928 AUTOMATIC Torque Tube Differences

#1

Hey Guys, I know that the 5-speed TT's have a seperate shaft extension into the clutch but have not seen any good pics in these forums about the 928 AUTOMATIC Torque Tube driveshafts and what are the differences in dimensions between the years on the front end of them where the shaft extends past the 928 BH mating flange. I'm going to Build a 928 TT adapter using a Corvette C5 bellhousing since I already have a C5 BH adapter designed for the 944 that fits any GM small Block V8....Chime in if you have info, thanks

#2

Race Director

actually the 5 speed TT's are longer...since the trans is shorter and there is no torque convertor in the way!

I am not 100% sure but I think the splines on all the TT's are the same....so in theory either the clutch of flexplate could be attached at the front.....

I am not 100% sure but I think the splines on all the TT's are the same....so in theory either the clutch of flexplate could be attached at the front.....

#3

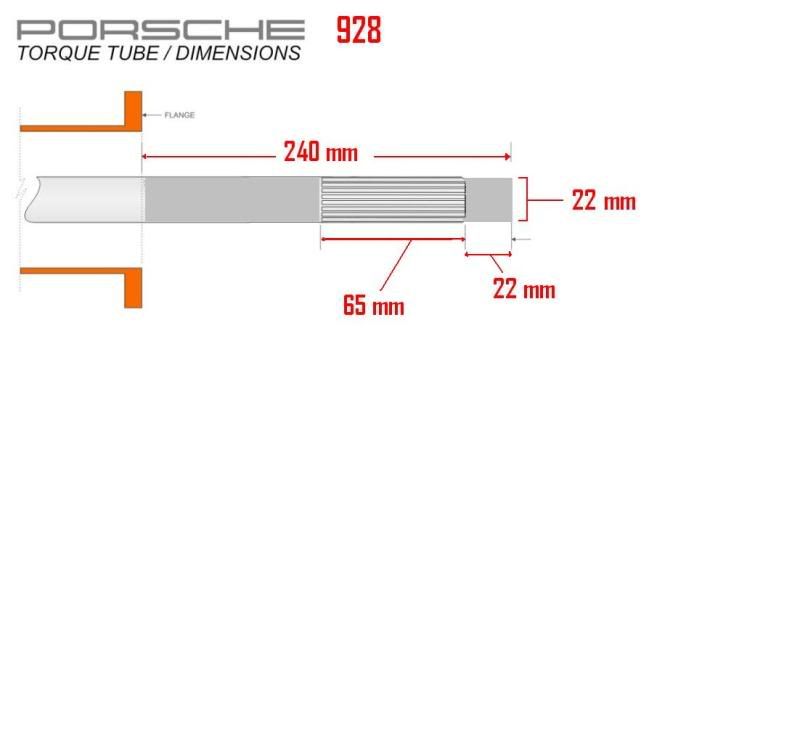

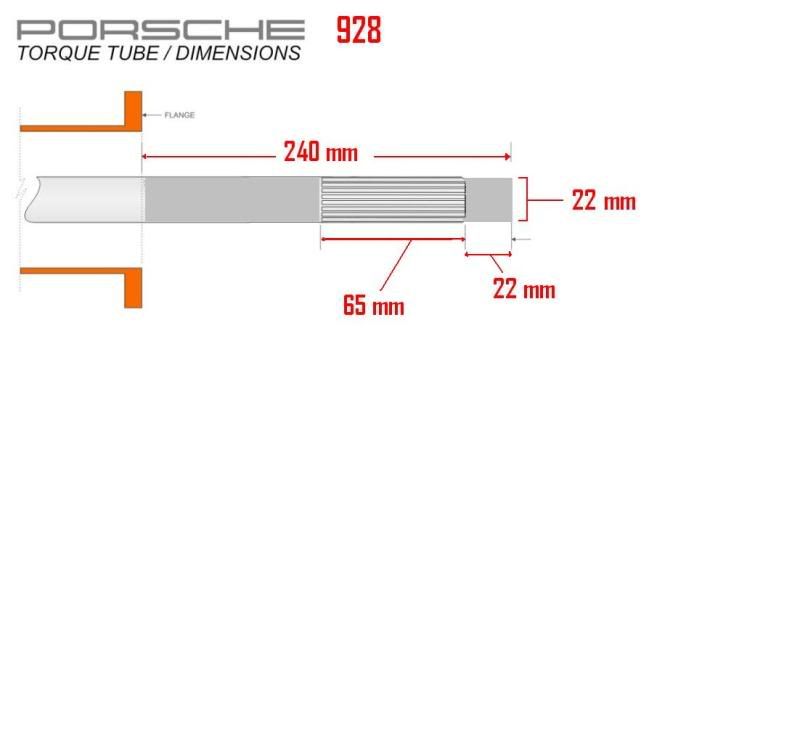

When I originally went yard diving for dimension I got these dims off a 928 TT. At the time I thought it was a 5-speed, but found the thread about the Early and Late 5-speed TT's with their 30mm length differences on the tubes and shaft coupler which this one does not have.

Somewhere I read that the Automatics have 2 different shaft designs and I saw a pic of one from BH flange forward that was different from the one I Mic'd at the Yard here.....

Somewhere I read that the Automatics have 2 different shaft designs and I saw a pic of one from BH flange forward that was different from the one I Mic'd at the Yard here.....

#5

For discussion purposes it will help to correctly identify each part of the torque tube assembly.

There is the drive shaft and the torque tube which houses it.

There are two styles of torque tubes, a 5 speed which is longer and an automatic which is shorter.

The 5 speed drive shaft is a two part drive shaft. A short shaft which is hardened and lives in the clutch and it's attached to the longer drive shaft in the torque tube. The drive shaft for all 928 5 speeds are 25mm in diameter.

The automatic drive shaft had two versions, an older style which is 25mm and has an area at it's front to allow for some parts to be placed on it, like in your diagram.

Then the 28mm drive shaft which does not have a portion at it's front end to place anything. These drive shafts are necked down to a 25mm splined area, both front and rear, so they can fit into the 25mm couplers for the front flex plate and the transmission input shaft.

The bellhousings are the same for both the 5 speeds and the autos, except the 5 speed version has a ball where the front of the shift mechanism attaches on the top of it.

There is a shorter torque tube and drive shaft auto version for MY 1978-79 which was then changed to the longer version in late 1979 on.

The auto drive shaft is not correctly hardened at the front to work in a clutch mechanism.

I'm not at home to give you exact measurements at the moment for each torque tube assembly, sorry.

HTH,

There is the drive shaft and the torque tube which houses it.

There are two styles of torque tubes, a 5 speed which is longer and an automatic which is shorter.

The 5 speed drive shaft is a two part drive shaft. A short shaft which is hardened and lives in the clutch and it's attached to the longer drive shaft in the torque tube. The drive shaft for all 928 5 speeds are 25mm in diameter.

The automatic drive shaft had two versions, an older style which is 25mm and has an area at it's front to allow for some parts to be placed on it, like in your diagram.

Then the 28mm drive shaft which does not have a portion at it's front end to place anything. These drive shafts are necked down to a 25mm splined area, both front and rear, so they can fit into the 25mm couplers for the front flex plate and the transmission input shaft.

The bellhousings are the same for both the 5 speeds and the autos, except the 5 speed version has a ball where the front of the shift mechanism attaches on the top of it.

There is a shorter torque tube and drive shaft auto version for MY 1978-79 which was then changed to the longer version in late 1979 on.

The auto drive shaft is not correctly hardened at the front to work in a clutch mechanism.

I'm not at home to give you exact measurements at the moment for each torque tube assembly, sorry.

HTH,

#6

Just the person to chime in. Thanks for the schoolin'.

If you are able this week can you post all the dims like the drawing?

Are the splines the same as the 944, 1x23 ? ( I know they are technically metric) ...I don't think 0.4mm on a ridge cut is going to make a whole lotta difference between a True Porsche spline pattern and the Chrysler. Anyways I'm working on an automatic 928 first and will mate the 928 flex plate coupler to the GM flexplate anyways.

If you are able this week can you post all the dims like the drawing?

Are the splines the same as the 944, 1x23 ? ( I know they are technically metric) ...I don't think 0.4mm on a ridge cut is going to make a whole lotta difference between a True Porsche spline pattern and the Chrysler. Anyways I'm working on an automatic 928 first and will mate the 928 flex plate coupler to the GM flexplate anyways.

#7

Not to bore others about this I can converse with you by PM or email for the dimensions you need. Please contact me after this weekend when I'm back home.

As far as the 944 splines being the same as the 928 splines, yes they are the same.

Cheers,

As far as the 944 splines being the same as the 928 splines, yes they are the same.

Cheers,

Trending Topics

#8

I have more questions anyways about the real reason for the 928 thrust bearing failures and how the shaft is or is not held at the back coupler/bearing. Anyways I was just looking at your avatar and thinking what a treat it would be if the 928 Flexplate-to-coupler PCD were the same as the LS PCD.......

PM sent.

PM sent.

#9

This write-up contradicts what I've been told about thrust bearing failure mechanism. How can the the coupler to spline end relation increase if the 928 shaft "grows" after torsional forces are applied over long periods?

http://members.rennlist.com/v1uhoh/9...earticleTH.pdf

http://members.rennlist.com/v1uhoh/9...earticleTH.pdf

#10

Rennlist Member

Shaft slips out of clamp on application of torque, but doesn't re-enter clamp afterward.

Accumulation of this effect results in increasing flexplate bow.

Seems consistent with what I've seen, making regular inspections and releases of tension on an 86 car.

Longer I wait between inspections, the more flex I see. And that's with a new pinch bolt at 66 Ft-lb.

That writeup illustrates very well the empirical situation with pictures, thanks for posting it.

The mechanistic explanation is best articulated by Constantine who has studied this deeply prior to engineering a robust solution. Discount other explanations including mine in lieu of his.

Accumulation of this effect results in increasing flexplate bow.

Seems consistent with what I've seen, making regular inspections and releases of tension on an 86 car.

Longer I wait between inspections, the more flex I see. And that's with a new pinch bolt at 66 Ft-lb.

That writeup illustrates very well the empirical situation with pictures, thanks for posting it.

The mechanistic explanation is best articulated by Constantine who has studied this deeply prior to engineering a robust solution. Discount other explanations including mine in lieu of his.

#11

Now that makes sense.

So in the tech article can I assume that the rear clamp between shaft and trans coupler is stronger and does not let the shaft walk out? Or does it do something similar?

So in the tech article can I assume that the rear clamp between shaft and trans coupler is stronger and does not let the shaft walk out? Or does it do something similar?

#12

Rennlist Member

Well, there is a locator notch in the drive shaft, manuals and automatics, through-which the rear bolt passes.

Front is not setup that way.

That said, Mr. Merlin repeatedly recommends checking the rear bolt for tightness, and to lock down the rear before locking down the front.

Here is a picture showing an the fronts of '89 auto drive shaft vs an '84 auto drive shaft (circlip).

(I can't remember if the rear ends were both aligned the same or not / didn't snap a picture / I think they are even on the rear though for this front picture)

I'm running the '84 (top) shaft / tube to drive an '89 S4 auto trans. (It had the better sounding bearings)

I've been told that the 85/6 shafts also have the extra length for the circlip, but I don't have one out to compare.

Front is not setup that way.

That said, Mr. Merlin repeatedly recommends checking the rear bolt for tightness, and to lock down the rear before locking down the front.

Here is a picture showing an the fronts of '89 auto drive shaft vs an '84 auto drive shaft (circlip).

(I can't remember if the rear ends were both aligned the same or not / didn't snap a picture / I think they are even on the rear though for this front picture)

I'm running the '84 (top) shaft / tube to drive an '89 S4 auto trans. (It had the better sounding bearings)

I've been told that the 85/6 shafts also have the extra length for the circlip, but I don't have one out to compare.

Last edited by Landseer; 10-08-2010 at 01:42 PM.

#13

What is the function of the circlip? My 86.5 has the notch but no circlip. Would placing a circilp on my drive shaft help eliminate the drive shaft movement that causes TBF? If so why didn't the porsche factory install a circlip on the 86.5 drive shafts? I have checked my flex plate for stress, and end play two times and I have not found any problems. The next time I check them I would like to add one of Constantine clamps and or the circlip. Any thoughts on this?

Ray

Ray

#14

Thank You, That answers the big question (I'm assuming the spline distances are the same from both flanges).

The other big question is if the automatic TT AND driveshafts had the 30mm difference between mid 80 MY as what I saw for the 5-speed TT and shafts ? I'll find that thread...

https://rennlist.com/forums/928/3850...d-tools-3.html

Also I can see Porsche having an Oh $hit moment and realizing the logistics of installing and removing a circlip there as it doesn't punch through the coupler too easy LOL.

The other big question is if the automatic TT AND driveshafts had the 30mm difference between mid 80 MY as what I saw for the 5-speed TT and shafts ? I'll find that thread...

https://rennlist.com/forums/928/3850...d-tools-3.html

Also I can see Porsche having an Oh $hit moment and realizing the logistics of installing and removing a circlip there as it doesn't punch through the coupler too easy LOL.

Last edited by xschop; 10-08-2010 at 02:46 PM.

#15

Addict

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Ray, Porsche increased the shoulder bearing surfaces on the thrust bearing main bearing around 1984. They then issued a tech bulletin stating it was no longer needed. Speculation is the technicans working on 928s were having difficulty /or ignored the correct method to measure and shim the shaft. In retrospect, we now know that the clip and shims will prevent the movement. How ever screw up the shim measurements and you can preload the flex plate and stress the trust bearing surface.