Torque tube rebuild pictures and tools

#32

These are very explicit pictures. Thanks a lot, Erkka.

Just for the sake of making a comparison, I saw an early 944 TT on which the plastic bearing supports have their grooves pointing to the front of the TT, meaning the driveshaft has to be pushed out rearwards.

I cannot remember which way those supports are pointing on my spare 944 TT that came off a late 944 S2, but if they are pointing the opposite way you are maybe onto something here and the factory probably changed the manufacturing process on all transaxle models. I will give it a close look asap.

Just for the sake of making a comparison, I saw an early 944 TT on which the plastic bearing supports have their grooves pointing to the front of the TT, meaning the driveshaft has to be pushed out rearwards.

I cannot remember which way those supports are pointing on my spare 944 TT that came off a late 944 S2, but if they are pointing the opposite way you are maybe onto something here and the factory probably changed the manufacturing process on all transaxle models. I will give it a close look asap.

#33

Addict

Rennlist Member

Rennlist Member

Thread Starter

Tube inside diameter is 94.0mm and bearing support outside diameter 94.2mm on both tubes.  Tube diameter is few mm wider for first 2" towards inside on all ends except front end of '78. Not that we have all six bearings out and cleaned it was easier to see that difference between '78 and '92 versions are really small. Not significant at all.

Tube diameter is few mm wider for first 2" towards inside on all ends except front end of '78. Not that we have all six bearings out and cleaned it was easier to see that difference between '78 and '92 versions are really small. Not significant at all.

One small trick we found helpful was to position flat iron at end of fishing tool in up down direction. When flat iron was pointing sideways, for some reason bearing support was more eager to turn slanted. Pulling while flat iron pointed up down made them come out straight.

Tube diameter is few mm wider for first 2" towards inside on all ends except front end of '78. Not that we have all six bearings out and cleaned it was easier to see that difference between '78 and '92 versions are really small. Not significant at all.

Tube diameter is few mm wider for first 2" towards inside on all ends except front end of '78. Not that we have all six bearings out and cleaned it was easier to see that difference between '78 and '92 versions are really small. Not significant at all.One small trick we found helpful was to position flat iron at end of fishing tool in up down direction. When flat iron was pointing sideways, for some reason bearing support was more eager to turn slanted. Pulling while flat iron pointed up down made them come out straight.

#34

Addict

Rennlist Member

Rennlist Member

Thread Starter

Some progress during last weekend. We took bearings apart. It was easier than what we thought. All what was needed was vice, four different size sockets and two blocks of wood. First we removed bearing from outer support by pushing it out with suitable sized sockets thicker end. It gave uniform pressure to black plastic and didn't damage it at all. There was noo need to try to preserve bearing by pushing it out agains outer race as they are going to be changed.

Once bearing was out it was little easier to push out inner black plastic and metal piece attached to it. Bearings inner diameter is 30mm. First we pushed with socket what's outer diameter is about 31-32mm to make metal tube start to move. Then we changed to other smaller diamater socket what just cleared bearings inside. It was easier this way than using smaller socket from the start. It tried to turn sideways until it started to go little inside bearing and couldn't anymore.

There is no need to try to straighten four point of metal tube and black plastic that are turned outwards. Infact trying to do so easily makes tube and black plastic inside it twist out of round. If they need to be bend it can be done more easily once tube is out of bearing. Socket that we used on other side was 36mm. It just about cleared larger end of black plastic. One or two mm smaller would be too small.

Now all six are in pieces and we are looking for new bearings locally and thinking of ways to make sure bearing supports can not move inside TT once they are back together.

Once bearing was out it was little easier to push out inner black plastic and metal piece attached to it. Bearings inner diameter is 30mm. First we pushed with socket what's outer diameter is about 31-32mm to make metal tube start to move. Then we changed to other smaller diamater socket what just cleared bearings inside. It was easier this way than using smaller socket from the start. It tried to turn sideways until it started to go little inside bearing and couldn't anymore.

There is no need to try to straighten four point of metal tube and black plastic that are turned outwards. Infact trying to do so easily makes tube and black plastic inside it twist out of round. If they need to be bend it can be done more easily once tube is out of bearing. Socket that we used on other side was 36mm. It just about cleared larger end of black plastic. One or two mm smaller would be too small.

Now all six are in pieces and we are looking for new bearings locally and thinking of ways to make sure bearing supports can not move inside TT once they are back together.

#35

Rennlist Member

Erkka,

Enjoy your excellent reporting - on a rebuild I hope I never have to do!

Thanks to Thom in his TT survey thread https://rennlist.com/forums/928-forum/183537-rebuilt-torque-tubes-survey.html , I now know something additional about C3, C4, and C5 clearances - and followed the debate on shielded vs. sealed bearings.

So, what specification bearings are you hoping to use ?

Enjoy your excellent reporting - on a rebuild I hope I never have to do!

Thanks to Thom in his TT survey thread https://rennlist.com/forums/928-forum/183537-rebuilt-torque-tubes-survey.html , I now know something additional about C3, C4, and C5 clearances - and followed the debate on shielded vs. sealed bearings.

So, what specification bearings are you hoping to use ?

#37

Addict

Rennlist Member

Rennlist Member

Thread Starter

Probably will end up with shielded C3 and high temperature grease as those are readily available. I'm not sure how important C value is in this application but Porsche seems to think it's needed. Othervise they wouldn't have bothered to use non 'standard' hard to find part. As exhaust heats up TT grease should stand as much heat as possible without turning too much liquid IMHO. Especially if we end up adding more stuff inside tube for bearing support hold down. This could prevent bearings to cool down.

#38

Rennlist Member

The C values indicate ability to self align, or allow for misalignments in mounting the bearing. ie, the inner race of a C3 will be able to move out of true with outer race more than lower numbers, indicating either the ***** are a tad smaller, or the grooves are a tad bigger . Probably to allow for race not being dead true in the rubber......is my guess anyway.

jp 83 Euro S AT 48k

jp 83 Euro S AT 48k

#39

Has the tube been put back together yet? I just took my 89 tube apart. I've done a rebuild before, but I have more tools this time, so...

#40

Addict

Rennlist Member

Rennlist Member

Thread Starter

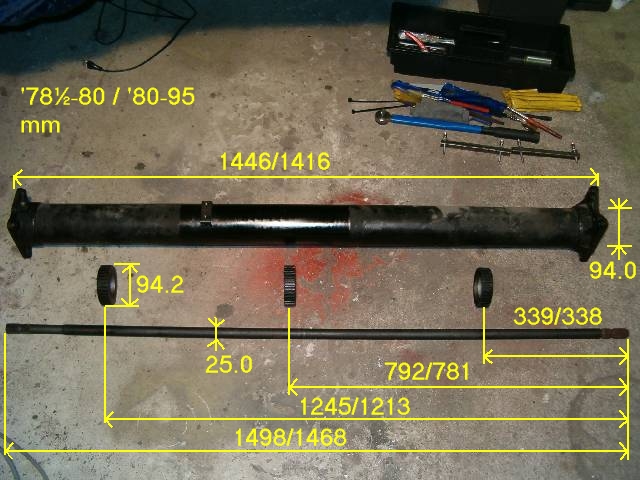

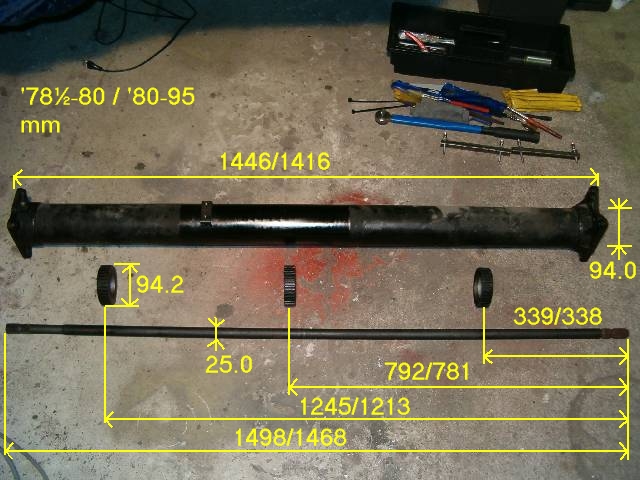

Unfortunately no. Do not have bearings yet, still thinking of wayt to make supports stay in their right places, been distracted with gearbox teardown... Haven't even had time time to put measurements we took on this picture.

We'll get to it eventually. '78 needs to be back on wheels by end of May to have time to test it before 11th of June Lempäälä 928 gathering.

We'll get to it eventually. '78 needs to be back on wheels by end of May to have time to test it before 11th of June Lempäälä 928 gathering.

#42

Addict

Rennlist Member

Rennlist Member

Thread Starter

'78 is 1446mm

'92 is 1416mm

So difference is 30mm. These are not absolutely correct as there can be errors in our measurements. Difference is visible though.

'92 is 1416mm

So difference is 30mm. These are not absolutely correct as there can be errors in our measurements. Difference is visible though.

#43

Addict

Rennlist Member

Rennlist Member

Thread Starter

Tried to find correct measurement for drive shaft protrusion from WSM. Managed to find four mentions:

For automatic gearbox

WSM Vol 2 page 39-49 dated IV 1980 protrusion A = 36 +/- 0.5 mm measured with coupling

WSM Vol 2 page 39-50 dated IV 1980 intrusion A = 30 +/- 0.5 mm measured without coupling (17 +/- 0.5 mm protrusion with coupling)

WSM Vol 3 page 39-139 VIII 1984 protrusion A = 2 +/- 0.5 mm

For manual gearbox

WSM Vol 2 page 39-65 dated IV 1980 protrusion A = 46.85 - 0.5 mm

I think all four are measured at the rear end. AFAIK they refer to these versions:

39-50 = first 120 made (ROW+US or only US models?) 3sp automatic gearboxes

39-49 = 3sp automatic gearbox

39-139 = 4sp automatic gearbox

39-65 = manual gearbox with shorter (1416mm) central tube starting from middle (not from beginning but not exact middle either) of model year 1980 (with introduction of gearbox type G28/05)

One of the TT's we are rebuilding is older style long (1446mm) tube. More specifically long tubes second (long clamping sleeve) variation even though car is well withing earlier shorter clamp VIN's ('78 VIN 221 and last one was 753 in ROW cars).

Now question is does these long early TT's use same 39-65 measurement 46,85 - 0.5 mm or is there other number for them? Couldn't find anything in WSM. Would like to get center shaft II positioned correctly so that shaft I front end fits perfectly inside pilot bearing. Shaft had moved and we do not have original G28/03 gearbox anymore to use as guide.

Also we are finally trying to properly marry old type TT and G28/10 gearbox together by changing position of clamp bolt groove in rear end of TT. TT rear bores look really bad after piece of gearbox input shaft broke off and shafts rotated against each other. Center shaft had also moved causing clamp bolt to make more damage to shaft. Plan is to have more metal welded to TT shaft and new bores made to it while input shaft is also welded back into one piece. Hope it works. Spare TT's are hard to find in here and shipping from big three is very expensive.

Unfortunately still no progress on tube rebuild.

For automatic gearbox

WSM Vol 2 page 39-49 dated IV 1980 protrusion A = 36 +/- 0.5 mm measured with coupling

WSM Vol 2 page 39-50 dated IV 1980 intrusion A = 30 +/- 0.5 mm measured without coupling (17 +/- 0.5 mm protrusion with coupling)

WSM Vol 3 page 39-139 VIII 1984 protrusion A = 2 +/- 0.5 mm

For manual gearbox

WSM Vol 2 page 39-65 dated IV 1980 protrusion A = 46.85 - 0.5 mm

I think all four are measured at the rear end. AFAIK they refer to these versions:

39-50 = first 120 made (ROW+US or only US models?) 3sp automatic gearboxes

39-49 = 3sp automatic gearbox

39-139 = 4sp automatic gearbox

39-65 = manual gearbox with shorter (1416mm) central tube starting from middle (not from beginning but not exact middle either) of model year 1980 (with introduction of gearbox type G28/05)

One of the TT's we are rebuilding is older style long (1446mm) tube. More specifically long tubes second (long clamping sleeve) variation even though car is well withing earlier shorter clamp VIN's ('78 VIN 221 and last one was 753 in ROW cars).

Now question is does these long early TT's use same 39-65 measurement 46,85 - 0.5 mm or is there other number for them? Couldn't find anything in WSM. Would like to get center shaft II positioned correctly so that shaft I front end fits perfectly inside pilot bearing. Shaft had moved and we do not have original G28/03 gearbox anymore to use as guide.

Also we are finally trying to properly marry old type TT and G28/10 gearbox together by changing position of clamp bolt groove in rear end of TT. TT rear bores look really bad after piece of gearbox input shaft broke off and shafts rotated against each other. Center shaft had also moved causing clamp bolt to make more damage to shaft. Plan is to have more metal welded to TT shaft and new bores made to it while input shaft is also welded back into one piece. Hope it works. Spare TT's are hard to find in here and shipping from big three is very expensive.

Unfortunately still no progress on tube rebuild.

#44

Addict

Rennlist Member

Rennlist Member

Thread Starter

Finally took measurements out from mobile phone and added them to picture.

First numbers (in mm's) are for '78½-80 model year in conjunction with G28.03 gearbox. Second numbers are '80-95 starting with introduction of G28.05.

PET lists ealier style '78-78½ model year TT which has same outside tube lenght as '78½-80 tube but different longer center shaft lenght because shorter clamping sleeve is used. According to one factory document these early TT's had only two support bearings. It was used up to chassis numbers:

What is interesting in those numbers is that ROW is so much higher than US and Japan numbers. Does this mean factory used early type parts longer in ROW cars or that US model production started later and/or was slower at first? Possibly this gives clues that US standard production started later after ROW production was well underway already.

Automatic TT's can be devided into these four versions IIRR:

First numbers (in mm's) are for '78½-80 model year in conjunction with G28.03 gearbox. Second numbers are '80-95 starting with introduction of G28.05.

PET lists ealier style '78-78½ model year TT which has same outside tube lenght as '78½-80 tube but different longer center shaft lenght because shorter clamping sleeve is used. According to one factory document these early TT's had only two support bearings. It was used up to chassis numbers:

Code:

92881 00753 ROW 92882 00054 USA 92882 09522 Japan

Automatic TT's can be devided into these four versions IIRR:

Code:

'78 -> '82US/83ROW 3sp gearbox, long TT, 25mm center shaft '83US/84ROW -> '84 4sp, washers for front flex plate, short TT, 25mm shaft '85 -> '88 Without front flex plate adjustment, still 25mm shaft '89 -> '95 28mm thick center shaft