CO2 Cap at crossover pipe -- how to seal?

#1

Drifting

Thread Starter

Though many suggest a lug nut, not having one, to replace the CO2 tube I got the proper cap from Porsche.

I just don't get something: how is it --or a lug nut for that matter-- supposed to seal? If I put teflon tape on the threads, won't it burn off?

Clearly not a plumber.. or mechanic lol

I just don't get something: how is it --or a lug nut for that matter-- supposed to seal? If I put teflon tape on the threads, won't it burn off?

Clearly not a plumber.. or mechanic lol

#2

Rainman

Rennlist Member

Rennlist Member

Dunno,

But I've had just a lug nut on that port for 12 years and it's never leaked..lol

I don't think it'll ever come off now, though...12 years of aluminum->steel contact with corrosive exhaust gas and moisture...one piece, now

But I've had just a lug nut on that port for 12 years and it's never leaked..lol

I don't think it'll ever come off now, though...12 years of aluminum->steel contact with corrosive exhaust gas and moisture...one piece, now

#4

Rainman

Rennlist Member

Rennlist Member

just FYI, teflon tape does nothing whatsoever for sealing joints. i mean, maybe if you used a **** load of it on straight threads it would form a sort of gasket...

it's only purpose is as an easily-applied lubricant to screw together tapered metal threads (mainly north american plumbing pipe)...the threads deform to create a fluid-tight seal but need to be engaged to a certain depth.

to get that metal-metal thread seal, the tape reduces the torque required to twist the pipe/fitting together.

it's only purpose is as an easily-applied lubricant to screw together tapered metal threads (mainly north american plumbing pipe)...the threads deform to create a fluid-tight seal but need to be engaged to a certain depth.

to get that metal-metal thread seal, the tape reduces the torque required to twist the pipe/fitting together.

#6

Rennlist Member

Use the stock Porsche block off nut. No issues whatsoever with that on Porsche used that on the Cup cars.

#7

Rennlist Member

just FYI, teflon tape does nothing whatsoever for sealing joints. i mean, maybe if you used a **** load of it on straight threads it would form a sort of gasket...

it's only purpose is as an easily-applied lubricant to screw together tapered metal threads (mainly north american plumbing pipe)...the threads deform to create a fluid-tight seal but need to be engaged to a certain depth.

to get that metal-metal thread seal, the tape reduces the torque required to twist the pipe/fitting together.

it's only purpose is as an easily-applied lubricant to screw together tapered metal threads (mainly north american plumbing pipe)...the threads deform to create a fluid-tight seal but need to be engaged to a certain depth.

to get that metal-metal thread seal, the tape reduces the torque required to twist the pipe/fitting together.

The thread form of the NPT thread does not seal at the root of the thread. When you screw the threads together the Teflon is forced into the root area sealing that passage way for leaks. When you use Teflon tape you should use a maximum of 2 wraps pulled tight.

I used a ball bearing, then when I had the header off one time, I cut it off and welded up the hole.

Trending Topics

#8

Rainman

Rennlist Member

Rennlist Member

The thread roots aren't the sealing point though I'm sure tape bunched up in those spaces helps a joint not turned tight enough.

NPT threads seal on their faces..

Ball bearing is a good idea to seal that spot though, but welding it up is even better

NPT threads seal on their faces..

Ball bearing is a good idea to seal that spot though, but welding it up is even better

#9

Rennlist Member

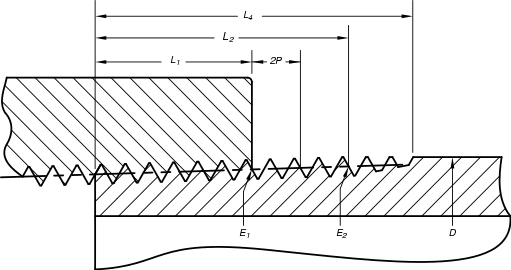

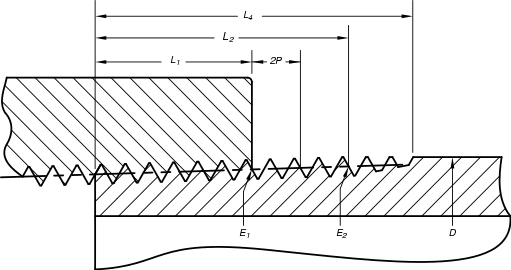

You have a stylized drawing. If you take the thread form make it up to spec and then cut it length ways across the coupling you will see the gaps in the roots. The die method of cutting threads gives varying tolerances due to wear. Feel free not to use a thread compound, I will continue to use it for sealing.

#10

Drifting

Thread Starter

Well folks, after a week of daily driving and a stop at the exhaust shop to check for leaks, all seems fine.

Learned a lot about different thread types though! Who knew? Not I, clearly lol

Learned a lot about different thread types though! Who knew? Not I, clearly lol

#12

Three Wheelin'

I removed the test pipe on mine and put a lug nut on it. It sealed nicely, but it came off and left me with a massive leak a long way from home. I realized there's not much I can do to prevent that from happening with any certainty so I just put the test pipe back on again. It's not that inconvenient having it in there and there's no way it'll ever back out by itself.

#13

Drifting

Thread Starter

Surprisingly, there is plenty of room to get a 3/8" torque wrench up there, so I torqued it to specification (I had found it, 22lbft IIRC) and figure that ought to be good.

Not looking forward to taking that crossover pipe off any time soon again lol

Not looking forward to taking that crossover pipe off any time soon again lol