Porsche t belt tensioner or porken tensioner ?

#46

Shameful Thread Killer

Rennlist Member

Rennlist Member

The stock tensioner does an OK job but only by pre-stretching the belt with an overly high static tension.

It all boils down to if you are happy with something that works OK, with occasional manual fiddling (hey, fiddling may be your thing) or if you want something that works better, without the fiddling (driving is more your thing).

It all boils down to if you are happy with something that works OK, with occasional manual fiddling (hey, fiddling may be your thing) or if you want something that works better, without the fiddling (driving is more your thing).

As for fiddling, I believe the WSM says that aside from the 1500 miles tension and inspection check after a new belt, the tensioner will remain in service until the next belt interval at which time it's serviced/inspected again. Not sure the 1500 mile check would count as occasional fiddling.

#47

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

The time delay feature on the belt warning system waiting until it has a chance to warm up a bit implies that when cold it probably is a bit loose......not that one should be beating on a cold engine

#48

Inventor

Rennlist Member

Rennlist Member

Are you sure that the original tension is set with high static setting? Since the engine grows as it warms, this is counter intuitive to me. I would think it has low static tension and that the belden stack does it's best to maintain the stretch of the belt under engine growth. It's just empirically not likely.

As for fiddling, I believe the WSM says that aside from the 1500 miles tension and inspection check after a new belt, the tensioner will remain in service until the next belt interval at which time it's serviced/inspected again. Not sure the 1500 mile check would count as occasional fiddling.

As for fiddling, I believe the WSM says that aside from the 1500 miles tension and inspection check after a new belt, the tensioner will remain in service until the next belt interval at which time it's serviced/inspected again. Not sure the 1500 mile check would count as occasional fiddling.

Empirically speaking, IE. having tested running with center cover removed, I have observed that belt pre-stretch and the stock tensioner extension together are not enough to absorb the extra belt created when the engine is cold or at high rpms, both leading to belt flapping. (You will never see flapping with a PKT.) In this uncontrolled state, without the 'idler' or guide pulleys the belt would hit itself or walk around the 1-4 cam gear or crank gear.

Regarding inspection of the stock 'tensioning' system: IIRC, it has been suggested to check the system every 15,000 miles or YMMV before the light comes on.

Again, the stock system works fine, albeit just barely, with careful inspection. Porsche could have made this system better, for example in '92 at the same time the 968 tensioner/damper was introduced, but the sales numbers must not have added up. Easier to just limp along, with frequent dealer inspections.

#49

Shameful Thread Killer

Rennlist Member

Rennlist Member

The stock static tension is higher than needed to keep the belt on the gears.

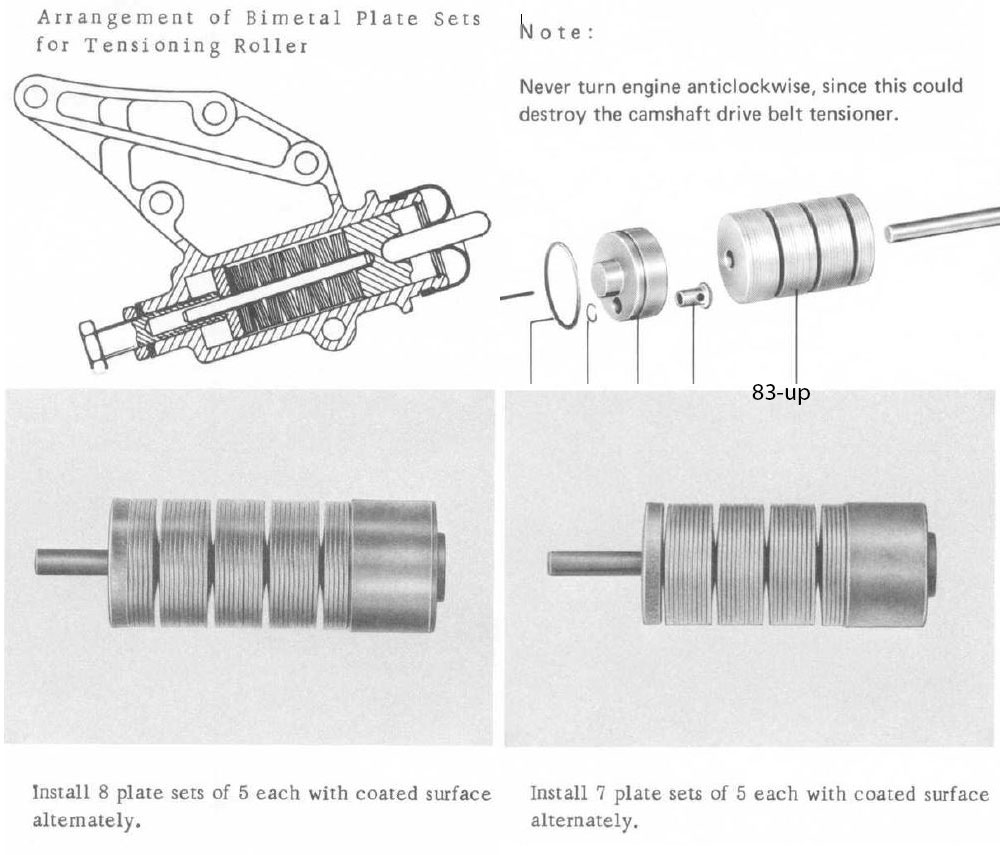

Tension is set at 'shop' temperature, from there the bi-metal Belleville washers allegedly flatten as they get hotter to match the engine expanding with temperature. (I say allegedly because AFAIK, no one has ever measured this movement, especially a 32V car with some miles on it.) Pre-stretching the belt with high tension allows for a reaction independent of the tensioner when the belt is further stretched or the engine size is reduced, but tension can only be set so high.

Empirically speaking, IE. having tested running with center cover removed, I have observed that belt pre-stretch and the stock tensioner extension together are not enough to absorb the extra belt created when the engine is cold or at high rpms, both leading to belt flapping. (You will never see flapping with a PKT.)

Regarding inspection of the stock 'tensioning' system: IIRC, it has been suggested to check the system every 15,000 miles or YMMV before the light comes on.

Tension is set at 'shop' temperature, from there the bi-metal Belleville washers allegedly flatten as they get hotter to match the engine expanding with temperature. (I say allegedly because AFAIK, no one has ever measured this movement, especially a 32V car with some miles on it.) Pre-stretching the belt with high tension allows for a reaction independent of the tensioner when the belt is further stretched or the engine size is reduced, but tension can only be set so high.

Empirically speaking, IE. having tested running with center cover removed, I have observed that belt pre-stretch and the stock tensioner extension together are not enough to absorb the extra belt created when the engine is cold or at high rpms, both leading to belt flapping. (You will never see flapping with a PKT.)

Regarding inspection of the stock 'tensioning' system: IIRC, it has been suggested to check the system every 15,000 miles or YMMV before the light comes on.

This is not the same as saying it's higher than needed to keep the belt on the gears. I would presume that any belt tension system will maintain a secure tension to keep the belt on the gears for wear and stretch.

My 83 Ferrari has a very primitive spring pre-loaded tensioner for the belts. There is absolutely no run-time adjustment once the tension is adjusted at belt change. The tension spring inside the tensioner sets the pre-load at a normal load when adjusted cold, and the engine grows, and tensions the belt as it warms. At least Porsche used the Belleville stack to take up the change.

I'm sorry to still disagree with your tested conclusion but I'm going to go with the tension being set to a normal tension for the driven cams, pumps, idler in the circuit and the Belleville stack doing it's thing by flattening under heat thus reducing the path distance and maintaining the basic tension.

BTW, I have tested and observed(empirically) the tension with the 9201 tool both at ~70F with a cold engine, and the same engine at ~180F and there was no significant change in the reading. This would almost surely indicate that the Belleville(not Belden, sorry) stack was functioning as designed. I used the Porsche tool because I wanted to not be concerned about the MoE of the belt at different temps which may have caused different readings using the little twisty belt tool.

James also brought up a good point that the tension check system is time-delayed so that the engine will be up to temp when it comes online. If the belt were overly tensioned, then this delay wouldn't be needed, and the belt tension circuit which saved my engine during a WP failure would be active at engine start.

#50

Inventor

Rennlist Member

Rennlist Member

The Audi T/D can operate at a lower tension and still keep the belt in check because it is constantly adapting to belt length as opposed to the stock system which reacts only, and then only indirectly, to engine temperature. No compensation for actual temperatures or belt wear or pulling force is made.

Why wouldn't the Engineers let you know that you can't rev the engine when cold (you can, if you have to, with a PKT, BTW) instead of hiding the result?

Of course: "If you like your {tensioner}, you can keep your {tensioner}."

#51

Rennlist Member

The BS was you pretending that two failures out of "a couple hundred sold" is near 2%...as if those were highly precise numbers you were using. I really need to spell this out for you?

#52

Shameful Thread Killer

Rennlist Member

Rennlist Member

I think that is a stretch on your part...any tension higher than needed to keep the belt smoothly fed to the crank gear is higher than necessary and will cause additional wear. (A concern compounded by the use of plastic bushings in the tensioner arm pivot and a puny bearing in the tensioner pulley, etc., etc.)

The Audi T/D can operate at a lower tension and still keep the belt in check because it is constantly adapting to belt length as opposed to the stock system which reacts only, and then only indirectly, to engine temperature. No compensation for actual temperatures or belt wear or pulling force is made.

Why wouldn't the Engineers let you know that you can't rev the engine when cold (you can, if you have to, with a PKT, BTW) instead of hiding the result?

Of course: "If you like your {tensioner}, you can keep your {tensioner}."

The Audi T/D can operate at a lower tension and still keep the belt in check because it is constantly adapting to belt length as opposed to the stock system which reacts only, and then only indirectly, to engine temperature. No compensation for actual temperatures or belt wear or pulling force is made.

Why wouldn't the Engineers let you know that you can't rev the engine when cold (you can, if you have to, with a PKT, BTW) instead of hiding the result?

Of course: "If you like your {tensioner}, you can keep your {tensioner}."

I posted a while back asking if anyone had ever heard if there was ever a failure of the stock tensioner. I never heard of one. I've never heard of the isolator phenolic failing, and although I changed my 99k mile tensioner bearing after +25 years, I've never heard of one of those failing(catastrophic) either.

I kept my stock tensioner, but it was a close call. If I were keeping the car for decades I would have switched over.

#53

Rennlist Member

now, if the tensioner is a "anti tensioner" the, the belt is too tight and gets tighter when the engine expands.. the tensioner relieves that tension with heat?

which is it?

#54

Inventor

Rennlist Member

Rennlist Member

I thought like this at first. then, someone posted the "anti tension" action of the tensioner washers.... do the washers get flat under temp or warp under tension? my entire pitch about the oil in the tensioner is that i thought the belt was kind of loose when cold and having no oil , just delayed the activity of being "hard on the engine" until things really were at full temp.

now, if the tensioner is a "anti tensioner" the, the belt is too tight and gets tighter when the engine expands.. the tensioner relieves that tension with heat?

now, if the tensioner is a "anti tensioner" the, the belt is too tight and gets tighter when the engine expands.. the tensioner relieves that tension with heat?

As each bi-metal concave washer is heated it flattens. Suppose each group of 5 washers can move 1 mm (each washer in a group combines their effort in one direction). The early stack could then move 8 mm (when new). The late stack has only 7 groups to make room for the damping valve block, so it only has 7 mm acting directly on the tensioner pulley centerline (no leverage ratio). This should counter engine 'growth' somewhat and when cold, the stack might have some spring pressure to act as a damper but the hotter the stack gets, the more it becomes a solid tensioner. Only belt stretch/tension provides movement for damping with no rebound. The stack cannot expand when hot to counter torque pulses or high rpm belt stretch, so the resulting extra, uncontrolled, untensioned, belt length...flutters.

Loose belt affects cam timing and promotes wear just as an overly tightened belt will accelerate wear (and steal HP).

More info on changes for '83 - https://rennlist.com/forums/928-foru...ml#post1851058

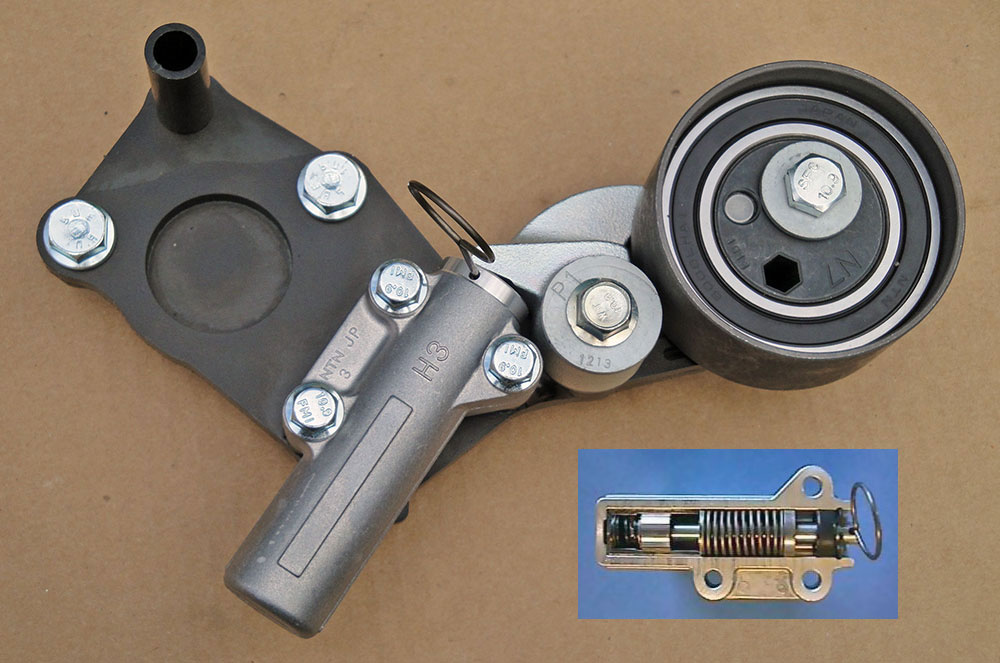

Contrast that with the Audi tensioner/damper with an 11 mm range which is then transferred by a lever to an offset pin on the pulley. Tension is constantly maintained by a spring dampened by a sealed oil reservoir. The pulley is always free to move in and out to dampen torque pulses and keep the belt from ever being too loose or too tight, or, perish the thought, flapping!

Add to that the compact stable nature of the PKT, the much more robust (steel) bearing surfaces in the lever and pulley axis, not to mention the YUUUGE pulley bearing, machined flat belt surface, et cetera, et cetera, et cetera.

Last edited by PorKen; 12-16-2015 at 05:55 PM.

#55

Rennlist Member

Thread Starter

Join Date: Oct 2014

Location: Montréal, Québec, Canada

Posts: 82

Received 0 Likes

on

0 Posts

Has anyone ever hade to replace the Porsche Tensionner with à new OEM ?

The mecanics i work with both recommed that i stick with the original concept and REPLACE the Porsche Tensionner with à new one ?!?

But it on lt only hâve oil leaking ... Because they dont know what has to be replaced to make sûre the Porsche Tensioner is secur for the motor !

Is a refurbished Porsche tensioner secur for the motor ?

Tanks .

The mecanics i work with both recommed that i stick with the original concept and REPLACE the Porsche Tensionner with à new one ?!?

But it on lt only hâve oil leaking ... Because they dont know what has to be replaced to make sûre the Porsche Tensioner is secur for the motor !

Is a refurbished Porsche tensioner secur for the motor ?

Tanks .

#56

Nordschleife Master

Has anyone ever hade to replace the Porsche Tensionner with à new OEM ?

The mecanics i work with both recommed that i stick with the original concept and REPLACE the Porsche Tensionner with à new one ?!?

But it on lt only hâve oil leaking ... Because they dont know what has to be replaced to make sûre the Porsche Tensioner is secur for the motor !

Is a refurbished Porsche tensioner secur for the motor ?

Tanks .

The mecanics i work with both recommed that i stick with the original concept and REPLACE the Porsche Tensionner with à new one ?!?

But it on lt only hâve oil leaking ... Because they dont know what has to be replaced to make sûre the Porsche Tensioner is secur for the motor !

Is a refurbished Porsche tensioner secur for the motor ?

Tanks .

See this for servicing the tensioner. Have your mechanic have a look too...

http://dwaynesgarage.norcal928.org/1...0Procedure.htm

#57

this is a no-brainer PK tensioner all the way...although I do recommend to changing the Audi tensioner with a fresh tensioner every time you replace the belt in the future...as I have always done when I replaced timing belts on Audis in the past...they are cheap and it's good insurance....another point is it is impossible to over-tighten a belt with a PK tensioner since it's auto-adjusting but with the stock tensioner that option is still open for you.

Last edited by 928phantom; 12-16-2015 at 08:38 AM.

#58

Installed PK tensioner last belt change. Do all work myself and plan to keep car a long time. The PK is a well engineered high quality item which installs beautifully and does what it says it does. I have checked tensions and the system (frequently at first) since installation and my confidence just keeps increasing. Surprising to me: my piece of mind about my timing belt has increased quite a bit since I installed it.

The factory unit just wasn't the best solution to belt tensioning. PK unit is.

The factory unit just wasn't the best solution to belt tensioning. PK unit is.

#59

Captain Obvious

Super User

Super User

The belt warning system of the 32V engines alone is worth keeping the stock tensioner. Said it many times that it saved my engine when the water pump pulley siezed. There are pictures on this forum of what my belt looked like and how close it was from snapping. If you think the belt warning system is useless and you would sacrifice it to extend the life of the cam gears then by all means, go with the Audi tensioner.

#60

Rennlist Member

I wouldn't purchase a new tensioner. I would rebuild it. They are likely to be expensive (?).

See this for servicing the tensioner. Have your mechanic have a look too...

http://dwaynesgarage.norcal928.org/1...0Procedure.htm

See this for servicing the tensioner. Have your mechanic have a look too...

http://dwaynesgarage.norcal928.org/1...0Procedure.htm

So I'm thinking that is the current price, also as Ken pointed out once the Teflon cylinder liner wears out they stick and do not work, so rebuilding is not always an option.

We should revisit the Warning Light solution thread as when most of the T-Belt systems fail or start to fail that I've seen the belts tracking is always off. So maybe with Kens system we need to monitor the tracking and not the tension?

Dave