Settings for Innovate SCG-1 and Vitesse MAF?

#1

Thread Starter

Three Wheelin'

Already asked John for the settings, and understandably so he said I’d need to contact Innovate. With that said I’m waiting on them for an answer but thought I’d ask here if anyone knows.

What I’m needing are the Settings for Innovate SCG-1 when used with Vitesse MAF (or maybe the Vitesse aspect isn’t a factor). 1986 Turbo, stock turbo and intercooler, upgraded injectors, OEM wastegate modified by John to dusk port. John did share that the spring is 7 pounds.

instructions for it, https://www.innovatemotorsports.com/...1%20Manual.pdf

Pages 10-13 it lists the following. What settings should I input for the below or are the default settings OK?

I searched the documents you sent and could not find any references, for setting up an EBC. ex: Spring pressure, etc.

I have it all hooked up, including wideband O2 installed via a bung had welded on.

From the Innovate install link above

1. Wastegate Duty (WG Duty) – Adjusts the solenoid duty cycle in 2% increments. The higher the duty cycle percentage the higher boost pressure will be achieved over the base wastegate spring pressure. When wastegate duty is active, the SCG-1 will display the duty cycle percentage on the upper right-hand corner viewport.

Default setting is 4%

Tuning Tip: Start small and work up. Do not increase Wastegate Duty if Boost/AFR cuts occur. Remedy Boost/AFR cuts before increasing Wastegate Duty.

Note: Because of flow restrictions, wastegate spring size, and other factors, not all applications will be able to achieve desired target boost pressure.

2. Gain – Ramps up the solenoid Duty Cycle to help with boost pressure drop at high engine speeds. Gain is calculated as a percentage of what the current wastegate duty is set at (Max Duty with Gain = (Gain% * Duty%) + Duty%). For example, if your Wastegate Duty is set at 30% and your Gain is 50% the SCG-1 will gain up to an additional 15% (Max Duty with Gain =45%). Gain is triggered 1.5 seconds into active boost and will ramp up until Max Duty is gained. The SCG-1 will display the active duty cycle and progressive Gain on the upper right-hand corner viewport when active.

Default setting is 0%.

Tuning Tip: Tune your wastegate duty and spring pressure settings before gain.

3. Spring Pressure (Spring Press) – Sets the activation pressure for the solenoid. Set this value at or less than your mechanical spring pressure. Be aware that setting this value too low may cause boost spikes, setting it too high may cause an extreme delay in the activation of the solenoid.

Default setting is 4.9 PSI

Tuning Tip: A good starting point is 1 to 2 PSI below the wastegate's mechanical spring pressure.

4. Boost Cut by Pressure - This is a safety trigger to cut boost by a desired wastegate duty percentage at a specific manifold absolute pressure. There are two setup parameters to trigger this safely cut:

Max Pressure (Boost Cut Press) and Cut Percent (Boost Cut %).

Max Pressure (Boost Cut Press) is the maximum manifold absolute pressure that is safe for the application. Cut Percent (Boost Cut %) is the percentage of wastegate duty that the trigger will cut when the max defined pressure is hit. When the safety Boost Cut by Pressure is triggered, the SCG-1 will display “B Cut” on the upper right-hand corner viewport.

Default setting is 8 PSI with a 100% cut.

Tuning Tip: Start with a 100% Cut Percentage.

5. Boost Cut by AFR – This is a safety trigger to cut boost by a defined AFR . There are two setup parameters to trigger this safely cut: Start Pressure (AFR Start Press) and AFR Cut. Start Pressure (AFR Start Press) is the minimum manifold absolute pressure where the safety cut will become active. AFR Cut is the defined lean A/F that will trigger the safety cut. When the Boost Cut by AFR is triggered, the SCG-1 will display “O2 Cut” on the upper right hand corner.

Default setting is a start pressure of 4.9 PSI and 13 AFR.

Tuning Tip: Set the Start Pressure at the same pressure value as Spring Pressure.

6. Boost Control ON/OFF – When configured from the gauge, this setting is accessed from the main screen. Press and HOLD both the left and right interface buttons, this will disable/enable solenoid control. If there are no other error codes on the status viewport of the screen, the SCG-1 will display “SC OFF”. In LM Programmer, use the Boost Control ON checkbox to turn the solenoid control ON/OFF.

Default setting is ON.

What I’m needing are the Settings for Innovate SCG-1 when used with Vitesse MAF (or maybe the Vitesse aspect isn’t a factor). 1986 Turbo, stock turbo and intercooler, upgraded injectors, OEM wastegate modified by John to dusk port. John did share that the spring is 7 pounds.

instructions for it, https://www.innovatemotorsports.com/...1%20Manual.pdf

Pages 10-13 it lists the following. What settings should I input for the below or are the default settings OK?

I searched the documents you sent and could not find any references, for setting up an EBC. ex: Spring pressure, etc.

I have it all hooked up, including wideband O2 installed via a bung had welded on.

From the Innovate install link above

1. Wastegate Duty (WG Duty) – Adjusts the solenoid duty cycle in 2% increments. The higher the duty cycle percentage the higher boost pressure will be achieved over the base wastegate spring pressure. When wastegate duty is active, the SCG-1 will display the duty cycle percentage on the upper right-hand corner viewport.

Default setting is 4%

Tuning Tip: Start small and work up. Do not increase Wastegate Duty if Boost/AFR cuts occur. Remedy Boost/AFR cuts before increasing Wastegate Duty.

Note: Because of flow restrictions, wastegate spring size, and other factors, not all applications will be able to achieve desired target boost pressure.

2. Gain – Ramps up the solenoid Duty Cycle to help with boost pressure drop at high engine speeds. Gain is calculated as a percentage of what the current wastegate duty is set at (Max Duty with Gain = (Gain% * Duty%) + Duty%). For example, if your Wastegate Duty is set at 30% and your Gain is 50% the SCG-1 will gain up to an additional 15% (Max Duty with Gain =45%). Gain is triggered 1.5 seconds into active boost and will ramp up until Max Duty is gained. The SCG-1 will display the active duty cycle and progressive Gain on the upper right-hand corner viewport when active.

Default setting is 0%.

Tuning Tip: Tune your wastegate duty and spring pressure settings before gain.

3. Spring Pressure (Spring Press) – Sets the activation pressure for the solenoid. Set this value at or less than your mechanical spring pressure. Be aware that setting this value too low may cause boost spikes, setting it too high may cause an extreme delay in the activation of the solenoid.

Default setting is 4.9 PSI

Tuning Tip: A good starting point is 1 to 2 PSI below the wastegate's mechanical spring pressure.

4. Boost Cut by Pressure - This is a safety trigger to cut boost by a desired wastegate duty percentage at a specific manifold absolute pressure. There are two setup parameters to trigger this safely cut:

Max Pressure (Boost Cut Press) and Cut Percent (Boost Cut %).

Max Pressure (Boost Cut Press) is the maximum manifold absolute pressure that is safe for the application. Cut Percent (Boost Cut %) is the percentage of wastegate duty that the trigger will cut when the max defined pressure is hit. When the safety Boost Cut by Pressure is triggered, the SCG-1 will display “B Cut” on the upper right-hand corner viewport.

Default setting is 8 PSI with a 100% cut.

Tuning Tip: Start with a 100% Cut Percentage.

5. Boost Cut by AFR – This is a safety trigger to cut boost by a defined AFR . There are two setup parameters to trigger this safely cut: Start Pressure (AFR Start Press) and AFR Cut. Start Pressure (AFR Start Press) is the minimum manifold absolute pressure where the safety cut will become active. AFR Cut is the defined lean A/F that will trigger the safety cut. When the Boost Cut by AFR is triggered, the SCG-1 will display “O2 Cut” on the upper right hand corner.

Default setting is a start pressure of 4.9 PSI and 13 AFR.

Tuning Tip: Set the Start Pressure at the same pressure value as Spring Pressure.

6. Boost Control ON/OFF – When configured from the gauge, this setting is accessed from the main screen. Press and HOLD both the left and right interface buttons, this will disable/enable solenoid control. If there are no other error codes on the status viewport of the screen, the SCG-1 will display “SC OFF”. In LM Programmer, use the Boost Control ON checkbox to turn the solenoid control ON/OFF.

Default setting is ON.

#2

Three Wheelin'

Already asked John for the settings, and understandably so he said I’d need to contact Innovate. With that said I’m waiting on them for an answer but thought I’d ask here if anyone knows.

What I’m needing are the Settings for Innovate SCG-1 when used with Vitesse MAF (or maybe the Vitesse aspect isn’t a factor). 1986 Turbo, stock turbo and intercooler, upgraded injectors, OEM wastegate modified by John to dusk port. John did share that the spring is 7 pounds.

instructions for it, https://www.innovatemotorsports.com/...1%20Manual.pdf

Pages 10-13 it lists the following. What settings should I input for the below or are the default settings OK?

I searched the documents you sent and could not find any references, for setting up an EBC. ex: Spring pressure, etc.

I have it all hooked up, including wideband O2 installed via a bung had welded on.

From the Innovate install link above

1. Wastegate Duty (WG Duty) – Adjusts the solenoid duty cycle in 2% increments. The higher the duty cycle percentage the higher boost pressure will be achieved over the base wastegate spring pressure. When wastegate duty is active, the SCG-1 will display the duty cycle percentage on the upper right-hand corner viewport.

Default setting is 4%

Tuning Tip: Start small and work up. Do not increase Wastegate Duty if Boost/AFR cuts occur. Remedy Boost/AFR cuts before increasing Wastegate Duty.

Note: Because of flow restrictions, wastegate spring size, and other factors, not all applications will be able to achieve desired target boost pressure.

2. Gain – Ramps up the solenoid Duty Cycle to help with boost pressure drop at high engine speeds. Gain is calculated as a percentage of what the current wastegate duty is set at (Max Duty with Gain = (Gain% * Duty%) + Duty%). For example, if your Wastegate Duty is set at 30% and your Gain is 50% the SCG-1 will gain up to an additional 15% (Max Duty with Gain =45%). Gain is triggered 1.5 seconds into active boost and will ramp up until Max Duty is gained. The SCG-1 will display the active duty cycle and progressive Gain on the upper right-hand corner viewport when active.

Default setting is 0%.

Tuning Tip: Tune your wastegate duty and spring pressure settings before gain.

3. Spring Pressure (Spring Press) – Sets the activation pressure for the solenoid. Set this value at or less than your mechanical spring pressure. Be aware that setting this value too low may cause boost spikes, setting it too high may cause an extreme delay in the activation of the solenoid.

Default setting is 4.9 PSI

Tuning Tip: A good starting point is 1 to 2 PSI below the wastegate's mechanical spring pressure.

4. Boost Cut by Pressure - This is a safety trigger to cut boost by a desired wastegate duty percentage at a specific manifold absolute pressure. There are two setup parameters to trigger this safely cut:

Max Pressure (Boost Cut Press) and Cut Percent (Boost Cut %).

Max Pressure (Boost Cut Press) is the maximum manifold absolute pressure that is safe for the application. Cut Percent (Boost Cut %) is the percentage of wastegate duty that the trigger will cut when the max defined pressure is hit. When the safety Boost Cut by Pressure is triggered, the SCG-1 will display “B Cut” on the upper right-hand corner viewport.

Default setting is 8 PSI with a 100% cut.

Tuning Tip: Start with a 100% Cut Percentage.

5. Boost Cut by AFR – This is a safety trigger to cut boost by a defined AFR . There are two setup parameters to trigger this safely cut: Start Pressure (AFR Start Press) and AFR Cut. Start Pressure (AFR Start Press) is the minimum manifold absolute pressure where the safety cut will become active. AFR Cut is the defined lean A/F that will trigger the safety cut. When the Boost Cut by AFR is triggered, the SCG-1 will display “O2 Cut” on the upper right hand corner.

Default setting is a start pressure of 4.9 PSI and 13 AFR.

Tuning Tip: Set the Start Pressure at the same pressure value as Spring Pressure.

6. Boost Control ON/OFF – When configured from the gauge, this setting is accessed from the main screen. Press and HOLD both the left and right interface buttons, this will disable/enable solenoid control. If there are no other error codes on the status viewport of the screen, the SCG-1 will display “SC OFF”. In LM Programmer, use the Boost Control ON checkbox to turn the solenoid control ON/OFF.

Default setting is ON.

What I’m needing are the Settings for Innovate SCG-1 when used with Vitesse MAF (or maybe the Vitesse aspect isn’t a factor). 1986 Turbo, stock turbo and intercooler, upgraded injectors, OEM wastegate modified by John to dusk port. John did share that the spring is 7 pounds.

instructions for it, https://www.innovatemotorsports.com/...1%20Manual.pdf

Pages 10-13 it lists the following. What settings should I input for the below or are the default settings OK?

I searched the documents you sent and could not find any references, for setting up an EBC. ex: Spring pressure, etc.

I have it all hooked up, including wideband O2 installed via a bung had welded on.

From the Innovate install link above

1. Wastegate Duty (WG Duty) – Adjusts the solenoid duty cycle in 2% increments. The higher the duty cycle percentage the higher boost pressure will be achieved over the base wastegate spring pressure. When wastegate duty is active, the SCG-1 will display the duty cycle percentage on the upper right-hand corner viewport.

Default setting is 4%

Tuning Tip: Start small and work up. Do not increase Wastegate Duty if Boost/AFR cuts occur. Remedy Boost/AFR cuts before increasing Wastegate Duty.

Note: Because of flow restrictions, wastegate spring size, and other factors, not all applications will be able to achieve desired target boost pressure.

2. Gain – Ramps up the solenoid Duty Cycle to help with boost pressure drop at high engine speeds. Gain is calculated as a percentage of what the current wastegate duty is set at (Max Duty with Gain = (Gain% * Duty%) + Duty%). For example, if your Wastegate Duty is set at 30% and your Gain is 50% the SCG-1 will gain up to an additional 15% (Max Duty with Gain =45%). Gain is triggered 1.5 seconds into active boost and will ramp up until Max Duty is gained. The SCG-1 will display the active duty cycle and progressive Gain on the upper right-hand corner viewport when active.

Default setting is 0%.

Tuning Tip: Tune your wastegate duty and spring pressure settings before gain.

3. Spring Pressure (Spring Press) – Sets the activation pressure for the solenoid. Set this value at or less than your mechanical spring pressure. Be aware that setting this value too low may cause boost spikes, setting it too high may cause an extreme delay in the activation of the solenoid.

Default setting is 4.9 PSI

Tuning Tip: A good starting point is 1 to 2 PSI below the wastegate's mechanical spring pressure.

4. Boost Cut by Pressure - This is a safety trigger to cut boost by a desired wastegate duty percentage at a specific manifold absolute pressure. There are two setup parameters to trigger this safely cut:

Max Pressure (Boost Cut Press) and Cut Percent (Boost Cut %).

Max Pressure (Boost Cut Press) is the maximum manifold absolute pressure that is safe for the application. Cut Percent (Boost Cut %) is the percentage of wastegate duty that the trigger will cut when the max defined pressure is hit. When the safety Boost Cut by Pressure is triggered, the SCG-1 will display “B Cut” on the upper right-hand corner viewport.

Default setting is 8 PSI with a 100% cut.

Tuning Tip: Start with a 100% Cut Percentage.

5. Boost Cut by AFR – This is a safety trigger to cut boost by a defined AFR . There are two setup parameters to trigger this safely cut: Start Pressure (AFR Start Press) and AFR Cut. Start Pressure (AFR Start Press) is the minimum manifold absolute pressure where the safety cut will become active. AFR Cut is the defined lean A/F that will trigger the safety cut. When the Boost Cut by AFR is triggered, the SCG-1 will display “O2 Cut” on the upper right hand corner.

Default setting is a start pressure of 4.9 PSI and 13 AFR.

Tuning Tip: Set the Start Pressure at the same pressure value as Spring Pressure.

6. Boost Control ON/OFF – When configured from the gauge, this setting is accessed from the main screen. Press and HOLD both the left and right interface buttons, this will disable/enable solenoid control. If there are no other error codes on the status viewport of the screen, the SCG-1 will display “SC OFF”. In LM Programmer, use the Boost Control ON checkbox to turn the solenoid control ON/OFF.

Default setting is ON.

Top of my head it looks like Race Car stuff or you know pretty much most of Japanese Engines where the waste gate is (right there) in the engine bay so changing (WG) springs in and out is not that big deal. But on a 951 ... good luck with that!

I suppose the whole point of it is, to accurately calibrate the WG .. because then the WB, can determine a safe level of Boost based on AFR?? But not of much value if you can't set it up?? I would tend to agree it's not the Vitesse stuff. As it's set to run X amount of boost with X supporting mods so you know ... job done. This is on Innovate with there requirements to run there boot with there WB. EBC for there unit.

Most likely ... time to call your local Innovate installer $$$, and have them do it. OR you know cut your losses and throw it up on the bay and get a ... simpler stand alone EBC??? Just a thought.

#3

Three Wheelin'

I doubt anyone will be able to give you settings that work well for you, absent some luck and additional tuning. With that kind of controller, you need to tune on the road/dyno starting slowly and making small increments until you have it dialed in for your particular car/preferences. The Vitesse MAF isn't really a factor per se, other than keeping the max boost in a safe range for the tune/fuel you are using (say 14-15psi on 91+ pump gas/maps). A long long time ago, I had an Apexi boost controller that you needed to program with duty cycles and gear selections, etc. I'm sure it's a great controller once all dialed in, but I yanked it out in favor of the (much simpler) Profec B so that I didn't need to spend hours programming it every time I wanted to make a change. With the Vitesse MAF and profec, I can literally go from 12psi to 22psi with the turn of a ****, without changing the tune.

I live in the high desert in NV 4000 ft above sea level and I run 17 psi with a Max chip and supporting mods. I use a manual BC. And it's fine around here. But when I go to sea level (San Jose Ca) the boost level goes up as I loose elevation?? I found to my surprise that when I got to sea level, I was now at 21 psi!??? Kinda cool but not suppose to be doing that stuff on 91 octane with that chip! So I quickly dialed it down! So to me 17 psi means well uh 17 psi??

So my question would be ... with the "Profec B, does 17 psi mean 17 psi .,.., without screwing around, with the waste gate??? I like to KISS as it were.

#4

Rennlist Member

Well a EBC is on my list of stuff to get.

I live in the high desert in NV 4000 ft above sea level and I run 17 psi with a Max chip and supporting mods. I use a manual BC. And it's fine around here. But when I go to sea level (San Jose Ca) the boost level goes up as I loose elevation?? I found to my surprise that when I got to sea level, I was now at 21 psi!??? Kinda cool but not suppose to be doing that stuff on 91 octane with that chip! So I quickly dialed it down! So to me 17 psi means well uh 17 psi??

So my question would be ... with the "Profec B, does 17 psi mean 17 psi .,.., without screwing around, with the waste gate??? I like to KISS as it were.

I live in the high desert in NV 4000 ft above sea level and I run 17 psi with a Max chip and supporting mods. I use a manual BC. And it's fine around here. But when I go to sea level (San Jose Ca) the boost level goes up as I loose elevation?? I found to my surprise that when I got to sea level, I was now at 21 psi!??? Kinda cool but not suppose to be doing that stuff on 91 octane with that chip! So I quickly dialed it down! So to me 17 psi means well uh 17 psi??

So my question would be ... with the "Profec B, does 17 psi mean 17 psi .,.., without screwing around, with the waste gate??? I like to KISS as it were.

#5

Three Wheelin'

That's a great question and can honestly say I've never checked at higher elevations. My guess (just a guess) is that it would act just like yours. There is no "17" on the Profec -- just one **** to turn up and down the boost, and another **** to alter how quickly the boost ramps up. I usually set it to be X psi at WOT in 4th gear, which usually means less than X in 1st and 2nd, so I'm guessing it's just setting a duty cycle that mimics a manual boost controller. Could be wrong, but that's my guess.

But if you don't go from sea level to altitude or the opposite then 17 psi, means 17 psi. No big deal. But if you want to make a road trip ... to see what it does?? I can put you up for a week end! And you can see what a lightly modded 89 951 S, looks like in a garage on jack stands! It's been there for an embarrassing longgg, amount of time! I find it a true PIA to work on! And I'd certainly not entertain any thoughts of screwing with it's dual port waste gate!! If it were a thing, I'd gladly trade it for a 89 vette with a blown motor.

It's got "issues" but none, related to the motor ... sigh. Up on jack stands on a slanted drive way ... it tried to kill me! When it was on the road at low rpm ... it tried to kill me!! Low speed and not quite fast enough, with left turns at a dead stop ... you know more throttle?? So it went from no interest to, "exhibition of speed" in the blink of an eye, wth???

OH well hopefully ... I'll get it back on the road this year! So there is that and I can the Profec B, EBC to the stack of new parts not installed pile.

#6

Electronic boost controllers work in one of two modes (some boost controllers can be switched between the two, others are stuck as one or the other) - open loop or closed loop. Fancier electronic boost controllers add features such as boost by rpm, boost by gear, boost by load, scramble mode, etc.

In closed loop, you tell the boost controller how much boost you want to make, the boost controller watches the actual boost vs. the target boost, and adjusts the wastegate duty cycle to try to get the two to match. These are PID controllers, and usually give you the ability to adjust the proportional/integral/derivative terms to get the least amount of boost variation and overshoot, ringing, etc. Many times, though, no matter how much you mess around with the PID terms, you will still get a wavy boost curve because the controller can only react to changes that it sees. However, if it's setup right, it should be able to keep boost reasonably constant over changes in elevation, gear, etc.

Open loop means that when you set the wastegate duty cycle, that's the duty cycle that you get, thus that's the boost you get. There's no targeted boost level - if you need more boost, or want to reduce the amount of boost, you need to go into the controller and change the duty cycle.

Best way to set either of these is on a dyno with load control, but you can do it on the street if you can data log rpm, manifold pressure (boost), and afr. Logging wastegate duty cycle would help, too. No matter which mode your boost controller uses, ALWAYS work your way up from low to high, incrementally. Even if your boost controller works in closed loop, the actual boost you get may not match the targeted boost - you may get spikes, oscillations, overshoot, etc., any of which has the potential to damage your engine.

If your boost controller works in closed loop, set your target boost level (remember, start low), do a wide-open throttle run while data logging. Keep an eye on afr and boost levels - if it starts to run lean, or your boost climbs too high, then abort your run. if you can complete the run, graph boost vs. rpm, and see how the boost level comes up. Adjust the PID settings until the boost curve is what you want. Check the afrs to make sure the fuel system is keeping up with the boost - if not, make whatever adjustments you need to make. If the afrs are lean, and you can't make any adjustments to compensate, you'll have to lower the boost level and call it a day. If not, raise the target boost level and repeat until you get to where you want to be.

Tuning an open loop boost controller works pretty much the same - do a run while data logging, go through the data, make your adjustments, repeat. However, instead of changing target boost level, you need to change the wastegate duty cycle. Be careful - the wastegate duty cycle does not have a 1:1 relationship with the amount of boost you'll get. If you start with a low duty cycle (for instance 4%), changing the duty cycle may not have any effect until you reach something much higher, after which the amount of boost you get will not increase linearly with changes in duty cycle. For example, you may not see any changes in boost until you reach 30% duty cycle, after which, a 5% change in duty cycle may give you only 1 pound more boost. Once you reach 50%, a 2% change may give you a 2 pounds of boost, and when you reach 65%, you may be getting 3 pounds of boost for a 1% change in duty cycle...

For the Innovate boost controller, it looks like you have two safety settings - the boost cut by pressure and the boost cut by afr. Set the boost cut by pressure to the max that you ever want to see for your engine, usually a little above your targeted boost level. However, you may need to set this differently to account for boost fluctuations, spikes, etc. Best bet is, while you're tuning, set this a few pounds above your target boost level, and as you increase the target, increase this setting. Boost cut by afr should be set to the leanest afr that you feel comfortable will keep the engine from harm.

After you tune wastegate duty cycle, you can look at the boost curve and set the gain and spring pressure settings to get the smoothest curve, with the fastest spool and the least amount of overshoot.

Hope this helps!

In closed loop, you tell the boost controller how much boost you want to make, the boost controller watches the actual boost vs. the target boost, and adjusts the wastegate duty cycle to try to get the two to match. These are PID controllers, and usually give you the ability to adjust the proportional/integral/derivative terms to get the least amount of boost variation and overshoot, ringing, etc. Many times, though, no matter how much you mess around with the PID terms, you will still get a wavy boost curve because the controller can only react to changes that it sees. However, if it's setup right, it should be able to keep boost reasonably constant over changes in elevation, gear, etc.

Open loop means that when you set the wastegate duty cycle, that's the duty cycle that you get, thus that's the boost you get. There's no targeted boost level - if you need more boost, or want to reduce the amount of boost, you need to go into the controller and change the duty cycle.

Best way to set either of these is on a dyno with load control, but you can do it on the street if you can data log rpm, manifold pressure (boost), and afr. Logging wastegate duty cycle would help, too. No matter which mode your boost controller uses, ALWAYS work your way up from low to high, incrementally. Even if your boost controller works in closed loop, the actual boost you get may not match the targeted boost - you may get spikes, oscillations, overshoot, etc., any of which has the potential to damage your engine.

If your boost controller works in closed loop, set your target boost level (remember, start low), do a wide-open throttle run while data logging. Keep an eye on afr and boost levels - if it starts to run lean, or your boost climbs too high, then abort your run. if you can complete the run, graph boost vs. rpm, and see how the boost level comes up. Adjust the PID settings until the boost curve is what you want. Check the afrs to make sure the fuel system is keeping up with the boost - if not, make whatever adjustments you need to make. If the afrs are lean, and you can't make any adjustments to compensate, you'll have to lower the boost level and call it a day. If not, raise the target boost level and repeat until you get to where you want to be.

Tuning an open loop boost controller works pretty much the same - do a run while data logging, go through the data, make your adjustments, repeat. However, instead of changing target boost level, you need to change the wastegate duty cycle. Be careful - the wastegate duty cycle does not have a 1:1 relationship with the amount of boost you'll get. If you start with a low duty cycle (for instance 4%), changing the duty cycle may not have any effect until you reach something much higher, after which the amount of boost you get will not increase linearly with changes in duty cycle. For example, you may not see any changes in boost until you reach 30% duty cycle, after which, a 5% change in duty cycle may give you only 1 pound more boost. Once you reach 50%, a 2% change may give you a 2 pounds of boost, and when you reach 65%, you may be getting 3 pounds of boost for a 1% change in duty cycle...

For the Innovate boost controller, it looks like you have two safety settings - the boost cut by pressure and the boost cut by afr. Set the boost cut by pressure to the max that you ever want to see for your engine, usually a little above your targeted boost level. However, you may need to set this differently to account for boost fluctuations, spikes, etc. Best bet is, while you're tuning, set this a few pounds above your target boost level, and as you increase the target, increase this setting. Boost cut by afr should be set to the leanest afr that you feel comfortable will keep the engine from harm.

After you tune wastegate duty cycle, you can look at the boost curve and set the gain and spring pressure settings to get the smoothest curve, with the fastest spool and the least amount of overshoot.

Hope this helps!

#7

Rennlist Member

Joined: Sep 2013

Posts: 74

Likes: 0

Received 2 Likes

on

2 Posts

From: Mooresville, NC & Parkville, MD

I would follow the "inch things up a little at a time" philosphy as well. I just installed the SCG-1 also along with a Tial F38 (1bar spring) and A-Tune from Lindsey. I haven't welded in the bung for the wideband yet. For its maiden voyage last night, I set the SCG-1 as follows:

- duty cycle to 0%

- gain 0%

- active pressure (spring pressure) 8spi

- Boost cut 12.5psi

- % Boost cut 50%

Drove it about 20 minutes. Saw 11.5psi average for max boost on the gauge while driving. Unit showed 12.9psi peak boost when I reviewed it after. With the combination of the A-Tune and controller, it didn't even feel like the same car. Off-idle and mid-range acceleration were night and day better compared to before.

I'll post updates as I tweak it, but so far, so good.

Trending Topics

#8

Thread Starter

Three Wheelin'

I would follow the "inch things up a little at a time" philosphy as well. I just installed the SCG-1 also along with a Tial F38 (1bar spring) and A-Tune from Lindsey. I haven't welded in the bung for the wideband yet. For its maiden voyage last night, I set the SCG-1 as follows:

- duty cycle to 0%

- gain 0%

- active pressure (spring pressure) 8spi

- Boost cut 12.5psi

- % Boost cut 50%

Drove it about 20 minutes. Saw 11.5psi average for max boost on the gauge while driving. Unit showed 12.9psi peak boost when I reviewed it after. With the combination of the A-Tune and controller, it didn't even feel like the same car. Off-idle and mid-range acceleration were night and day better compared to before.

I'll post updates as I tweak it, but so far, so good.

#9

One thing to remember - your boost controller cannot lower boost below the amount of spring you have in your wastegate. What the boost controller does is use air pressure to assist the mechanical spring.

So, as you inch up your boost controller, nothing will happen until you reach the bottom threshold set by the spring - once you cross that threshold, your boost controller will start to make an effect.

Seeing 12.9 psi when you have a wastegate spring at 14.5 psi (1bar) is common. Very seldom does your actual boost match the targeted boost from the spring chart. The springs themselves may not have the precise spring rate, and the entire exhaust routing from the manifold through the wastegate to the exhaust all makes a difference in actual boost.

What I usually do is decide on a ballpark amount of boost that I want to make, then choose a spring that’s lighter than the target, and make up the difference with the boost controller. For example, if I want to make around 14.5 psi of boost, I’ll put springs in the wastegate to make 7-10 pounds of boost and do the rest with the boost controller. That way, it’s easy to set up a low boost (I.e. spring only) and a normal (14.5 psi) boost setting. Also, if something goes wrong in the boost control system, like a wastegate hose pops off, it should reduce the amount of boost a noticeable amount.

So, as you inch up your boost controller, nothing will happen until you reach the bottom threshold set by the spring - once you cross that threshold, your boost controller will start to make an effect.

Seeing 12.9 psi when you have a wastegate spring at 14.5 psi (1bar) is common. Very seldom does your actual boost match the targeted boost from the spring chart. The springs themselves may not have the precise spring rate, and the entire exhaust routing from the manifold through the wastegate to the exhaust all makes a difference in actual boost.

What I usually do is decide on a ballpark amount of boost that I want to make, then choose a spring that’s lighter than the target, and make up the difference with the boost controller. For example, if I want to make around 14.5 psi of boost, I’ll put springs in the wastegate to make 7-10 pounds of boost and do the rest with the boost controller. That way, it’s easy to set up a low boost (I.e. spring only) and a normal (14.5 psi) boost setting. Also, if something goes wrong in the boost control system, like a wastegate hose pops off, it should reduce the amount of boost a noticeable amount.

#10

Rennlist Member

Joined: Sep 2013

Posts: 74

Likes: 0

Received 2 Likes

on

2 Posts

From: Mooresville, NC & Parkville, MD

After playing with it a bit more, I did some more research since yesterday, and think I had my start pressure way too low. I'm going to go back to the beginning, set the start pressure to 12.5 (2psi under the spring press) and then tweak from there

Others using similar controllers seem to begin with start pressure adjustments, then duty cycle adjustments and lastly gain. Also very hard to see everything happening while driving, so I downloaded their logworks software to compare boost curves better as I tweak it. I'll post more as I play with it, probably this weekend.

#11

Thread Starter

Three Wheelin'

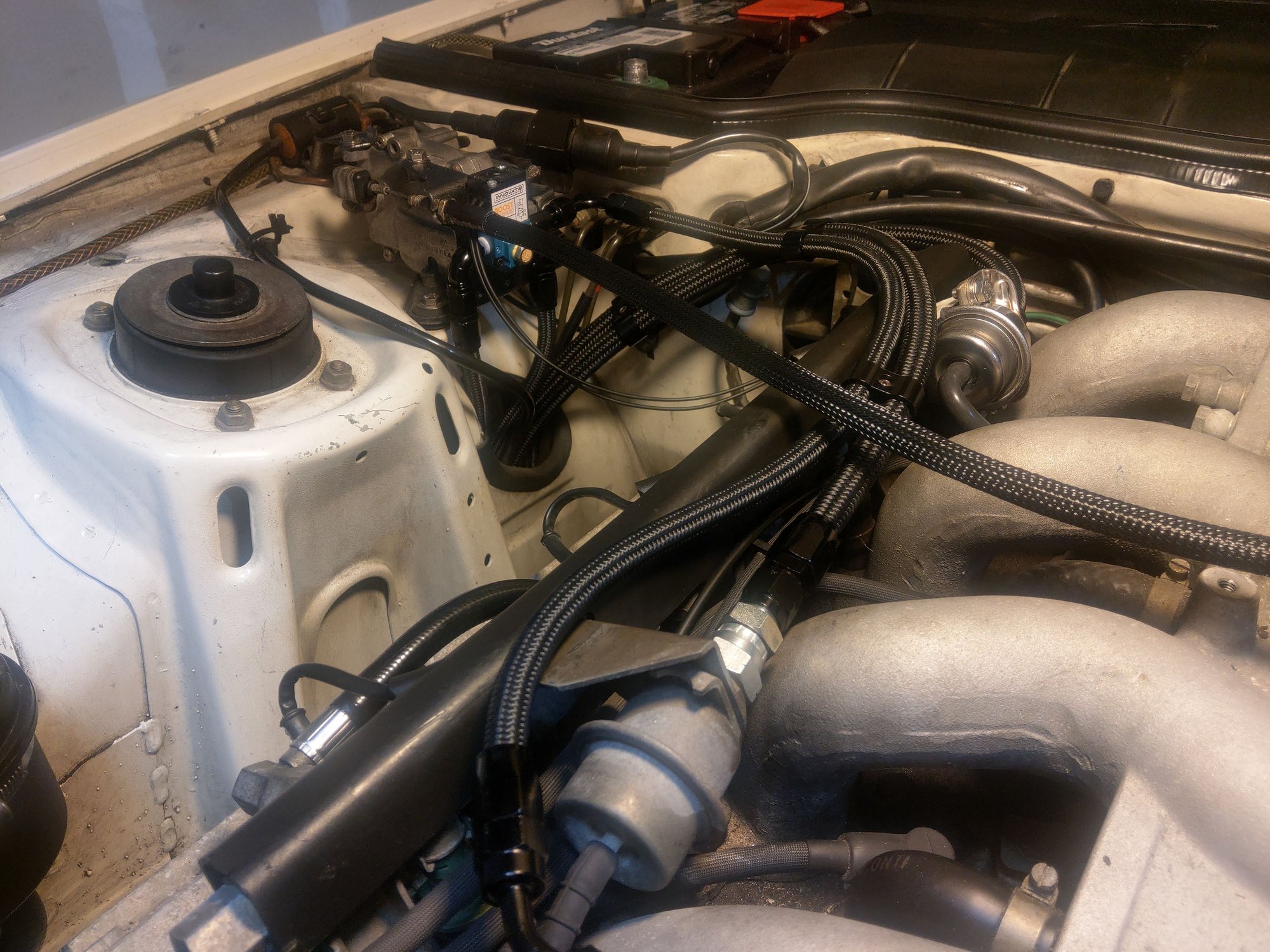

It seemed like a good place to put it to me with minimal plumbing. I then just followed the fuel lines back under the fender liner and away from heat to the wastegate. All those hoses and fittings for the controller are -4an steel braided hose with the black nylon outer layer. The fuel lines were one of the kits from Lart. The only thing I sleeved and heat shrinked (shrunk, shrank....) was the cruise control cable (old and ugly) and the wires for the A-tune which were just loose wires from the map sensor to ecm (I know I'm just picky, but they should come with a loom or sleeve and maybe something more neutral than the neon green connector).

After playing with it a bit more, I did some more research since yesterday, and think I had my start pressure way too low. I'm going to go back to the beginning, set the start pressure to 12.5 (2psi under the spring press) and then tweak from there

Others using similar controllers seem to begin with start pressure adjustments, then duty cycle adjustments and lastly gain. Also very hard to see everything happening while driving, so I downloaded their logworks software to compare boost curves better as I tweak it. I'll post more as I play with it, probably this weekend.

After playing with it a bit more, I did some more research since yesterday, and think I had my start pressure way too low. I'm going to go back to the beginning, set the start pressure to 12.5 (2psi under the spring press) and then tweak from there

Others using similar controllers seem to begin with start pressure adjustments, then duty cycle adjustments and lastly gain. Also very hard to see everything happening while driving, so I downloaded their logworks software to compare boost curves better as I tweak it. I'll post more as I play with it, probably this weekend.