on with the teeth down pointing towards the table (the teeth should sit on the shims), then put on the pressure plate, big thick washer, and the retaining clip. You should have to compress the PP to slide the clip in.

In this orientation there is no movement so no shims should be needed.

I was concerned because there is a lot of play when the toothed ring is oriented the other way.

I think everything is actually OK so I'll reinstall later this week. This time after install, though, I'll look though the inspection hole to ensure the fork engaged the bearing properly.

#25

Rennlist Member

The following users liked this post:

FRporscheman (03-20-2020)