BILLET HUBS FOR THE 928

#16

Thanks Hacker for pointing out problem #2 which multiplies problem #1. While I was building my 948 last year I went thru the trouble of putting on Non-ABS Late hubs/stronger spindles and custom control arms just so I didn't have to run a 29mm spacer to get 18" Turbo Twist II's on my Early (85.5) offset car ( I left Early offset Control Arms in back because no spacer required)

#17

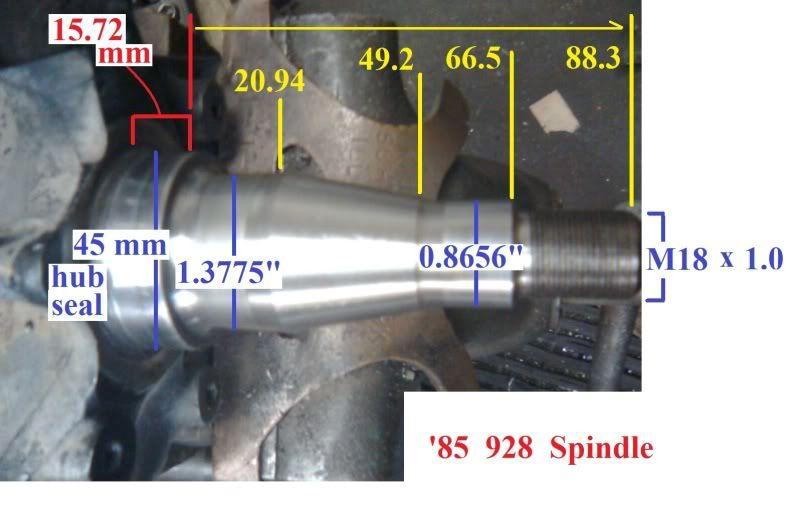

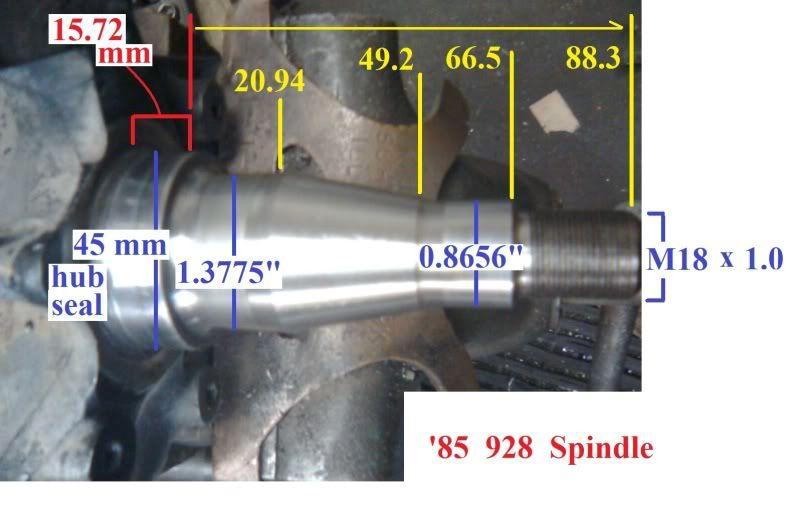

The 79-85 928 spindles have the beefiest dims of all the 9-cars I've measured so far....

If you have a 86-up 928 spindle please post these dims, it is easier than measuring the Inner dims of a hub to check for differences.....

If you have a 86-up 928 spindle please post these dims, it is easier than measuring the Inner dims of a hub to check for differences.....

#19

Rennlist Member

Join Date: Jan 2006

Location: central cal

Posts: 975

Likes: 0

Received 0 Likes

on

0 Posts

xschop, some one does make a billet hub for 944's- I think it may be kelly-moss? Theirs is 7075 aluminum, which is much stronger than 6061--- 70ksi tensile vs 40ksi for 6061. I have seen the ads in Pano and Excellence mags. You may want to look them up before going all-out on this...

#20

Rennlist Member

Join Date: Jan 2006

Location: central cal

Posts: 975

Likes: 0

Received 0 Likes

on

0 Posts

#21

These will for the 928 and no one makes them, period. My 6061-T6 hub design for my 944 will be stronger and just as light than the RE's where it counts, I'm not running ABS either as this is the determining factor/weak spot.

#22

Rennlist Member

Join Date: Jan 2006

Location: central cal

Posts: 975

Likes: 0

Received 0 Likes

on

0 Posts

OK, just wanted you to know...

Which T6? T651 or T6511, as there is about a 10ksi tensile difference. You will have to make the 6061 part bigger to equal the strength of 7075, or 7050, or 2024...

Which T6? T651 or T6511, as there is about a 10ksi tensile difference. You will have to make the 6061 part bigger to equal the strength of 7075, or 7050, or 2024...

#23

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

If it's possible to make these 5mm or so inward from the stock hub, that would really open up the wheel choices.

#24

7075-T6 tensile strength is around 76 ksi. 6061-T6 is around 42 ksi

The actual values vary with grain direction and form (extrusion versus plate for example). I'm using extruded T6 round billet.

Another issue with 7075 is Stress Crack Corrosion (SCC) and the higher tensile strength contributes to it's brittleness under imapact loads.

I don't plan on anodizing so the 6061 is more corrosion resistant than 7075

T6 condition

Corrosion resistance 6061>7075

Cold Workability: 6061>7075

Machinability: 6061<7075

General Weldability: 6060>7075

The actual values vary with grain direction and form (extrusion versus plate for example). I'm using extruded T6 round billet.

Another issue with 7075 is Stress Crack Corrosion (SCC) and the higher tensile strength contributes to it's brittleness under imapact loads.

I don't plan on anodizing so the 6061 is more corrosion resistant than 7075

T6 condition

Corrosion resistance 6061>7075

Cold Workability: 6061>7075

Machinability: 6061<7075

General Weldability: 6060>7075

#25

Rennlist Member

Join Date: Jan 2006

Location: central cal

Posts: 975

Likes: 0

Received 0 Likes

on

0 Posts

Extruded 6061 T6511 in large diameters has a lower tensile strength than T651 cold finished. 7050 has better corrosion and mechanical properties than 7075, and we have been using more of it lately for aerospace parts because of this.

Any 6061 is better than the casting, so your hub will be an improvement over stock, just not as much as if it were a high strength alloy.

Good luck, in any case...

Any 6061 is better than the casting, so your hub will be an improvement over stock, just not as much as if it were a high strength alloy.

Good luck, in any case...

#26

Former Sponsor

This is a cool project....not sure how many people will actually step up and buy these, but there will be a market.

No doubt that the 944 series cars had hub issues, as people reached the limits of the vehicle and exceeded significantly exceeded the hour limits of the stock pieces. Everything built has a life limit. Grabbing up a 944 with 100,000 miles on it and turning it into a serious racecar with slicks, with total disregard to the amount of hours on everything isn't always going to turn out perfectly....hubs and other pieces failed and continue to fail.

There is a reason that Porsche wants all the "loaded" suspension pieces replaced in an RSR every 40 hours! When we replaced the broken 944 hubs with brand new Porsche hubs....they were fine....never had a failure, of a new hub.

The hubs had reached their design limits, in terms of hours of use.

Exceeding the design limits of pieces is also going to be a disaster. If the design limnits are exceeded, things are going to break. When we were younger and more naive, some of us thought that we could do anything we wanted with a 944 based racecar. This turned out not to be true. You can exceed the limits of design and from that point forward, it gets really tough to keep things together. Willow Springs was our local basic play ground, back then. Highly modified 944 series cars would turn in the 1:28/1:29 range (pretty fast laps) and last virtually forever. Modifing further, so the cars would turn laps is the 1:25range (which seems like a pretty small percentage faster) was a disaster....you couldn't bolt pieces on quickly enough to keep up with the rate of parts destroyed.

Unless you were really lucky, every event became a DNF.

Here's a simple/logical way to get your head around this:

If you go out and buy an old Formula Ford and stuff a decent small block Chevy into it and put wide, new design slicks on it....it might run a few laps...but you have exceeded the design limits of everything on the vehicle and the result is that you is going to break every last piece on the car. You can start with the failed hub...but the forces that are destroying the car are just going to move to another place.

No doubt that the 944 series cars had hub issues, as people reached the limits of the vehicle and exceeded significantly exceeded the hour limits of the stock pieces. Everything built has a life limit. Grabbing up a 944 with 100,000 miles on it and turning it into a serious racecar with slicks, with total disregard to the amount of hours on everything isn't always going to turn out perfectly....hubs and other pieces failed and continue to fail.

There is a reason that Porsche wants all the "loaded" suspension pieces replaced in an RSR every 40 hours! When we replaced the broken 944 hubs with brand new Porsche hubs....they were fine....never had a failure, of a new hub.

The hubs had reached their design limits, in terms of hours of use.

Exceeding the design limits of pieces is also going to be a disaster. If the design limnits are exceeded, things are going to break. When we were younger and more naive, some of us thought that we could do anything we wanted with a 944 based racecar. This turned out not to be true. You can exceed the limits of design and from that point forward, it gets really tough to keep things together. Willow Springs was our local basic play ground, back then. Highly modified 944 series cars would turn in the 1:28/1:29 range (pretty fast laps) and last virtually forever. Modifing further, so the cars would turn laps is the 1:25range (which seems like a pretty small percentage faster) was a disaster....you couldn't bolt pieces on quickly enough to keep up with the rate of parts destroyed.

Unless you were really lucky, every event became a DNF.

Here's a simple/logical way to get your head around this:

If you go out and buy an old Formula Ford and stuff a decent small block Chevy into it and put wide, new design slicks on it....it might run a few laps...but you have exceeded the design limits of everything on the vehicle and the result is that you is going to break every last piece on the car. You can start with the failed hub...but the forces that are destroying the car are just going to move to another place.

#27

early CAST alloy = 17 ksi

7075 is better for compression parts, but more brittle than 6061 as it has higher content alloying agents than 6061 and susceptible to SCC. That's why I'm going with it, plus the areas on the hubs for strength will be increased to match that of 7075 without the worry of corrosion and SCC anyway.

7075 is better for compression parts, but more brittle than 6061 as it has higher content alloying agents than 6061 and susceptible to SCC. That's why I'm going with it, plus the areas on the hubs for strength will be increased to match that of 7075 without the worry of corrosion and SCC anyway.

#28

Chronic Tool Dropper

Lifetime Rennlist

Member

Lifetime Rennlist

Member

#29

Administrator - "Tyson"

Lifetime Rennlist

Member

Lifetime Rennlist

Member

#30

Got my CMM printout.

Anywhere between 0 to -15mm offset is safely doable on the Early hubs, the later hubs have a larger O.D. outer bearing and could maybe go -10mm

Anywhere between 0 to -15mm offset is safely doable on the Early hubs, the later hubs have a larger O.D. outer bearing and could maybe go -10mm

Last edited by xschop; 01-04-2011 at 05:15 PM.