Need help removing Federalization/Lamda equiptment

#1

Rennlist Member

Thread Starter

Join Date: Dec 2013

Location: North Texas

Posts: 46

Likes: 0

Received 0 Likes

on

0 Posts

I guys. I need help, let me start off by saying since this ordeal I have ordered a set of the WSM on cd from Roger.

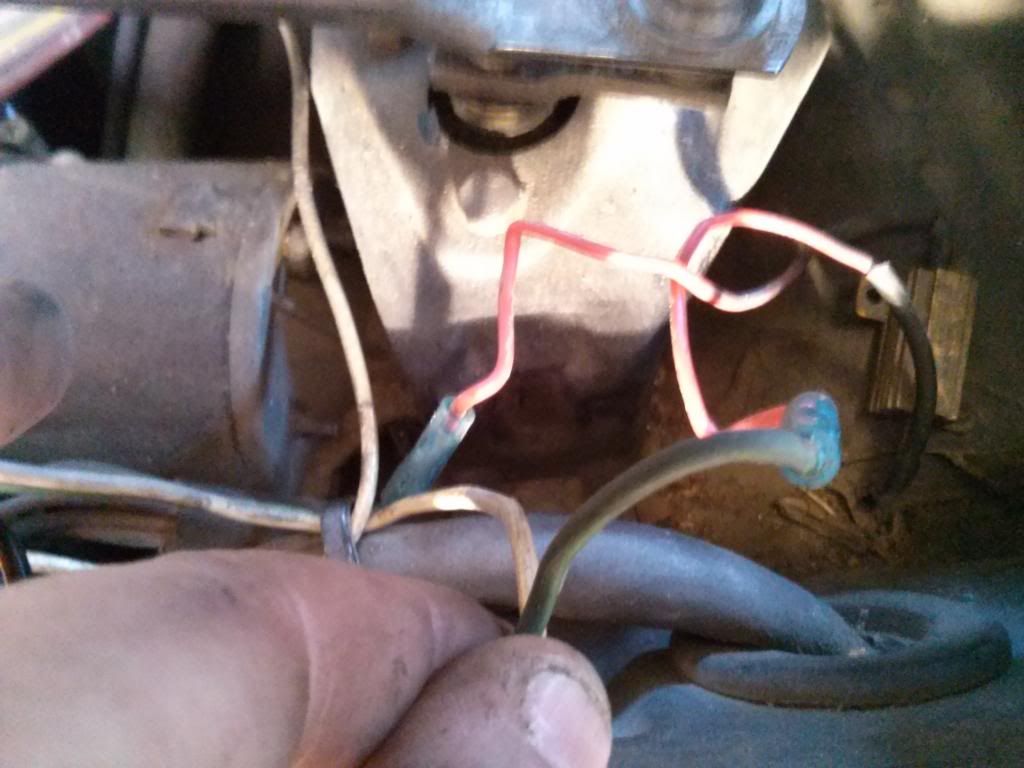

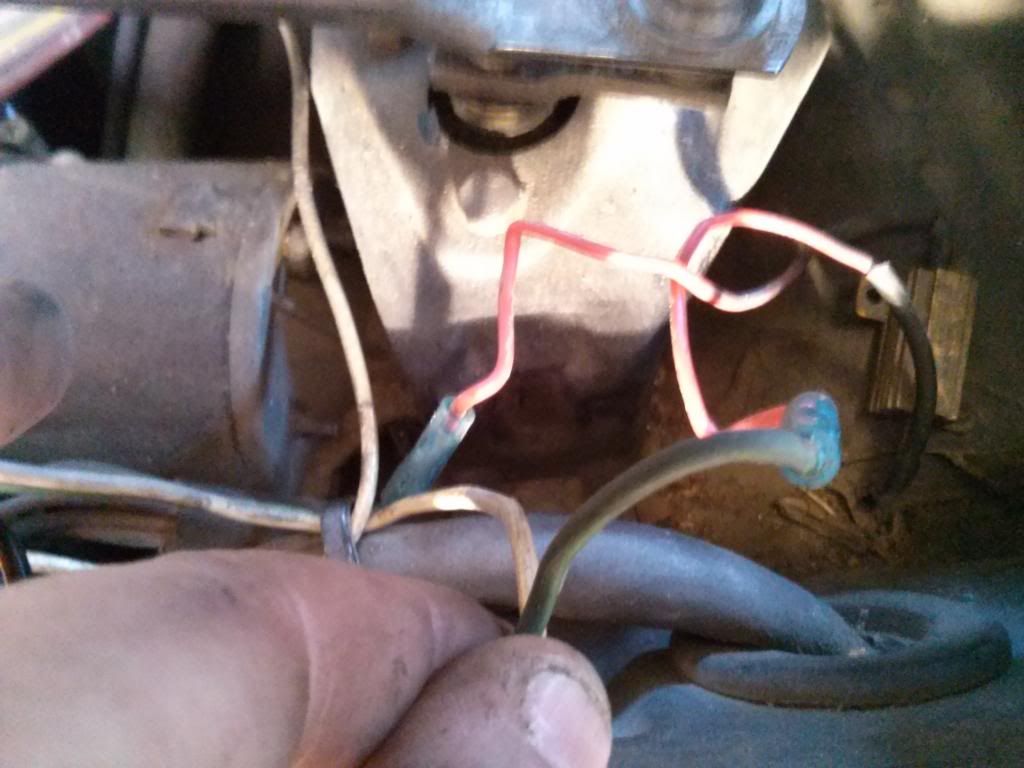

This injector into the wur was causing a no start, the injector was getting hot I mean dam hot. The lines are bad (wiggle the small one and it hissed) so it had to go

I replaced the lines with fuel injection hose and left the injector in place as a temporary fix to get the car running until It goes to Sean R's on the 4/21. This is where I should have stopped, but that's not the case. I follow the wiring up to the cowl area.

I find this harness, the green and white go to the driver side, yellow and brown to the passenger.

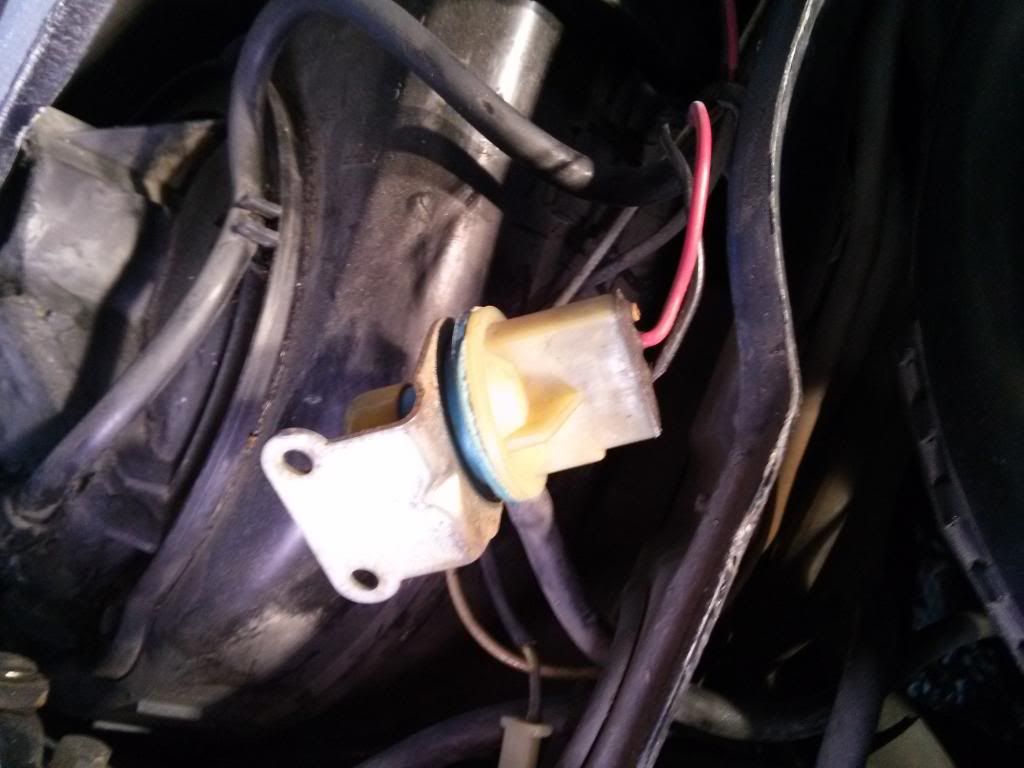

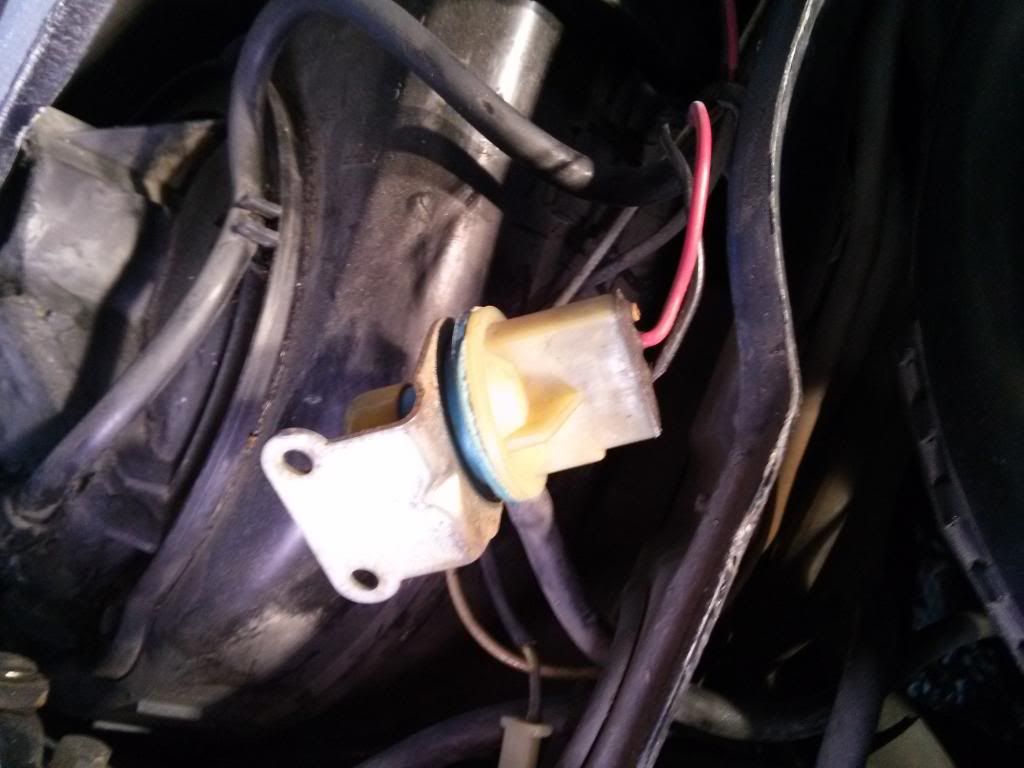

This is the green and white side, this device is wired into the green wire only, where my fingers are is the end to the wur injector. I removed this piece and the car started and ran/idled fine. so I moved to the passenger side to investigate the yellow and brown wire.

yellow/brown turn to red/black and to the ? (idle control valve)

The vaccum hose continues to the the top of the passenger side head

My fingers go back to the cowl, it tee's off and goes under the spider to another Tee that has the carbon filter/canister on it

My fingers goes back to the passenger side head and the line to the right is the canister which I removed. The line at the bottom leads to a sensor in the intake behind the passenger side cam cover.

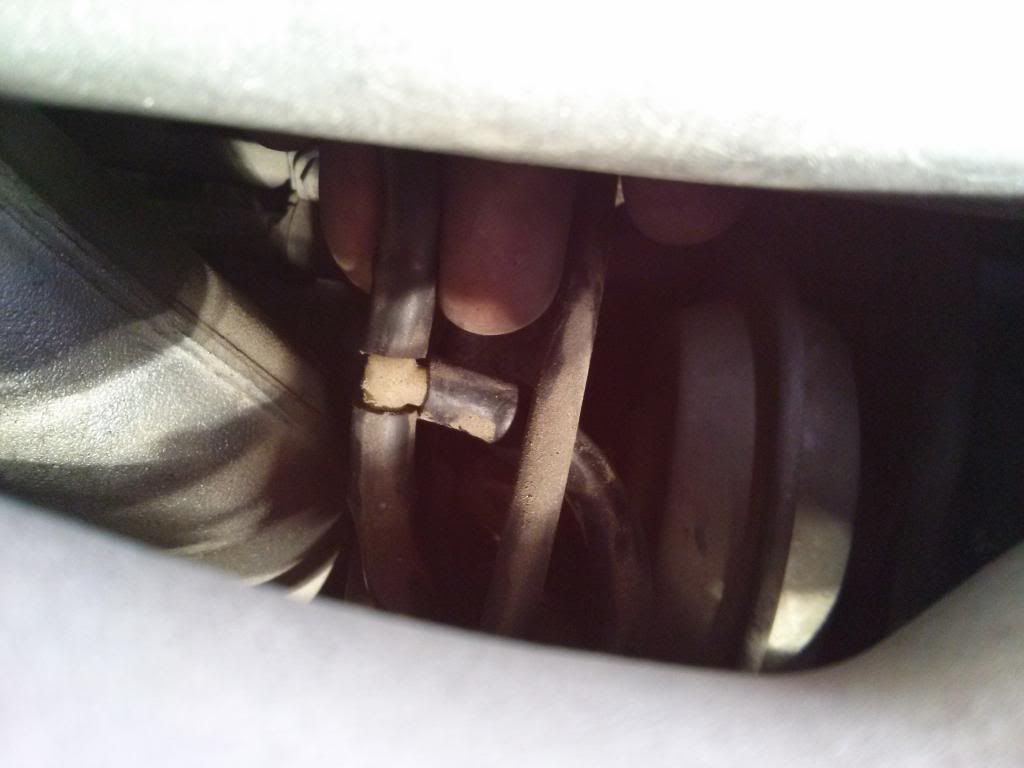

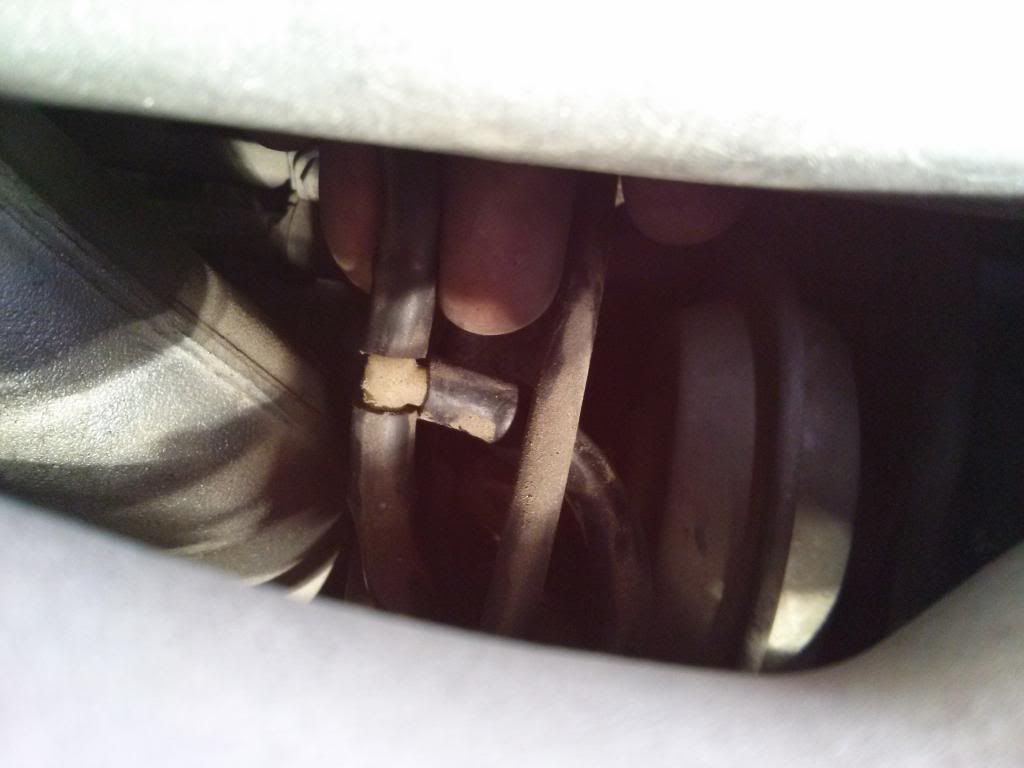

I broke this piece trying to remove the vac line and am left with this. The car is still running at this point, I noticed it raised the idle when this was open and lowered when I put the screw in with a little Teflon tape. Lower was normal for the car apx. 700.

Now for the problem I was going to rewire this piece, but made the mistake of trying to start the car with this disconnected and it ran extremely rough so I shut it off and rewired it back in. The problem continued so I shut it down, tried again and starter just spun, no ra-ra-ra. Ok that's it to Rennlist I go. Any help is appreciated, 81 euro row non s.

Fish

This injector into the wur was causing a no start, the injector was getting hot I mean dam hot. The lines are bad (wiggle the small one and it hissed) so it had to go

I replaced the lines with fuel injection hose and left the injector in place as a temporary fix to get the car running until It goes to Sean R's on the 4/21. This is where I should have stopped, but that's not the case. I follow the wiring up to the cowl area.

I find this harness, the green and white go to the driver side, yellow and brown to the passenger.

This is the green and white side, this device is wired into the green wire only, where my fingers are is the end to the wur injector. I removed this piece and the car started and ran/idled fine. so I moved to the passenger side to investigate the yellow and brown wire.

yellow/brown turn to red/black and to the ? (idle control valve)

The vaccum hose continues to the the top of the passenger side head

My fingers go back to the cowl, it tee's off and goes under the spider to another Tee that has the carbon filter/canister on it

My fingers goes back to the passenger side head and the line to the right is the canister which I removed. The line at the bottom leads to a sensor in the intake behind the passenger side cam cover.

I broke this piece trying to remove the vac line and am left with this. The car is still running at this point, I noticed it raised the idle when this was open and lowered when I put the screw in with a little Teflon tape. Lower was normal for the car apx. 700.

Now for the problem I was going to rewire this piece, but made the mistake of trying to start the car with this disconnected and it ran extremely rough so I shut it off and rewired it back in. The problem continued so I shut it down, tried again and starter just spun, no ra-ra-ra. Ok that's it to Rennlist I go. Any help is appreciated, 81 euro row non s.

Fish

#2

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Federalization often included that solenoid, along with an analog controller that reads an oxy sensor. It sends a pwm pulse width modulated signal to that solenoid to modulate control pressure some. In other cars it's called KE-Jetronic when Bosch builds it. The analog controller is deceptively simple. It also works /pretty well when the rest of the CIS is functioning. Besides dropping emissions so a cat can survive, it substantially improves fuel economy when tuned well. Were it mine, it get it working right rather than remove it.

#3

Rennlist Member

Thread Starter

Join Date: Dec 2013

Location: North Texas

Posts: 46

Likes: 0

Received 0 Likes

on

0 Posts

Dr. Bob, thanks for the advice, it was running with all that in place. When I was at Sean's awhile back he unhooked it while the engine was running and it had no affect. When working correctly is the key, I do have terrible fuel economy.

#4

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

CIS cars generally have no way to differentiate load other than looking at airflow. No serious artificial/temporary enrichment when accelerating, beyond the pressure change when the throttle is opened. So they tend to run richer all the time, so they can be rich enough for hard acceleration. The KE-jet system uses a narrow-band oxy sensor to read the CO in the exhaust stream to tell the solenoid what percentage of time it needs to be open, biasing the effective control pressure. With the controller working, you can set the mixture by reading the oxy sensor voltage and looking at the pulsed signal to the solenoid. For the latter I used an oscilloscope because I had one. You can also use an old-school "dwell meter", a tool that's left over from the points-and-condenser igniton days for setting point gap. Back on the KE-jet, the portable 'scope, analog voltmeter, and a CO analyzer are used along with the standard pressure gauges to fine tune the system for both performance and emissions. To allow a catalyst to survive, the fuel mixture (read: control pressure) needs to be carefully managed. Tune too much towards performance, and the honeycomb catalyst will quickly melt into a ceramic brick.