X-pipe diameter

#1

Three Wheelin'

Thread Starter

i'm wondering about the following diameters :

my MSDS headers collectors are 76 mm ( do you call that 3" ? )

the dual exhaust is 60 mm ( 2 1/2 " ? )

now for the X-pipe ? does one reduce best after header collectors and make a X from 60 mm tubing or X in 76 mm tubing and reducers after the X ?

or should that make no big difference ?

thanks for replys

Norbert

my MSDS headers collectors are 76 mm ( do you call that 3" ? )

the dual exhaust is 60 mm ( 2 1/2 " ? )

now for the X-pipe ? does one reduce best after header collectors and make a X from 60 mm tubing or X in 76 mm tubing and reducers after the X ?

or should that make no big difference ?

thanks for replys

Norbert

#4

Three Wheelin'

i'm wondering about the following diameters :

my MSDS headers collectors are 76 mm ( do you call that 3" ? )

the dual exhaust is 60 mm ( 2 1/2 " ? )

now for the X-pipe ? does one reduce best after header collectors and make a X from 60 mm tubing or X in 76 mm tubing and reducers after the X ?

or should that make no big difference ?

thanks for replys

Norbert

my MSDS headers collectors are 76 mm ( do you call that 3" ? )

the dual exhaust is 60 mm ( 2 1/2 " ? )

now for the X-pipe ? does one reduce best after header collectors and make a X from 60 mm tubing or X in 76 mm tubing and reducers after the X ?

or should that make no big difference ?

thanks for replys

Norbert

#5

Race Director

It all depends on how much HP you plan on running.......Louie hit it perfectly.....

For example I have the 928intl race headers (1.75" into a merge then into ??) with a mandrel bent 2.5" exhaust including the X pipe.....on my 360 crank HP car it works great....but slap it on Louies monster and you would loose all kinds of HP

For example I have the 928intl race headers (1.75" into a merge then into ??) with a mandrel bent 2.5" exhaust including the X pipe.....on my 360 crank HP car it works great....but slap it on Louies monster and you would loose all kinds of HP

#6

Three Wheelin'

Thread Starter

Thanks guys for the help !

Now Louie mentioned a step further as i was thinking , i tought the X as a bypass to help cilinders exhaust between also from left and right bank...but it all relates together , high speed, low pressure..... vacuum .

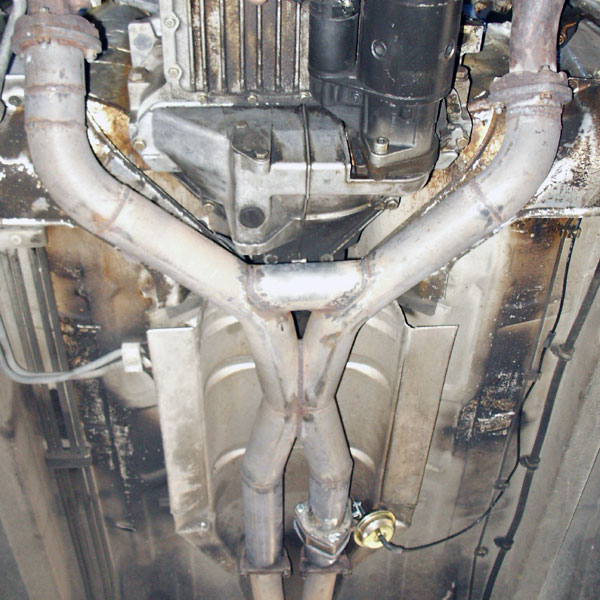

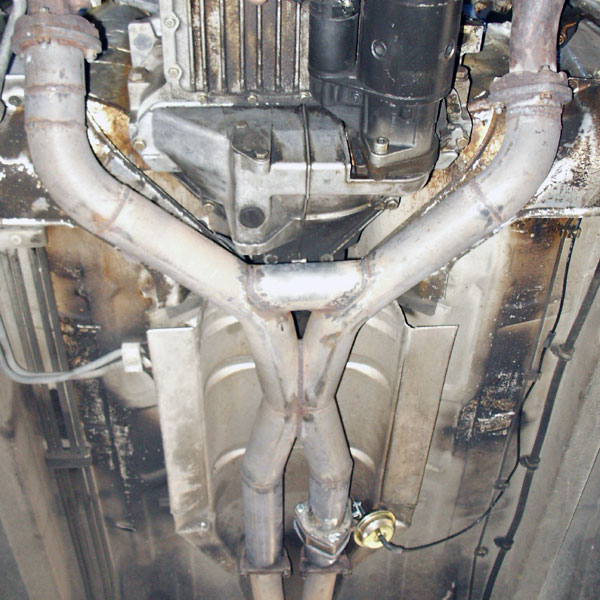

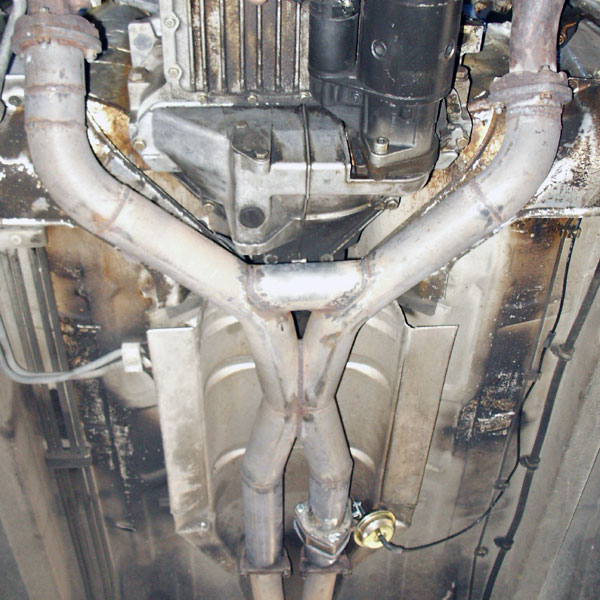

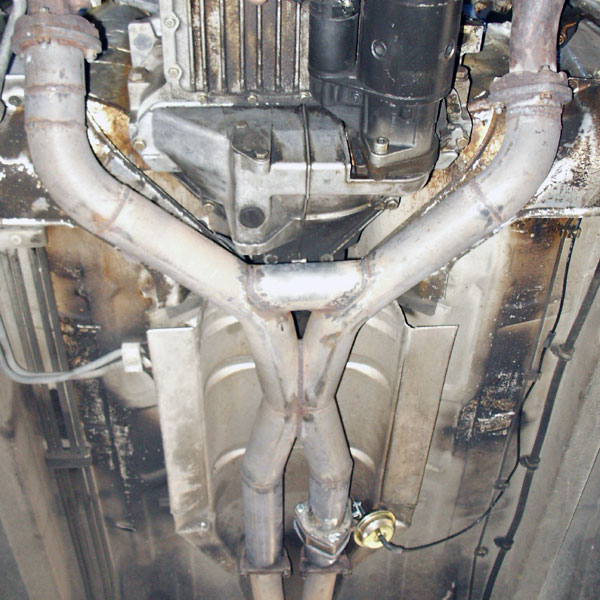

Without "know" i made one from the 60 mm pipe as the exhaust and placed reducers just after the header collectors. Width at smallest is around 1.5 x 60 mm , so i average the 1.4 to 1.6... ( it's a 5 spd)

So Louie reassured me i can hold that design for the first trials... thanks.

Now Louie mentioned a step further as i was thinking , i tought the X as a bypass to help cilinders exhaust between also from left and right bank...but it all relates together , high speed, low pressure..... vacuum .

Without "know" i made one from the 60 mm pipe as the exhaust and placed reducers just after the header collectors. Width at smallest is around 1.5 x 60 mm , so i average the 1.4 to 1.6... ( it's a 5 spd)

So Louie reassured me i can hold that design for the first trials... thanks.

#7

Rennlist Member

what are the diameters of the outlet of my devek level II headers? when is it benificial to go to the next size up in diameter on the headers? above 400rwhp?

Have we confirmed that the x pipe and duals, are better or the same as a 3.5" single pipe leading from the merged y pipe?

mk

Have we confirmed that the x pipe and duals, are better or the same as a 3.5" single pipe leading from the merged y pipe?

mk

Trending Topics

#8

Hi Barry

There is no science to my set up but I'm running MSDs headers and kept the 3" collector dia. all the way to the rear of the car. Mine is all home-built but this set up gave me about 30hp over stock.

There is no science to my set up but I'm running MSDs headers and kept the 3" collector dia. all the way to the rear of the car. Mine is all home-built but this set up gave me about 30hp over stock.

#9

Three Wheelin'

Thanks guys for the help !

Now Louie mentioned a step further as i was thinking , i tought the X as a bypass to help cilinders exhaust between also from left and right bank...but it all relates together , high speed, low pressure..... vacuum .

Without "know" i made one from the 60 mm pipe as the exhaust and placed reducers just after the header collectors. Width at smallest is around 1.5 x 60 mm , so i average the 1.4 to 1.6... ( it's a 5 spd)

So Louie reassured me i can hold that design for the first trials... thanks.

Now Louie mentioned a step further as i was thinking , i tought the X as a bypass to help cilinders exhaust between also from left and right bank...but it all relates together , high speed, low pressure..... vacuum .

Without "know" i made one from the 60 mm pipe as the exhaust and placed reducers just after the header collectors. Width at smallest is around 1.5 x 60 mm , so i average the 1.4 to 1.6... ( it's a 5 spd)

So Louie reassured me i can hold that design for the first trials... thanks.

#10

Three Wheelin'

what are the diameters of the outlet of my devek level II headers? when is it benificial to go to the next size up in diameter on the headers? above 400rwhp?

Have we confirmed that the x pipe and duals, are better or the same as a 3.5" single pipe leading from the merged y pipe?

mk

Have we confirmed that the x pipe and duals, are better or the same as a 3.5" single pipe leading from the merged y pipe?

mk

I've done dyno runs with both X and 2.5" duals after that and a (venturi) merge to a single 3.5" (no X). The merge was like the one Burns Stainless makes. Above 5000 rpm, there was no difference in power. Between around 3000 and 5000 the 2.5" duals made more torque. The torque gain with the duals was only about 5 ft lbs., but something. The dual 2.5" is easier to muffle than the single 3.5", but is heavier and more costly to make. For a mostly track car, the single 3.5" is likely the choice. For street driven cars, I'd say the dual 2.5" would be the way to go.

Some dyno runs here. The top two are the 2.5" merge to 3.5" single and 2.5" X to 2.5" duals.

http://www.performance928.com/cgi-bi...ss_parent=1125

The collector size on your Devek L2 headers is 3" OD. I don't know at what power level you'd see a gain by going up in size from your single 3.5". I think right now, you'd see good gain by helping the intake breathing. That would be 968 intake valves, better cams that your S3 cams, intake side plates and extrude hone the intake. Things like that will help. Then try a 4" pipe and see if it helps. Don Hanson used a single 3.5" on his track car with stroker at around 420 - 440 rwhp. He went to a single 4" when he changed to ITB intake and Devek B1 cams and had 580 or so SAE rwhp.

#11

Three Wheelin'

Thread Starter

on the other hand i got your opinion "between the lines" Louie... what you think could be better ? are the X-pipe bends to short in radius ? bigger mid section width ?

please tell your idea, it's no big deal for us to make another one to test ...

please tell your idea, it's no big deal for us to make another one to test ...

Last edited by belgiumbarry; 01-07-2009 at 07:47 PM.

#12

Inventor

Rennlist Member

Rennlist Member

I think Louie likes a shallower angle into the ><, but I'm sure he'll chime back in.

I recommend a balance pipe before the X (HeX-pipe™ ). It doesn't necessarily change the power output (it didn't lose power on the dyno), but it does make it a bit quieter, and most importantly, makes a decent place to put a (wideband) O2 sensor. Mounted on the down pipes, the O2 sensor is nearly horizontal, and may not last as long (condensation)?

). It doesn't necessarily change the power output (it didn't lose power on the dyno), but it does make it a bit quieter, and most importantly, makes a decent place to put a (wideband) O2 sensor. Mounted on the down pipes, the O2 sensor is nearly horizontal, and may not last as long (condensation)?

I recommend a balance pipe before the X (HeX-pipe™

). It doesn't necessarily change the power output (it didn't lose power on the dyno), but it does make it a bit quieter, and most importantly, makes a decent place to put a (wideband) O2 sensor. Mounted on the down pipes, the O2 sensor is nearly horizontal, and may not last as long (condensation)?

). It doesn't necessarily change the power output (it didn't lose power on the dyno), but it does make it a bit quieter, and most importantly, makes a decent place to put a (wideband) O2 sensor. Mounted on the down pipes, the O2 sensor is nearly horizontal, and may not last as long (condensation)?

#13

Three Wheelin'

Also, a book I used as a guide to help figure this stuff out (after I made one) had the two V (merge collectors really) sections welded end to end in their example with the included angle at about 20 degrees. That's what I ended up using. Here is some information I put on my web site.

http://www.performance928.com/cgi-bi...ss_parent=1128 Check out the link to Burns Stainless. I see they use my design. It's ok, I don't mind.

Note: I can't call these X pipes so I note them as V2, or )( or anything other than X.

About the time I got the letter from an attorney telling me I couldn't refer to them as X pipes, or anything that could be construed as X pipe, I decided I didn't want to make these anymore. I gave all the information I had to Dave Lomas of Motorsports in Salt Lake City. Dr.Gas is in Salt Lake and is a well known manufacturer of exhaust systems and most notably NASCAR exhaust. Dave decided to enlist their aid in building the pipes for him. Dr Gas took one look at my X pipe and said it was all wrong. They made one for a 928 that was to their specs and tried it. That version lost 13hp over what mine had done. It was Dr. Gas back to the drawing board for several other versions until they got something that worked as well. The final version had the exact back section I had, but the front was shortened with the inlet angle steepened a little. The front is very similar to yours in front of the narrowest part. Overall it's a little shorter than mine and gives more length in the rear for cats, or short mufflers, if desired. It made more power on the '86 Dave used for testing than mine did. I developed mine on a GT so maybe a little difference there. I've tested mine and Dave's version on S4 and GT and don't see a difference. That's about all I can add.

#14

Three Wheelin'

Thread Starter

Louie, thank you very much Sir for that professional explanation ! You guys must have made alot of study, work and trials on such "small" item as the X piece ! Didn't even know that it all could make that much difference and/or importance...

think of making a new one ... so i should use +/-"25░" bends first to get the pipes angled at 20░ for the X , made of straight welded tubing ... and than again 20 ░ out to after piping.

But , again, sorry , what diameters should i use , knowing i start at the headers collectors which are 76 mm... to end with dual 60 mm... where to put the reducers ? What diameter of the venturi middle section X ?

i know, i'm asking alot , but hope you chime in with some advise

thanks !

Norbert

think of making a new one ... so i should use +/-"25░" bends first to get the pipes angled at 20░ for the X , made of straight welded tubing ... and than again 20 ░ out to after piping.

But , again, sorry , what diameters should i use , knowing i start at the headers collectors which are 76 mm... to end with dual 60 mm... where to put the reducers ? What diameter of the venturi middle section X ?

i know, i'm asking alot , but hope you chime in with some advise

thanks !

Norbert

#15

Three Wheelin'

Thread Starter

I think Louie likes a shallower angle into the ><, but I'm sure he'll chime back in.

I recommend a balance pipe before the X (HeX-pipeÖ ). It doesn't necessarily change the power output (it didn't lose power on the dyno), but it does make it a bit quieter, and most importantly, makes a decent place to put a (wideband) O2 sensor. Mounted on the down pipes, the O2 sensor is nearly horizontal, and may not last as long (condensation)?

). It doesn't necessarily change the power output (it didn't lose power on the dyno), but it does make it a bit quieter, and most importantly, makes a decent place to put a (wideband) O2 sensor. Mounted on the down pipes, the O2 sensor is nearly horizontal, and may not last as long (condensation)?

I recommend a balance pipe before the X (HeX-pipeÖ

). It doesn't necessarily change the power output (it didn't lose power on the dyno), but it does make it a bit quieter, and most importantly, makes a decent place to put a (wideband) O2 sensor. Mounted on the down pipes, the O2 sensor is nearly horizontal, and may not last as long (condensation)?

). It doesn't necessarily change the power output (it didn't lose power on the dyno), but it does make it a bit quieter, and most importantly, makes a decent place to put a (wideband) O2 sensor. Mounted on the down pipes, the O2 sensor is nearly horizontal, and may not last as long (condensation)?

Ofcourse it could be a good idea for it's "quieter" ability ....as on our circuits as Zolder max is 95 dbA... could become a problem with my 928 ( sucking carbs

) .....

) .....