I need some tips on removing this one turbo bolt please!!

#1

Drifting

Thread Starter

Join Date: Sep 2001

Location: Massachusetts

Posts: 2,597

Likes: 0

Received 0 Likes

on

0 Posts

I am removing my stock turbo. I have 3 of the 4 bolts that attach the crossover pipe to the turbin inlet. The one that is left is the one that has the nut welded to the flange. It is one of the bottom ones and the bolt head is close to the engine block. I can get a wrench in there but can't get any leverage or room to wack it with a hammer. Plus the O2 sensor is in the way. I can get a ratchet in there from underneath but the crossover and down pipe are in the way of a breaker bar. I was going to leave the downpipe attached to the turbo. maybe i should try and remove the down pipe first. What do you think?

#2

Addict

Rennlist Member

Rennlist

Site Sponsor

Rennlist Member

Rennlist

Site Sponsor

Remove the o2 sensor to give yourself some more room. Then all you can do is get a long handled rachet on there and pop it loose. After that it is a 1/4 turn with an open end wrench until you get it off...a real pain in the butt. You can't use a rachet, because it will back against something, and you won't be able to remove the rachet off the bolt.

#3

Once you break the bolt & get it moving........

Costco has a set of Cresent stubby ratchet wrenches for under $30 [I've seen 'em in catalogs for near $100!]. I got 'em without really having a good reason other than the deal. Hit the same problem you are having, and discovered that the 17mm Cresent works beautifully to get that nut off.

Costco has a set of Cresent stubby ratchet wrenches for under $30 [I've seen 'em in catalogs for near $100!]. I got 'em without really having a good reason other than the deal. Hit the same problem you are having, and discovered that the 17mm Cresent works beautifully to get that nut off.

#4

Banned

Join Date: Feb 2004

Location: In self-imposed exile.

Posts: 14,072

Likes: 0

Received 8 Likes

on

7 Posts

You still have to do the two allen head bolts for the turbo itself. If you think you're having fun now, just wait. . .

Have you removed the brake booster heat shield? It's a bit of a pain, but worth it, IMO.

Have you removed the brake booster heat shield? It's a bit of a pain, but worth it, IMO.

#5

Drifting

Thread Starter

Join Date: Sep 2001

Location: Massachusetts

Posts: 2,597

Likes: 0

Received 0 Likes

on

0 Posts

Finally got the brake booster heat shield off. Now I need some thermal blanket to wrap the turbo. The two allen bolts are still waiting. I need to stock up on some beer.

#6

Originally Posted by Porsche-O-Phile

You still have to do the two allen head bolts for the turbo itself. If you think you're having fun now, just wait. . .

If you got a long enough extensioner and a ratchet you don`t have to loosen the steering rack either

#7

Yeah, get about three long extensions, a set of allen sockets, and a swivel and the the two turbo bolts are easy. It took me about two hours of alternating between beer breaks and tiny turns to get that flange bolt off though.

Trending Topics

#8

Rennlist Member

I just went through thid job and yes, it is not fun. If I remember correctly, I was able to loosen the bolt that is attached to the welded nut (who thought of that???) with a flex gearwrench (http://www.thetoolwarehouse.net/shop/KD-9700.html). It takes lots of patience and the right tools but it can be done. Good luck.

#9

I used my ratchet wrenches for that chore. Sears offers a line by Gearworks (I think?) with a one way ratchet and a flexible head. If you keep the packaging, they offer a replacement warranty (only catch is, you have to replace the set... I'll take a new set if one breaks  ). They were $80 something for the set when I got them a little over a year ago, but I think they're more now. They have proved to be invaluable.

). They were $80 something for the set when I got them a little over a year ago, but I think they're more now. They have proved to be invaluable.

). They were $80 something for the set when I got them a little over a year ago, but I think they're more now. They have proved to be invaluable.

). They were $80 something for the set when I got them a little over a year ago, but I think they're more now. They have proved to be invaluable.

#10

Race Director

"The one that is left is the one that has the nut welded to the flange. It is one of the bottom ones and the bolt head is close to the engine block."

I just remove the O2-sensor, no need to remove the heat-shield off the brake-booster. I use box-end of a normal 15mm open-end wrench. I cut off the open-end part and slip a pipe over the end to get extra leverage. Too long of a pipe won't let you swing it more than 10-degrees. About a 4-5" extension in length works about right to increase leverage to break that bolt loose and still let you swing the wrench. Also for those yet to do this job, remove that bolt first, not last...

I just remove the O2-sensor, no need to remove the heat-shield off the brake-booster. I use box-end of a normal 15mm open-end wrench. I cut off the open-end part and slip a pipe over the end to get extra leverage. Too long of a pipe won't let you swing it more than 10-degrees. About a 4-5" extension in length works about right to increase leverage to break that bolt loose and still let you swing the wrench. Also for those yet to do this job, remove that bolt first, not last...

#11

Drifting

Thread Starter

Join Date: Sep 2001

Location: Massachusetts

Posts: 2,597

Likes: 0

Received 0 Likes

on

0 Posts

Fiddled for 15 minutes then dedided to take Danno's advice. I got the O2 sensor off. Hacked off the open end of a box end wrench and used one of my second besttools I have, an iron pipe, as a breaker and had enough room from under there to snap it loose.

#12

I finally got the bottom flange bolt off - without taking the O2 sensor off. Lucky that I have small hands and double jointed shoulders. *lol* I'm down to the last two dreaded bolts. I bought a hex socket but it looks like it's going to be a tight fit to get it on the lower bolt without hitting the steering rack. I can get it on but I'm not sure it's straight and I don't want to strip it. Is there such a thing as a low profile hex socket?

#13

Rennlist Member

Please don't take this the wrong way, but next time, make that bolt the first one you take off not the last

See Tom M"Ginn's write up I found it very helpful ... That was one of the tips he gave....

One other tip When removing those allen bolts under the turbo I found a wobble extension invaluable

I also used a pipe extension on the end of the ratchet to provide extra leverage ( trust me its needed )

I also was told to literally hammer the allen key into the bolt and to push as hard up as you do turing the ratchet ..

and finally bath the $hit outta the two bolts with PB blaster for days and hit them a few times as well ....

good luck

Regards

Ed

ps I had a hella time getting of the O2 sensor ...Thank God I got it out with the crossover removed ...I had to put a wrench on it and hit it with a dead blow hammer

See Tom M"Ginn's write up I found it very helpful ... That was one of the tips he gave....

One other tip When removing those allen bolts under the turbo I found a wobble extension invaluable

I also used a pipe extension on the end of the ratchet to provide extra leverage ( trust me its needed )

I also was told to literally hammer the allen key into the bolt and to push as hard up as you do turing the ratchet ..

and finally bath the $hit outta the two bolts with PB blaster for days and hit them a few times as well ....

good luck

Regards

Ed

ps I had a hella time getting of the O2 sensor ...Thank God I got it out with the crossover removed ...I had to put a wrench on it and hit it with a dead blow hammer

#14

Race Director

Really? I've never had an issue with the O2-sensor. I just use a long 22mm open-end wrench on it and it comes out, even though I only get to push it 20-degrees at first.

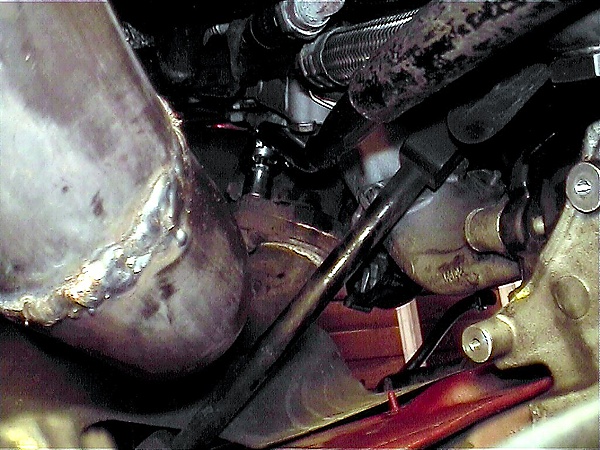

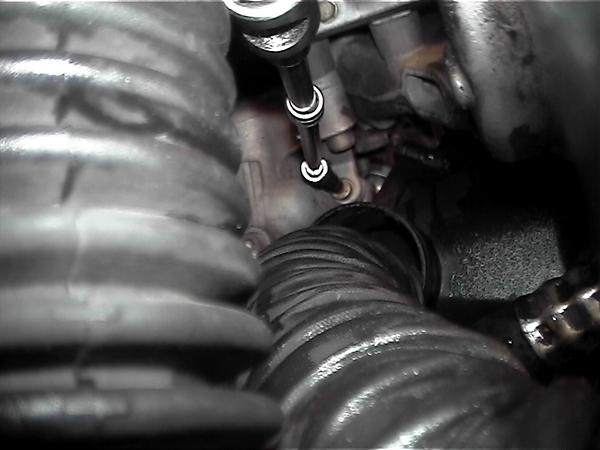

Ok, found a better tool to remove the lower turbine-flange bolt. It's a thin Craftsman flex-head ratchet:

Similar to this other one I had earlier, but it was a little too wide and too thick. Still works well on the upper bolts:

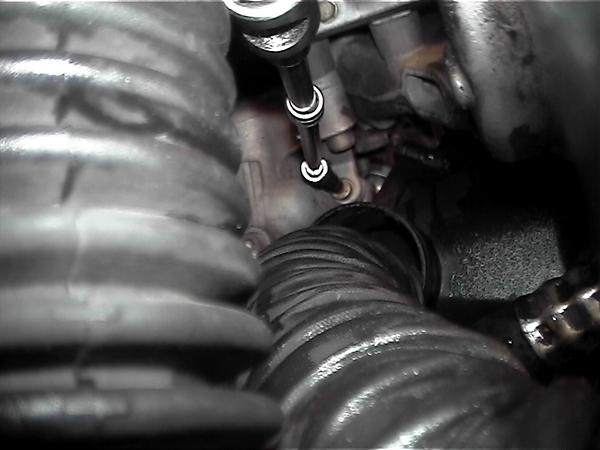

As for the allen-head turbo-mount bolts, Crazy Eddie & Tom's got the right idea. I use a 1/4" drive allen-key socket with a wobble attachment (1/4" drive will be apparent later):

The electrical tape keeps the wobble from flopping all over the place; bends just enough to give flex. The upper bolt's the easiest to remove because it's out in the open:

See how the wobble allows the allen-key to fit perfectly inline with the head of the bolt. Would be a good idea to clean out the hole in the allen-head with a small flat screwdriver beforehand. Then hammer the end of the extensions to drive the tool all the way into the allen-head. Attach ratchet-handle and keep steady pressure on the bolt with the other hand. When spinning the ratchet, keep firm pressure and spin in one direction only. If you relax or do the back & forth ratcheting motion, it'll cause the allen-key socket to wobble and you'll strip out the bolt. Then you'll have to remove your alternator to get a small drill in there to drill out the bolt-head. So take your time, get the right tools and practice the technique.

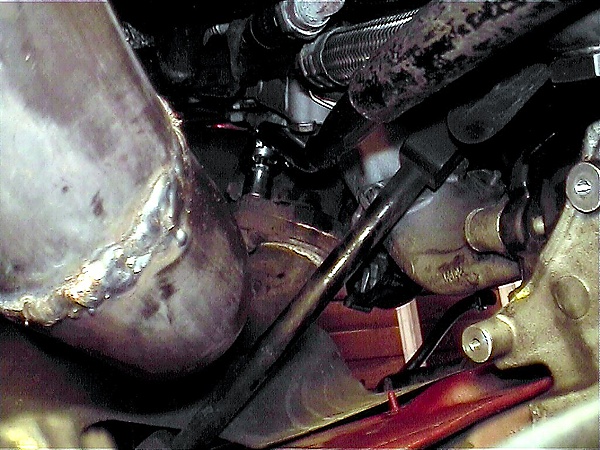

The lower bolt's a little more of pain because you've got the steering-shaft U-joint right below the bolt:

Rotate the steering so that the open corners of the U-joint is below the bolt-head. Then you'll need to reach up with your long tool between the steering-rack and crossmember to get as straight a shot at the bolt as possible:

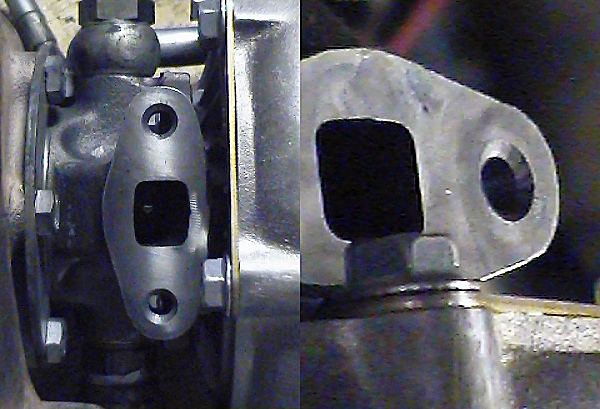

Hammer in the allen-key to make sure it's fully seated. Note that the 1/4" drive allows the tool to fit into the open corner of the U-joint and stay as straight as possible so you don't strip the bolt-head:

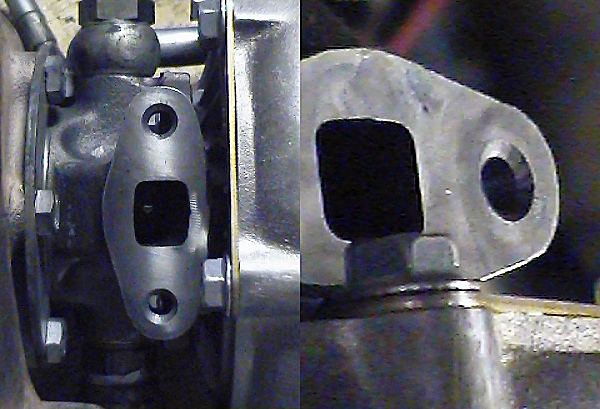

To re-assemble, I find cuting some diagonal chamfers into the turbo's center-mount really helps to re-install the bolts:

You also want to grind a 45-degree bevel on the tip of the bolts as well. Then peek through the gap beween the crossmember and steering-rack to line up the upper-bolt's hole with the hole in the turbo. With the bevels, you can be off by as much as 1/2 the diameter of the bolt and it'll still wiggle the turbo over on-center.

Ok, found a better tool to remove the lower turbine-flange bolt. It's a thin Craftsman flex-head ratchet:

Similar to this other one I had earlier, but it was a little too wide and too thick. Still works well on the upper bolts:

As for the allen-head turbo-mount bolts, Crazy Eddie & Tom's got the right idea. I use a 1/4" drive allen-key socket with a wobble attachment (1/4" drive will be apparent later):

The electrical tape keeps the wobble from flopping all over the place; bends just enough to give flex. The upper bolt's the easiest to remove because it's out in the open:

See how the wobble allows the allen-key to fit perfectly inline with the head of the bolt. Would be a good idea to clean out the hole in the allen-head with a small flat screwdriver beforehand. Then hammer the end of the extensions to drive the tool all the way into the allen-head. Attach ratchet-handle and keep steady pressure on the bolt with the other hand. When spinning the ratchet, keep firm pressure and spin in one direction only. If you relax or do the back & forth ratcheting motion, it'll cause the allen-key socket to wobble and you'll strip out the bolt. Then you'll have to remove your alternator to get a small drill in there to drill out the bolt-head. So take your time, get the right tools and practice the technique.

The lower bolt's a little more of pain because you've got the steering-shaft U-joint right below the bolt:

Rotate the steering so that the open corners of the U-joint is below the bolt-head. Then you'll need to reach up with your long tool between the steering-rack and crossmember to get as straight a shot at the bolt as possible:

Hammer in the allen-key to make sure it's fully seated. Note that the 1/4" drive allows the tool to fit into the open corner of the U-joint and stay as straight as possible so you don't strip the bolt-head:

To re-assemble, I find cuting some diagonal chamfers into the turbo's center-mount really helps to re-install the bolts:

You also want to grind a 45-degree bevel on the tip of the bolts as well. Then peek through the gap beween the crossmember and steering-rack to line up the upper-bolt's hole with the hole in the turbo. With the bevels, you can be off by as much as 1/2 the diameter of the bolt and it'll still wiggle the turbo over on-center.

#15

Addict

Rennlist Member

Rennlist Member

Originally Posted by Danno