Short Engine / Crankcase Question

#1

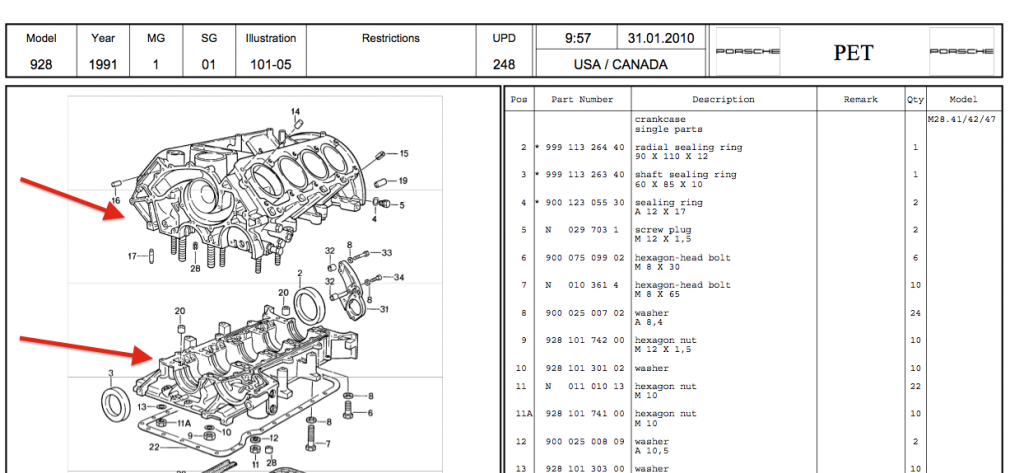

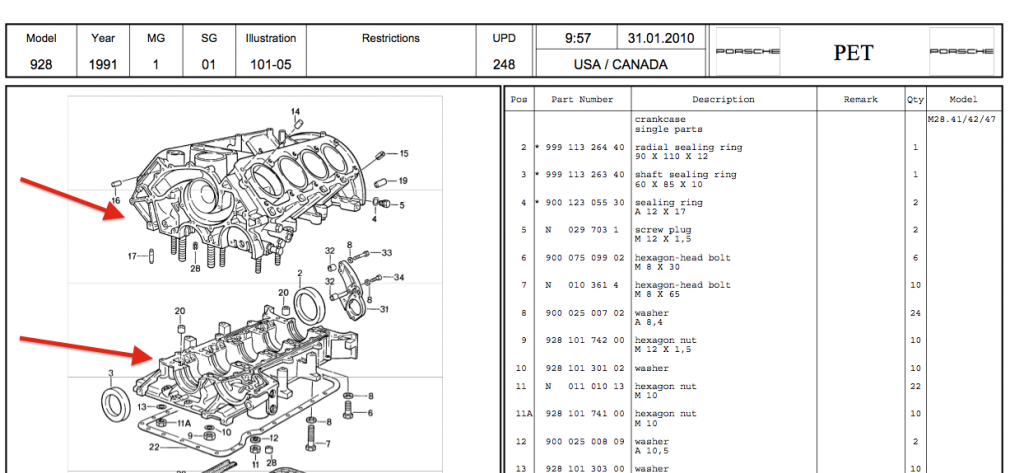

We are rebuilding a 1988 S4 Engine.

There is a problem with the lower part of the crankcase and needs some welding on more than one points

I also have a another extra engine, in which this lower part of the crankcase is in very good condition.

I know that upper and lower parts of the crankcase is manufactured together and stamped on the side. Is there any way I can use the upper half of the crankcase and lower part of the extra engine. is this totally impossible or is there a way out. Just trying to figure out a solution.

Thanks for your help

There is a problem with the lower part of the crankcase and needs some welding on more than one points

I also have a another extra engine, in which this lower part of the crankcase is in very good condition.

I know that upper and lower parts of the crankcase is manufactured together and stamped on the side. Is there any way I can use the upper half of the crankcase and lower part of the extra engine. is this totally impossible or is there a way out. Just trying to figure out a solution.

Thanks for your help

#2

Archive Gatekeeper

Rennlist Member

Rennlist Member

I think you'd need to bolt them together and align-bore the mains. At least that's my sense from the discussion below:

https://rennlist.com/forums/928-foru...nd-girdle.html

https://rennlist.com/forums/928-foru...nd-girdle.html

#3

I think you'd need to bolt them together and align-bore the mains. At least that's my sense from the discussion below:

https://rennlist.com/forums/928-foru...nd-girdle.html

https://rennlist.com/forums/928-foru...nd-girdle.html

I am not an expert on engines at all and have limited info and experience.

If this is done and and we align-bore the mains, can we still use the main bearings. I think there are oversize main bearings but these are for machining the crank. If the align-boring is done and do we need some special main bearings with standard crank diameter and oversized crankcase diameters.

Thanks

#4

Former Sponsor

No.

While you might find a cradle that fit close enough to allow the two surfaces to be skimmed and then align bored, the odds are so slim, you'd have a better chance of winning the lottery.

If the cradle is badly damaged and you need to do extensive welding, you will most likely distort it in the welding process.

20 years from now.....this would be worth the hassle. However, today, it's easy enough to find a used engine block. I'd suggest doing that.

928 International is one place to check....they should be able to help you.

While you might find a cradle that fit close enough to allow the two surfaces to be skimmed and then align bored, the odds are so slim, you'd have a better chance of winning the lottery.

If the cradle is badly damaged and you need to do extensive welding, you will most likely distort it in the welding process.

20 years from now.....this would be worth the hassle. However, today, it's easy enough to find a used engine block. I'd suggest doing that.

928 International is one place to check....they should be able to help you.

#5

Archive Gatekeeper

Rennlist Member

Rennlist Member

Phew, been sitting here wondering whether I'd guessed right or wrong (it was a 50-50 shot). Now I no longer need to worry.

Begs the question- During initial manufacture, what was the order of operations? Were the block and girdles machined on their mating surfaces, then bolted together and the mains machined? Were the cylinder bores then done after that once the crank center line is established?

I need to read that Reher-Morrison book a bit more....

Begs the question- During initial manufacture, what was the order of operations? Were the block and girdles machined on their mating surfaces, then bolted together and the mains machined? Were the cylinder bores then done after that once the crank center line is established?

I need to read that Reher-Morrison book a bit more....

#7

Will post photos tomorrow.

I live in İstanbul and its quite difficult to find a block in good shape.

My engine builder proposed the following solution which might work. The top of the credle will be machined by 0.2 mm or so . Following that he will bolt both parts and machine the mains of the credle to specified size. He will also take care of the oilpump housing and the transmission facing side. Any comments on that solution?

Thanks,

I live in İstanbul and its quite difficult to find a block in good shape.

My engine builder proposed the following solution which might work. The top of the credle will be machined by 0.2 mm or so . Following that he will bolt both parts and machine the mains of the credle to specified size. He will also take care of the oilpump housing and the transmission facing side. Any comments on that solution?

Thanks,

Trending Topics

#8

Former Sponsor

Will post photos tomorrow.

I live in İstanbul and its quite difficult to find a block in good shape.

My engine builder proposed the following solution which might work. The top of the credle will be machined by 0.2 mm or so . Following that he will bolt both parts and machine the mains of the credle to specified size. He will also take care of the oilpump housing and the transmission facing side. Any comments on that solution?

Thanks,

I live in İstanbul and its quite difficult to find a block in good shape.

My engine builder proposed the following solution which might work. The top of the credle will be machined by 0.2 mm or so . Following that he will bolt both parts and machine the mains of the credle to specified size. He will also take care of the oilpump housing and the transmission facing side. Any comments on that solution?

Thanks,

On two pieces that do not match originally, his idea may fix (if the hole isn't too "oval") any up and down problems....because of the material removed from the block....however any "offset" in the hole from side to side is impossible to repair....because there is not any material that can be removed.

The "side to side" problem is why you would have to be incredibly lucky to find a cradle that would work as a "donor".

I've welded up a lot of air conditioner and alternator mounting tabs on cradles....with minimal warping, which can then be cured by an align bore, like your machinist is talking about...except material is removed from both the cradle and the block.

How much welding and where is the welding required?

A picture would tell a whole lot....

#9

Addict

Rennlist Member

Rennlist Member

Were the cylinder bores then done after that once the crank center line is established?