Rod Bearing Clearance Madness

#1

Rennlist Member

Thread Starter

An issue was raised in another thread where Glyco bearings were stated to be a bit on the tight side. And it was stated that this could be a contributing factor to 2/6 bearing failures – which makes perfect sense to me. Also, that genuine Porsche rod bearings come in 3 tolerances and can be used to mix and match to get a desired clearance (an expensive proposition).

What I’d like to discuss is when using Glyco rod bearings, what are the steps to get the clearance you need?

Let’s say you preassemble, plastigauging the clearance of the rod journals. I’d expect that you’d get different clearance measurements for each bearing, even those sharing a common crank journal.

The different clearances obviously would result from varying bearing sizes and crank journal sizes.

So I have a question, can you play with the clearance by swapping bearings around between rods? Or are the bearings’ tolerances tight enough that they will all be the same thickness and this would be a waste of time?

If so, how do you increase tolerance for a tight measurement? Do you have the crank journal machined? I’d think the machine shop would need the crank and the rod assembled with the bearing to get this right.

What if you get out of tolerance readings for rods on a shared journal? Would this mean that the rod bearings tolerance is inconsistent? I wouldn’t think you machine ½ of the crank journal. At this point I guess you start moving rod bearings around to get consistency on a journal?

If clearance is too loose, what then? Toss the rod bearings and machine for the next undersize? Would the machine shop want the preassembled rod to measure before turning the crank?

Can you really measure this stuff with gauges you could buy. Or are the measurements so fine that the gauges would be too expensive. Or maybe you would have trouble measuring correctly?

What I’d like to discuss is when using Glyco rod bearings, what are the steps to get the clearance you need?

Let’s say you preassemble, plastigauging the clearance of the rod journals. I’d expect that you’d get different clearance measurements for each bearing, even those sharing a common crank journal.

The different clearances obviously would result from varying bearing sizes and crank journal sizes.

So I have a question, can you play with the clearance by swapping bearings around between rods? Or are the bearings’ tolerances tight enough that they will all be the same thickness and this would be a waste of time?

If so, how do you increase tolerance for a tight measurement? Do you have the crank journal machined? I’d think the machine shop would need the crank and the rod assembled with the bearing to get this right.

What if you get out of tolerance readings for rods on a shared journal? Would this mean that the rod bearings tolerance is inconsistent? I wouldn’t think you machine ½ of the crank journal. At this point I guess you start moving rod bearings around to get consistency on a journal?

If clearance is too loose, what then? Toss the rod bearings and machine for the next undersize? Would the machine shop want the preassembled rod to measure before turning the crank?

Can you really measure this stuff with gauges you could buy. Or are the measurements so fine that the gauges would be too expensive. Or maybe you would have trouble measuring correctly?

#2

Rennlist Member

Have you searched the archives? I remember a thread on machining the journals for some clearance issue. It was quite detailed discussion. It was a couple years old, I don't think it is the one you are referring to.

Last edited by SteveG; 01-11-2008 at 11:08 AM. Reason: make it gooder

#3

Dan,

I've never heard of a machine shop intentionally cutting different sized rod journals. They normally set up their lathe then check each cut with a micrometer as they proceed. I have seen bearings that have been mishandled/sprung which will change the shape or thickness of the babbit (softer top alloy). I don't have the WSM here at work, but most rod bearings specs have a tolerance of .001 to .004" when measured with plastigage. Are yours within the range specified in the WSM? There are micrometer sets than are set up to measure inside and outside diameters. Last time I checked the good one were expensive. It would probably be cheaper to have a good machine shop measure and install the for you.

Dennis

I've never heard of a machine shop intentionally cutting different sized rod journals. They normally set up their lathe then check each cut with a micrometer as they proceed. I have seen bearings that have been mishandled/sprung which will change the shape or thickness of the babbit (softer top alloy). I don't have the WSM here at work, but most rod bearings specs have a tolerance of .001 to .004" when measured with plastigage. Are yours within the range specified in the WSM? There are micrometer sets than are set up to measure inside and outside diameters. Last time I checked the good one were expensive. It would probably be cheaper to have a good machine shop measure and install the for you.

Dennis

#4

Rennlist Member

Thread Starter

I've seen lots of postings on bearing clearances, but I can find any on how to fix if the clearances are too tight.

Read on post where clearance measured to tight, but within tolerance when measured with plastigage.

I'd need to buy rod bearings. Like to buy Glyco due to price. Just not 100% clear on what is done if they measure too tight.

#5

An issue was raised in another thread where Glyco bearings were stated to be a bit on the tight side. And it was stated that this could be a contributing factor to 2/6 bearing failures

So I have a question, can you play with the clearance by swapping bearings around between rods? Or are the bearings’ tolerances tight enough that they will all be the same thickness and this would be a waste of time?

?

So I have a question, can you play with the clearance by swapping bearings around between rods? Or are the bearings’ tolerances tight enough that they will all be the same thickness and this would be a waste of time?

?

But on your first comment, there has only been ONE person that I know of here that has even mentioned the differences between the Glyco and Porsche boxed bearings. Only one.

Secondly, what you describe regarding swapping bearings is EXACTLY what Honda and a few other manuf. prescribe when you assemble them, or at least it is best practice. They have different "colored" bearings and you must measure before you buy to create the proper clearances on each rod journal.

So you are on the right track IMO.

#6

Rennlist Member

Thread Starter

I think I'll take this approach:

Measure each rod journal. Plastigauge rod bearing clearances. Based on clearances measured, determine if some bearings are looser than others. Swap these around to get the best overall fit, reassemble and replastigauge.

Hopefully I'll get this done sometime soon.

(After helping me pull my engine,my dad asked when I thought I'd have it all back together, I said hopefully before Summer.)

Measure each rod journal. Plastigauge rod bearing clearances. Based on clearances measured, determine if some bearings are looser than others. Swap these around to get the best overall fit, reassemble and replastigauge.

Hopefully I'll get this done sometime soon.

(After helping me pull my engine,my dad asked when I thought I'd have it all back together, I said hopefully before Summer.)

#7

Nordschleife Master

Brendan,

Is the one person your refering to Greg Brown?

I remember him making bringing this up (most likely in a thread not specifically about Rod bearings, which is why search dosen't always work)

Is the one person your refering to Greg Brown?

I remember him making bringing this up (most likely in a thread not specifically about Rod bearings, which is why search dosen't always work)

Trending Topics

#9

Three Wheelin'

Join Date: Jan 2007

Location: not where you think I am

Posts: 1,466

Likes: 0

Received 0 Likes

on

0 Posts

Dan--

we regularly adjust the bearing clearance by using scotch brite pads, or similar, if the clearances are too tight.

if the clearances are too loose, it's time for a crank grind to the nest "under size".

you still should recheck clearances even if it's a new (or freshly reground) crank and new bearings.....

clearances are in the FWM's for your engine. be sure to have the same clearances for each bearing, regardless of position, mains or rods. use some kind of assembly lube as well. I prefer "Lubriplate", and have had good results with it for decades.

Also, you should note that rod cap nuts on 928 engines are "one time use only". They're pretty cheap, but use them only once after you torque them down.

while I can't remember the figures in "metric" right off the top of my head, we have always run .005" on a street engine, .015" on our drag race engines.

same clearances for piston skirt to cylinder wall as well. (yep, the race motors rattle like crazy.......but they rev up really quick!!!!)

--Russ

we regularly adjust the bearing clearance by using scotch brite pads, or similar, if the clearances are too tight.

if the clearances are too loose, it's time for a crank grind to the nest "under size".

you still should recheck clearances even if it's a new (or freshly reground) crank and new bearings.....

clearances are in the FWM's for your engine. be sure to have the same clearances for each bearing, regardless of position, mains or rods. use some kind of assembly lube as well. I prefer "Lubriplate", and have had good results with it for decades.

Also, you should note that rod cap nuts on 928 engines are "one time use only". They're pretty cheap, but use them only once after you torque them down.

while I can't remember the figures in "metric" right off the top of my head, we have always run .005" on a street engine, .015" on our drag race engines.

same clearances for piston skirt to cylinder wall as well. (yep, the race motors rattle like crazy.......but they rev up really quick!!!!)

--Russ

#10

Rennlist Member

Some makers used to also recommend checking bearing 'nip' in the rod - assemble and torque shells in rod end off the crank and loosen one bolt - cap should open a couple of thou . If less, shells are not well enough clamped; if too much opening, shell is likely to distort and the end curl in and damage the journal. The last part was the best - 'achieve necessary fit by selective assembly ' - ie have a bunch of shell sets you can find the best fit from.

jp 83 Euro S AT 51k

jp 83 Euro S AT 51k

#11

Rennlist Member

Thread Starter

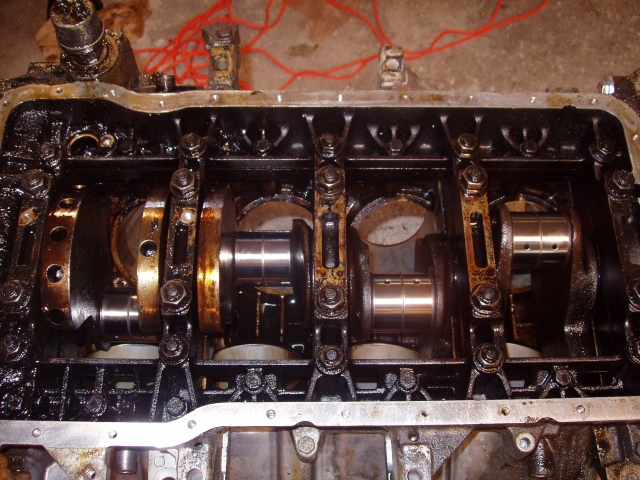

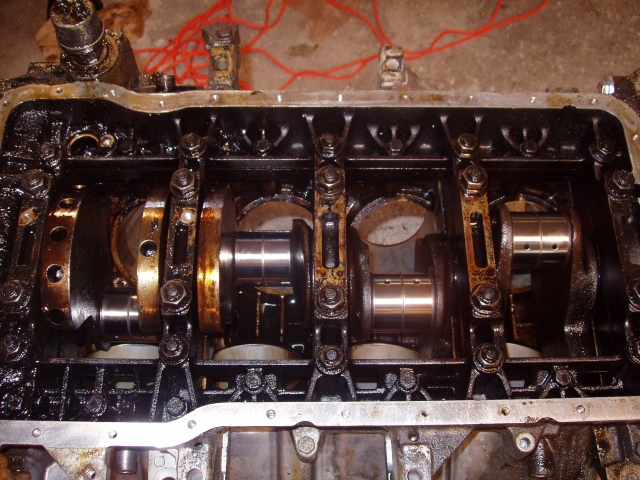

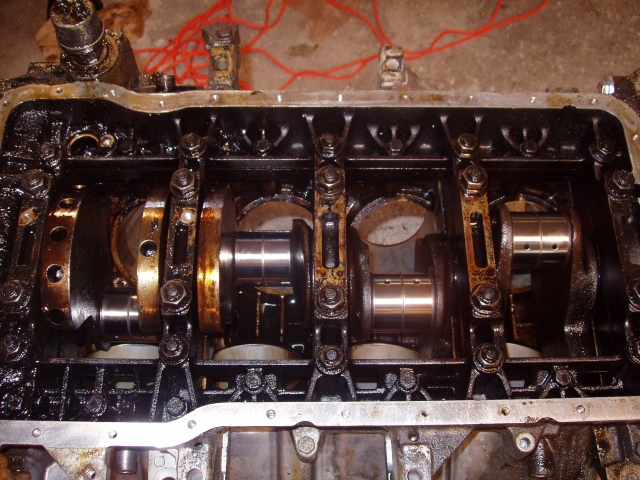

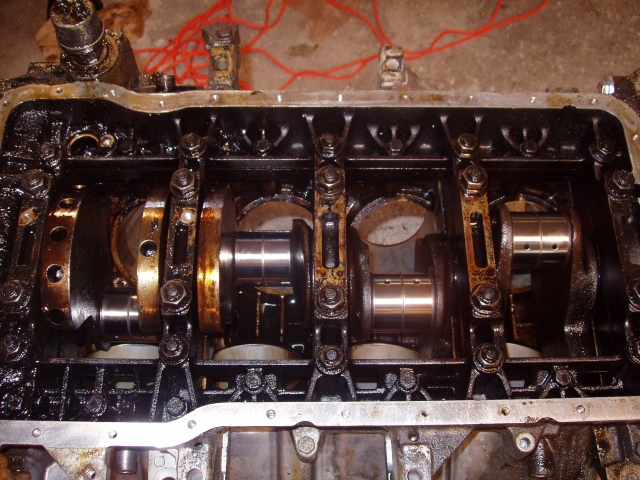

I did a quick measurement of each rod bearing

Using this dial caliper

I got 2 and 47/1000's inch on each one. Well maybe 2 and 46/1000's. Which is right on the 51.971 to 51.990 in th eTech Spec Book.

My tech spec book says .034 - .092 mm radial play. So 1.5 - 3.6/1000's

I need to try for more accurate measurements and I'll swap things around and use lots of plastigauge.

Using this dial caliper

I got 2 and 47/1000's inch on each one. Well maybe 2 and 46/1000's. Which is right on the 51.971 to 51.990 in th eTech Spec Book.

My tech spec book says .034 - .092 mm radial play. So 1.5 - 3.6/1000's

I need to try for more accurate measurements and I'll swap things around and use lots of plastigauge.

#12

I did a quick measurement of each rod bearing

Using this dial caliper

I got 2 and 47/1000's inch on each one. Well maybe 2 and 46/1000's. Which is right on the 51.971 to 51.990 in th eTech Spec Book.

My tech spec book says .034 - .092 mm radial play. So 1.5 - 3.6/1000's

I need to try for more accurate measurements and I'll swap things around and use lots of plastigauge.

Using this dial caliper

I got 2 and 47/1000's inch on each one. Well maybe 2 and 46/1000's. Which is right on the 51.971 to 51.990 in th eTech Spec Book.

My tech spec book says .034 - .092 mm radial play. So 1.5 - 3.6/1000's

I need to try for more accurate measurements and I'll swap things around and use lots of plastigauge.

#13

Three Wheelin'

Dan, the dial caliper is inadequate for measuring bearing journals. A micrometer, bore gage and calibration standards are necessary, you also need a ground pin to measure bearing shell thickness with a mic.

Why not take everything to an automotive machine shop? The have the equipment and experience and could see things you can't, most are nice people and with modern cars never needing to have engine work, they're probably eager for something to do.

Here's what to look for:

Rod big end size and roundness. The'yre likely egg shaped but can be resized easily. With the final big end bore size number handy you subtract the next one from it:

Bearing shell thickness. Here's where that pin can be used along with a mic to measure the thickness. The middle section is the thickest and where clearance is determined, that measurment along with the bore size determines clearance when the journal size is subtracted from it. While you're at it measure towards the parting line and notice how it gets thinner. That's eccentricity and is very important for a high performance engine because rods pull under high stress and squeeze the journal at the parting line.

Mixing and matching rod bores with journals is good practice, a tenth or 2 bigger bore matched with a journal a tenth or so over is good but you can't cover big discerpancies that way.

Why not take everything to an automotive machine shop? The have the equipment and experience and could see things you can't, most are nice people and with modern cars never needing to have engine work, they're probably eager for something to do.

Here's what to look for:

Rod big end size and roundness. The'yre likely egg shaped but can be resized easily. With the final big end bore size number handy you subtract the next one from it:

Bearing shell thickness. Here's where that pin can be used along with a mic to measure the thickness. The middle section is the thickest and where clearance is determined, that measurment along with the bore size determines clearance when the journal size is subtracted from it. While you're at it measure towards the parting line and notice how it gets thinner. That's eccentricity and is very important for a high performance engine because rods pull under high stress and squeeze the journal at the parting line.

Mixing and matching rod bores with journals is good practice, a tenth or 2 bigger bore matched with a journal a tenth or so over is good but you can't cover big discerpancies that way.

#14

A lot of worry for something that hasn't happened yet. I would get the bearings and some plastigauge.

BTW, cleanliness is way up the list on engine longevity. You will have serious trouble with a couple of pieces of grit in the oil passageways getting pushed to a bearing surface. On a Kamikazie rebuild, the idea is to take as little apart as possible, and replace as little as needed.

You are way beyond that, and you need to dissasemble totally and clean, clean, clean. I have rented steam pressure washers and they can really get you through the bulk of cleaning, and even blow out oil galleys and passages. Many buy sets of bottle brushes in various sizes. You need to clean out the crank too, and a compressor can help blow out any solvent or water residue after cleaning.

You can get the stuff hot tanked at the machinists shop, but don't assume that means you are finished. It sounds like a lot of work, but when you have everything super clean, you will have a nicer time with assembly.

I assume you have a nice area set aside for your work station. Even a couple of saw horses and an old door will make a good bench. an old sheet, or some butchers paper will give you a place to lay out the clean parts in order.

You are off to a great start. Break your rebuild up into phases, and don't feel like you have to rush. Taking your time, and getting things together nicely is far more enjoyable and productive in the long run.

Remember, if things seem difficult, or don't want to go together, stop and step back. It often seems as if there is never enough time or money to do it right, but there is always enough time and money to do it over. Ask me how I know.

BTW, cleanliness is way up the list on engine longevity. You will have serious trouble with a couple of pieces of grit in the oil passageways getting pushed to a bearing surface. On a Kamikazie rebuild, the idea is to take as little apart as possible, and replace as little as needed.

You are way beyond that, and you need to dissasemble totally and clean, clean, clean. I have rented steam pressure washers and they can really get you through the bulk of cleaning, and even blow out oil galleys and passages. Many buy sets of bottle brushes in various sizes. You need to clean out the crank too, and a compressor can help blow out any solvent or water residue after cleaning.

You can get the stuff hot tanked at the machinists shop, but don't assume that means you are finished. It sounds like a lot of work, but when you have everything super clean, you will have a nicer time with assembly.

I assume you have a nice area set aside for your work station. Even a couple of saw horses and an old door will make a good bench. an old sheet, or some butchers paper will give you a place to lay out the clean parts in order.

You are off to a great start. Break your rebuild up into phases, and don't feel like you have to rush. Taking your time, and getting things together nicely is far more enjoyable and productive in the long run.

Remember, if things seem difficult, or don't want to go together, stop and step back. It often seems as if there is never enough time or money to do it right, but there is always enough time and money to do it over. Ask me how I know.