Spoolup 500-600 too slow. *updated with dyno chart

#31

The Impaler

Rennlist Member

Rennlist Member

Thread Starter

Recalibrated sensor, Replaced SMT-6 with shorting plug, neither made any difference.

Ordering a new FPR right now, just in case that's the problem.

Ordering a new FPR right now, just in case that's the problem.

#32

The Impaler

Rennlist Member

Rennlist Member

Thread Starter

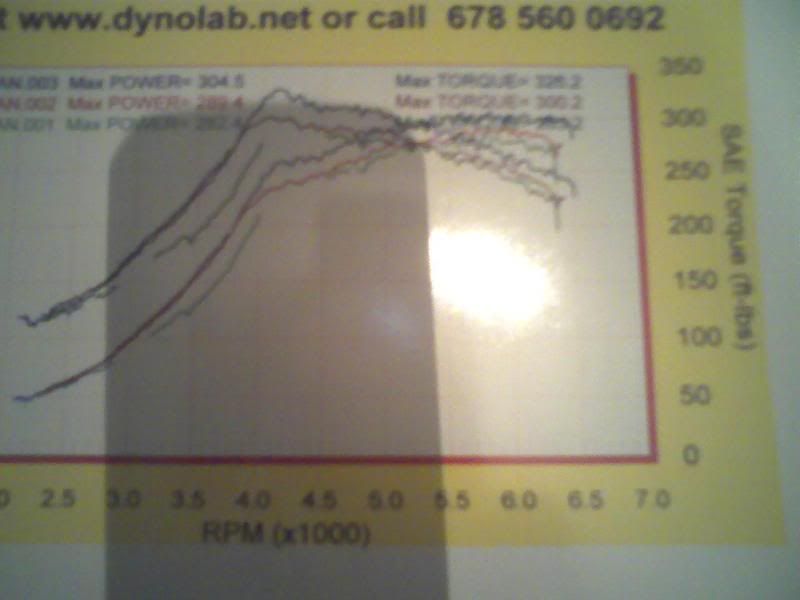

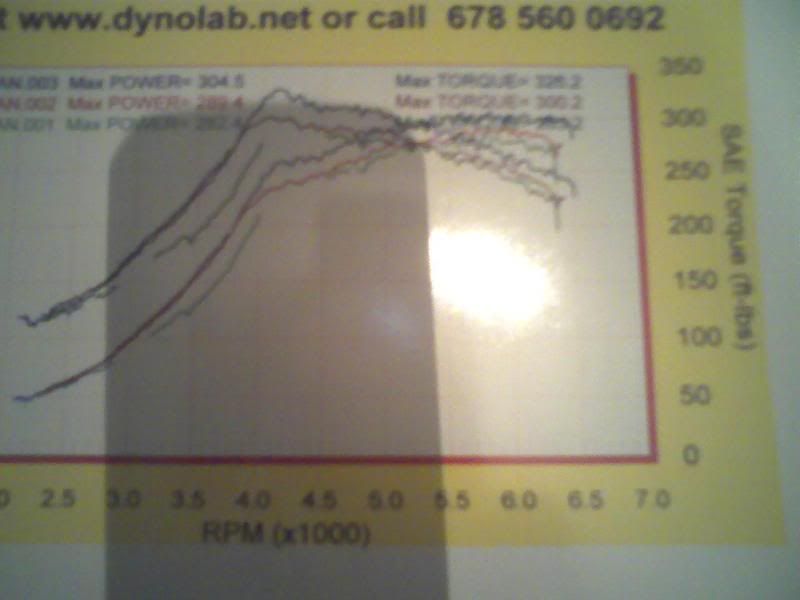

Sorry for the crappy pics! Turns out my WB02 was just giving me crappy readings. AFR wasn't half bad.

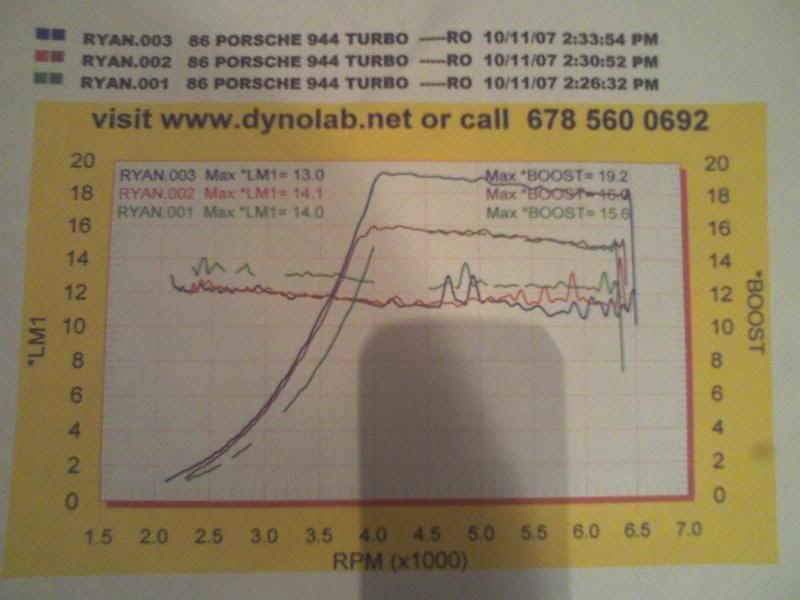

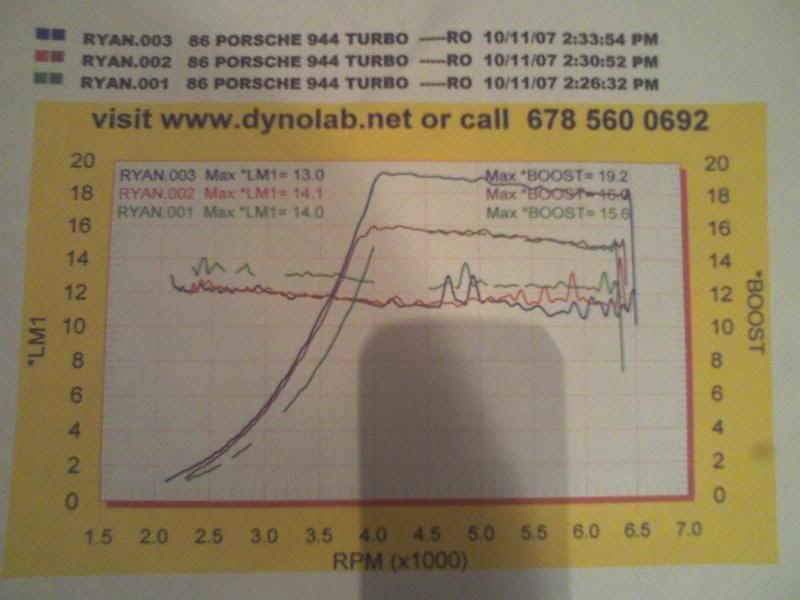

You can see the obviously slow spoolup in this graph

These numbers are hard to read -

16psi with really super crappy clogged air filter - 282/283tq

16psi with no air filter - 289/300tq

19psi - 305/326tq

You can see the obviously slow spoolup in this graph

These numbers are hard to read -

16psi with really super crappy clogged air filter - 282/283tq

16psi with no air filter - 289/300tq

19psi - 305/326tq

#34

The Impaler

Rennlist Member

Rennlist Member

Thread Starter

#35

The Impaler

Rennlist Member

Rennlist Member

Thread Starter

Ok, I have just finished pressure testing the system by placing an adapter in place of the MAF. This allows me to pressurize from the turbo compressor back to check for boost leaks.

I plugged her in, set the pressure to 30 psi, and it wont even build any pressure. There is a massive leak under pressure coming off what i think is the AOS connection under the intake manifold. Its a big enough leak to not allow my puny little air compressor to build at all, so wouldnt that be much more noticeable than just spoolup coming late??

I plugged her in, set the pressure to 30 psi, and it wont even build any pressure. There is a massive leak under pressure coming off what i think is the AOS connection under the intake manifold. Its a big enough leak to not allow my puny little air compressor to build at all, so wouldnt that be much more noticeable than just spoolup coming late??

#36

Drifting

Join Date: Feb 2003

Location: Akron, Ohio

Posts: 2,254

Likes: 0

Received 0 Likes

on

0 Posts

I had a leak coming from one of the vacuum lines from the manifold to the ISV. It was cracked on the bottom half of the bend at the top, half way around. It effected my boost by 400RPM difference in build up to full boost.

#37

Race Car

leak under the intake manifold....

The ISV will pretty much always leak, some have tried their best to seal it and IIRC nobody has really succeeded. Expect some small leaks from it. Using a tire compressor to pressurize the intake is not the best solution, since as you experienced it will not build any pressure at the slightest leak. If you know somebody close by with a bigger compressor use that and make sure it is not running when you test, you will be able to hear/find the leaks much better.

The ISV will pretty much always leak, some have tried their best to seal it and IIRC nobody has really succeeded. Expect some small leaks from it. Using a tire compressor to pressurize the intake is not the best solution, since as you experienced it will not build any pressure at the slightest leak. If you know somebody close by with a bigger compressor use that and make sure it is not running when you test, you will be able to hear/find the leaks much better.

#38

Rennlist Member

You have to unplug the line to the AOS, it will pressurize the crankcase which is not good and you can not get enough air in there to do anyting. Disconnect that line and cap then you should be able to pressurise. I would only pressurise max of 15 psi.

#40

Drive-by provocation guy

Rennlist Member

Rennlist Member

Join Date: Apr 2002

Location: NAS PAX River, by way of Orlando

Posts: 10,439

Likes: 0

Received 0 Likes

on

0 Posts

#42

Addict

Rennlist Member

Rennlist Member

Join Date: Nov 2002

Location: right next to the right one

Posts: 2,486

Likes: 0

Received 1 Like

on

1 Post

My VR Stage 2 boost to 15 psi@2940rpm.

I had some serious spool issues with a Guru modified wastegate.

A TIAL solved that.

I`m currently hunting down a rich condition (10.8 WOT) but I┤m still seeing 15 psi@3100rpm.

A rich condition will not cause spoolup to increase by as much as 1000rpm.

This must be a leak or wastegate issue.

I had some serious spool issues with a Guru modified wastegate.

A TIAL solved that.

I`m currently hunting down a rich condition (10.8 WOT) but I┤m still seeing 15 psi@3100rpm.

A rich condition will not cause spoolup to increase by as much as 1000rpm.

This must be a leak or wastegate issue.

#43

Drive-by provocation guy

Rennlist Member

Rennlist Member

Join Date: Apr 2002

Location: NAS PAX River, by way of Orlando

Posts: 10,439

Likes: 0

Received 0 Likes

on

0 Posts

Also, anyone know the easiest way to test exhaust system for leaks?

#44

The Impaler

Rennlist Member

Rennlist Member

Thread Starter

Here is my high tech pressure testing adapter.

here is the plugged line. I initially just plugged the side connected to the intake, but air was still coming out of the other side (???)

Here is a spot where i was hearing some noise, till i clamped the hose coming from the intake that connects to it.

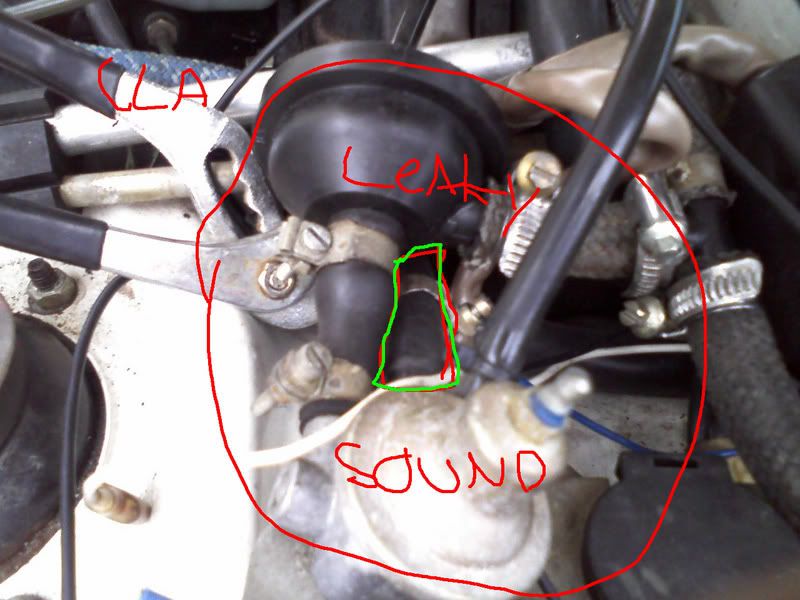

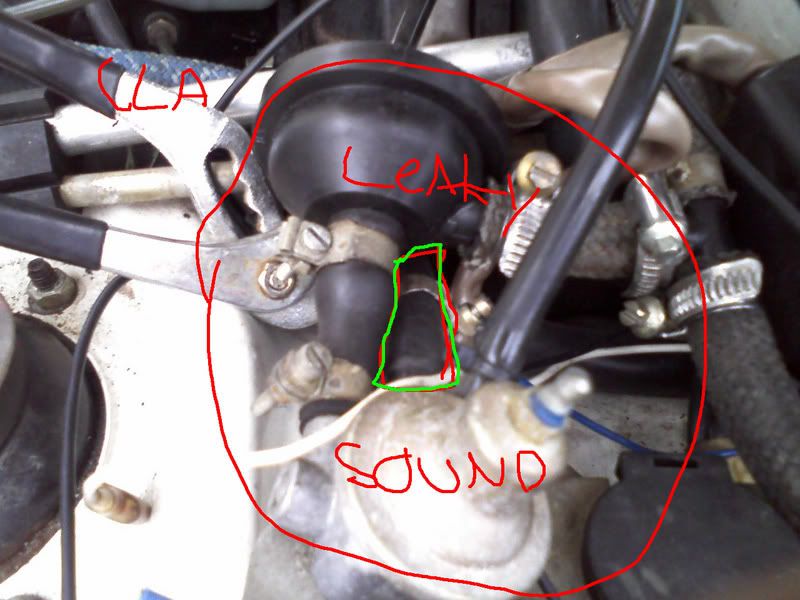

And here is the major leaky sounding area.

This is the same hose as the one in the previous photo, when i compress it with a screwdriver i can hear a difference in the sound.

What am i doing wrong?

here is the plugged line. I initially just plugged the side connected to the intake, but air was still coming out of the other side (???)

Here is a spot where i was hearing some noise, till i clamped the hose coming from the intake that connects to it.

And here is the major leaky sounding area.

This is the same hose as the one in the previous photo, when i compress it with a screwdriver i can hear a difference in the sound.

What am i doing wrong?

#45

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Ryan, You should disconnect the crankcase breather hose from the J-pipe.

Did you verify the WG to be installed correctly?

So you like the idea of cutting up the fuel filter and using as a pressure tester?

Did you verify the WG to be installed correctly?

So you like the idea of cutting up the fuel filter and using as a pressure tester?