Any Metallurgists Here? What specific material are Ball joint pins typically?

#1

Three Wheelin'

Thread Starter

So I have determined that no one makes a longer pin for the fabcar arms. The pin is now at a machine shop and they said it would be no problem to do a production run, However.. They cannot Identify the material. I need to know the stock to order. I figured this forum would be a good place to start. Comments? Suggestions?

#2

Race Car

Cannot identify the material....?

LOL, I have two friends that own massive machine/fab shops (I am right in Mississippi River industrial corridor) and both of them have a mobile metallurgist that calls on them every 1-2 weeks as regular visit and on demand when they need one asap.

I have had as many failures as pretty much anyone and I have seen them snap and bend so I would guess even among the small source selections for our apps, the type/quality is variable.

Surely to make initial machining easier, I would guess they are post treated, most likely with additional carbon...?

If you are in no rush, I could have at least the one you have id'ed.

Might take a couple weeks, but I guess analyzing any of the ones (stock-aftermarket stock) I have around here would work just the same.

Ping Max Energy, he travels as job in industrial settings and could probably get this done in no time.

T

LOL, I have two friends that own massive machine/fab shops (I am right in Mississippi River industrial corridor) and both of them have a mobile metallurgist that calls on them every 1-2 weeks as regular visit and on demand when they need one asap.

I have had as many failures as pretty much anyone and I have seen them snap and bend so I would guess even among the small source selections for our apps, the type/quality is variable.

Surely to make initial machining easier, I would guess they are post treated, most likely with additional carbon...?

If you are in no rush, I could have at least the one you have id'ed.

Might take a couple weeks, but I guess analyzing any of the ones (stock-aftermarket stock) I have around here would work just the same.

Ping Max Energy, he travels as job in industrial settings and could probably get this done in no time.

T

#3

Three Wheelin'

Thread Starter

T, No Problem The Pin that I have is at a machine shop now and will get it to you, Im in No Hurry.... This pin was in a car that hit the wall HARD at Road Atlanta… The car was Totaled and I have the arms off it. Bent Rim, Twisted the Castor Mount ECT... I was adjusting my Wheel Bearings after loosing my Dust cap and putting a set-screw in it. I had the bearing Tight and could still feel "Lash". It was coming from the mono-ball, So I replaced the mono-ball and the pin. When I took the pin out I looked at it and saw that it was bent slightly, (Could not see the bend it when it was installed.) so I confirmed it by spinning it in a drill... BUT The pin didn't break and therefore I have to believe that this design is a good one.. I just don't like the angle that the arms are at when I am at Ride Height. It HAS to screw up the RC. This might be the answer we are looking for. I assume Eon hasn't broken any lately? Or is he just not racing as much and is busy with the addition to the family? - Glen.

#4

Race Car

Yep, not racing as much with new baby, but the last couple he did was in friend's 968 anyway.

It had FabCar arms....

Friend sold the car though, actually to a guy we normally long haul with so I guess I'll still see it from time to time.

Sp2 has been pushed against a wall in my shop with a smashed 1/4 panel for quite a while.

Cut a donor off another tub.

Planned on just grafting in a large section by using a 1/2" crimper tool I have to recess the perimeter of remaining 1/4 after cutout where donor lays flush to spot weld.

BTW, pretty much tried everything on the grease caps.

Knurling...., tried drilled divots inside diameter of hub with clocked punch peens from inside the cap that line up and "lock" into the divots, etc, etc.

Thing that works is to drill a 1/16th hole in the center.

The aluminum hub expands more than the cap but it's the internal pressure that pushes it out.

Vent that and you are golden.

I have never seen enough grease on the cap near the hole to even wipe off.

T

It had FabCar arms....

Friend sold the car though, actually to a guy we normally long haul with so I guess I'll still see it from time to time.

Sp2 has been pushed against a wall in my shop with a smashed 1/4 panel for quite a while.

Cut a donor off another tub.

Planned on just grafting in a large section by using a 1/2" crimper tool I have to recess the perimeter of remaining 1/4 after cutout where donor lays flush to spot weld.

BTW, pretty much tried everything on the grease caps.

Knurling...., tried drilled divots inside diameter of hub with clocked punch peens from inside the cap that line up and "lock" into the divots, etc, etc.

Thing that works is to drill a 1/16th hole in the center.

The aluminum hub expands more than the cap but it's the internal pressure that pushes it out.

Vent that and you are golden.

I have never seen enough grease on the cap near the hole to even wipe off.

T

#5

Race Car

BTW - street car guys wondering...., "what the he11 are they talking about, grease caps popping out...?"

If you never lost grease caps..., you aint goin' fast enough.

T

If you never lost grease caps..., you aint goin' fast enough.

T

The following users liked this post:

Droops83 (07-24-2019)

#6

Racer

Join Date: May 2008

Location: Encinitas, ca PCA National DE instructor PCA San Diego chief driving instructor

Posts: 341

Likes: 0

Received 6 Likes

on

2 Posts

I would use 4142, which is a 4000 series chrome moly steel, and heat treat to Rc 34-36. If you are going to run the car in freezing weather, heat treat to Rc 32-34.

This steel has lead added to the alloy, the lead has no effect on physical properties other than ease of machining.

With this steel you have to rough out the parts leaving ~.100' on all surfaces and finish machine after austenizing (heat treat).

The other choice would be 8620, but it's harder to machine a nice surface finish in it.

This steel has lead added to the alloy, the lead has no effect on physical properties other than ease of machining.

With this steel you have to rough out the parts leaving ~.100' on all surfaces and finish machine after austenizing (heat treat).

The other choice would be 8620, but it's harder to machine a nice surface finish in it.

#7

Race Car

I would use 4142, which is a 4000 series chrome moly steel, and heat treat to Rc 34-36. If you are going to run the car in freezing weather, heat treat to Rc 32-34.

This steel has lead added to the alloy, the lead has no effect on physical properties other than ease of machining.

With this steel you have to rough out the parts leaving ~.100' on all surfaces and finish machine after austenizing (heat treat).

The other choice would be 8620, but it's harder to machine a nice surface finish in it.

This steel has lead added to the alloy, the lead has no effect on physical properties other than ease of machining.

With this steel you have to rough out the parts leaving ~.100' on all surfaces and finish machine after austenizing (heat treat).

The other choice would be 8620, but it's harder to machine a nice surface finish in it.

I see 4140 there but not 4142.

You a machinist Dave..?

T

Trending Topics

#8

Racer

Join Date: May 2008

Location: Encinitas, ca PCA National DE instructor PCA San Diego chief driving instructor

Posts: 341

Likes: 0

Received 6 Likes

on

2 Posts

I have a 35+ years of practical experience using alloy steels from a design standpoint as well as machining and heat treating. I'm also x-ray certified by NASA to weld these steels for space flight assemblies, so yeah, I've seen a few parts.....

You will probably have to order 4142 from a reputable source, but I greatly prefer this steel in this application. It will come condition A (annealed) and need to be heat treated after roughing, and before finish machining.

BTW, this is the steel I made my lower rear shock mounts out of, no issues after 18 years of punishing track use with high (750lb and up) spring rates. They have outlasted one set of JC Cross dampers, one set of JRZ's and are still going strong holding the current Motion Controls. I used JB Weld as bedding compound when I threaded them in.

The following 5 users liked this post by LUCKY DAVE:

951and944S (07-24-2019),

Droops83 (07-24-2019),

gruhsy (07-24-2019),

Jay Wellwood (07-24-2019),

SeaCay (07-24-2019)

#9

Three Wheelin'

Thread Starter

Cool, Thanks Guys, We are Lucky to have Lucky Dave on the list! Great Resource! Thank you!

T, Thanks for the Idea for the Grease caps.. Yea, I guess that is a sort of "Gauge" as to how hard you are driving.... I was turning my best times when the cap flew off... He came to me after the session and said, "Your Grease cap is way up in the grass at the toe of the boot"

T, Thanks for the Idea for the Grease caps.. Yea, I guess that is a sort of "Gauge" as to how hard you are driving.... I was turning my best times when the cap flew off... He came to me after the session and said, "Your Grease cap is way up in the grass at the toe of the boot"

#10

I served a four year formal apprenticeship as a machinist/tool and die maker (still have the journeyman card) while going to school to become a mechanical engineer. So I'm both.

I have a 35+ years of practical experience using alloy steels from a design standpoint as well as machining and heat treating. I'm also x-ray certified by NASA to weld these steels for space flight assemblies, so yeah, I've seen a few parts.....

You will probably have to order 4142 from a reputable source, but I greatly prefer this steel in this application. It will come condition A (annealed) and need to be heat treated after roughing, and before finish machining.

BTW, this is the steel I made my lower rear shock mounts out of, no issues after 18 years of punishing track use with high (750lb and up) spring rates. They have outlasted one set of JC Cross dampers, one set of JRZ's and are still going strong holding the current Motion Controls. I used JB Weld as bedding compound when I threaded them in.

I have a 35+ years of practical experience using alloy steels from a design standpoint as well as machining and heat treating. I'm also x-ray certified by NASA to weld these steels for space flight assemblies, so yeah, I've seen a few parts.....

You will probably have to order 4142 from a reputable source, but I greatly prefer this steel in this application. It will come condition A (annealed) and need to be heat treated after roughing, and before finish machining.

BTW, this is the steel I made my lower rear shock mounts out of, no issues after 18 years of punishing track use with high (750lb and up) spring rates. They have outlasted one set of JC Cross dampers, one set of JRZ's and are still going strong holding the current Motion Controls. I used JB Weld as bedding compound when I threaded them in.

That's quite the resume

Last edited by gruhsy; 04-02-2020 at 10:42 AM.

#12

Racer

Join Date: May 2008

Location: Encinitas, ca PCA National DE instructor PCA San Diego chief driving instructor

Posts: 341

Likes: 0

Received 6 Likes

on

2 Posts

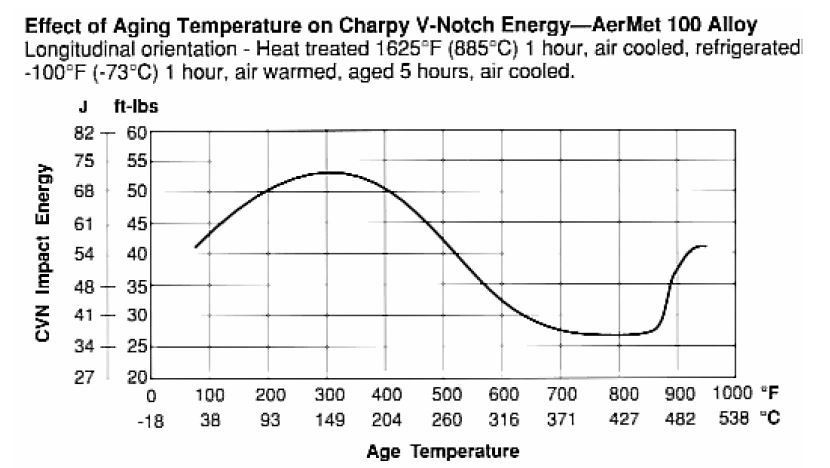

I'm not familiar with that alloy, maybe it's wonderful.

However, 31 points of chromium gives me the heebie jeebies about the charpy notch toughness value (brittle fracture), even with 12 points of molybdenum to moderate it.

But I repeat, I have zero experience with this alloy.

The Chrome Moly steel I like for this application, like all high carbon steels, corrodes like it's trying to win a championship, so it must be galvanically protected or painted, etc. Stay away from plating for structural parts. I simply sprayed my parts with rattle can cold galvanize (which is very soft) and top coated with some rattle can epoxy. Ball joint pins will typically be grease coated, and that's enough.

However, 31 points of chromium gives me the heebie jeebies about the charpy notch toughness value (brittle fracture), even with 12 points of molybdenum to moderate it.

But I repeat, I have zero experience with this alloy.

The Chrome Moly steel I like for this application, like all high carbon steels, corrodes like it's trying to win a championship, so it must be galvanically protected or painted, etc. Stay away from plating for structural parts. I simply sprayed my parts with rattle can cold galvanize (which is very soft) and top coated with some rattle can epoxy. Ball joint pins will typically be grease coated, and that's enough.

#14

Race Car

#15

Race Car

Got in the habit of just replacing them as a matter of course preventatively and in more than one instance, found the ball joint pins at and near failure mode.

We tow with through the wheel straps, pulling fwd on the wheels but the car weight still fully suspended, which obviously contributes to the duty life of these parts.

T