TPS. A look inside.

#2

Craic Head

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Yup, just mechanical contacts like most of the other early 80s vintage switches in these cars.

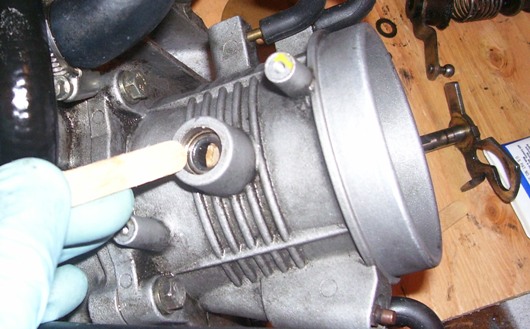

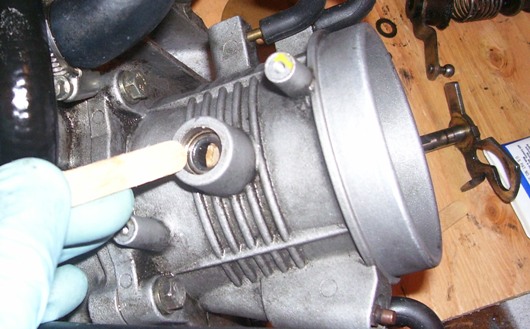

If your TPS is full of oil then the O-rings for the shaft are beat. Cleaning it out won't fix the problem. I would recommend complete disassembly and replacing those O-rings. I did a write-up HERE where I took it all apart and found an O-ring in each side of the throttle butterfly shaft. In mine they were brittle and cracked and weren't sealing anything. It was how the TPS got full of oil and also was the source of an air leak on mine.

The old one:

The new one

If your TPS is full of oil then the O-rings for the shaft are beat. Cleaning it out won't fix the problem. I would recommend complete disassembly and replacing those O-rings. I did a write-up HERE where I took it all apart and found an O-ring in each side of the throttle butterfly shaft. In mine they were brittle and cracked and weren't sealing anything. It was how the TPS got full of oil and also was the source of an air leak on mine.

The old one:

The new one

#3

Rennlist Member

Thread Starter

I think the original set-up has lip-sealed needle bearings in a housing.

Mike, do you feel the cam seal O-rings let the shaft move enough?

The TB is under vac, and the TPS is in the direct line of the spray from the broken hose that coated the whole engine compartment. In fact, only an inch or two away and always bathed. So, it can potentially draw oil in thorough the outside of its case. Its not oil from the organ pipes, not that it matters technically. The oil source is now gone, just like on the 86 car, but the shaft seal is indeed in question.

I just don't want it to bind on me.

Your write up is AWESOME, by the way.

Mike, do you feel the cam seal O-rings let the shaft move enough?

The TB is under vac, and the TPS is in the direct line of the spray from the broken hose that coated the whole engine compartment. In fact, only an inch or two away and always bathed. So, it can potentially draw oil in thorough the outside of its case. Its not oil from the organ pipes, not that it matters technically. The oil source is now gone, just like on the 86 car, but the shaft seal is indeed in question.

I just don't want it to bind on me.

Your write up is AWESOME, by the way.

#4

Ironic topic, I was having a problem with TPS and WOT. I took apart the TPS and it was filled with oil as well preventing contact! Do you recall the size of the o-ring that required?

Danny

Danny

#5

Rennlist Member

Thread Starter

Danny,

Mike used the cam cover bolt O-rings, one per side. Plus the O-ring that fits into the outside of the case of the TPS, somewhat bigger.

According to what I read in a thread supplemental to his write up, he picked out the old outer seals from the sealed bearing on the shaft on each side and the cam cover O-rings fit for him. OD about right, ID a little tight. Lubed them and feels it is working.

Dwayne, in an intake refresh write up on a later car, found that the flappy bearings are exact replacements for the TB shaft sealed bearings. So, he dremel-cut the little bearings and replaced them. Not sure if the diameter of the shafts is the same on our 85's and the flappy on the later car, though. Somebody needs to find out.

Me, I'm torn. Way A, Way B, or leave it.

Mike used the cam cover bolt O-rings, one per side. Plus the O-ring that fits into the outside of the case of the TPS, somewhat bigger.

According to what I read in a thread supplemental to his write up, he picked out the old outer seals from the sealed bearing on the shaft on each side and the cam cover O-rings fit for him. OD about right, ID a little tight. Lubed them and feels it is working.

Dwayne, in an intake refresh write up on a later car, found that the flappy bearings are exact replacements for the TB shaft sealed bearings. So, he dremel-cut the little bearings and replaced them. Not sure if the diameter of the shafts is the same on our 85's and the flappy on the later car, though. Somebody needs to find out.

Me, I'm torn. Way A, Way B, or leave it.

#6

Craic Head

Lifetime Rennlist

Member

Lifetime Rennlist

Member

I think the original set-up has lip-sealed needle bearings in a housing.

Mike, do you feel the cam seal O-rings let the shaft move enough?

The TB is under vac, and the TPS is in the direct line of the spray from the broken hose that coated the whole engine compartment. In fact, only an inch or two away and always bathed. So, it can potentially draw oil in thorough the outside of its case. Its not oil from the organ pipes, not that it matters technically. The oil source is now gone, just like on the 86 car, but the shaft seal is indeed in question.

I just don't want it to bind on me.

Your write up is AWESOME, by the way.

Mike, do you feel the cam seal O-rings let the shaft move enough?

The TB is under vac, and the TPS is in the direct line of the spray from the broken hose that coated the whole engine compartment. In fact, only an inch or two away and always bathed. So, it can potentially draw oil in thorough the outside of its case. Its not oil from the organ pipes, not that it matters technically. The oil source is now gone, just like on the 86 car, but the shaft seal is indeed in question.

I just don't want it to bind on me.

Your write up is AWESOME, by the way.

I can't see how oil from a breather line could get inside. Mine was dripping oil when I took it out and it had no breather hose issues so I assumed it had come from the inside. The side boxes always have oil in them as well as the lower air guide.

#7

Rennlist Member

Thread Starter

Well, you certainly could be right.

If I recall, you were the first guy that posted about the shaft seals. Its a great help. I think that may be where my whistle is coming when just touching the throttle. There or the ISV.

Its one of those situations where visibility is obscured when assembled. Just want to replace it all at once. But have a budget.

I gotta have some Porken Chips and S4 FPR. On the hunt.

If I recall, you were the first guy that posted about the shaft seals. Its a great help. I think that may be where my whistle is coming when just touching the throttle. There or the ISV.

Its one of those situations where visibility is obscured when assembled. Just want to replace it all at once. But have a budget.

I gotta have some Porken Chips and S4 FPR. On the hunt.

Trending Topics

#9

Craic Head

Lifetime Rennlist

Member

Lifetime Rennlist

Member

Well, you certainly could be right.

If I recall, you were the first guy that posted about the shaft seals. Its a great help. I think that may be where my whistle is coming when just touching the throttle. There or the ISV.

Its one of those situations where visibility is obscured when assembled. Just want to replace it all at once. But have a budget.

I gotta have some Porken Chips and S4 FPR. On the hunt.

If I recall, you were the first guy that posted about the shaft seals. Its a great help. I think that may be where my whistle is coming when just touching the throttle. There or the ISV.

Its one of those situations where visibility is obscured when assembled. Just want to replace it all at once. But have a budget.

I gotta have some Porken Chips and S4 FPR. On the hunt.

Yeah, working in that area is a PITA. I was able to wiggle out the 'T' section of the top of the TB and then move some stuff around by taking the nuts off of those three lower air guide standoffs, but I don't think the TB can be completely removed without taking off at least one of the intake runners.

If you've got a whistle from there I'd be surprised if it was coming from the 'metered air' section unless you've also got idle issues. If your air pump system is discoed, you might check the top and bottom of all of those tubes, I've seen those make some weird noises. You end up with a very small pipe organ working once the system is discoed but still running on the belt.

#10

Rennlist Member

Join Date: Jul 2002

Location: Deep in the Heart of Texas!

Posts: 3,267

Likes: 0

Received 5 Likes

on

4 Posts

Landseer, how did you open up your TPS and what did you clean it up with? Does the cover just snap on and off or something?

I'm working on my t-body (put in new bearings/seals yesterday in fact) and did see oil in the TPS ... at least around the throttle shat.

I'm working on my t-body (put in new bearings/seals yesterday in fact) and did see oil in the TPS ... at least around the throttle shat.

#11

Rennlist Member

Thread Starter

I clamped one of the attachment metal tabs in a vice.

Then, with a file, went around the case edge and knocked off any adhesive that I saw.

Then, used a sharp utility knive to score the seam a little, aiming to cut any glue there.

Then, used a 1/4 inch wood chisel to gently lift each of the four taps to ensure they were free. Yes they are tabs with slight hooks on them.

Then, kind of lifted one tab and tapped the case open a bit, then went around the case doing that.

To clean I used MAF cleaner from CRC. Its plastic safe. (Not Throttle Body Cleaner / its not!)

I wiped the sealing parts of the case with acetone carefully, then smeared a very thin layer of RTV in the joint and closed it all up.

Finally, a job I could do! Meanwhile, we have NASA guys doing sharktuning and superchargers and real stuff. Someday.

Then, with a file, went around the case edge and knocked off any adhesive that I saw.

Then, used a sharp utility knive to score the seam a little, aiming to cut any glue there.

Then, used a 1/4 inch wood chisel to gently lift each of the four taps to ensure they were free. Yes they are tabs with slight hooks on them.

Then, kind of lifted one tab and tapped the case open a bit, then went around the case doing that.

To clean I used MAF cleaner from CRC. Its plastic safe. (Not Throttle Body Cleaner / its not!)

I wiped the sealing parts of the case with acetone carefully, then smeared a very thin layer of RTV in the joint and closed it all up.

Finally, a job I could do! Meanwhile, we have NASA guys doing sharktuning and superchargers and real stuff. Someday.

Last edited by Landseer; 01-18-2010 at 11:54 AM.

#12

Rennlist Member

Keeper - thanks Chris